Method for supergravity refining of metal solidification structure

A technology of metal solidification and supergravity, which is applied in the field of metal grain refinement, can solve problems such as potential safety hazards and contamination of molten metal, and achieve the effects of ensuring purity, low cost, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

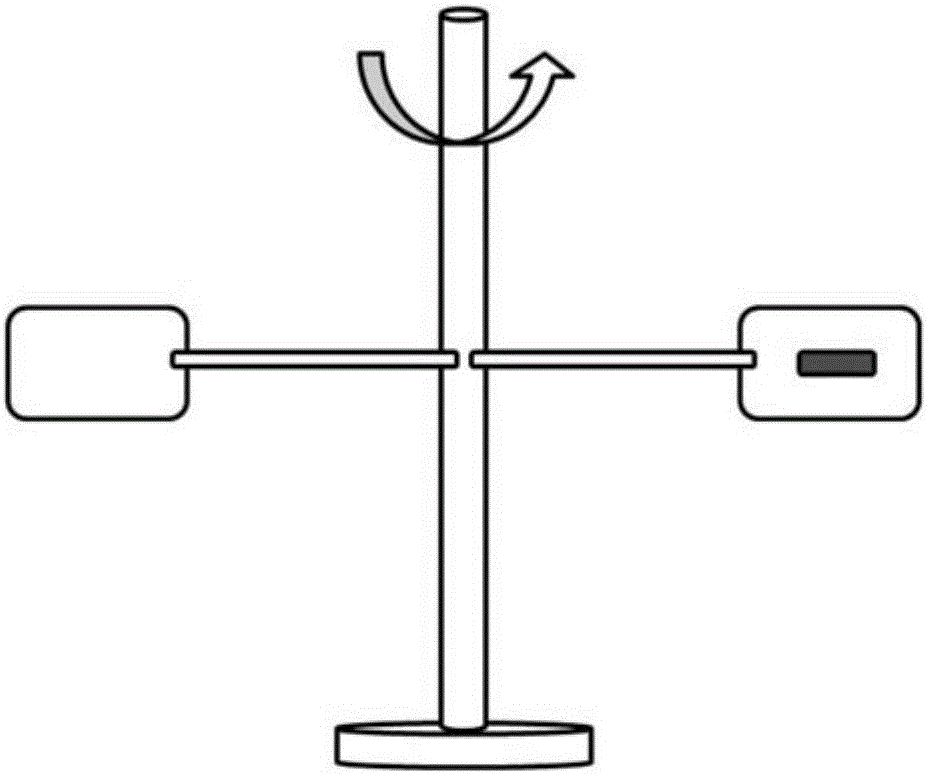

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, without loss of generality, Al-Cu (aluminum-copper) alloy is selected as the metal.

[0035] During the preparation of Al-Cu alloy, the industrial pure Al and industrial pure Cu selected can be any one known to those skilled in the art, for example: the metal Al block can be purchased from Beijing Cui Platinum Nonferrous Metals Technology Development Center. Al block, with a purity of 99.99%; industrially pure Cu may be an industrially pure Cu block purchased from Beijing Cui Platinum Nonferrous Metals Technology Development Center, with a purity of 99.99%.

[0036] Al-Cu master alloy preparation and supergravity treatment steps are as follows:

[0037] Step 1: Preparation of Al-Cu master alloy by smelting; take a proper amount of pure Al and pure Cu in an alumina crucible, heat up to 750°C in a molybdenum wire furnace protected by argon, and keep the temperature for not less than 2 hours to ensure that the alloy composition is uniform. After the he...

Embodiment 2

[0041] Except that centrifuge is adjusted to rotating speed in step 2 and is 1687r / min (coefficient of gravity is G=800) and carries out supergravity treatment, all the other are identical with embodiment 1.

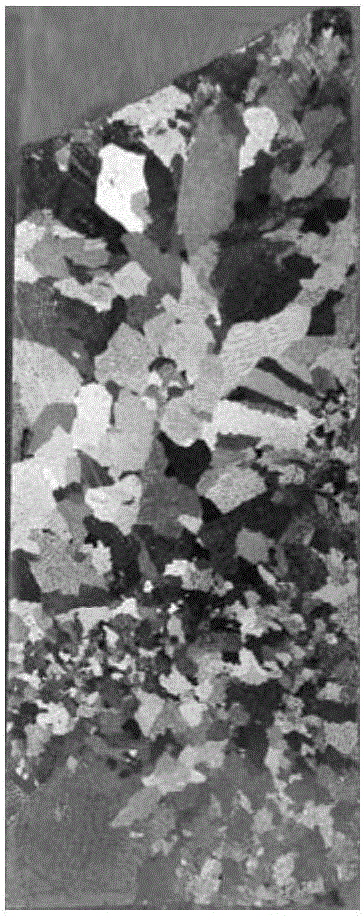

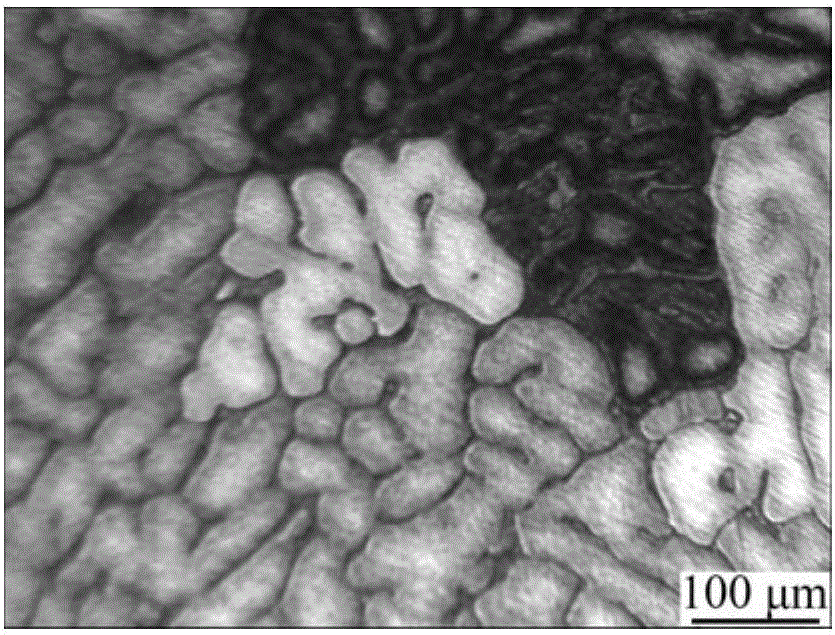

[0042] Cut the obtained sample from the middle along the direction of supergravity, half of which have been inlaid, numbered, ground and polished, and etched with a mixed acid H 2 O+HNO 3 +HF=92+7.5+2.5 (unit: ml) erosion for 8-12s, then take pictures with a digital camera, observe the macroscopic structure of the sample, the results are as follows Figure 4 As shown, the microstructure of the sample was observed with a metallographic microscope, and the results were as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com