Precision casting method for thin-wall high-temperature alloy floating wall tiles

A high-temperature alloy and precision casting technology, which is applied in the field of high-temperature alloy casting, can solve the problems of slow solidification cooling rate of castings and high heat preservation temperature of mold shells, and achieve the effects of grain refinement, improvement of casting performance, and promotion of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

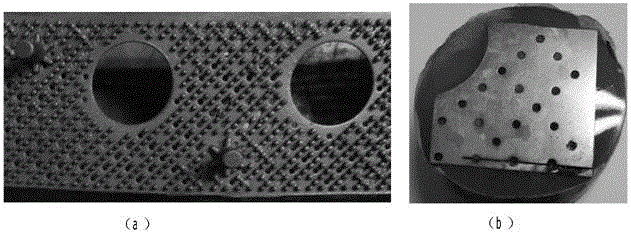

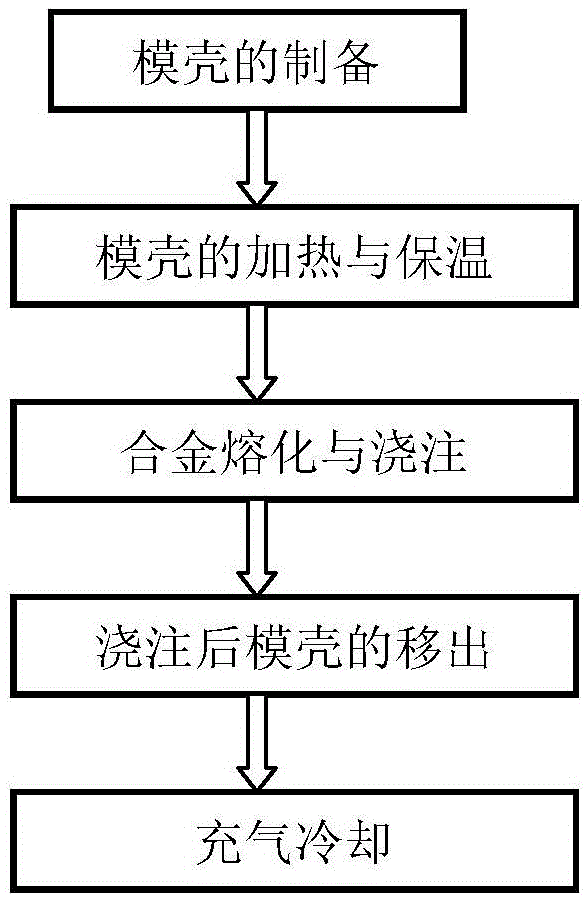

[0019] This embodiment is a high-temperature alloy floating wall tile precision casting technology. The casting material is a K4169 high-temperature alloy with a solidus temperature of 1270°C and a liquidus temperature of 1349°C. refer to figure 1 , the specific steps of this embodiment are as follows:

[0020] Step 1. Preparation of the formwork: The preparation technology of the formwork is the existing technology. The existing 3D rapid prototyping system is used to prepare the floating wall tile wax pattern, and the pouring system is added to form the module group. After cleaning, repeated sanding, and removal Waxed and baked to obtain the mold shell;

[0021] Step 2, refer to figure 1 Heating and insulation of the mold shell: place the K4169 superalloy in the crucible of the induction coil of the directional solidification vacuum induction furnace; place the obtained mold shell in the mold shell heating furnace of the directional solidification vacuum induction furnace; ...

Embodiment 2

[0026] The concrete steps of this embodiment are as follows:

[0027] Step 1. Preparation of the formwork: The preparation technology of the formwork is the existing technology. The existing 3D rapid prototyping system is used to prepare the floating wall tile wax pattern, and the pouring system is added to form the module group. After cleaning, repeated sanding, and removal Waxed and baked to obtain the mold shell;

[0028] Step 2, heating and heat preservation of the formwork: place the K4169 superalloy in the crucible of the induction coil of the directional solidification vacuum induction furnace; place the obtained formwork in the formwork heating furnace of the directional solidification vacuum induction furnace; place the directional solidification The upper heating zone and the lower heating zone of the heating body of the vacuum induction furnace are heated to 1300°C and kept for 80 minutes to heat the mold shell and make the mold shell temperature uniform;

[0029] ...

Embodiment 3

[0034] This embodiment is a high-temperature alloy floating wall tile precision casting technology. The casting material is a K4169 high-temperature alloy with a solidus temperature of 1270°C and a liquidus temperature of 1349°C. The concrete steps of this embodiment are as follows:

[0035] Step 1. Formwork preparation: The preparation technology of the formwork is the existing technology. The existing 3D rapid prototyping system is used to prepare the floating wall tile wax pattern, and the pouring system is added to form the module group. After cleaning, repeated sanding, and removal Waxed and baked to obtain the mold shell;

[0036] Step 2, heating and heat preservation of the formwork: place the K4169 superalloy in the crucible of the induction coil of the directional solidification vacuum induction furnace; place the obtained formwork in the formwork heating furnace of the directional solidification vacuum induction furnace; place the directional solidification The uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solidus temperature | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com