High-melting point lead-free solder and production technique thereof

A technology of lead-free solder and production process, which is applied in the direction of welding/cutting medium/material, welding medium, manufacturing tools, etc., and can solve the problems of high price, low precious metal content, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

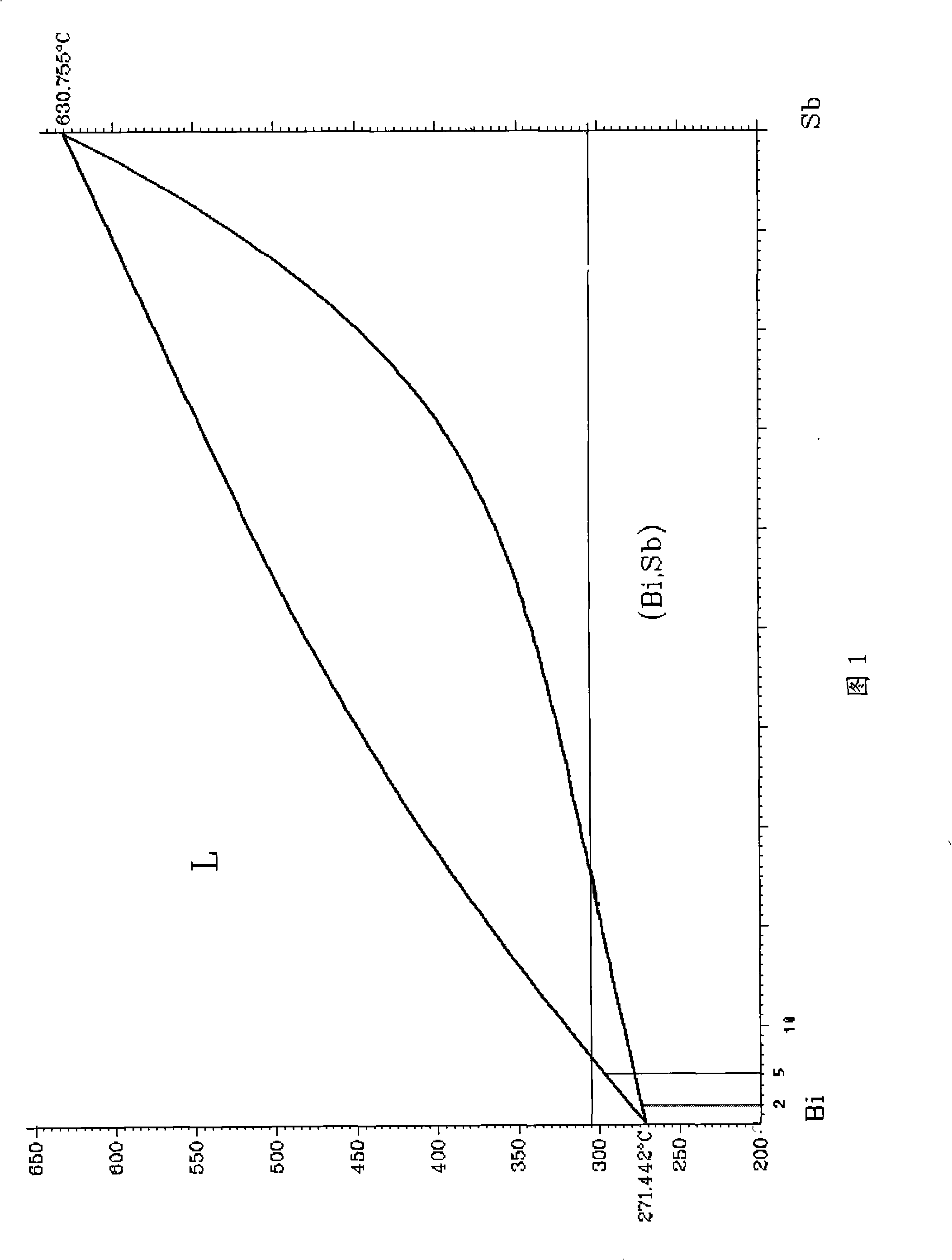

[0014] The high-melting-point lead-free solder of the present invention comprises a Bi-based alloy, the content of Bi in the alloy is 95wt%-98wt%, and it is made by alloying after adding Sb, wherein the content of Sb is 2wt%-5wt%. The solid phase point of the prepared solder is not lower than 270°C, and the liquid phase point is not higher than 310°C. It can replace leaded solder for chip soldering and IC package soldering.

[0015] Since the Bi-Sb alloy belongs to the infinite miscible alloy, the solid and liquid phase points of the alloy increase with the increase of the Sb content. The binary alloy phase diagram shown in Figure 1 is obtained through experiments. When the Sb content is equal to 2wt%, Its lowest solid phase point is higher than 270°C. When the Sb content is equal to 5wt%, its lowest liquid phase point is lower than 310°C. From this we can conclude that the solid phase point temperature of the solder is not lower than 270°C, and its liquid phase The point is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com