Method for preparing vanadium redox battery negative pole electrolyte

A negative electrode electrolyte, vanadium battery technology, applied in the field of battery manufacturing, can solve the problems affecting the performance of vanadium batteries, poor electrolyte stability, difficult to control the ratio, etc., to achieve electrochemical reaction activity and good reversibility, good stability, anti- The effect of improving low temperature environment capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare vanadium battery negative electrode electrolyte according to the following steps:

[0028] (1) to 1:1 dilute H 2 SO 4 Add 450g of industrial high-purity V to 1000mL of the solution 2 o 3 (total vanadium content is greater than 67%), in the solution, continuous feeding purity is 99.999% (O 2 ≤0.001%) of high-purity nitrogen, the solution is heated to 80 ℃ ~ 150 ℃, then add 90g additive Na 2 SO 4 , filter the insoluble matter, and get V 2 (SO 4 ) 3 solution;

[0029] (2) to 1:1 dilute H 2 SO 4 Add 450g of industrial high-purity V to 1000mL of the solution 2 o 3 (total vanadium content greater than 67%) and 240g reducing agent Na 2 S, the continuous feeding of the solution has a purity of 99.999% (O 2 ≤0.001%) of high-purity nitrogen, the solution is heated to 80 ℃ ~ 150 ℃, add 90g additive Na 2 SO 4 , filter the insoluble matter, and get VSO 4 solution;

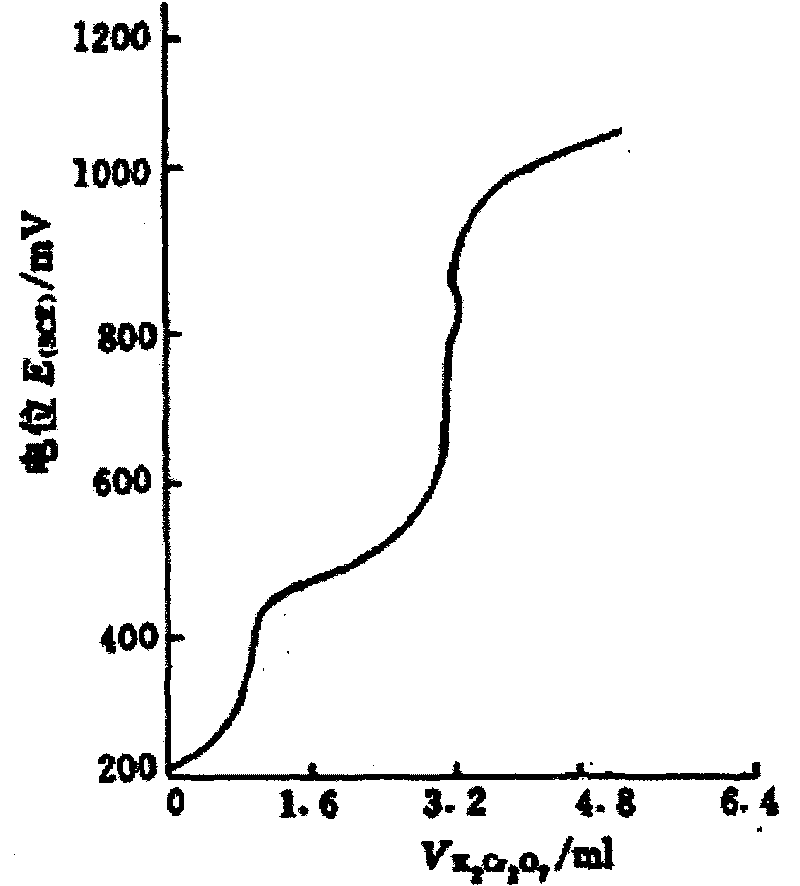

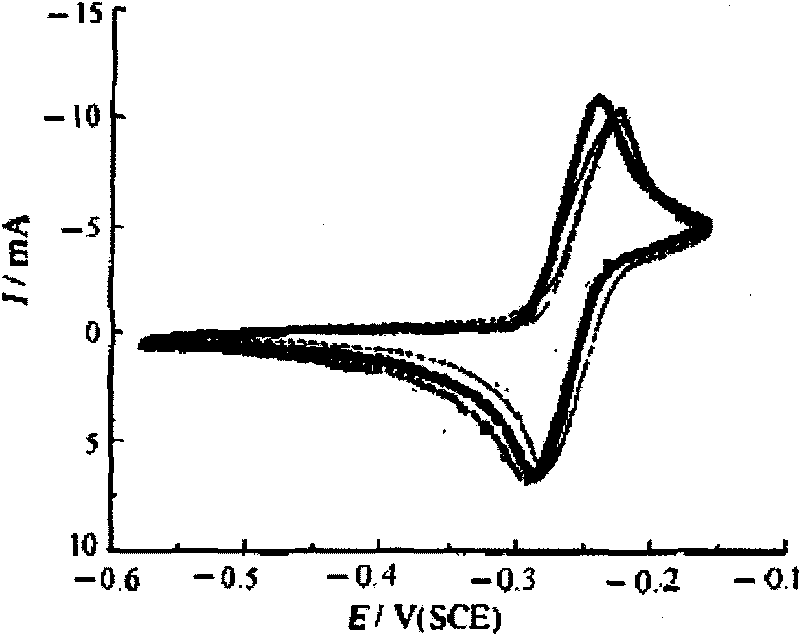

[0030] (3)VSO 4 solution and V 2 (SO 4 ) 3 The solution is mixed according to the molar ...

Embodiment 2

[0035] Prepare vanadium battery negative electrode electrolyte according to the following steps:

[0036] (1) to 1:1 dilute H 2 SO 4 Add 450g of industrial high-purity V to 1000mL of the solution 2 o 3 (total vanadium content is greater than 67%), in the solution, continuous feeding purity is 99.999% (O 2 ≤0.001%) of high-purity nitrogen, the solution is heated to 80 ℃ ~ 150 ℃, then add 90g additive Na 2 SO 4 , filter the insoluble matter, get V 2 (SO 4 ) 3 solution;

[0037] (2) Take the above V 2 (SO 4 ) 3 Solution 500mL, to which continuous feeding purity is 99.999% (O 2 ≤0.001%) of high-purity nitrogen, the solution is heated to 80 ℃ ~ 150 ℃, then add 220g of reducing agent Na 2 SO 3 , filter the insoluble matter to get VSO 4 solution;

[0038] (3)V 2 (SO 4 ) 3 solution and VSO 4 The solution is mixed according to the molar ratio of 1:2, that is, it is prepared by V 2 (SO 4 ) 3 、VSO 4 , water and additive Na 2 SO 4 A mixed solution consisting of, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com