Preparation method of RuO2 material with ordered porous structure

A porous structure and solution technology, applied in the field of ordered porous structure RuO2 materials and their preparation, can solve the problems such as no related literature reports, and achieve the effects of adjustable pore size, good catalytic activity, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

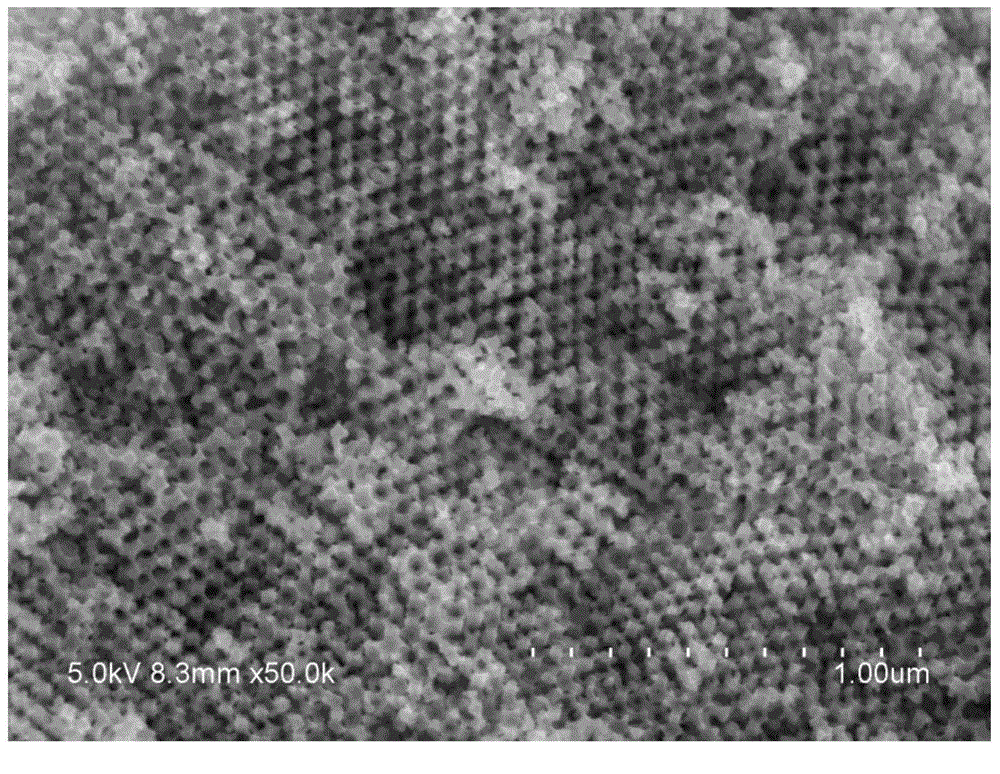

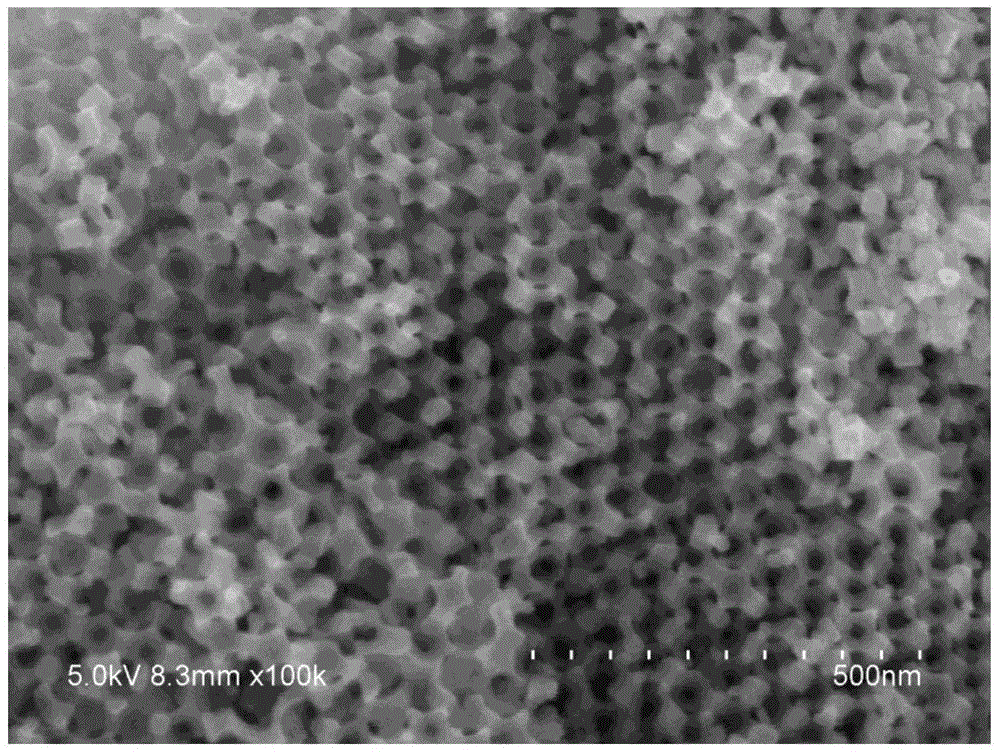

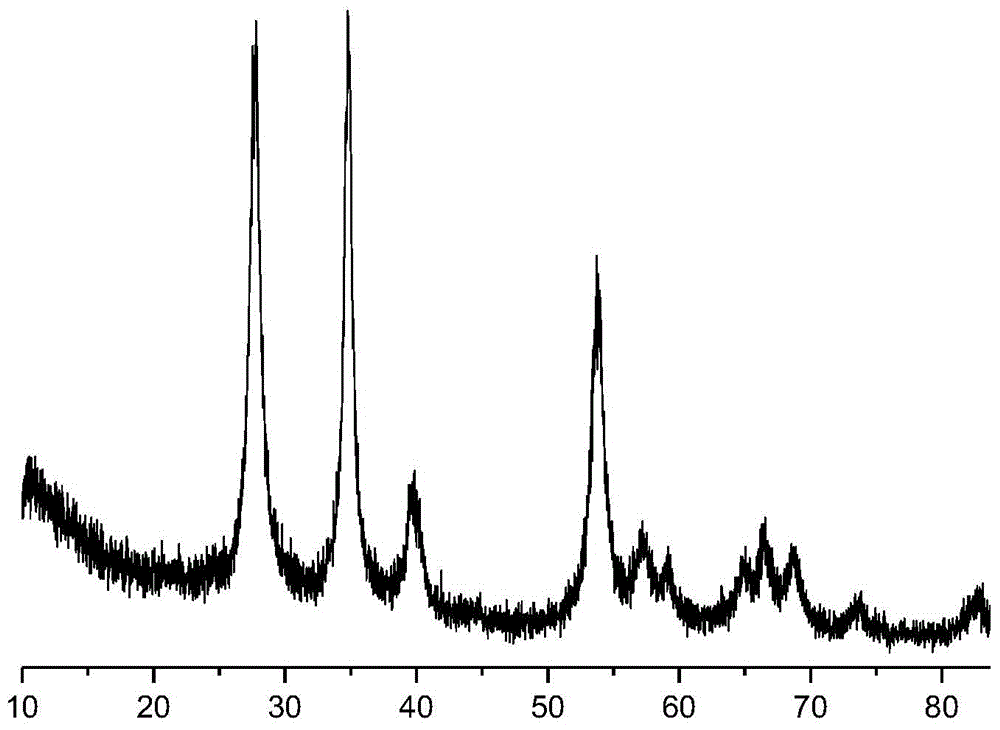

[0022] 1. Take 5mL SiO2 2 A 10% aqueous solution of nanospheres (65nm) is poured into a petri dish with a diameter of 2 cm, placed in a closed space, and volatilized slowly. After 5 days, densely packed blocks were obtained, which were annealed at 800° C. for 3 hours in air (heating rate 2° C. / minute) to obtain 0.5 g of a hard template. SiO with other diameters in the range of 10-300nm or beyond the range can also be selected 2 nanospheres, but the obtained ordered porous RuO 2 The pore size of the material will also vary.

[0023] 2. Put these hard templates in a 5cm Petri dish, add 0.2mL of RuCl dropwise 3 Ethanol solution (each 5-7mL solution can contain 0.38g Ru element), after the ethanol is completely volatilized, continue to add dropwise; repeat dropwise 5 times. 4 times is also acceptable.

[0024] 3. Anneal at 300°C in air for 1 hour (the best heating rate is 1°C / min); and the last annealing temperature before removing the template can reach 400-600°C, the anneal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com