Noble metal oxide nanocomposite material and preparation method and use thereof

A nanocomposite material, precious metal oxide technology, applied in chemical instruments and methods, carbon compounds, ruthenium/rhodium/palladium/osmium/iridium/platinum oxide/hydroxide, etc., can solve the problem of nanomaterials without a clear structure, Limiting the application of biological enzymes, difficulty in purification and storage, etc., to achieve the effect of simple and rapid preparation method, inhibiting the formation of nanoparticles, and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The specific embodiment part of the present invention provides a preparation method and application of a noble metal oxide nanocomposite material. The method includes the following steps:

[0065] (1) Adding the noble metal to the solvent, ablation with a pulsed laser to obtain a nano-dispersion comprising the noble metal oxide;

[0066] (2) Mixing the nano-dispersion liquid obtained in step (1) with the carrier dispersion liquid, standing still, drying and oxidizing after solid-liquid separation, to obtain a noble metal oxide nano-composite material.

Embodiment 1

[0069] This embodiment provides a method for preparing a noble metal oxide nanocomposite material, the method comprising the following steps:

[0070] (1) Put the precious metal iridium target into the bottom of the colorimetric tube, add 6mL of ethanol, focus the pulsed laser with energy of 80mJ, focal length of 77mm, and wavelength of 532nm on the surface of the target, and laser ablate it under the action of 300W ultrasound for 10min. Obtaining a nano-dispersion comprising iridium dioxide;

[0071] (2) After mixing the nano-dispersion liquid obtained in step (1) with 1 mL of polyacrylimide-modified graphene oxide dispersion liquid with a concentration of 1000 μg / mL, let it stand at 20 ° C for 4 h, centrifuge, and place in an air atmosphere Dry at 60°C to fully oxidize metal iridium to obtain iridium dioxide / graphene oxide (IrO 2 / GO) nanocomposites.

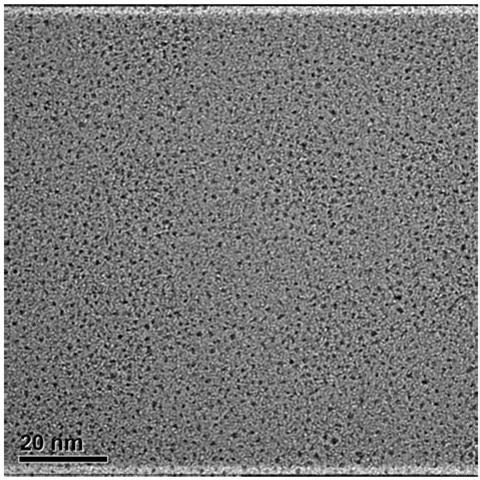

[0072] The iridium dioxide nanoparticles that step (1) obtains and the IrO that step (2) makes 2 / GO nanocomposites were ...

Embodiment 2

[0076] This embodiment provides a method for preparing a noble metal oxide nanocomposite material, the method comprising the following steps:

[0077] (1) Put the precious metal iridium target into the bottom of the colorimetric tube, add 6mL of acetone, focus the pulsed laser with energy of 120mJ, focal length of 250mm, and wavelength of 532nm on the surface of the target, and laser ablate it under the action of 400W ultrasound for 5min, Obtaining a nano-dispersion comprising iridium dioxide;

[0078] (2) After mixing the nano-dispersion liquid obtained in step (1) with 1 mL of polyacrylimide-modified graphene oxide dispersion liquid with a concentration of 1000 μg / mL, let it stand at 30 ° C for 6 h, centrifuge, and then Dry at 80°C to fully oxidize metal iridium to obtain iridium dioxide / graphene oxide (IrO 2 / GO) nanocomposites.

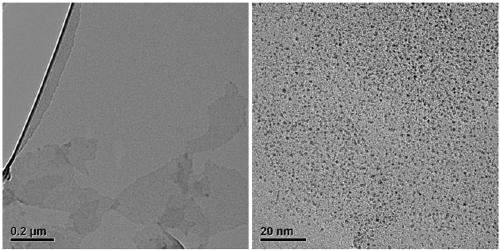

[0079] The prepared IrO 2 / GO nanocomposites were characterized by TEM, and the results are as follows Figure 5 shown.

[0080] The prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com