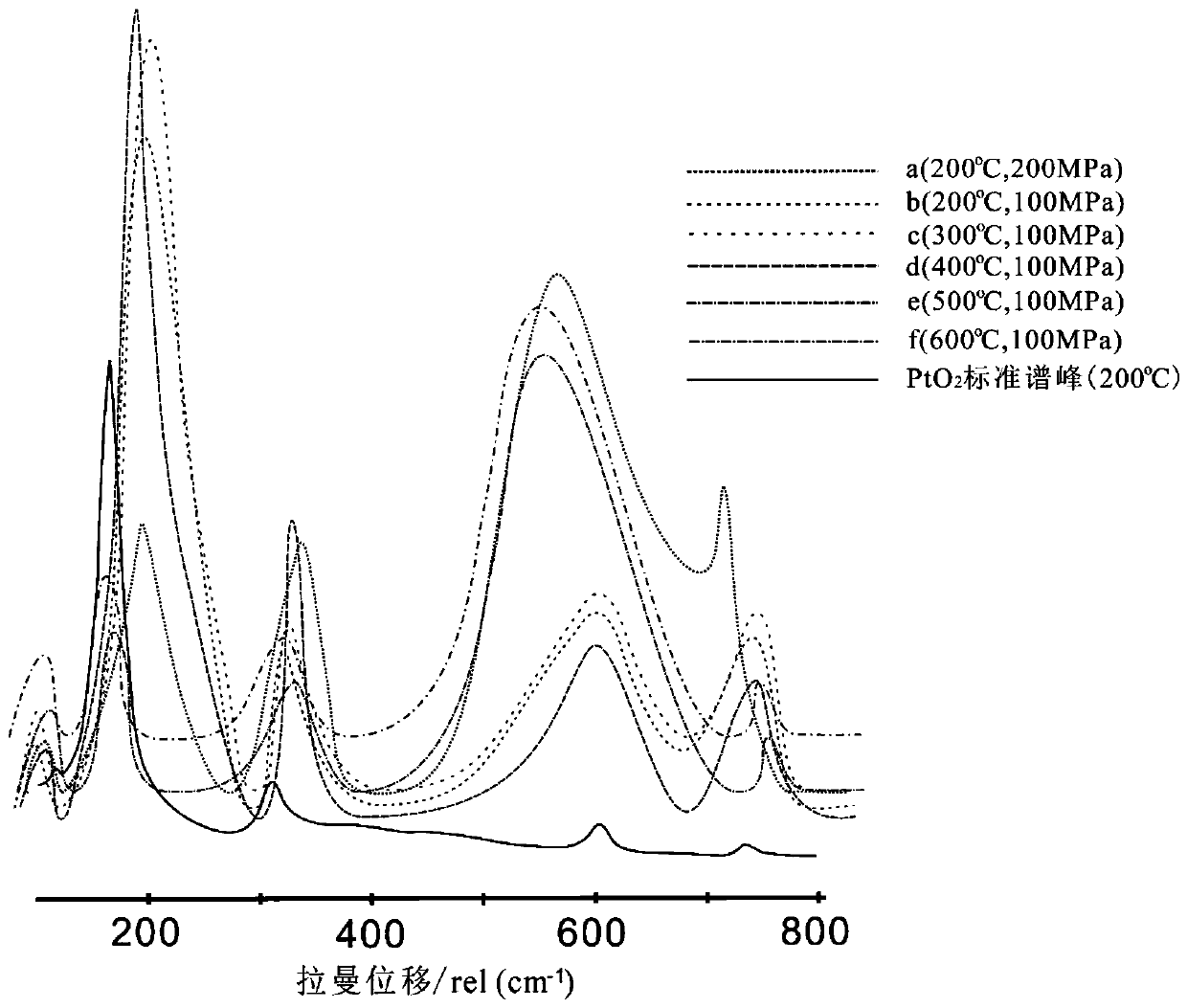

Method for preparing PtO2 conical nano granular material

A nanoparticle and cone-shaped technology is applied in the field of preparation of PtO2 cone-shaped nanoparticle materials, which can solve the problems of low PtO2 purity, complex process and high cost, and achieve the effects of low cost, simple process and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

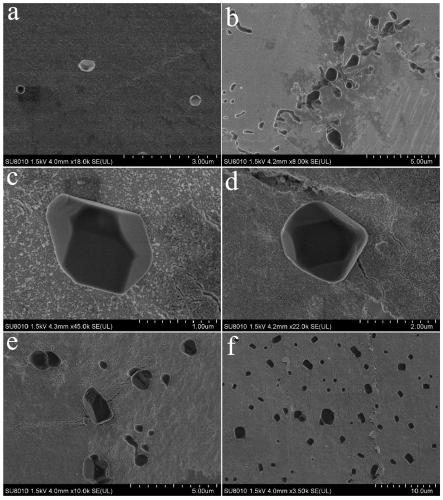

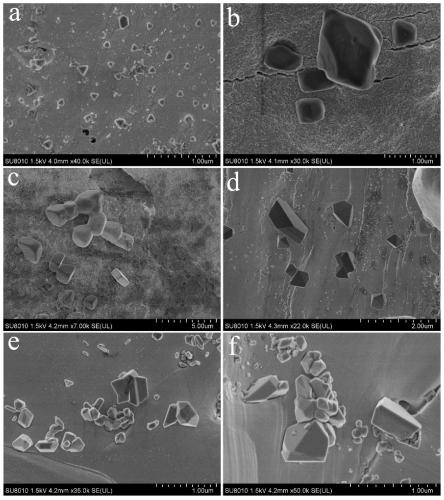

[0033] The PtO provided by this embodiment 2 The preparation method of conical nanoparticle, comprises the following steps:

[0034] (1) Cut the high-purity gold tube with a diameter of 4mm into the length required for the experiment, and carry out pre-treatments such as pickling, washing, quenching, and one end welding seal in advance to ensure that there are no impurities and cracks in the gold tube;

[0035] (2) Potassium chloroplatinate (K 2 PtCl 6 ) powder was dissolved in 100mL deionized water, fully dissolved to obtain 0.01mol / L K 2 PtCl 6 solution, put about 0.1mL of the prepared reaction solution into a gold tube, control the filling degree to about 40% to 50%, and seal it by welding. 110°C drying oven for more than 2 hours, and then weigh again to ensure that the weight error before and after weighing is less than 0.001g, indicating that the gold tube is well sealed;

[0036](3) Put the gold tube, which is confirmed to be well-sealed and contains the solution sa...

Embodiment 2

[0042] The PtO provided by this embodiment 2 The preparation method of conical nanoparticle, comprises the following steps:

[0043] (1) the pretreatment of gold tube is the same as embodiment 1;

[0044] (2) Potassium chloroplatinate (K 2 PtCl 6 ) powder was dissolved in 100mL deionized water, fully dissolved to obtain 0.01mol / L K 2 PtCl 6 solution, put about 0.1mL of the prepared reaction solution into a gold tube, control the filling degree to about 40% to 50%, and seal it by welding. 110°C drying oven for more than 2 hours, and then weigh again to ensure that the weight error before and after weighing is less than 0.001g, indicating that the gold tube is well sealed;

[0045] (3) Put the gold tube, which is confirmed to be well-sealed and contains the solution sample, into a high-temperature and high-pressure reactor, and inject deionized water as a medium. After tightening the reactor, check the tightness of the reactor. Inject argon gas to a pressure of 60MPa, as t...

Embodiment 3

[0051] The PtO provided by this embodiment 2 The preparation method of conical nanoparticle, comprises the following steps:

[0052] (1) the pretreatment of gold tube is the same as embodiment 1;

[0053] (2) Potassium chloroplatinate (K 2 PtCl 6 ) powder was dissolved in 100mL deionized water, fully dissolved to obtain 0.01mol / L K 2 PtCl 6 solution, put about 0.1mL of the prepared reaction solution into a gold tube, control the filling degree to about 40% to 50%, and seal it by welding. 110°C drying oven for more than 2 hours, and then weigh again to ensure that the weight error before and after weighing is less than 0.001g, indicating that the gold tube is well sealed;

[0054] (3) Put the gold tube, which is confirmed to be well-sealed and contains the solution sample, into a high-temperature and high-pressure reactor, and inject deionized water as a medium. After tightening the reactor, check the tightness of the reactor. Inject argon gas to a pressure of 60MPa, as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com