Method for manufacturing strepto-shaped cobalt platinum alloy by using octreotide acetate as template

A technology of octreotide acetate and streptopheroids, which is applied in the field of preparation of nanomaterials, can solve the problems of difficulty in large-scale production, high production costs, and high technical requirements, and achieve the effects of easy analysis and control, low equipment requirements, and simple preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 0.4 mg of octreotide acetate (produced by Jill Biochemical Shanghai Co., Ltd.), dissolve it in 1 mL of hydrochloric acid solution of pH 2, and prepare a 0.4 mM octreotide acetate solution with a pH value of 2; Platinum solution (Shaanxi Ruike New Material Co., Ltd.) and 100 μL 4mM cobalt chloride solution (Shanghai West Asia Reagent Co., Ltd.); put the above-prepared solution in a water bath constant temperature oscillator, and incubate at 130rpm., 13°C After 26 hours, 80 μL of 30 mM reducing agent sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) was added once for reduction, so that it changed from light yellow to dark black, and a chain-shaped cobalt-platinum alloy was obtained.

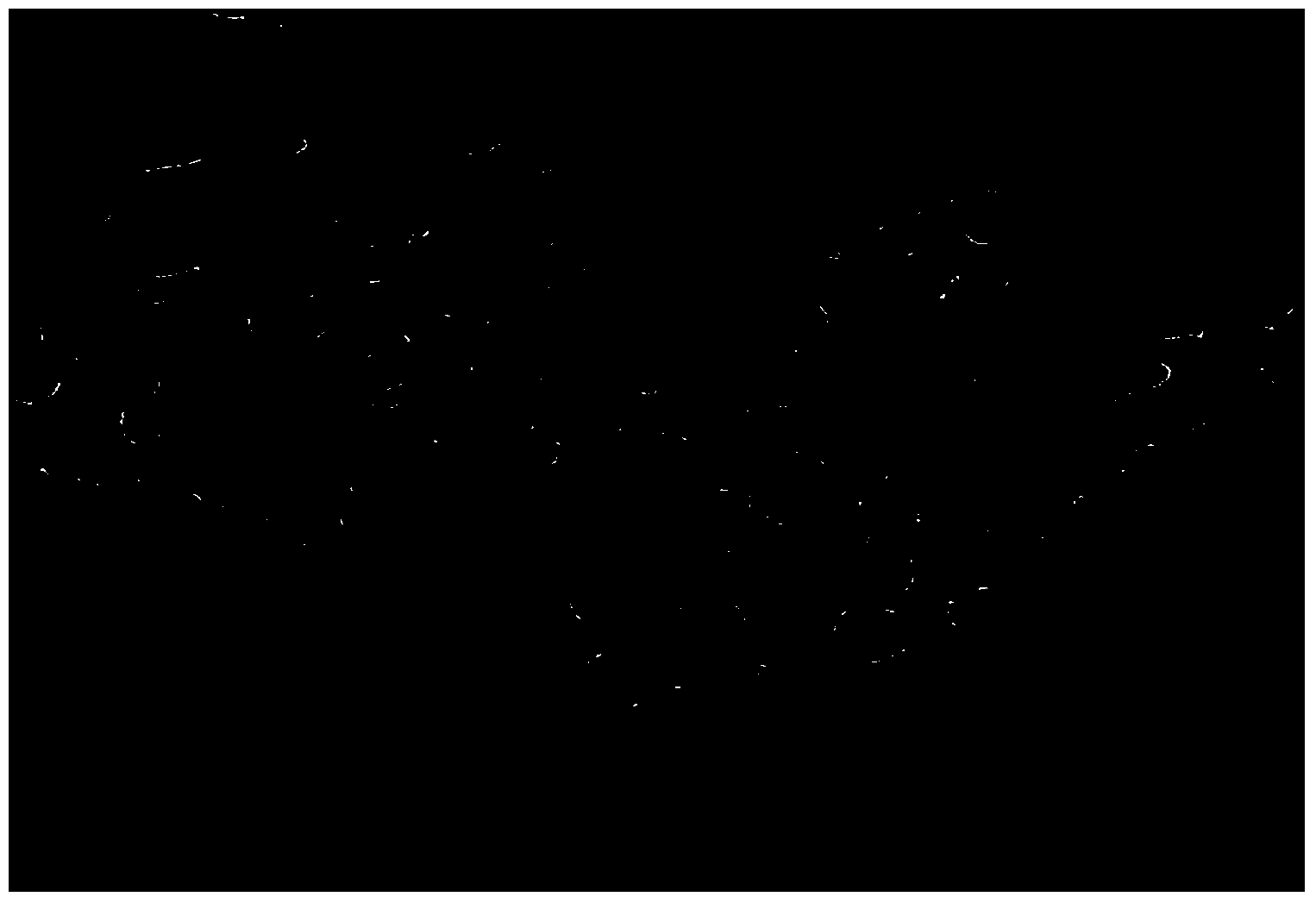

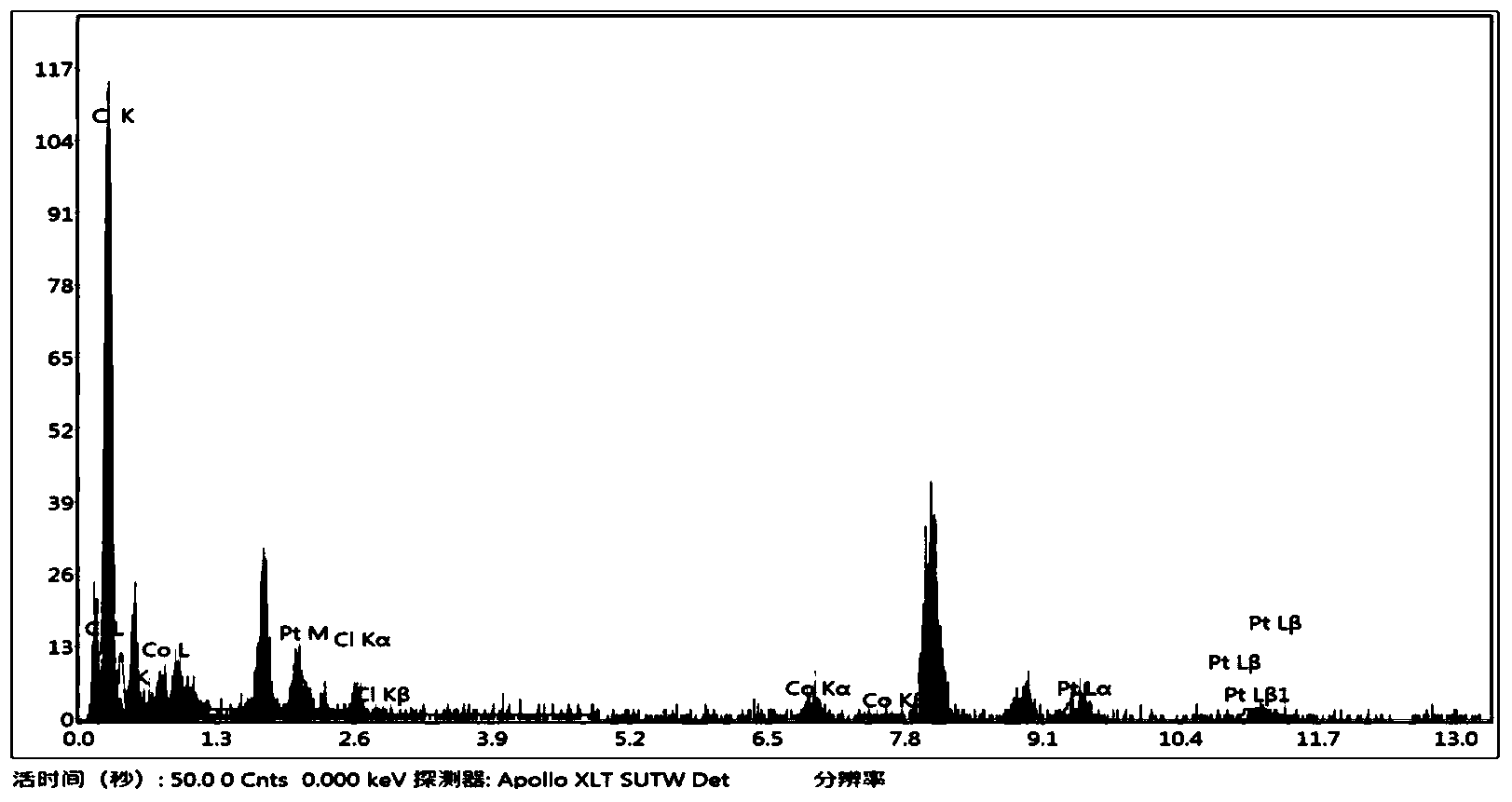

[0020] Morphological characterization of chain-like cobalt-platinum alloys using transmission electron microscopy, such as figure 1 As shown, the diameter of the coral-like cobalt nanoparticles is 45-55nm, the shape is regular, and the distribution is uni...

Embodiment 2

[0022] Take 0.6 mg of octreotide acetate (produced by Jill Biochemical Shanghai Co., Ltd.), dissolve it in 1 mL of hydrochloric acid solution with pH 2.5, and prepare a 0.6 mM octreotide acetate solution with a pH value of 2.5; Platinum chloride solution (produced by Tianjin Chemical Reagent Factory) and 100 μL of 6 mM cobalt chloride solution (Shanghai West Asia Reagent Co., Ltd.); put the above-prepared solution in a water bath constant temperature oscillator, and incubate at 160 rpm., 20 ° C After 24 hours, 100 μL of 24 mM reducing agent sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) was added once for reduction, so that it changed from light yellow to dark black, and a chain-shaped cobalt-platinum alloy was obtained.

[0023] Morphological characterization of chain-like cobalt-platinum alloys using transmission electron microscopy, such as figure 2 As shown, the diameter of the coral-like nano-cobalt particles is 40-50nm, the shape is reg...

Embodiment 3

[0026] Take 0.8 mg of octreotide acetate (manufactured by Jill Biochemical Shanghai Co., Ltd.), dissolve it in 1 mL of hydrochloric acid solution at pH 3, and prepare a 0.8 mM octreotide acetate solution with a pH value of 3; Platinum solution (produced by Tianjin Chemical Reagent Factory) and 100 μL 8mM cobalt chloride solution (Shanghai West Asia Reagent Co., Ltd.); put the above prepared solution in a water bath constant temperature oscillator, at 200rpm., after incubation at 25°C for 20h , adding 80 μL of 35 mM reducing agent sodium borohydride (produced by Beijing Zhongsheng Huateng Technology Co., Ltd.) at one time for reduction, making it change from light yellow to dark black, and obtain a chain-shaped cobalt-platinum alloy.

[0027] Morphological characterization of chain-like cobalt-platinum alloys using transmission electron microscopy, such as Figure 4 As shown, the diameter of the coral-like nano-cobalt particles is about 55nm, the shape is regular, and the distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com