Catalyst to prepare 1,3-dihydroxyacetone and preparation method thereof

A hydroxyacetone catalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Acetone selectivity is not good enough, the utilization rate of active components is not high, etc., to achieve the effect of rich loading active sites, good activity and selectivity, and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

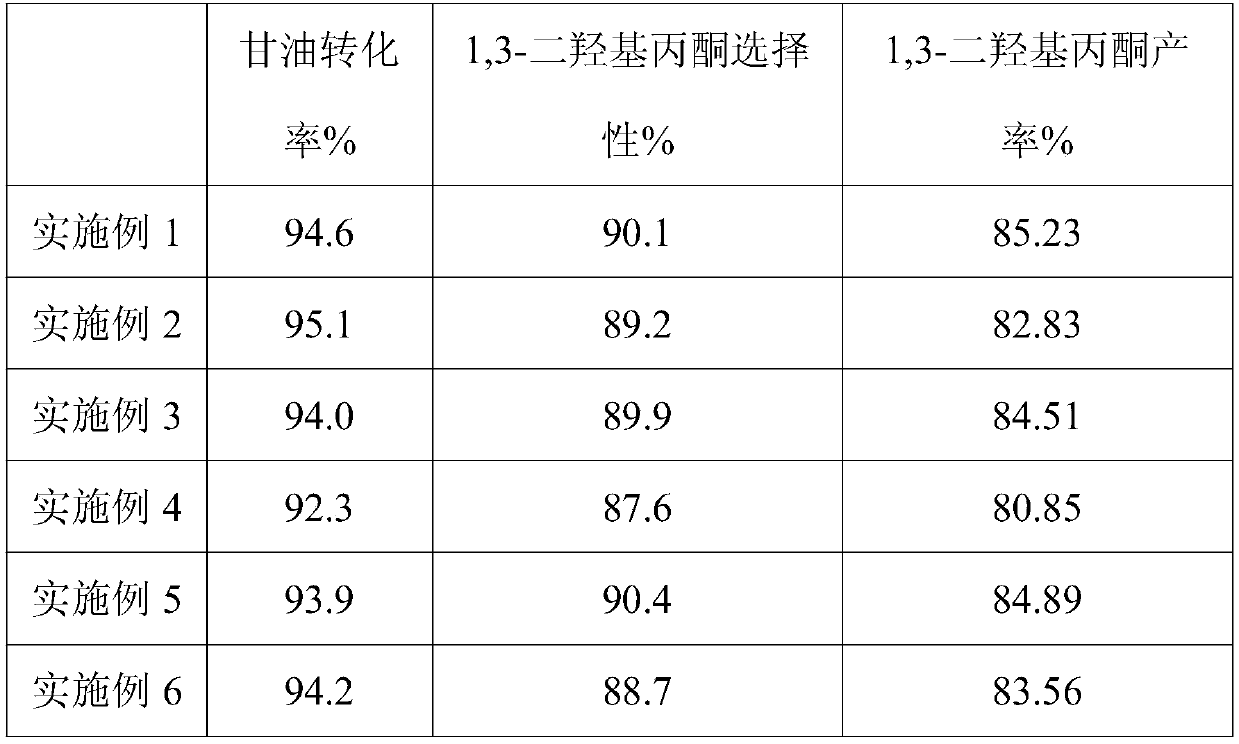

Examples

Embodiment 1

[0021] A preparation method for preparing 1,3-dihydroxyacetone catalyst, comprising the steps of:

[0022] (1) Preparation of ZnAl-HTLc: soluble 0.375gAl(NO 3 ) 3 9H 2 O, 0.891gZn(NO 3 ) 2 ·6H 2 O was dissolved in 150ml of deionized water to prepare mixed solution A, and 0.042gNa 2 CO 3 Dissolve 0.48g NaOH in 150ml deionized water to prepare mixed solution B, then quickly mix solution A and solution B under rapid stirring, and reflux reaction at 60°C for 10h. After the reaction, the product is centrifugally washed to neutral, Dry to get ZnAl-HTLc;

[0023] (2) Preparation of composite carrier: Add 80mL of ZnAl-HTLc12g prepared in step (1) into 0.6mol / L glucose monohydrate aqueous solution, stir at room temperature until uniformly mixed; then transfer the above mixture to poly In a tetrafluoroethylene reactor, react at a constant temperature of 180°C for 6 hours, cool to room temperature after the reaction, separate the product, then alternately wash with deionized wate...

Embodiment 2

[0026] A preparation method for preparing 1,3-dihydroxyacetone catalyst, comprising the steps of:

[0027] (1) Preparation of ZnAl-HTLc: soluble 0.375gAl(NO 3 ) 3 9H 2 O, 0.594gZn(NO 3 ) 2 ·6H 2 O was dissolved in 150ml of deionized water to prepare mixed solution A, and 0.042gNa 2 CO 3Dissolve 0.32g NaOH in 150ml deionized water to prepare mixed solution B, then quickly mix solution A and solution B under rapid stirring, and reflux reaction at 60°C for 10h. After the reaction, the product is centrifugally washed to neutral, Dry to get ZnAl-HTLc;

[0028] (2) Preparation of composite carrier: Add 15g of ZnAl-HTLc prepared in step (1) into 80mL of glucose monohydrate aqueous solution with a concentration of 0.6mol / L, stir at room temperature until uniformly mixed; then transfer the above mixture to poly In a tetrafluoroethylene reactor, react at a constant temperature of 180°C for 6 hours, cool to room temperature after the reaction, separate the product, then alternate...

Embodiment 3

[0031] A preparation method for preparing 1,3-dihydroxyacetone catalyst, comprising the steps of:

[0032] (1) Preparation of ZnAl-HTLc: soluble 0.375gAl(NO 3 ) 3 9H 2 O, 0.891gZn(NO 3 ) 2 ·6H 2 O was dissolved in 150ml of deionized water to prepare mixed solution A, and 0.05gNa 2 CO 3 Dissolve 0.40g NaOH in 150ml deionized water to prepare mixed solution B, then quickly mix solution A and solution B under rapid stirring, and reflux reaction at 60°C for 10h. After the reaction, the product is centrifugally washed to neutral, Dry to get ZnAl-HTLc;

[0033] (2) Preparation of the composite carrier: add the ZnAl-HTLc12g prepared in step (1) into 100mL, and the concentration is 0.5mol / L in the aqueous glucose monohydrate solution, and stir at room temperature until uniformly mixed; then transfer the above mixture to poly In a tetrafluoroethylene reactor, react at a constant temperature of 180°C for 6 hours, cool to room temperature after the reaction, separate the product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com