Method for low-mercury catalyst with good heat stability

A low-mercury catalyst and thermal stability technology, applied in the field of fine chemistry, can solve the problems of poor thermal stability, high loss rate of mercuric chloride, poor mechanical properties of the catalyst, etc., and achieve the effect of good thermal stability and low loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of preparation method of low mercury catalyst with good thermal stability

[0027] Step 1 Preparation of Activated Carbon

[0028] (1) Selection of raw coal

[0029] The raw coal is anthracite, with a moisture content of 6%, an ash content of 8.5%, a volatile matter content of 14.5%, and a fixed carbon content of 71%.

[0030] (2) Deashing of raw coal

[0031] Grind anthracite, pass through a 100-mesh sieve, put the coal powder in 13% HF solution, oscillate ultrasonically at 60°C for 7 hours, filter, wash with distilled water until the filtrate is neutral, then put the washed sample into 40% HCl solution, 75 ° C ultrasonic vibration for 6 hours, filtered, washed with distilled water until the filtrate was neutral; then let it into the 50ppm polyacrylamide solution, first stirred at 5000r / min for 15 minutes, then lowered to 2000r / min Stir at high speed for 8 minutes, filter, and wash with distilled water until the filtrate is neutral.

[0032]...

Embodiment 2

[0055] Embodiment 2 thermal stability test

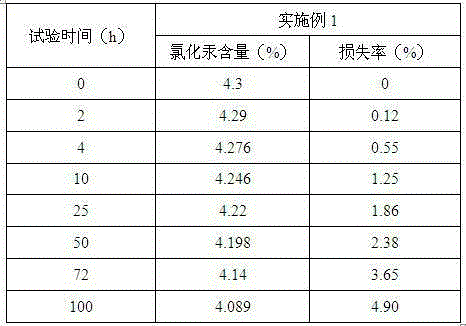

[0056] Mercury chloride catalyst prepared by the present invention carries out stability test under 260 ℃ of conditions, and measurement result is as follows:

[0057]

[0058] Under the condition of 260℃ for 100h, the content of mercuric chloride is 4.089%, and the loss rate of mercuric chloride is 4.90%.

Embodiment 3

[0059] Embodiment 3 above-mentioned catalyst is used for vinyl chloride synthetic reaction

[0060] In the reaction that the catalyst of the present invention is used to prepare vinyl chloride by acetylene hydrochlorination, the molar ratio of the reaction feed gas is C 2 h 2 / HCl=1 / 1.08, the space velocity of acetylene is 65h -1 , the reaction temperature is 110°C, and the hydrogen chloride activation time is 20 minutes.

[0061] The reaction tail gas was analyzed by chromatography, and the conversion rate of acetylene was 99.93%, the selectivity of vinyl chloride was nearly 100%, and the yield of vinyl chloride was 95.2%.

[0062] Unless otherwise specified, the percentages used in the present invention are all weight percentages, and the ratios described in the present invention are all mass ratios.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com