Preparation method of tetramine platinum chloride

A kind of technology of tetraammine platinum chloride and tetraammine chloride, which is applied in the field of preparation of platinum complex tetraammine platinum chloride

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

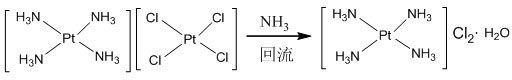

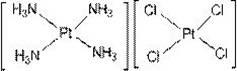

Method used

Image

Examples

Embodiment 1

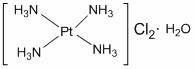

[0020] Embodiment 1: take by weighing the 10g Magnus salt that purity is 96%, join in the round bottom flask, add the 30ml ammoniacal liquor that concentration is 24%, under normal pressure, boiling condition, reflux 8h, until green Magnus salt all disappears, obtains pale Yellow tetraammineplatinum chloride solution was distilled under reduced pressure to obtain 3.49 g of pale yellow to colorless tetraammineplatinum chloride solid.

[0021] The model is 353[M+H] + Electrospray mass spectrometer (ESI-MS) for elemental analysis: actual value N% 15.97, H% 3.50 Pt% 55.48; theoretical value N% 15.91, H% 3.41 Pt% 55.40.

Embodiment 2

[0022] Embodiment 2: take by weighing the 20g Magnus salt that purity is 98%, join in the round bottom flask, add the 70ml ammoniacal liquor that concentration is 26%, under normal pressure, boiling condition, reflux 7h, until green Magnus salt all disappears, obtains pale Yellow to colorless tetraammine platinum chloride solution was distilled under reduced pressure to obtain 7.13 g of light yellow to colorless tetraammine platinum chloride solid.

[0023] The model is 353[M+H] + Electrospray mass spectrometer (ESI-MS) was used for elemental analysis, the actual value N%15.60, H%3.45 Pt%55.41; theoretical value N%15.91, H%3.41 Pt%55.40.

Embodiment 3

[0024] Embodiment 3: take by weighing the 30g Magnus salt that purity is 99%, join in the round bottom flask, add the 120ml ammoniacal liquor that concentration is 28%, under normal pressure, boiling condition, reflux about 6h, until green Magnus salt all disappears, obtains Light yellow to colorless tetraammine platinum chloride solution, this solution was distilled under reduced pressure to obtain 10.45 g of light yellow to colorless tetraammine platinum chloride solid.

[0025] The model is 353[M+H] + Electrospray mass spectrometer (ESI-MS) for elemental analysis: actual value N% 15.99, H% 3.47 Pt% 55.47; theoretical value N% 15.91, H% 3.41 Pt% 55.40.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com