Preparation method of nano platinum oxide powder

A technology of nano-platinum oxide and platinum hydroxide, which is applied in the field of catalysis, can solve the problems of easy agglomeration of platinum oxide and achieve uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of nano platinum oxide powder, comprising the steps of:

[0036] Step 1, adding platinum chloride to distilled water and stirring until completely dissolved, then slowly adding alkali solution dropwise until no precipitation occurs, filtering and washing to obtain platinum hydroxide precipitate;

[0037] Step 2, put the platinum hydroxide precipitate into absolute ethanol and stir to disperse evenly, then add crown ether and stir until completely dissolved to obtain a mixed ethanol solution;

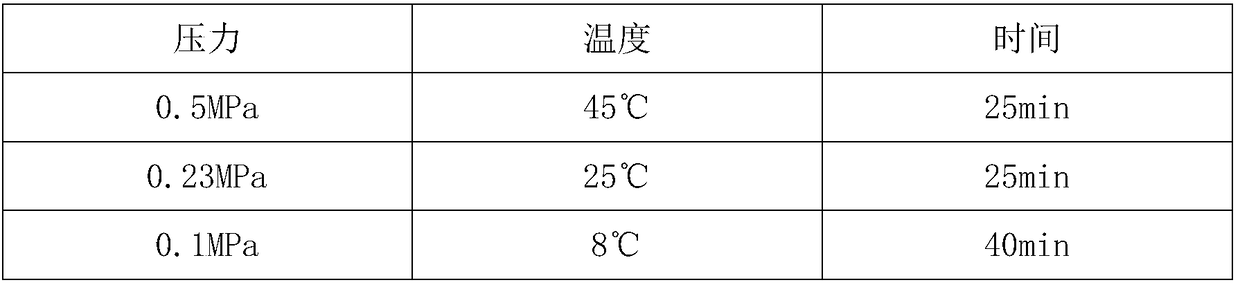

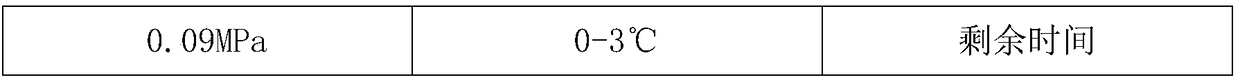

[0038] Step 3, the mixed ethanol solution was kept at a constant temperature for 2 hours, then left for 4 hours in a gradient decompression, and filtered to obtain crystals;

[0039] Step 4, putting the crystals into a ball milling device for constant temperature ball milling reaction for 1 hour to obtain crystal fine powder;

[0040] Step 5, adding the fine crystal powder into the electrolyte solution for electrolysis for 2 hours, and obtaining a precipitate...

Embodiment 2

[0053] A preparation method of nano platinum oxide powder, comprising the steps of:

[0054]Step 1, adding platinum chloride to distilled water and stirring until completely dissolved, then slowly adding alkali solution dropwise until no precipitation occurs, filtering and washing to obtain platinum hydroxide precipitate;

[0055] Step 2, put the platinum hydroxide precipitate into absolute ethanol and stir to disperse evenly, then add crown ether and stir until completely dissolved to obtain a mixed ethanol solution;

[0056] Step 3, the mixed ethanol solution was kept at a constant temperature for 5 hours, then left for 8 hours in a gradient depressurization, and filtered to obtain crystals;

[0057] Step 4, putting the crystals into a ball milling device for constant temperature ball milling reaction for 2 hours to obtain crystal fine powder;

[0058] Step 5, adding the fine crystal powder into the electrolyte solution for electrolysis for 4 hours, and obtaining a precipit...

Embodiment 3

[0071] A preparation method of nano platinum oxide powder, comprising the steps of:

[0072] Step 1, adding platinum chloride to distilled water and stirring until completely dissolved, then slowly adding alkali solution dropwise until no precipitation occurs, filtering and washing to obtain platinum hydroxide precipitate;

[0073] Step 2, put the platinum hydroxide precipitate into absolute ethanol and stir to disperse evenly, then add crown ether and stir until completely dissolved to obtain a mixed ethanol solution;

[0074] Step 3, the mixed ethanol solution was kept at a constant temperature for 4 hours, and then left for 6 hours by gradient depressurization, and filtered to obtain crystals;

[0075] Step 4, putting the crystals into a ball milling device for constant temperature ball milling reaction for 2 hours to obtain crystal fine powder;

[0076] Step 5, adding the fine crystal powder into the electrolyte solution for electrolysis for 3 hours, and obtaining a preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com