Synthesis of maleimidotriethoxy silane-series compounds, and preparation method of self-assembled film

A technology of maleimidotriethoxysilane and its synthesis method, which is applied in the fields of chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, organic chemistry, etc., and can solve the problem of catalytic yield and repeatability Poor and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Synthesis of self-assembly material 11-maleimidoundecyltriethoxysilane.

[0027]

[0028] Synthesis of 10-undecylenamide:

[0029]

[0030] Take urea (15g, 0.25mol) and undecylenic acid (23.01g, 0.125mol) in a two-necked flask, raise the temperature to 170-180°C, and stop heating after 4 hours of reaction. When the temperature drops to 110-120°C, add 5% Na 2 CO 3 The solution (100-150ml) was used to stop the reaction, and the mixture was placed in an ice-water bath, filtered after solid precipitation, recrystallized twice with 95% ethanol, and vacuum-dried to obtain a colorless solid with a yield of 60%. 1 HNMR (400MHz; CDCl 3 ): δ5.80 (1H, m), 5.47 (2H, s), 2.22 (2H, t), 2.04 (2H, m), 1.63 (2H, m), 1.38-1.29 (10H, m).

[0031] Synthesis of 11-amino-1-undecene:

[0032]

[0033] Take LiAlH 4 (2.3g, 60.6mmol), 50ml of dry THF in a 250ml two-necked flask, protected by nitrogen, heated to reflux for 30min and then stopped heating. Compound 10-undecylena...

Embodiment 2

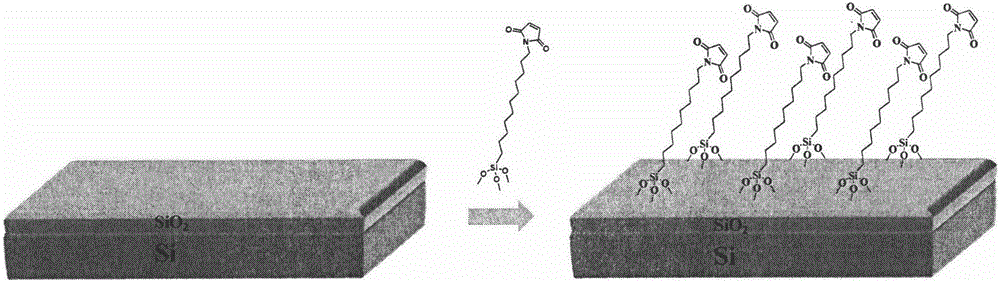

[0041] (1) Preparation of self-assembled membrane

[0042] Step 1: Wash the silicon wafer with a size of 1cm×1cm with a neutral detergent and wash it with a large amount of ultrapure water;

[0043] Step 2: Sonicate silicon wafers with acetone, ethanol, and ultrapure water for 10 minutes in sequence and use N 2 blow dry;

[0044] Step 3: Incorporate the cleaned Si / SiO 2 The substrate is immersed in the piranha solution (H 2 SO 4(conc.) / H 2 o 2(30%) =5:1) for 24h to form hydroxyl groups on its surface;

[0045] Step 4: Dip the activated silicon wafer in 10ml of toluene (dry) solution of 11-maleimidoundecyltriethoxysilane (10 -3 M), N 2 protected, heated to 75°C, and self-assembled for 48h, the Si / SiO 2 A self-assembled film of 11-maleimido undecyltriethoxysilane is self-assembled on a substrate.

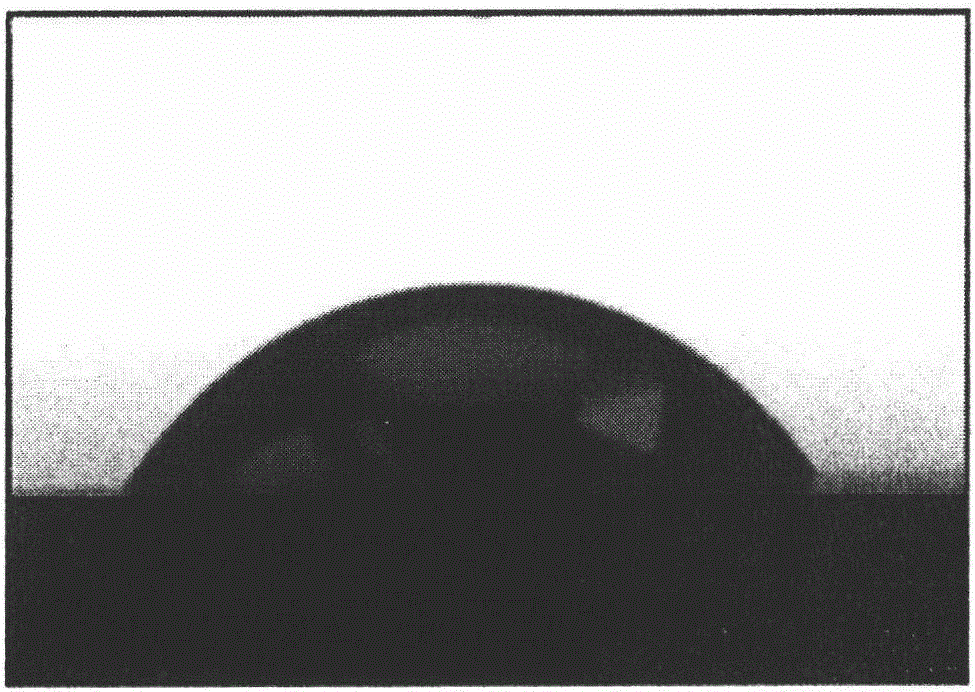

[0046] (2) Characterization of materials

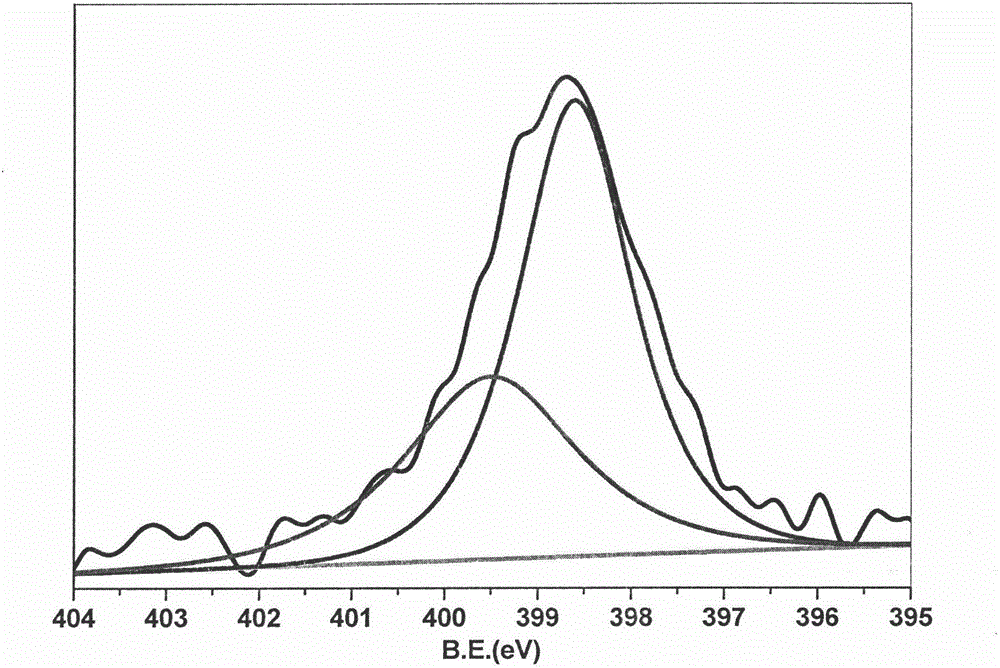

[0047] (a) X-ray photoelectron spectroscopy (XPS)

[0048] figure 2 It is the XPS schematic diagram of N1s. The peak with bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com