Polyphenylacetylene preparing method initiated by phenylsilane

A polyphenylene vinylene and phenylsilane technology, applied in the field of polyphenylene vinylene preparation, can solve the problems of large molecular weight distribution coefficient and low polymer yield, and achieve the effect of increasing the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

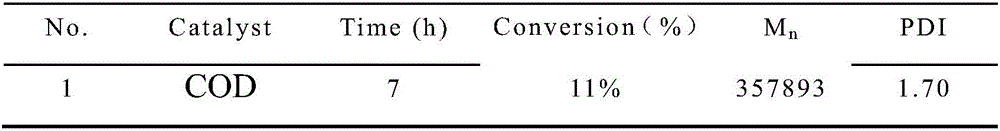

[0015] Catalyst (COD) consumption is 4.0‰ of monomer mass, initiator (PSH) consumption is 2% of monomer consumption, in N 2 In atmosphere protection, under 30 ℃, carry out phenylacetylene (PA) bulk polymerization reaction, gained experimental result is as follows table 1 (the number-average molecular weight M of polymer n and molecular weight polydispersity index PDI are measured by Malvern Viscotek 270Max multi-detector gel permeation chromatography):

[0016] Table 1 The results of PA polymerization with PSH as the initiator and 4.0‰COD as the catalyst

[0017] Table 1. Polymerization of PA initiated by PSH and catalyzed by CODcatalyst

[0018]

Embodiment 2

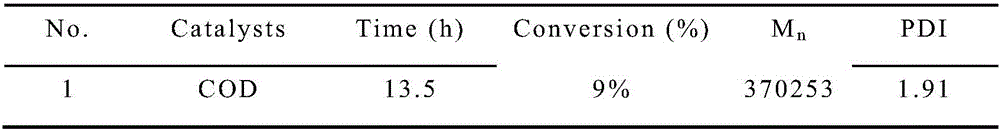

[0020] Reduce catalyst (COD) consumption to be 2.0‰ of monomer mass, initiator (PSH) consumption to be 2% of monomer consumption, in N 2 In the atmosphere protection, phenylacetylene (PA) polymerization was carried out at 30°C, and the experimental results obtained are as follows in Table 2:

[0021] Table 2 Effect of catalyst concentration on polymerization of PA in PSH / COD reaction system

[0022] Table 2. The effect of catalyst concentrations on the M n and PDI ofPPA

[0023]

[0024] With the reduction of catalyst consumption, the reaction time is obviously prolonged, but the molecular weight of the product is improved to some extent.

Embodiment 3

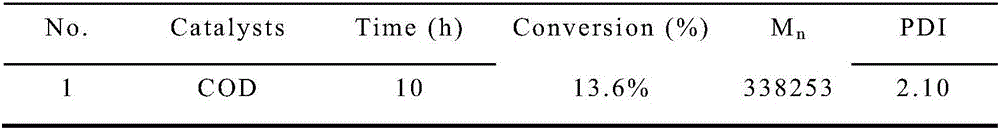

[0026] Keep catalyst (COD) consumption constant as 2.0‰ of monomer quality, same initiator (PSH) consumption is 2% of monomer consumption, in N 2 In the atmosphere protection, the phenylacetylene (PA) polymerization reaction was carried out at an elevated reaction temperature of 40°C. The experimental results obtained are shown in Table 3 below:

[0027] Table 3 The influence of temperature on the polymerization of PA in PSH / COD reaction system

[0028] Table 3. The effect of polymerization temperature on the M n and PDI ofPPA

[0029]

[0030] The raising of temperature accelerates the reaction rate, but the molecular weight of the product decreases and the PDI becomes larger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com