High-activity spiral Pt-Rh alloy nanocatalyst and preparation method thereof

A technology of alloy nanometer and high activity rattan, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complicated preparation process and increase of production cost, etc. , to achieve the effect of improving anti-carbon monoxide poisoning ability, reducing economic cost and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Insulin fibers with hollow helical structure

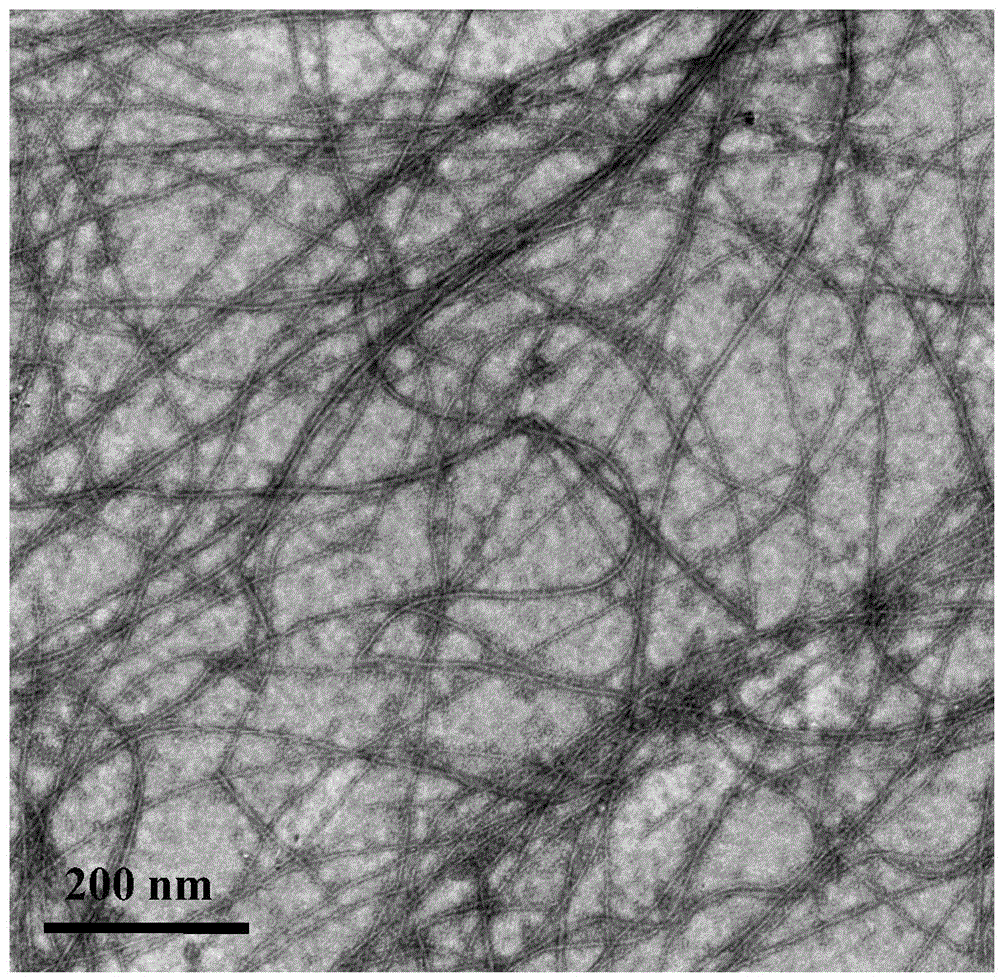

[0038] Put 0.0010g of bovine proinsulin powder in a centrifuge tube, add 1mL of freshly prepared hydrochloric acid solution with a pH of 2.0, dissolve and mix with ultrasound to obtain a 0.2mM insulin-hydrochloric acid solution, seal it with a parafilm, and dissolve the insulin-hydrochloric acid solution The solution was heated in a constant temperature metal bath at 75°C for 15 hours to obtain the insulin fiber suspension, and its appearance was observed under a transmission electron microscope as follows: figure 1 shown.

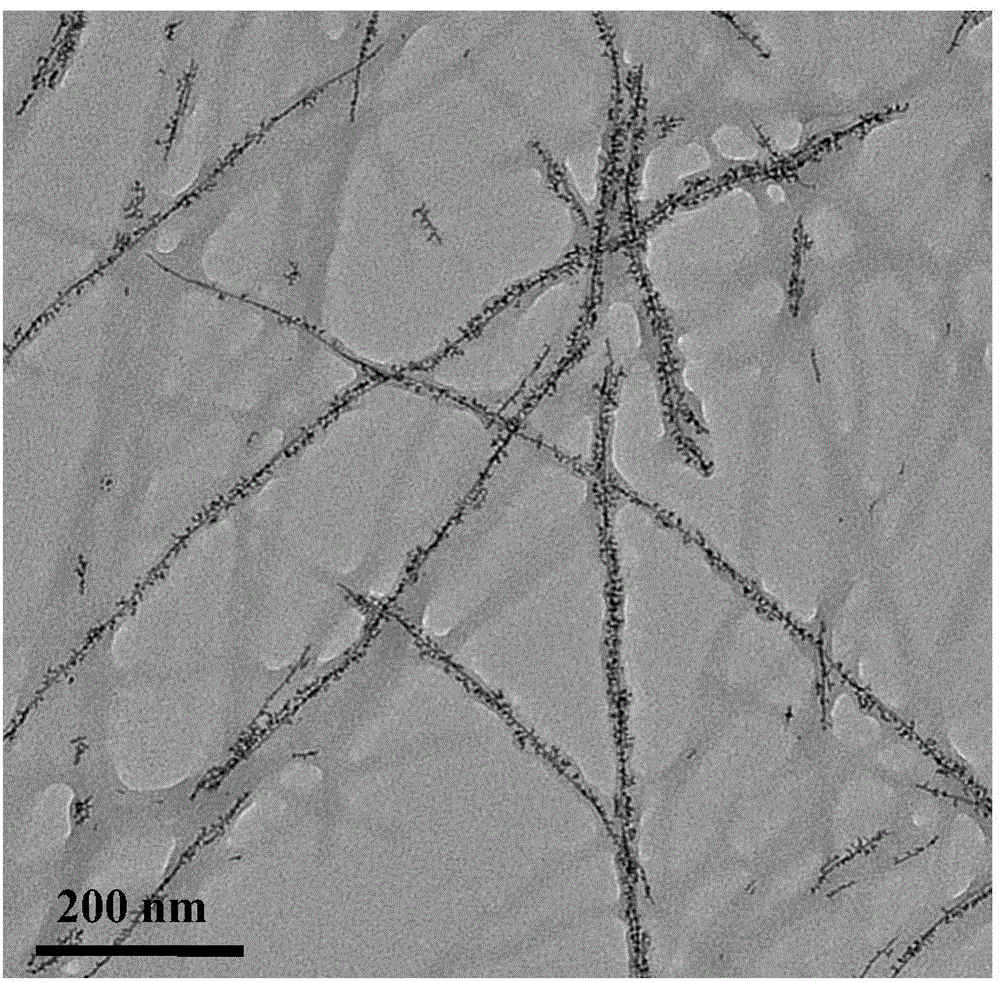

[0039] 2. Preparation of Pt-Rh alloy nanocatalyst with rattan-wrapped tree structure

[0040] Take the above 100 μL insulin fiber suspension in a centrifuge tube, add 100 μL, 1.0 mM PtCl 4 and 1.0mM RhCl 3 Mix the solution, mix well and put it into a water bath constant temperature shaker at 100rmp and incubate at 20°C for 20h. Add 150 μL of newly prepared sodium borohydride solution with a conce...

Embodiment 2

[0042] 1. Insulin fibers with hollow helical structure

[0043] Step 1 of Example 1 was repeated.

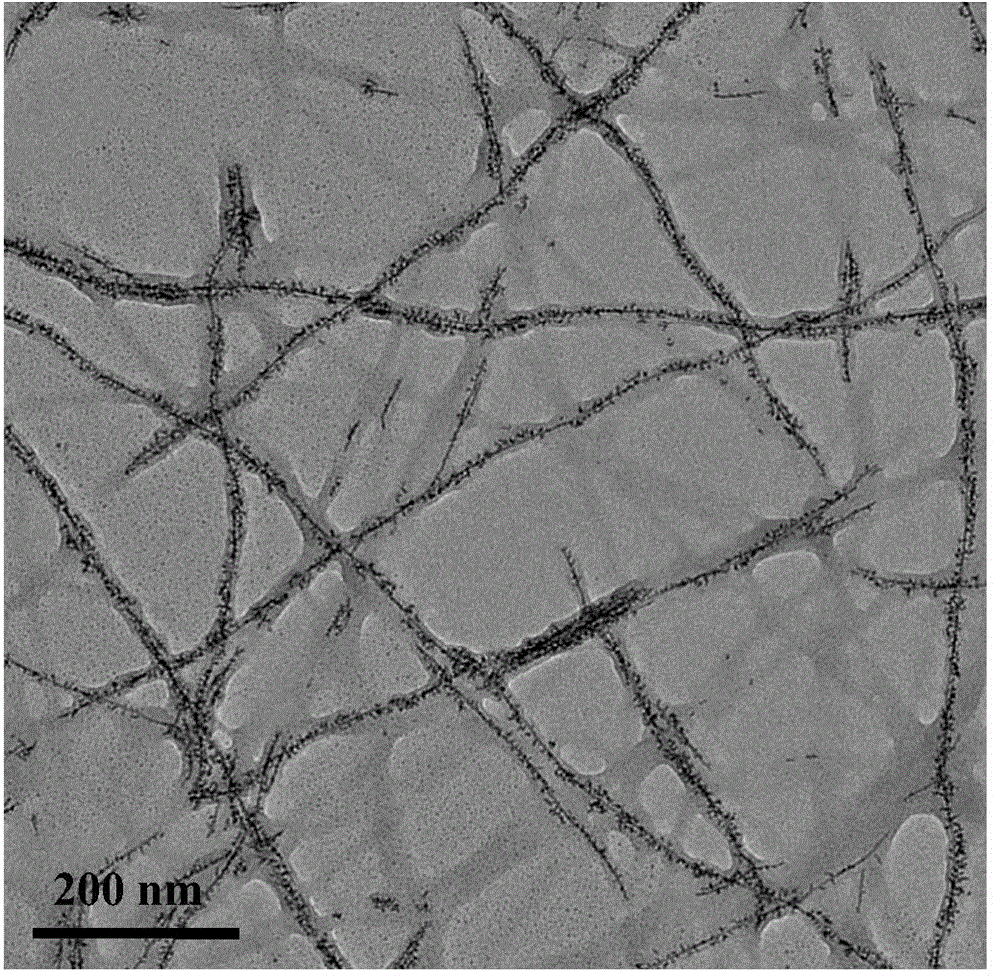

[0044] 2. Preparation of Pt-Rh alloy nanocatalyst with rattan-wrapped tree structure

[0045] Take the above 100 μL insulin fiber suspension in a centrifuge tube, add 100 μL, 2.0 mM PtCl 4 and 2.0mM RhCl 3 Mix the solution, mix well and put it into a water bath constant temperature shaker at 100rmp and incubate at 20°C for 20h. Add 150 μL of newly prepared sodium borohydride solution with a concentration of 10 mM to the above-incubated system, and add 30 μL / time with an interval of 5 min / time. After adding the reducing agent each time, ultrasonicate the reaction system once every 10s, and ultrasonicate for 2s each time. Finally, put the centrifuge tube into a shaker and incubate at 20° C. at 40 rpm for 10 h until the reaction is complete, and the rattan-wrapped tree structure Pt-Rh alloy nanocatalyst is prepared.

Embodiment 3

[0047] 1. Insulin fibers with hollow helical structure

[0048] Put 0.0015g of bovine proinsulin powder in a centrifuge tube, add 1mL of freshly prepared hydrochloric acid solution with a pH of 1.8, dissolve and mix with ultrasound to obtain a 0.3mM insulin-hydrochloric acid solution, seal it with a parafilm, and dissolve the insulin-hydrochloric acid solution The solution is placed in a constant temperature metal bath at 80°C and heated for 10 hours to obtain an insulin fiber suspension with a hollow helical structure.

[0049] 2. Preparation of Pt-Rh alloy nanocatalyst with rattan-wrapped tree structure

[0050] Take the above 100 μL insulin fiber suspension in a centrifuge tube. Add 100 μL of 2.0 mM PtCl 4 and 1.0mM RhCl 3 Mix the solution, mix well and put it into a constant temperature shaker in a water bath at 120rmp and incubate at 25°C for 15h. Add 120 μL of newly prepared sodium borohydride solution with a concentration of 10 mM to the above-incubated system, addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com