A kind of preparation method of room temperature hydrogen sensor

A sensor and room temperature technology, applied in the field of hydrogen sensors, can solve the problems of insufficient bonding of metal oxides, insufficient catalytic performance, and restrictions on wide application, and achieve uniform and stable catalytic performance, low cost, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the room temperature hydrogen sensor described in this embodiment comprises the following steps:

[0027] 1) For conventional WO 3 The nanosheets were pretreated with 1gWO at room temperature 3 The nanosheets are loaded into a quartz crucible, which is then placed inside a muffle furnace. Start the heating program of the muffle furnace, heat from room temperature to 500 °C at a heating rate of 5 °C / min, keep at 500 °C for 2 hours, then turn off the heating program of the muffle furnace, let it cool down naturally, and after cooling down to room temperature, put the WO 3 The nanosheets are packed into sample vials for use.

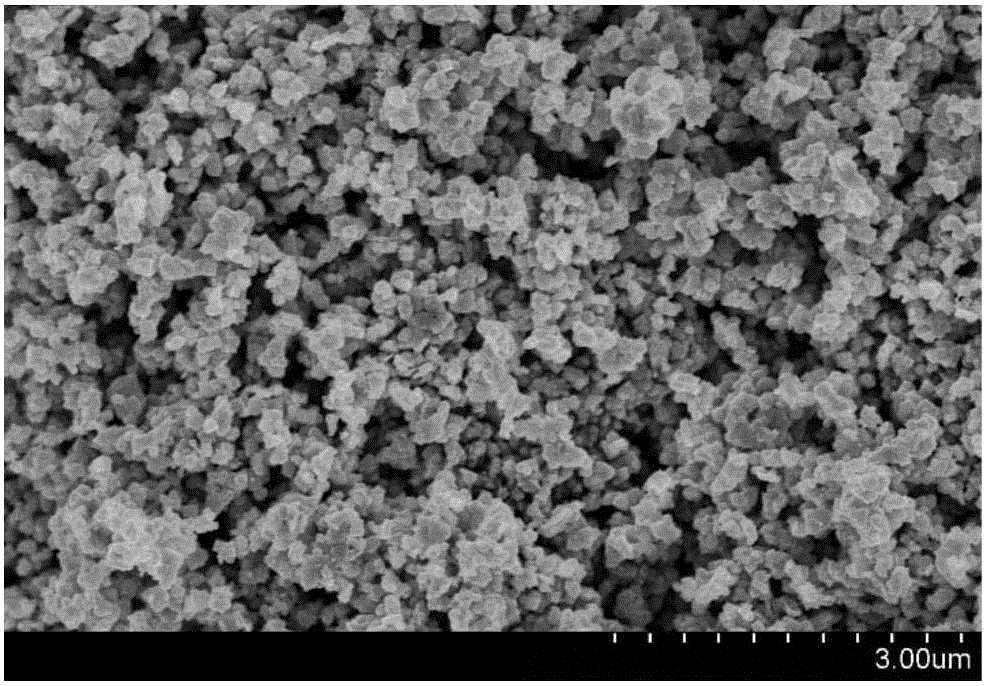

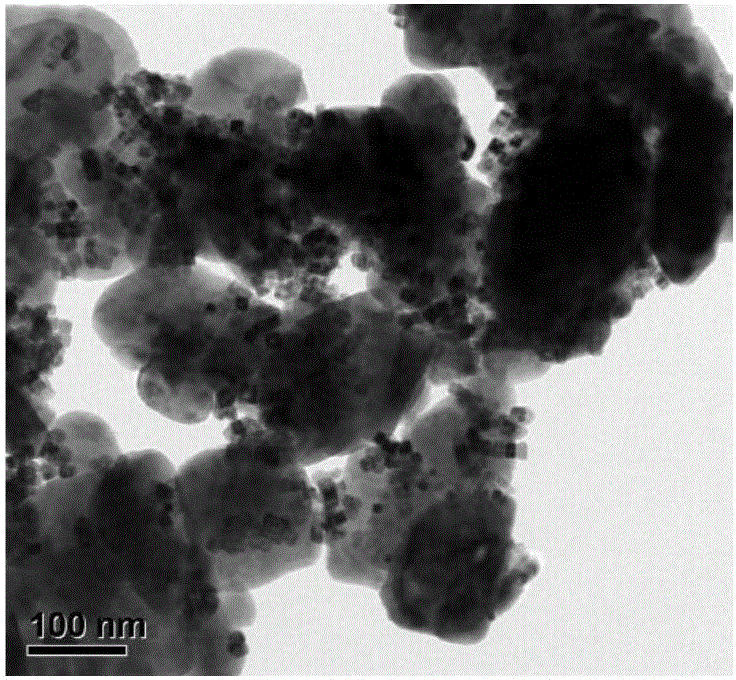

[0028] The conventional tungsten trioxide nanosheets are flakes with an average side length of 150 nm and an average thickness of 30 nm. It can be synthesized in the laboratory by a simple hydrothermal method, and commercially available similar products can also be purchased.

[0029] 2) Add 0.12g palladium chloride, 1.6...

Embodiment 2

[0035] The preparation method of the room temperature hydrogen sensor described in this embodiment comprises the following steps:

[0036] 1) For conventional WO 3 The nanosheets were pretreated with 1gWO at room temperature 3 The nanosheets are loaded into a quartz crucible, which is then placed inside a muffle furnace. Start the heating program of the muffle furnace, heat from room temperature to 600 °C at a heating rate of 5 °C / min, keep at 600 °C for 2 hours, then turn off the heating program of the muffle furnace, let it cool down naturally, and after cooling down to room temperature, put the WO 3 The nanosheets are packed into sample vials for use.

[0037] The conventional tungsten trioxide nanosheets are flakes with an average side length of 150 nm and an average thickness of 30 nm. It can be synthesized in the laboratory by a simple hydrothermal method, and commercially available similar products can also be purchased.

[0038] 2) Add 0.15 g of platinum chloride, 2....

Embodiment 3

[0044] The preparation method of the room temperature hydrogen sensor described in this embodiment comprises the following steps:

[0045] 1) For regular In 2 o 3 Nanocubes were pretreated with 1gIn 2 o 3 The nanocubes are loaded into a quartz crucible, which is then placed in a muffle furnace. Start the heating program of the muffle furnace, heat from room temperature to 400 °C at a heating rate of 5 °C / min, keep at 400 °C for 2 hours, then close the heating program of the muffle furnace, let it cool down naturally, and after it drops to room temperature, put In 2 o 3 The nanocubes are packed into vials for use.

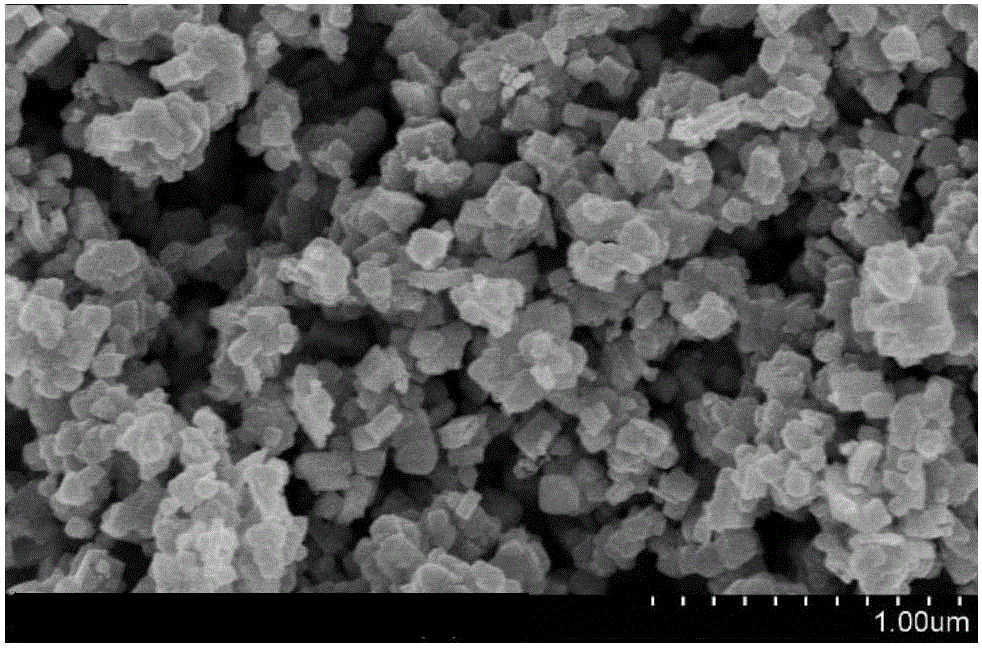

[0046] The conventional In 2 o 3 The nanocubes are indium oxide nanocubes with an average side length of 200 nm. It can be synthesized by a simple solvothermal method in the laboratory, or commercially available similar products can be purchased.

[0047] 2) Add 0.15g of platinum chloride, 1.6g of polyvinylpyrrolidone, 3.2g of sodium iodide and 20ml of deio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com