Method and apparatus of fuelling an internal combustion engine with hydrogen and methane

A technology for internal combustion engines and engines, applied to gaseous engine fuels, internal combustion piston engines, combustion engines, etc., can solve problems such as limiting the degree of delay of fuel injection timing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

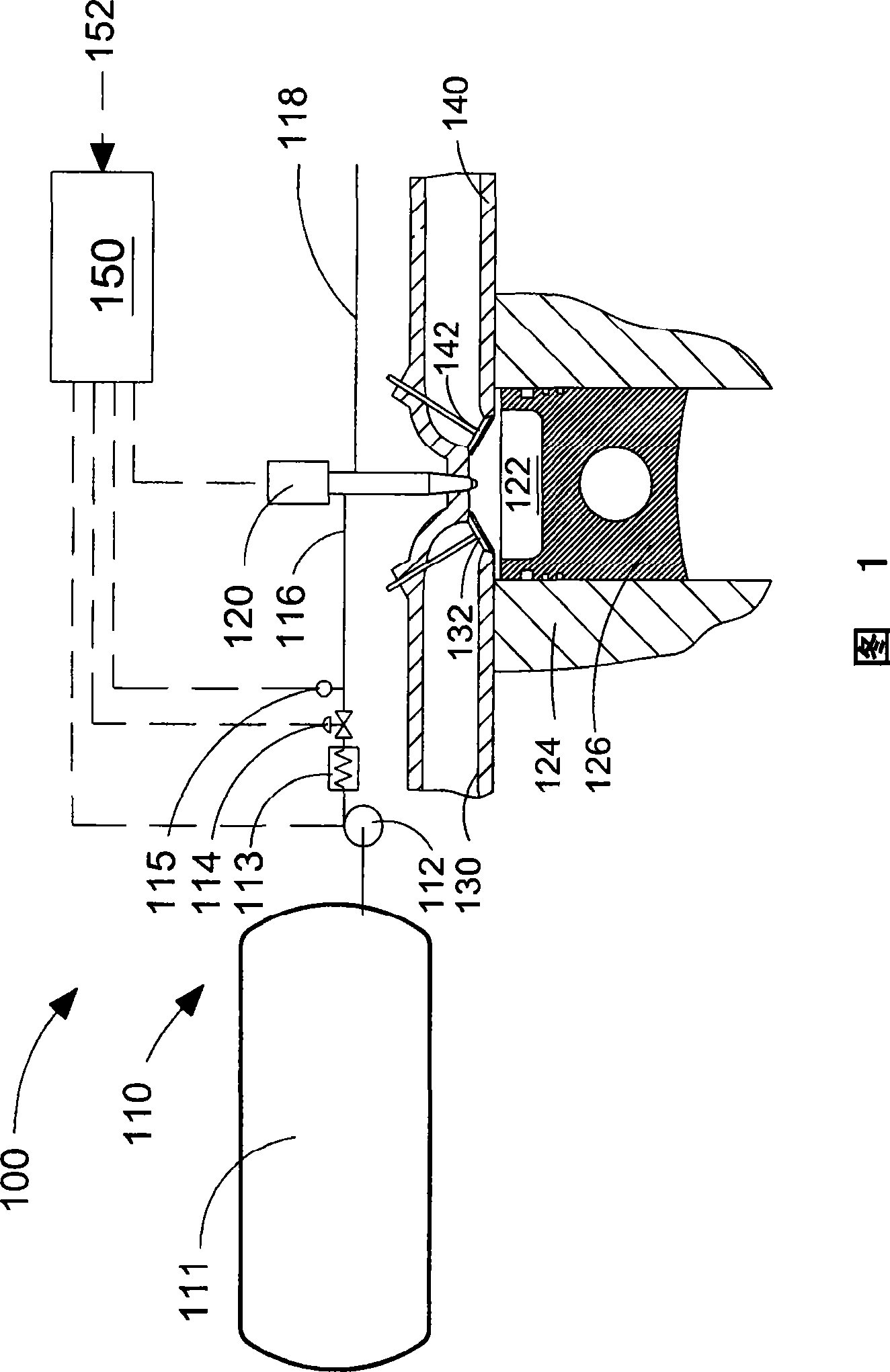

[0033] Figure 1 is an illustration of an engine plant 100 adapted to be fueled by a gaseous fuel mixture comprising methane and hydrogen. Fuel storage system 110 includes a storage vessel 111 for storing a compressed gaseous fuel mixture. In the illustrated embodiment, the premixed gaseous fuel mixture may be stored in storage vessel 111, which is used to store the compressed gaseous fuel mixture at a predetermined storage pressure. The storage container 111 is designed according to local regulations, which may specify safety factors to ensure that the gaseous fuel mixture does not leak even in the event of an impact, for example, if the storage container 111 is used in a vehicle that may be involved in a vehicle collision. fuel tank. In addition to safety factors and design strength requirements, local regulations often set maximum storage pressures. Compressor 112 is operable to deliver a gaseous fuel mixture from storage vessel 111 to fuel injection valve 120 via aftercoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com