Cordierite body

a cordierite body and body technology, applied in the field of cordierite bodies, can solve the problems of rising back pressure, diesel emissions have come under attack in the united states, harmful effects on the environment and on humans, etc., and achieves low pressure drop, high thermal durability, and high permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

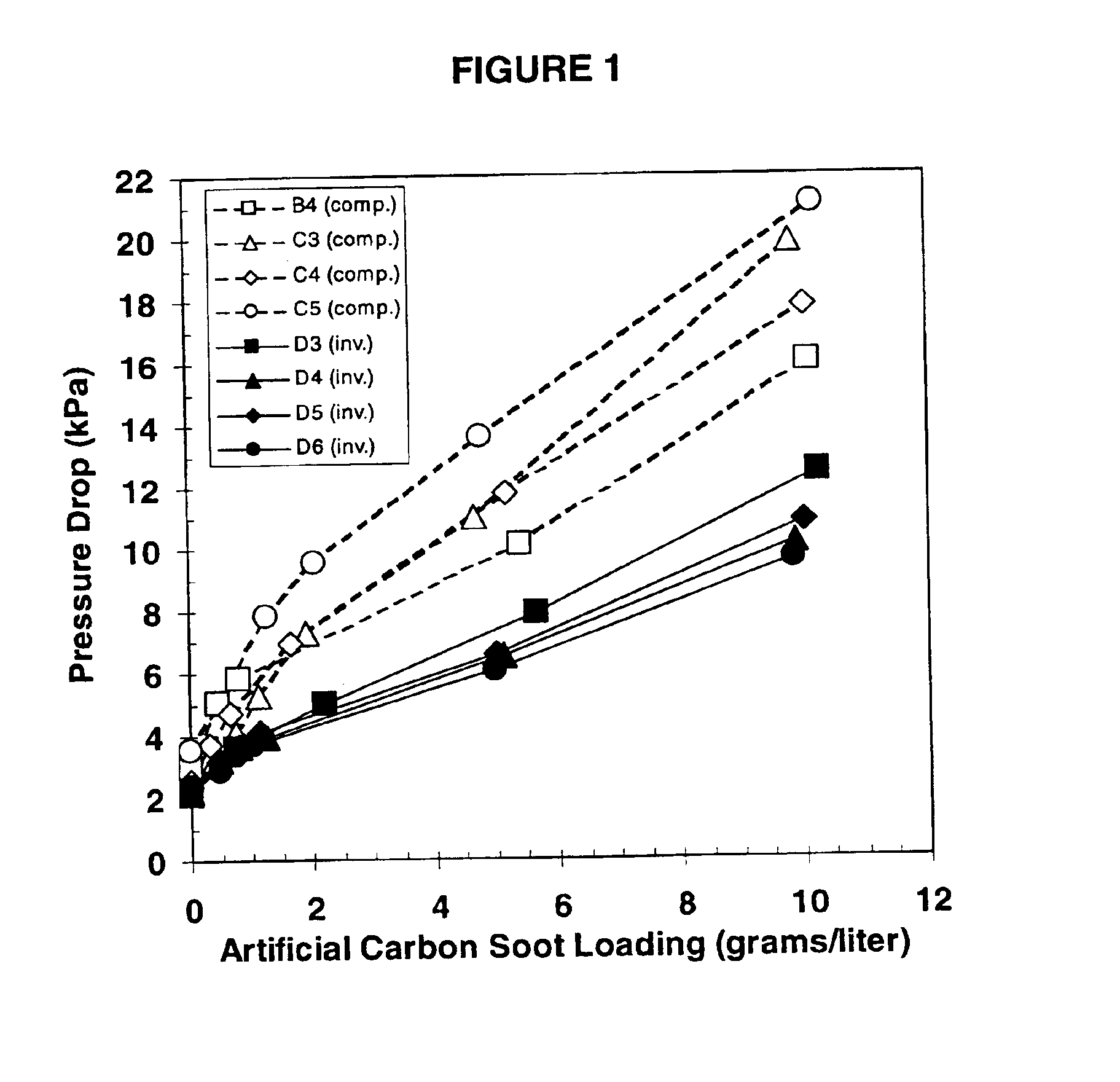

[0061]Inventive and comparative examples of cordierite bodies were prepared by weighing out the dry ingredients, mixing them with water and organic liquids and kneading the mixture in a stainless steel muller to form a plastic mass, and extruding the mixture into a ribbon having a thickness of about 0.020 inches and cellular honeycomb bodies consisting of multiple parallel channels of square cross section. The cellular bodies contained approximately 100 or 200 cells per square inch and had wall thicknesses of about 0.012 inches, 0.017 inches and 0.022 inches. After drying, the parts were fired at a rate of between 15 and 100° C. / hour to a maximum temperature of 1405° to 1430° C. and held for 6 to 25 hours. The cellular bodies were approximately 2 inches in diameter and were cut to about 6 inches in length. For each fired body, the alternate channels of one face were plugged to a depth of about 6 to 12 mm with a cementitious material, after which the ends of the channels that were op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com