Premix Burner Control System and Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

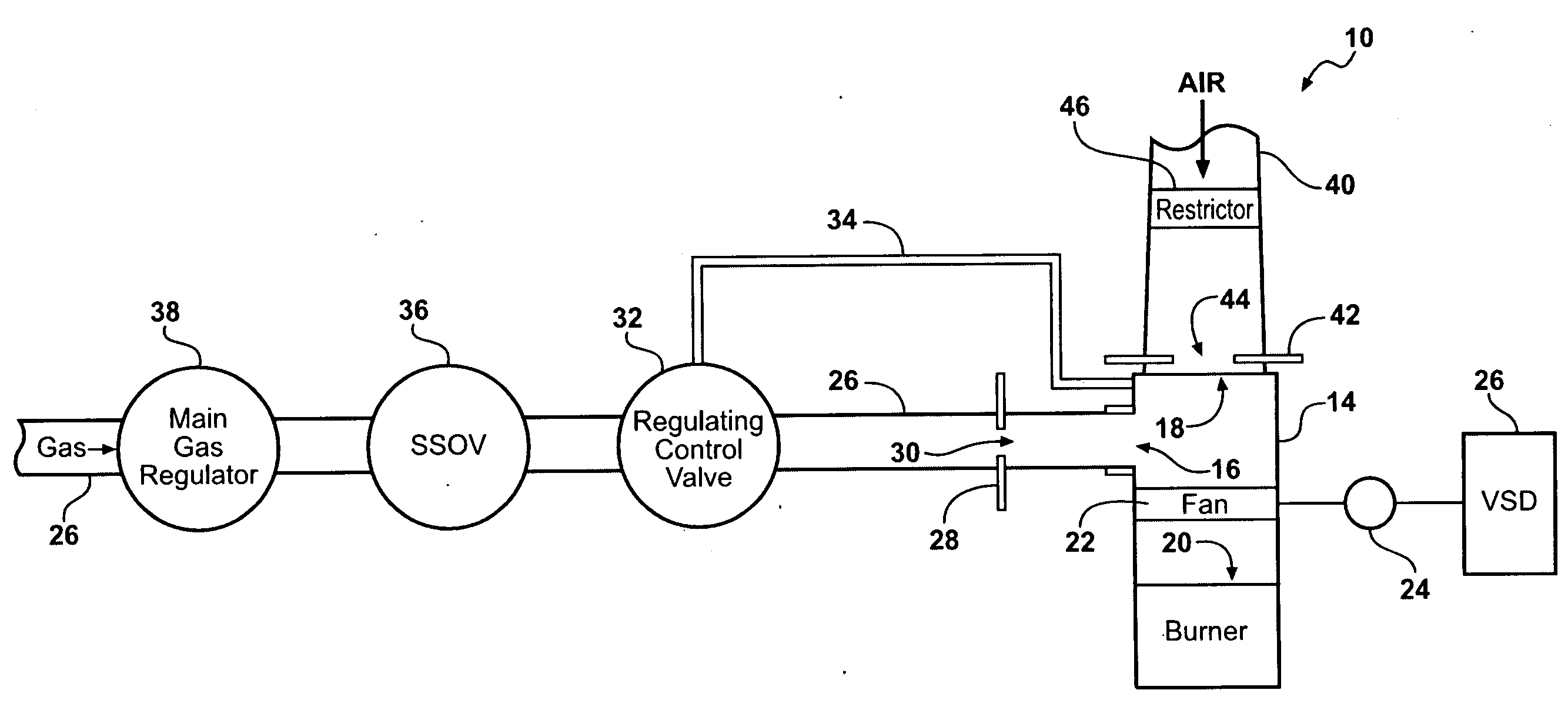

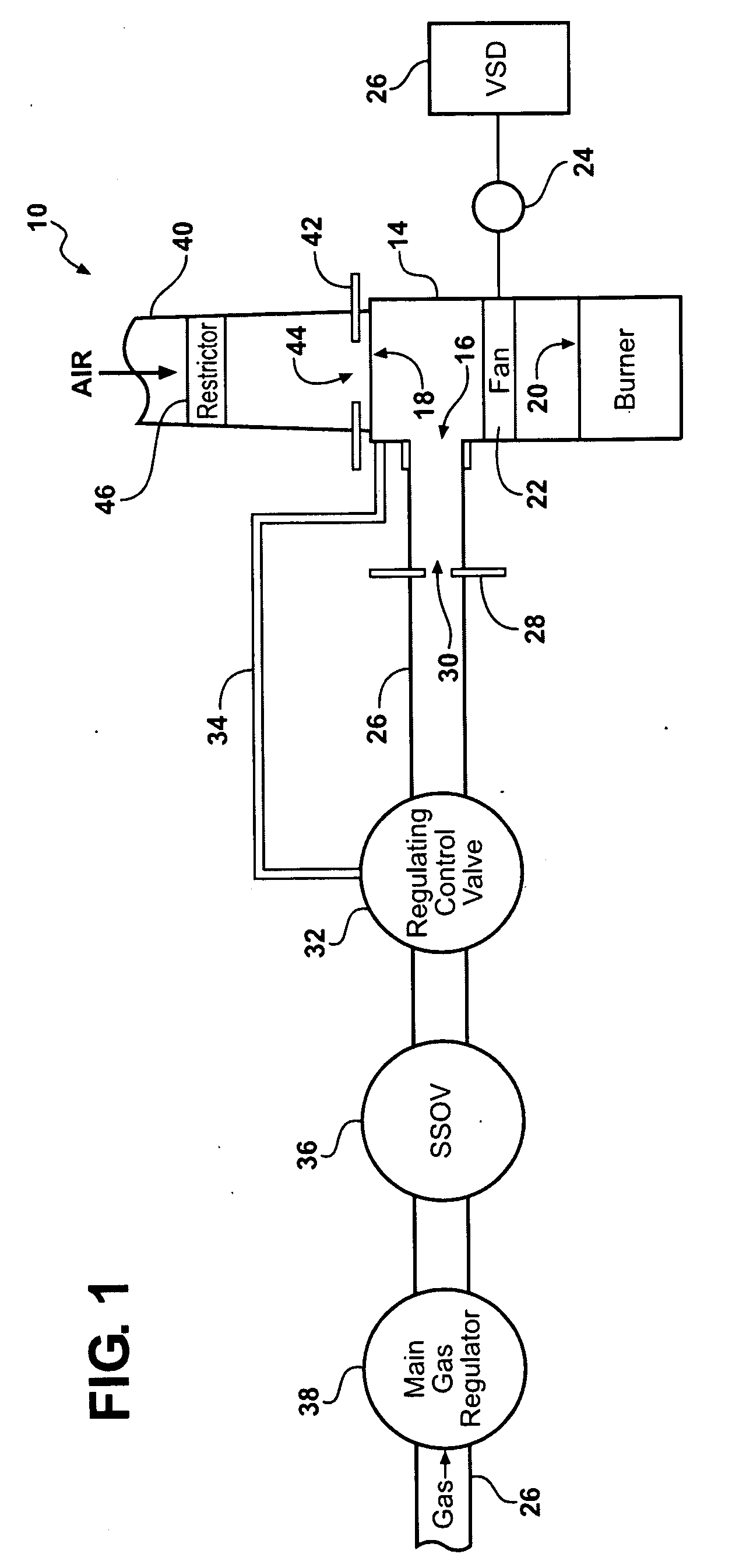

[0013]Referring to the Figures, wherein like numerals indicate like parts throughout the several views, a premix burner control system 10 and method of maintaining flow of an air / fuel mixture to a burner 12 is described herein.

[0014]Referring to FIG. 1, the premix burner control system 10 (hereafter referred to simply as the system 10) includes a housing 14 for mixing a gaseous fuel and air to produce an air / fuel mixture. Accordingly, the housing 14 defines a gas inlet 16 for receiving the gaseous fuel and an air inlet 18 for receiving air. The gaseous fuel may be natural gas; however, other suitable gaseous fuels may alternatively be utilized. The housing 14 may also be referred to as a pre-mix chamber by those skilled in the art.

[0015]The housing 14 also defines at least one outlet 20 for connection to the burner 12. The burner 12 preferably defines a plurality of burner ports (not shown) as is well known those skilled in the art. The air / fuel mixture is ignited and burned via the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com