Porous medium combustion apparatus of combustion use liquid fuel

A technology of porous media and burners, applied to gas fuel burners, burners, combustion methods, etc., to achieve full combustion, optimized combustion characteristics, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

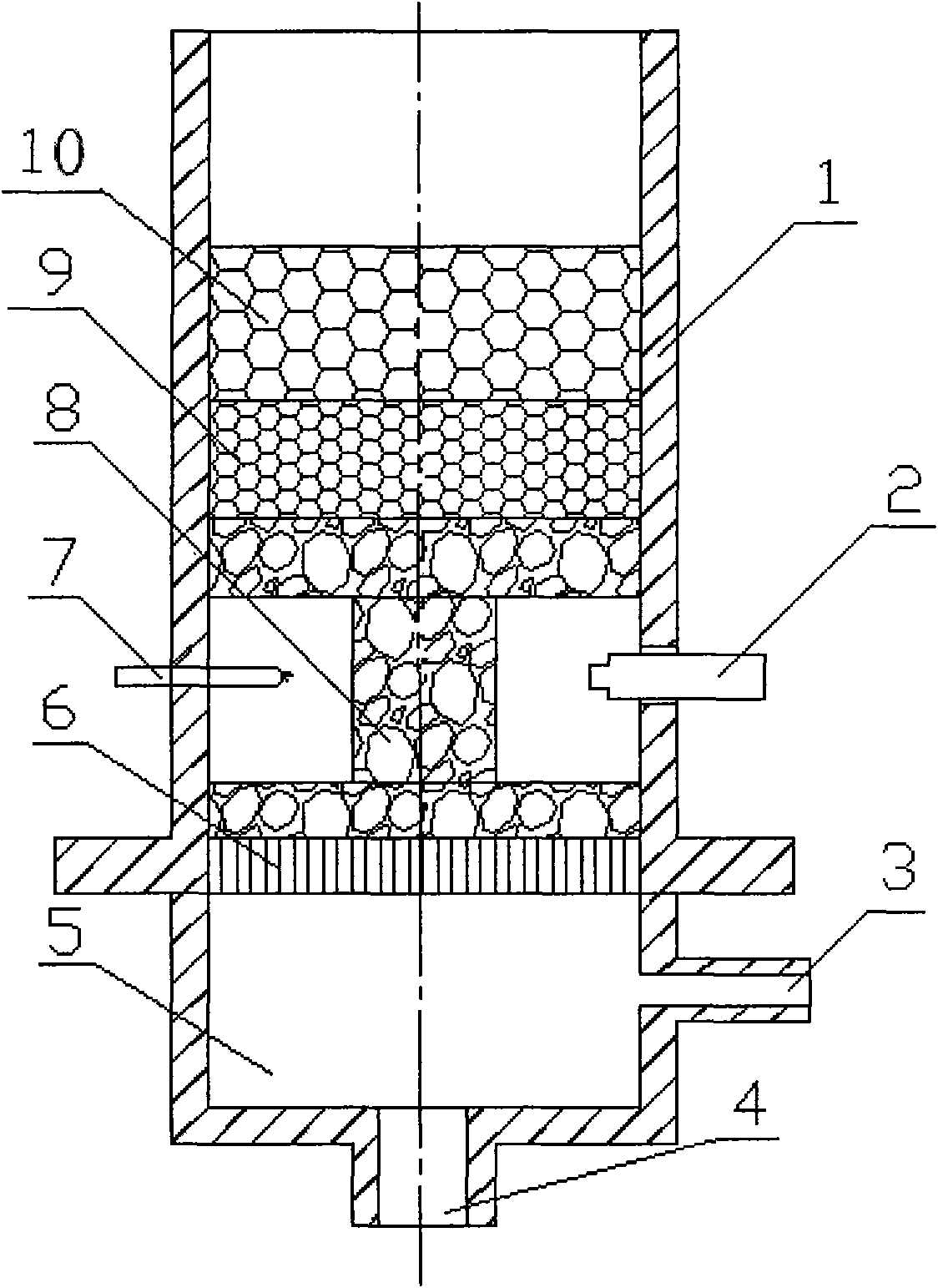

[0015] Step 1. First, let air and gas enter the pre-mixing chamber from the air inlet and the gas inlet respectively. After the pre-mixing chamber is mixed, the pulse igniter ignites, so that a combustion flame appears in the porous ceramic foam ceramic area.

[0016] Step 2. The combustion flame gradually moves from the porous ceramic foam area to the upper small-diameter porous medium ball area and the large-diameter porous medium ball area to realize the filtering and burning of the premixed gas in the multi-layer porous medium structure.

Embodiment 2

[0018] Step 1. First, let air and gas enter the pre-mixing chamber from the air inlet and the gas inlet respectively. After the pre-mixing chamber is mixed, the pulse igniter ignites to make a combustion flame appear in the foam ceramic area of the porous medium to preheat the foam ceramic.

[0019] Step 2. When the temperature of the ceramic foam area reaches the vaporization temperature of the liquid fuel, the liquid fuel is sprayed into the ceramic foam area, and the liquid fuel vaporizes quickly on the surface and inside of the ceramic foam and burns.

[0020] Step 3. After the combustion flame stabilizes in the porous medium ball area, close the gas inlet to achieve stable combustion of liquid fuel. The combustion process can be controlled by adjusting the fuel injection condition of the liquid fuel injector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com