Premix gas burner

a gas burner and pre-mix technology, applied in the direction of gaseous fuel burners, fuel supply regulation, combustion processes, etc., can solve the problems of not finding optimal reduction of deleterious effects of offset variations which may occur in gas valves during long working time, and achieve the effect of reducing the negative effects of offset variations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

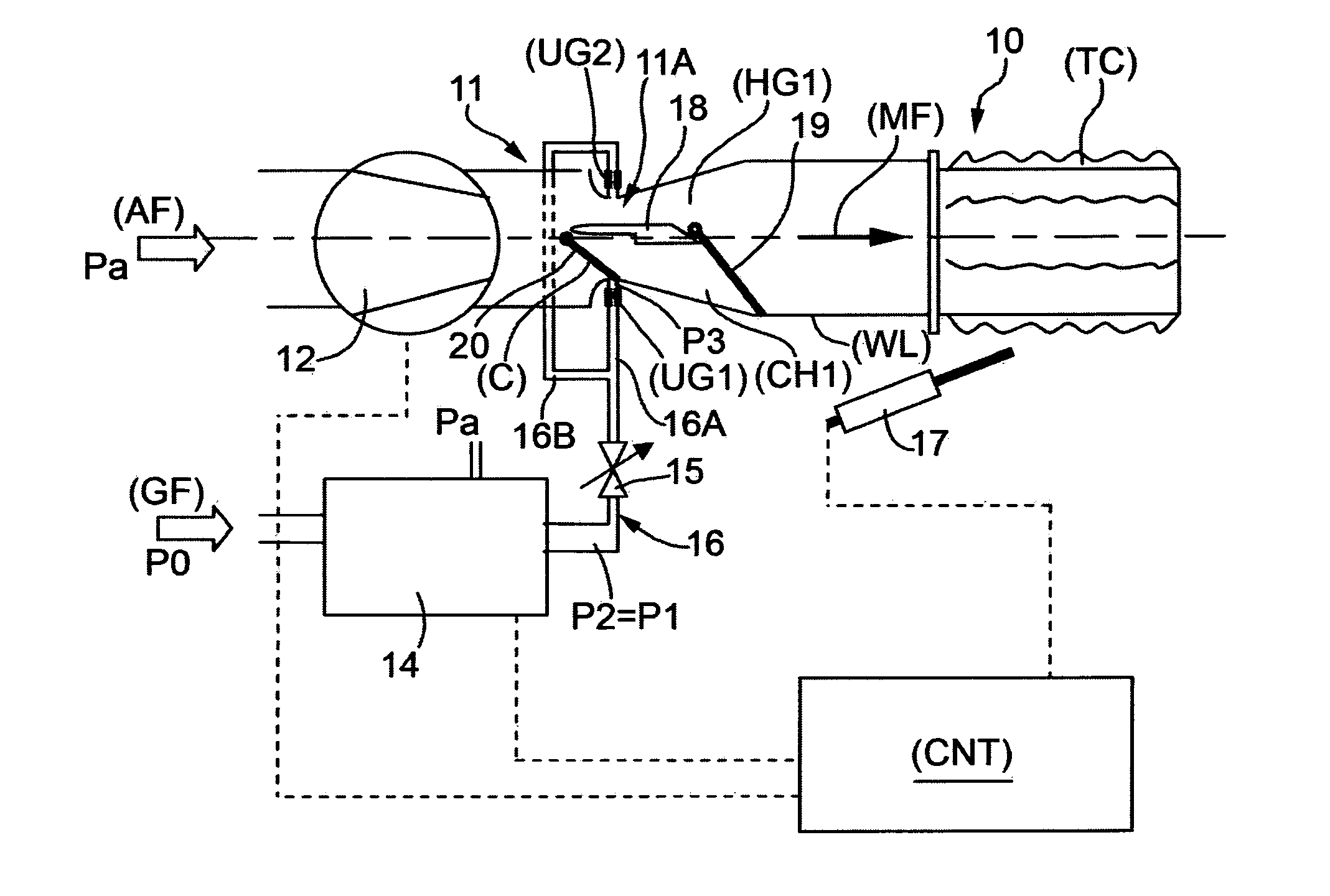

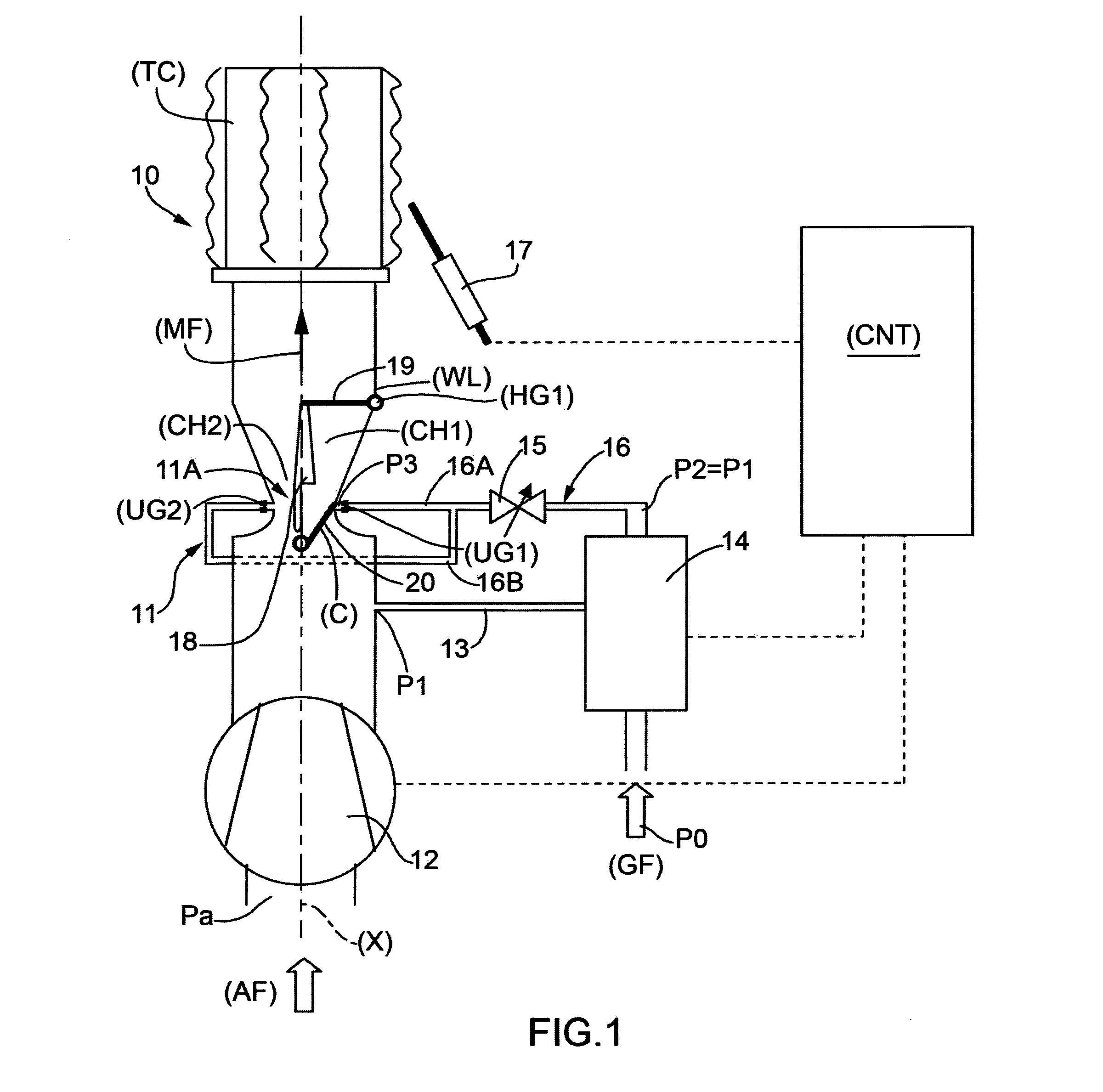

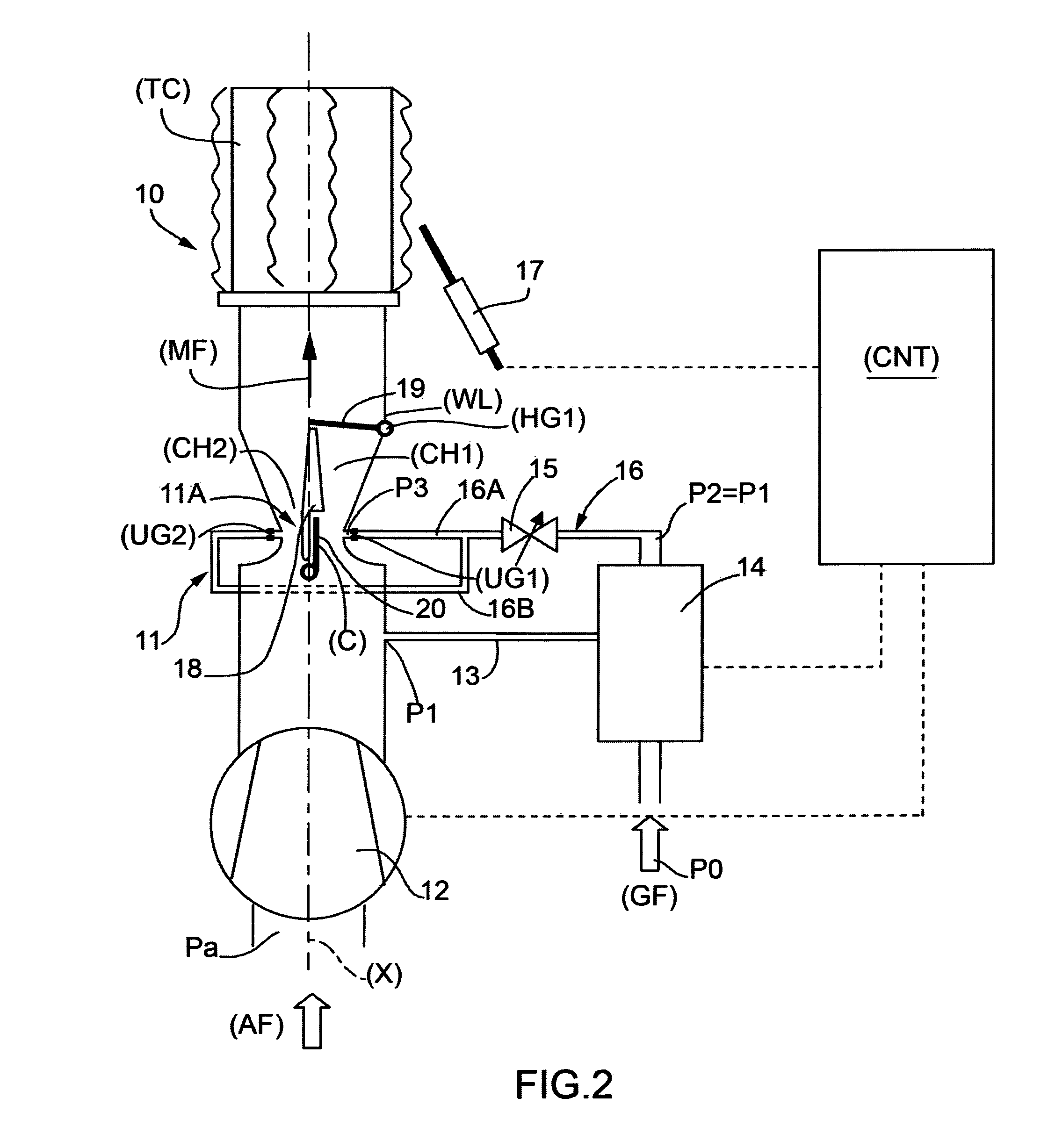

[0035]In a burner 10 illustrated in FIG. 1 a venturi channel air / gas mixer 11 is placed downstream of a fan 12 with respect to an air flow (AF). The mixer 11 comprises a localized pressure loss device 11A, in this case constituted by a venturi channel tube.

[0036]The burner 10 has a substantially longitudinal symmetry plane (X).

[0037]A pipe 13, which carries a pressure signal P1 to a gas valve 14, is connected upstream of the venturi channel type air gas mixer 11. Furthermore, a gas flow (GF) enters into the gas valve 14 at network pressure Po.

[0038]The amount of gas released by the gas valve 14 towards the mixer 11 is correlated to the pressure difference existing between an output pressure P2 of the gas valve 14 (pressure P2 equal to the pre-sure value P1) and a pressure P3 existing in the narrowest point (the localized loss of pressure device 11A) of the venturi channel type air / gas mixer 11.

[0039]The regulation of the air / gas ratio is mainly entrusted to the size of the nozzles (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com