Patents

Literature

32results about How to "Wide range of fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

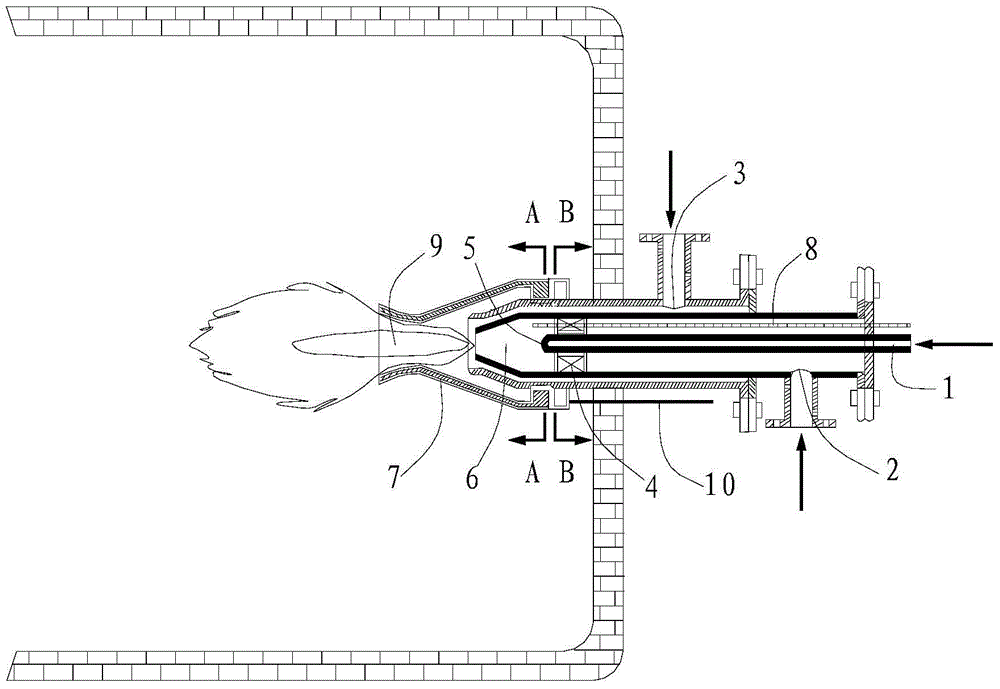

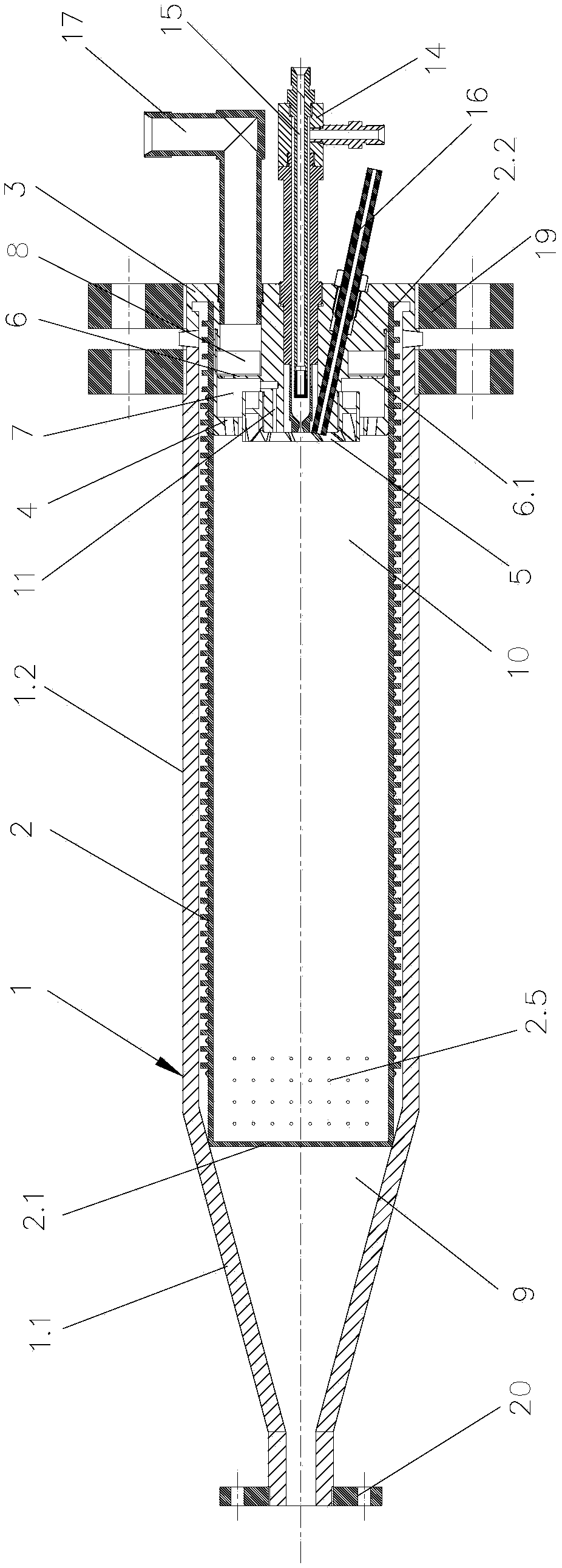

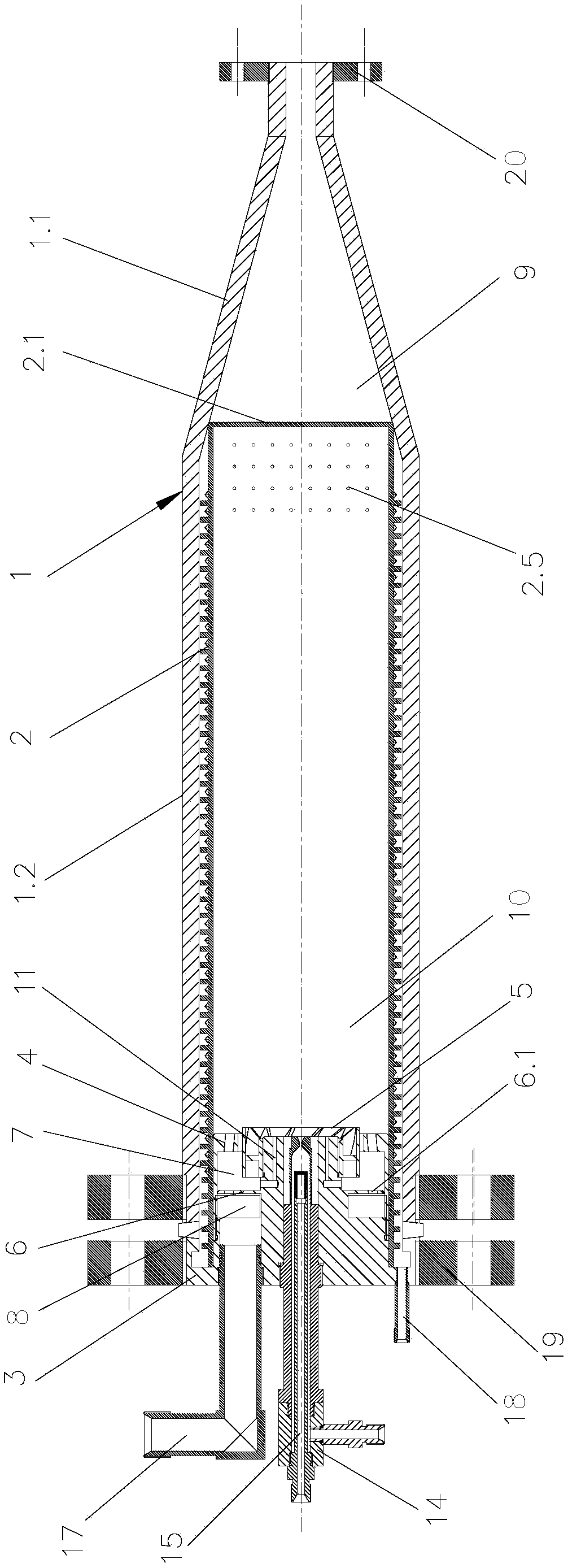

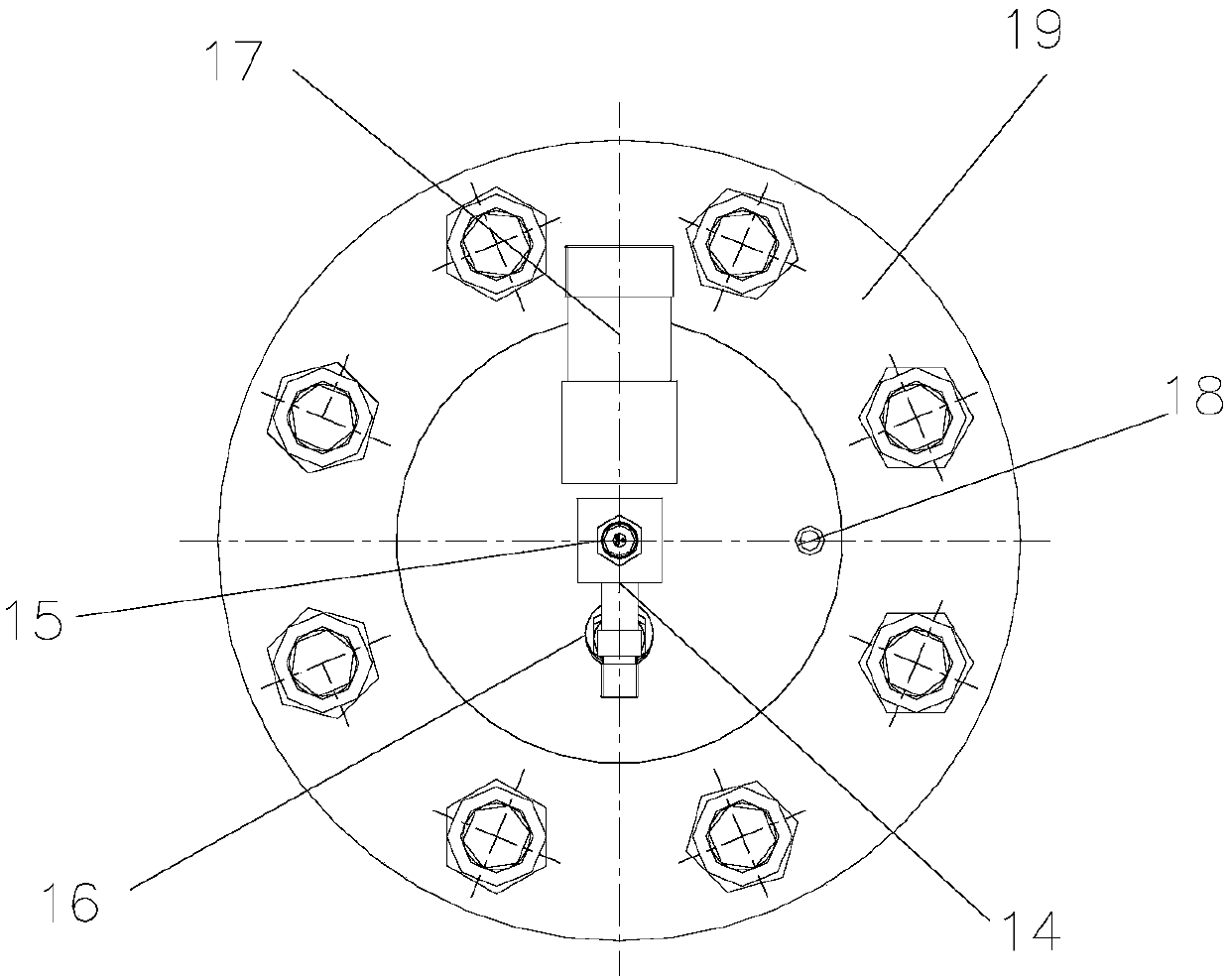

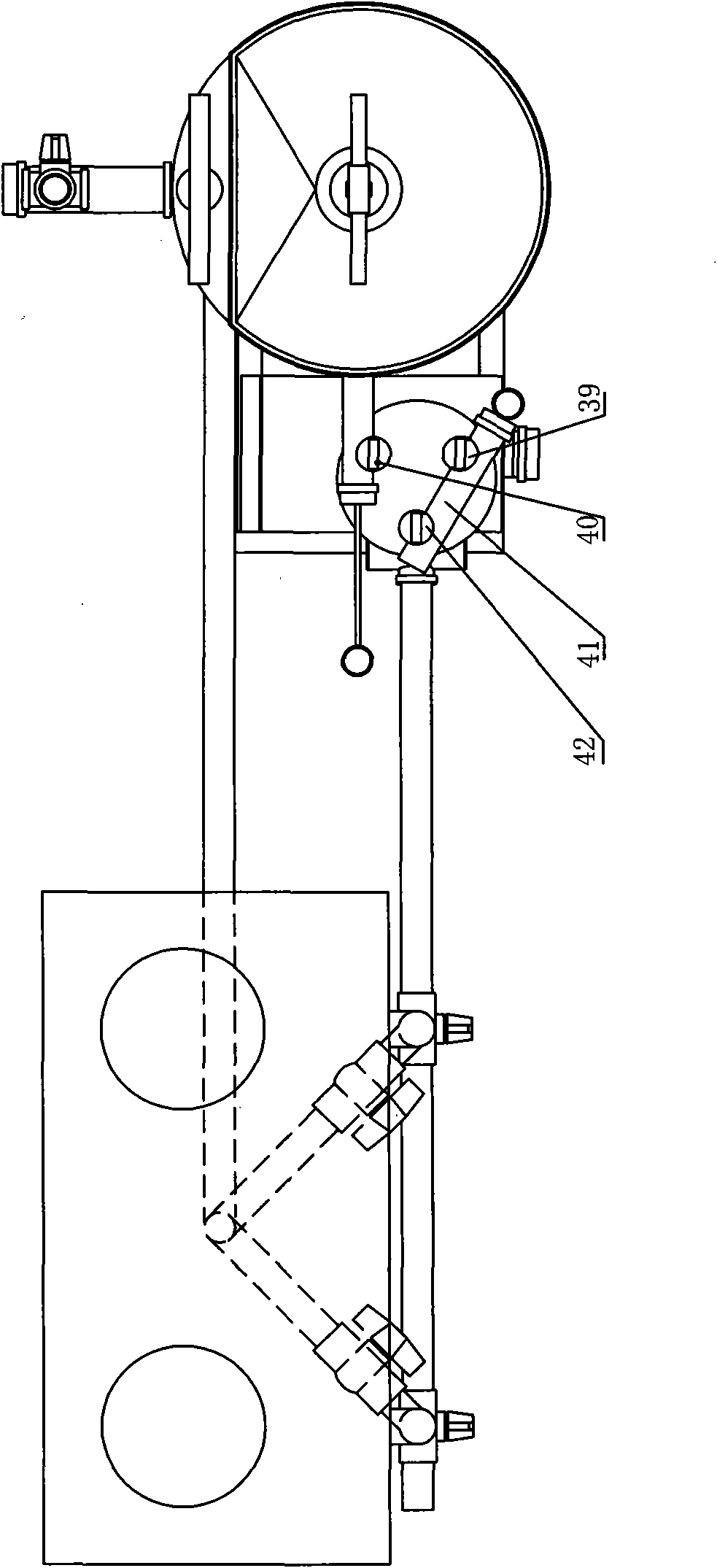

Gas burner capable of adjusting gas to be self-recycling

ActiveCN103277795AWide range of fuelImprove combustion efficiencyGaseous fuel burnerSpray nozzleGas burner

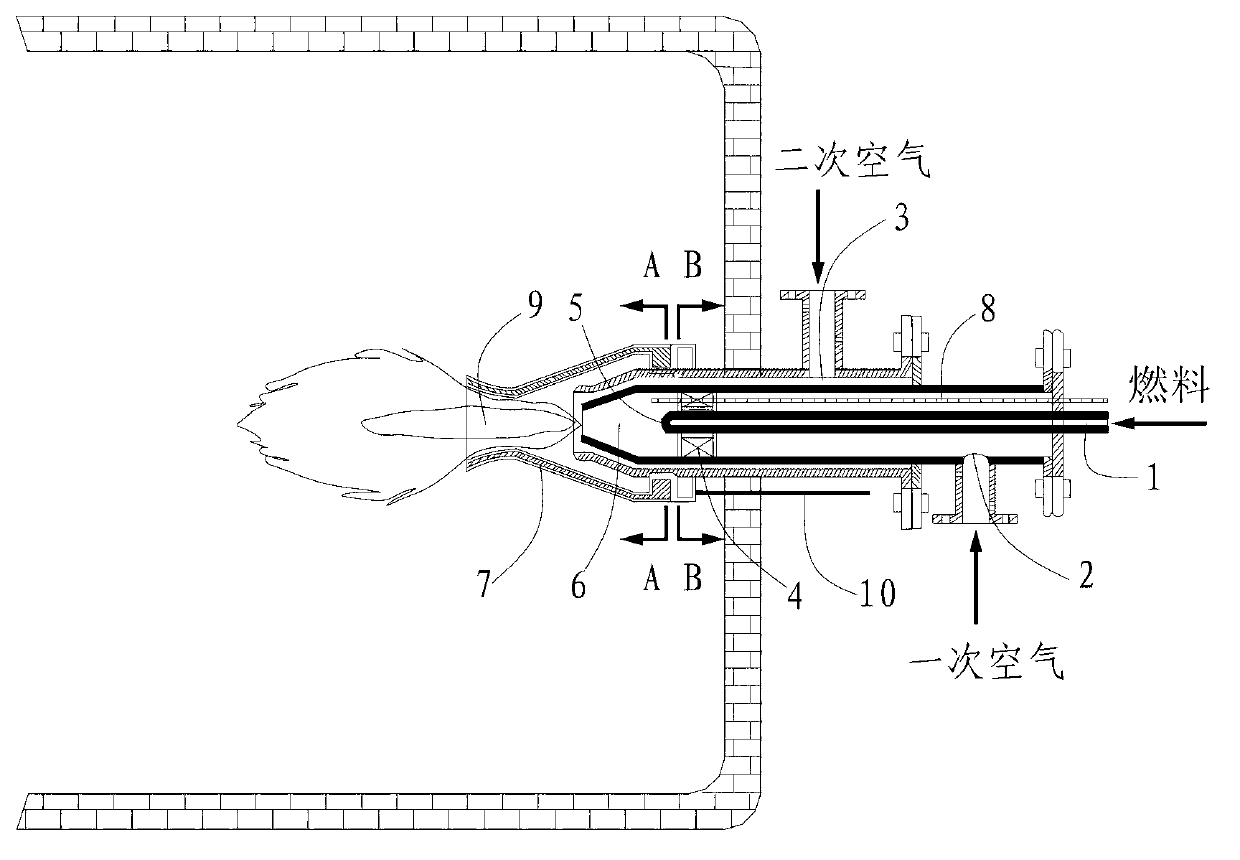

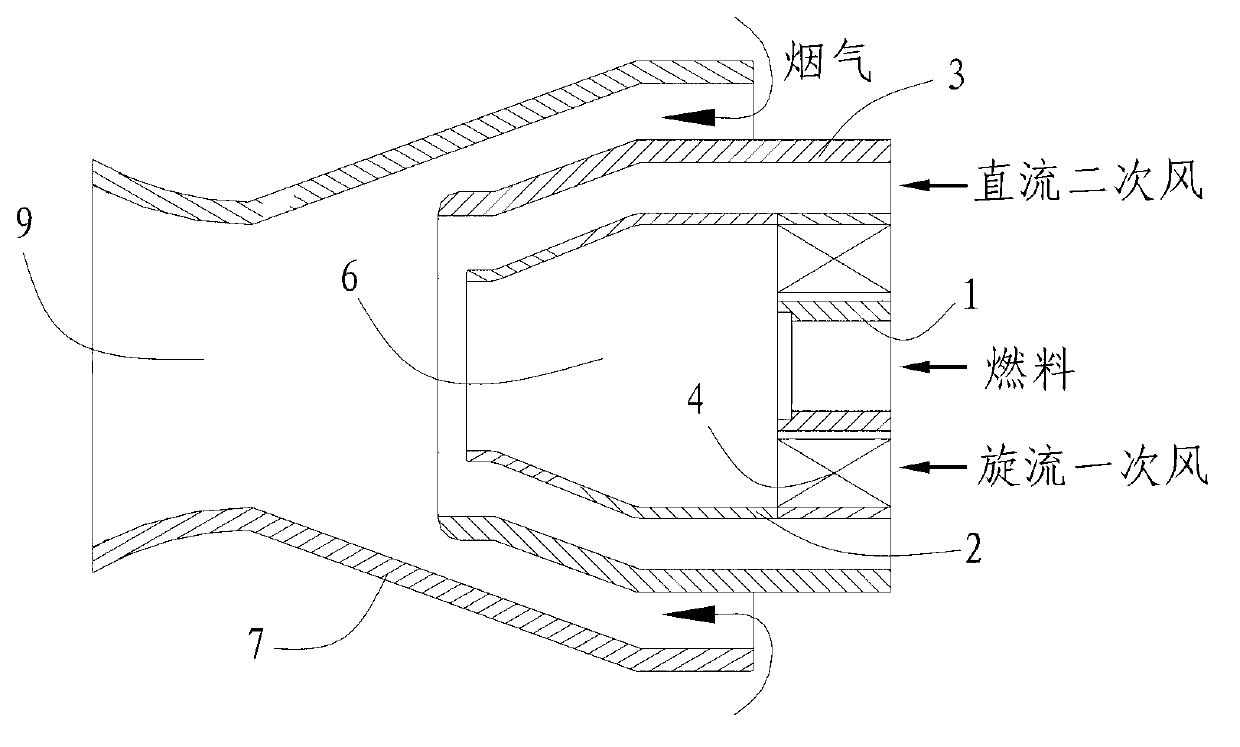

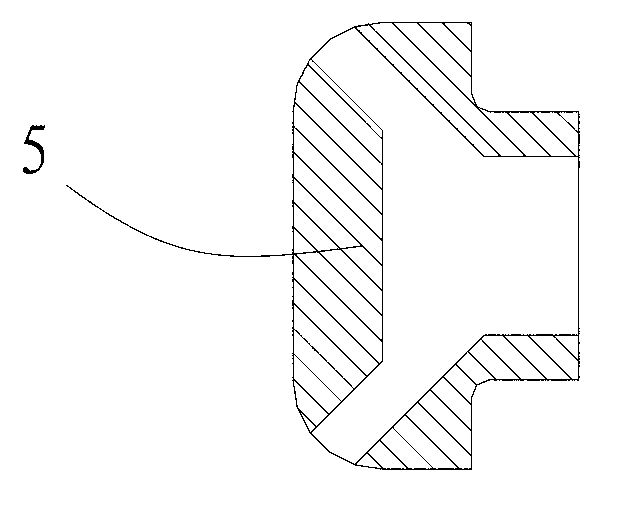

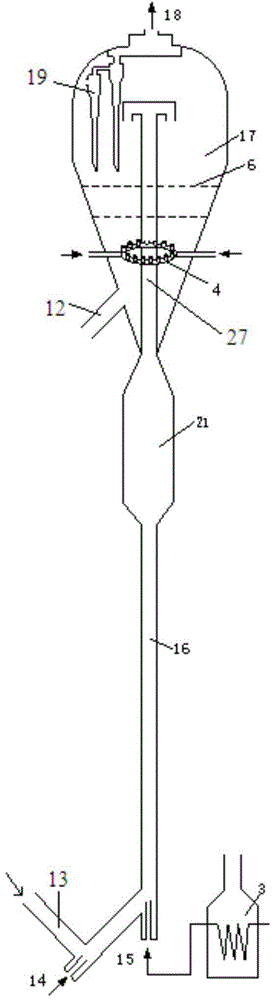

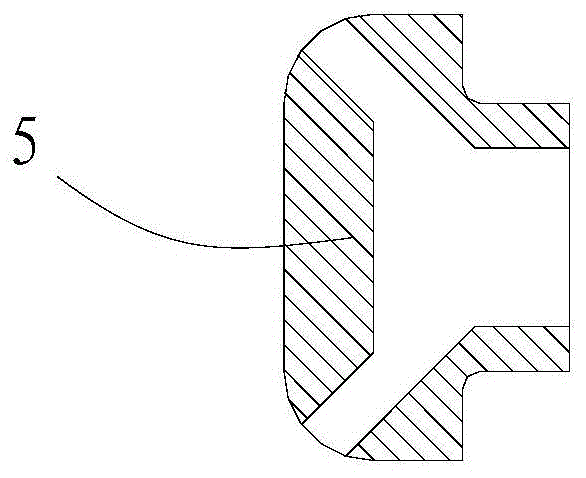

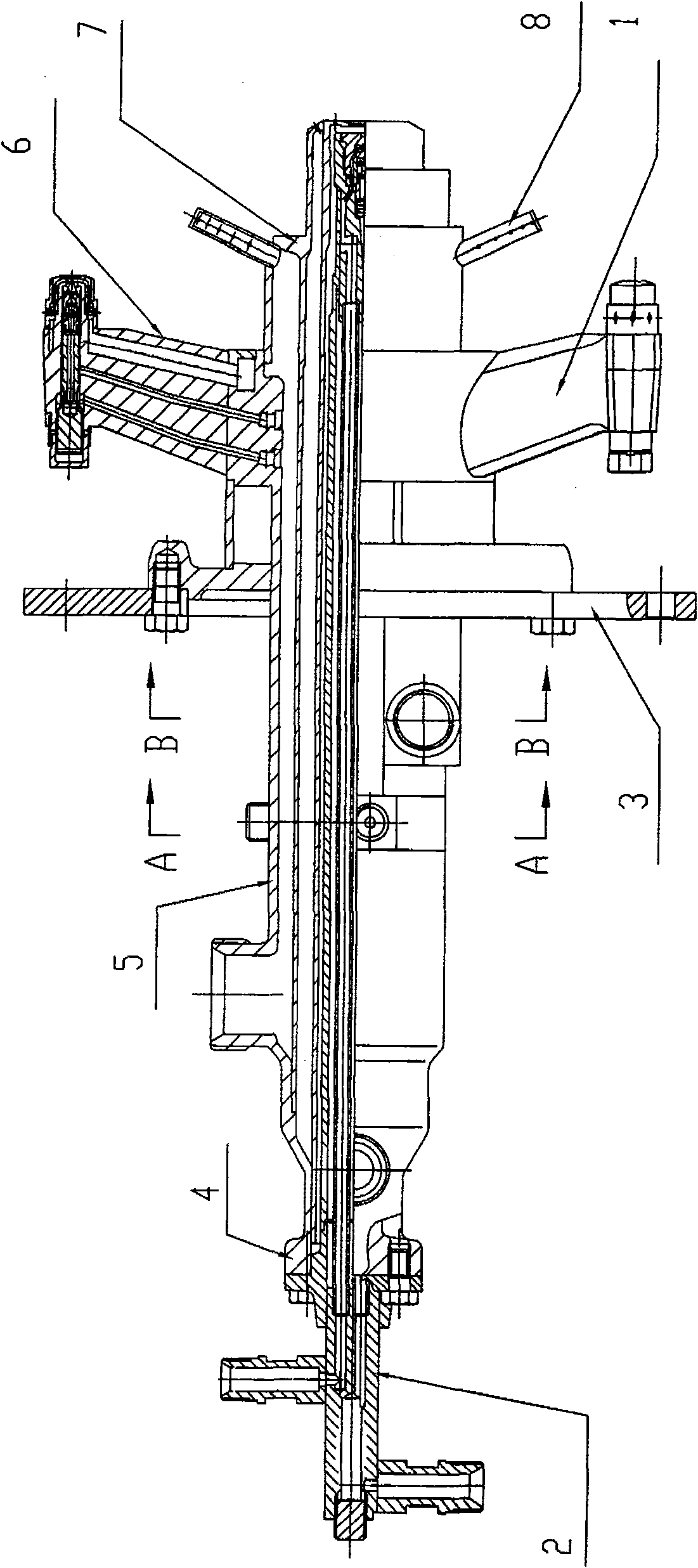

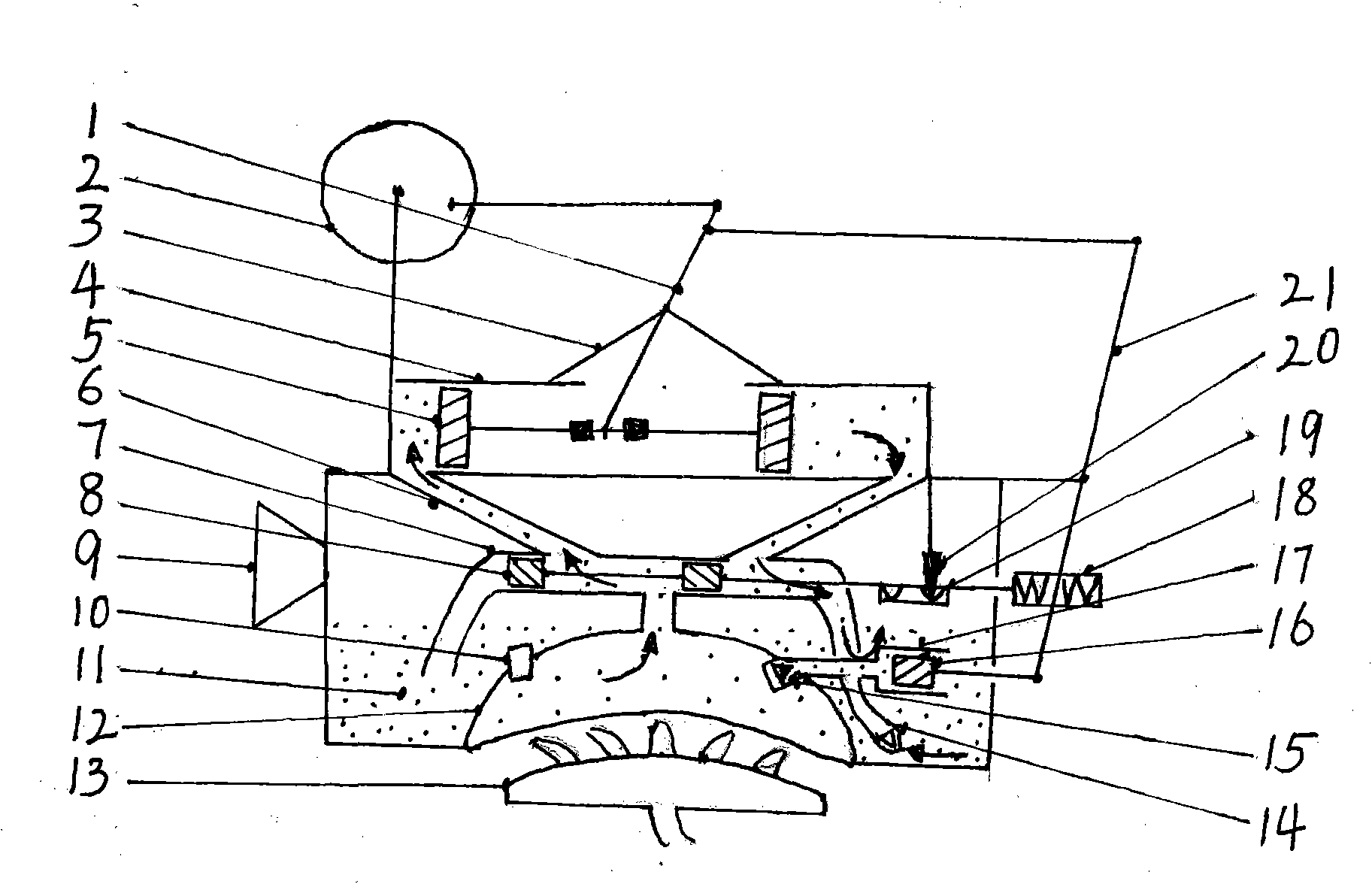

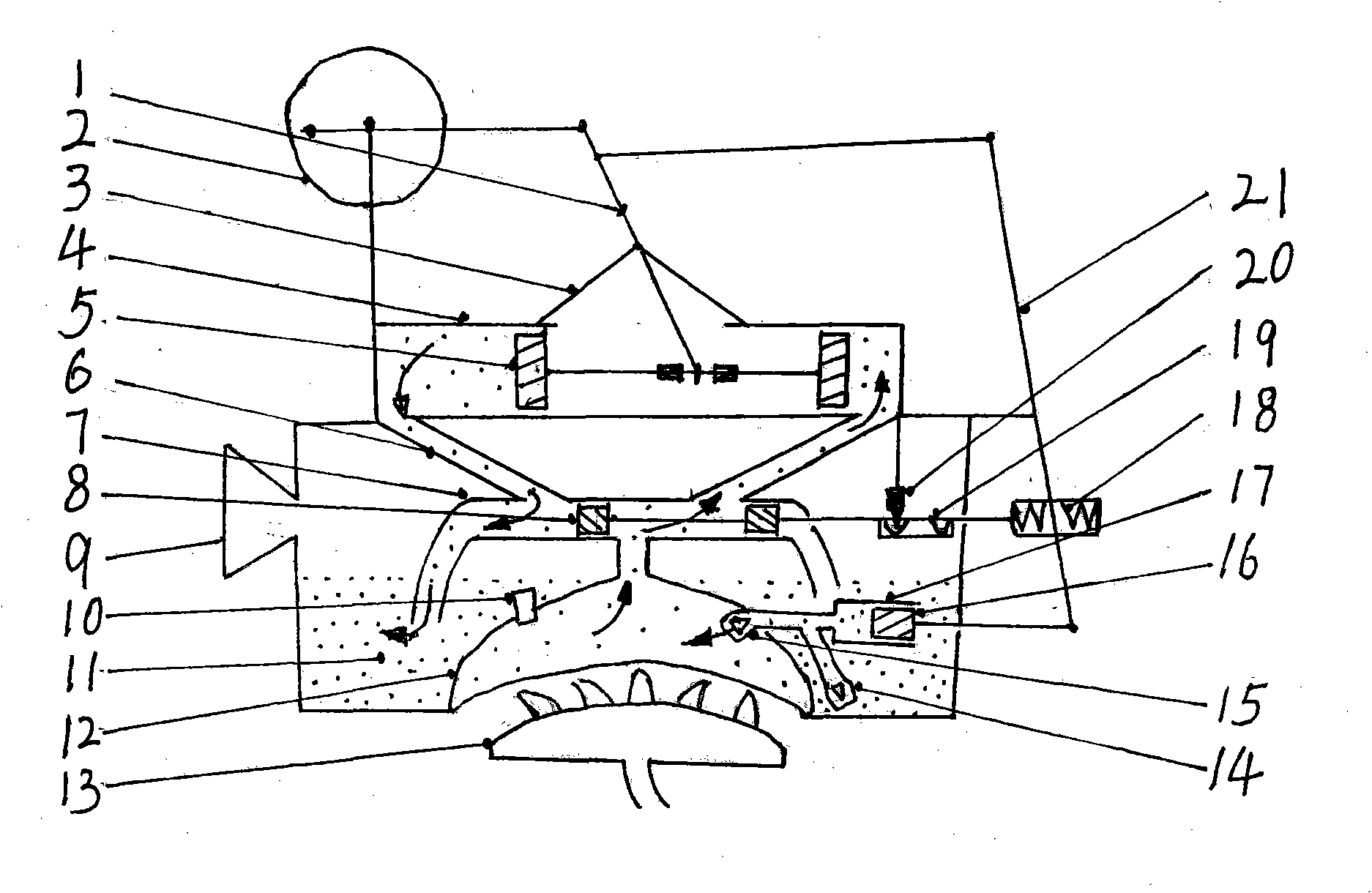

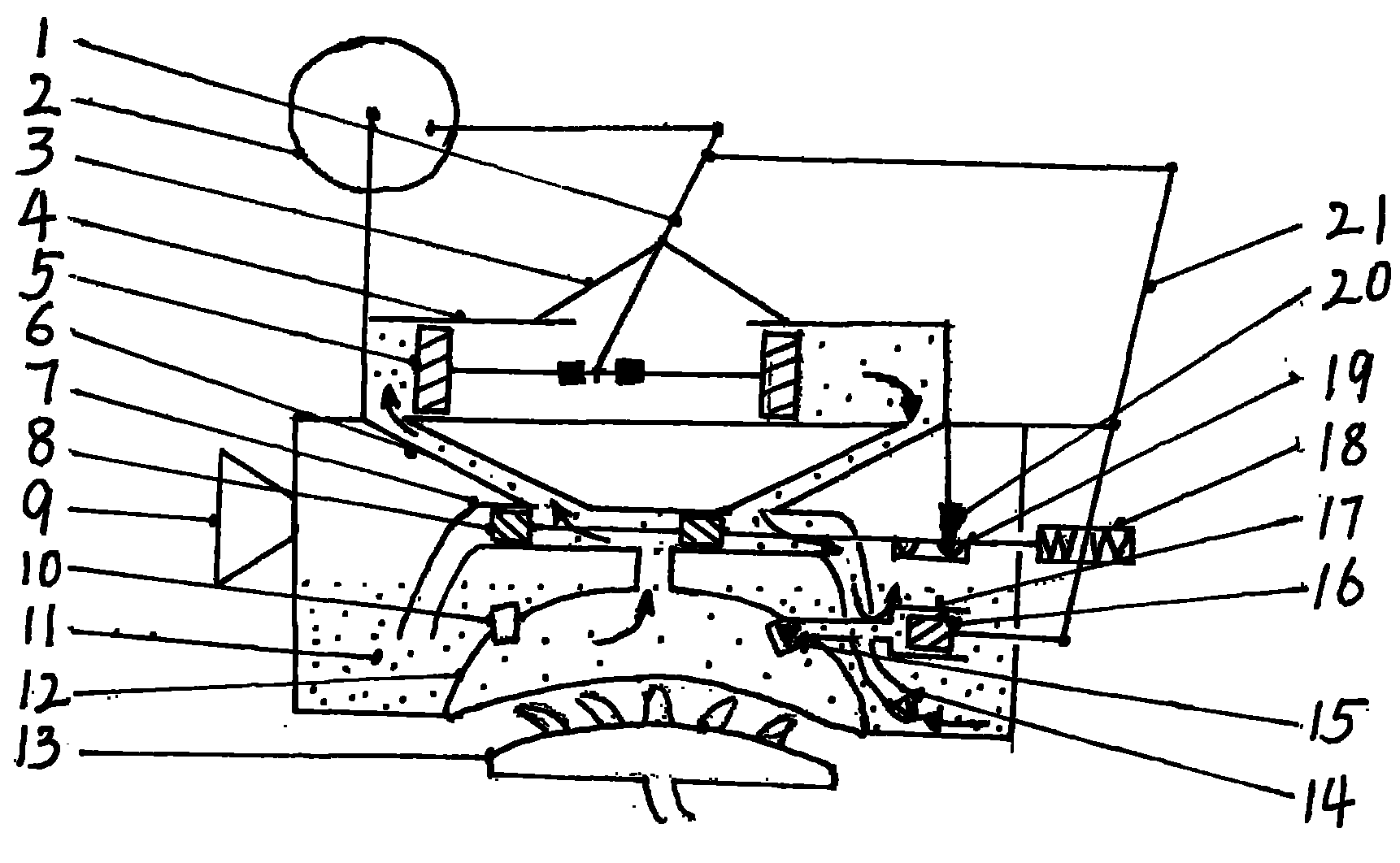

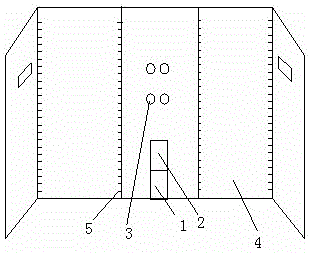

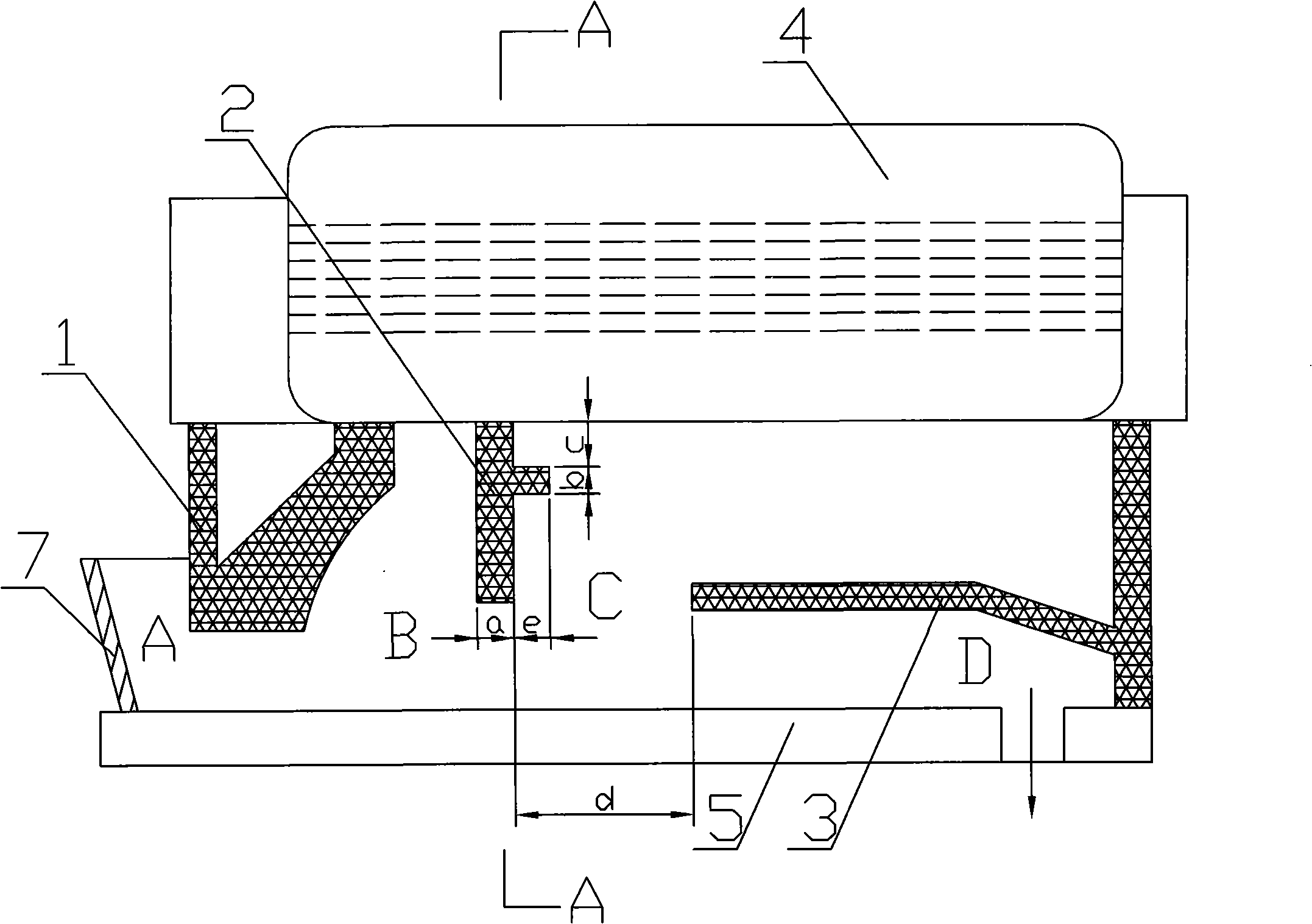

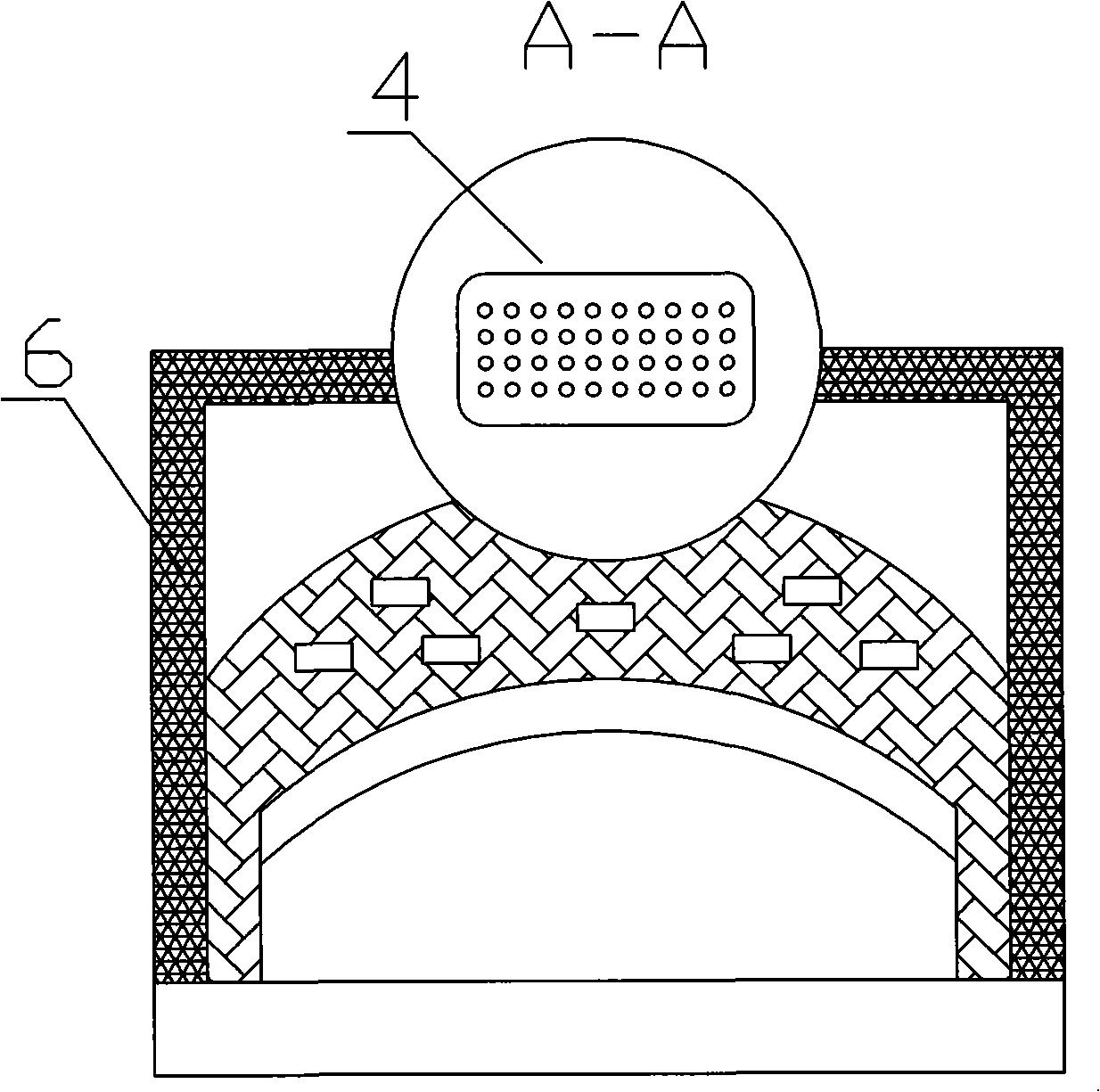

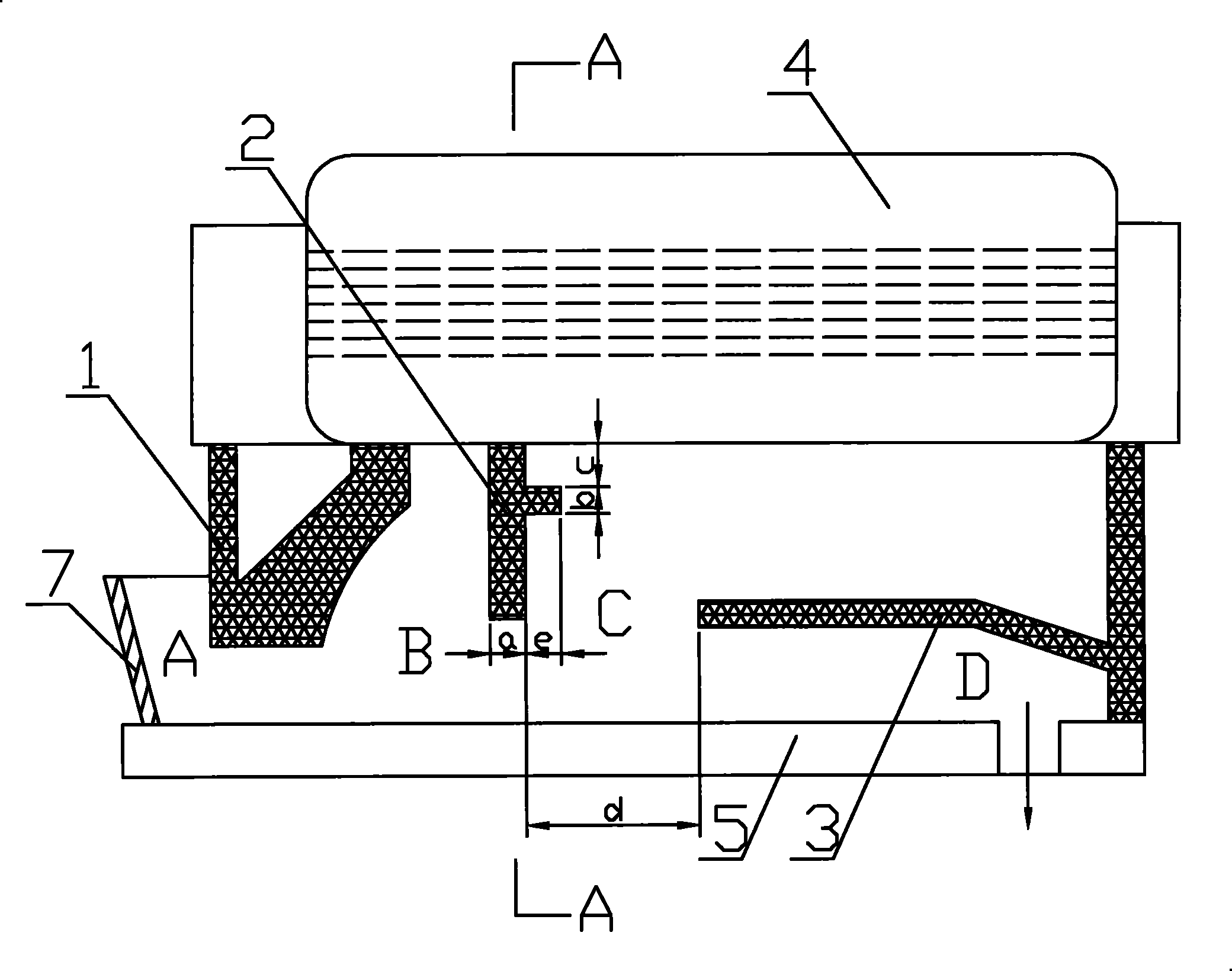

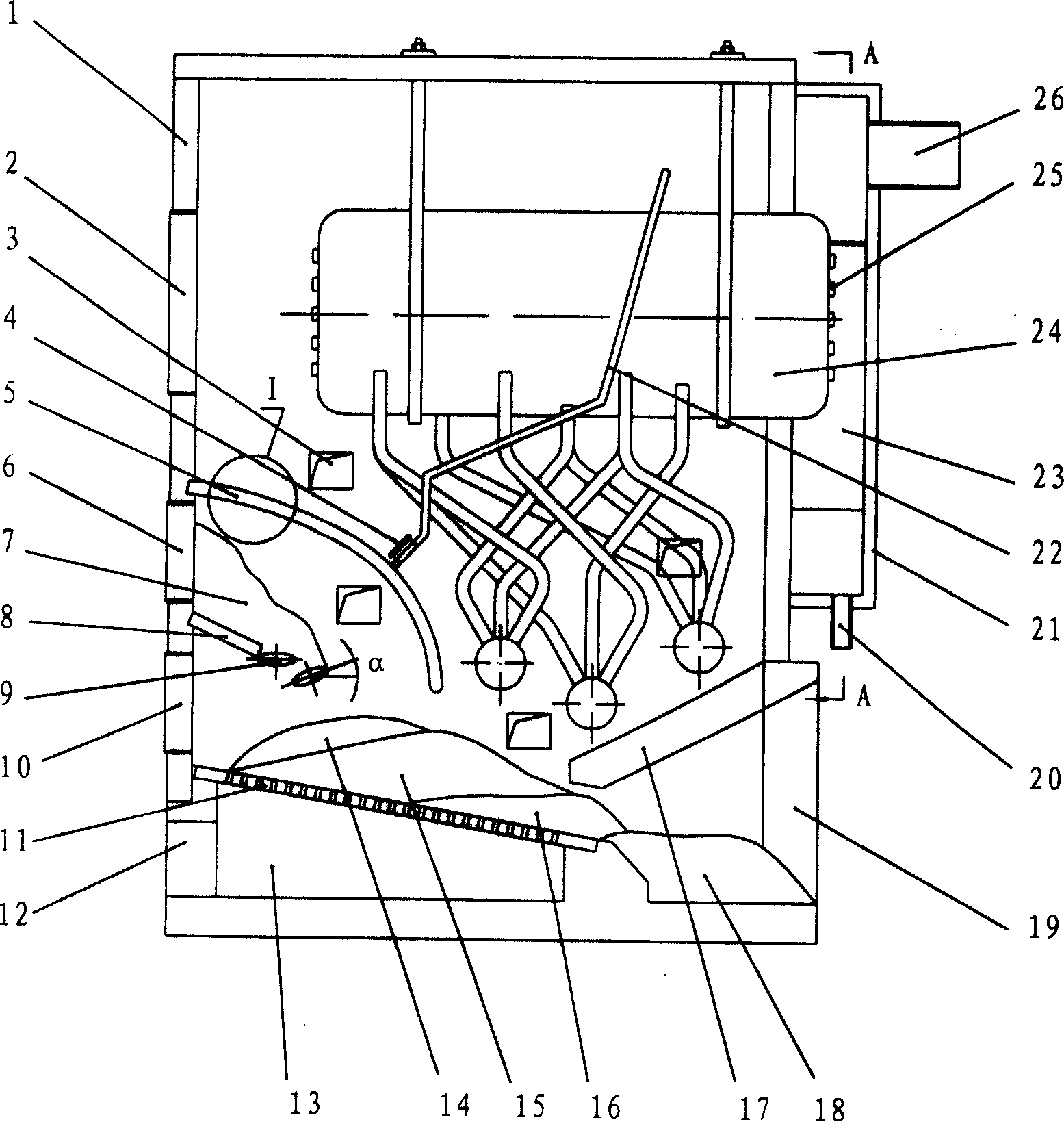

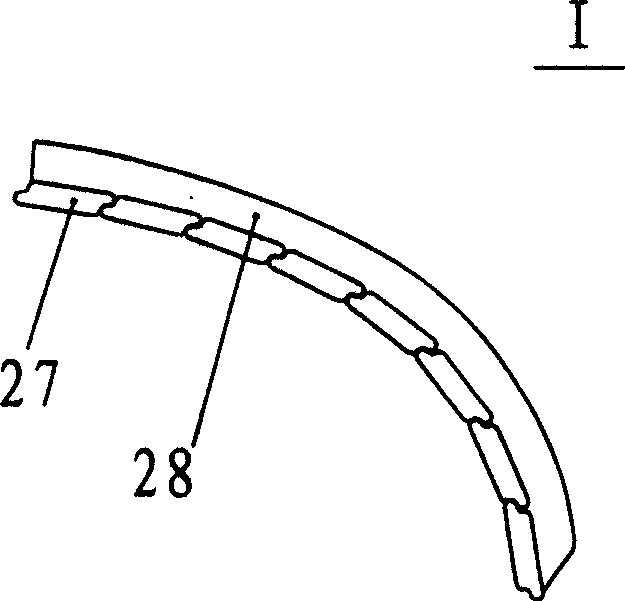

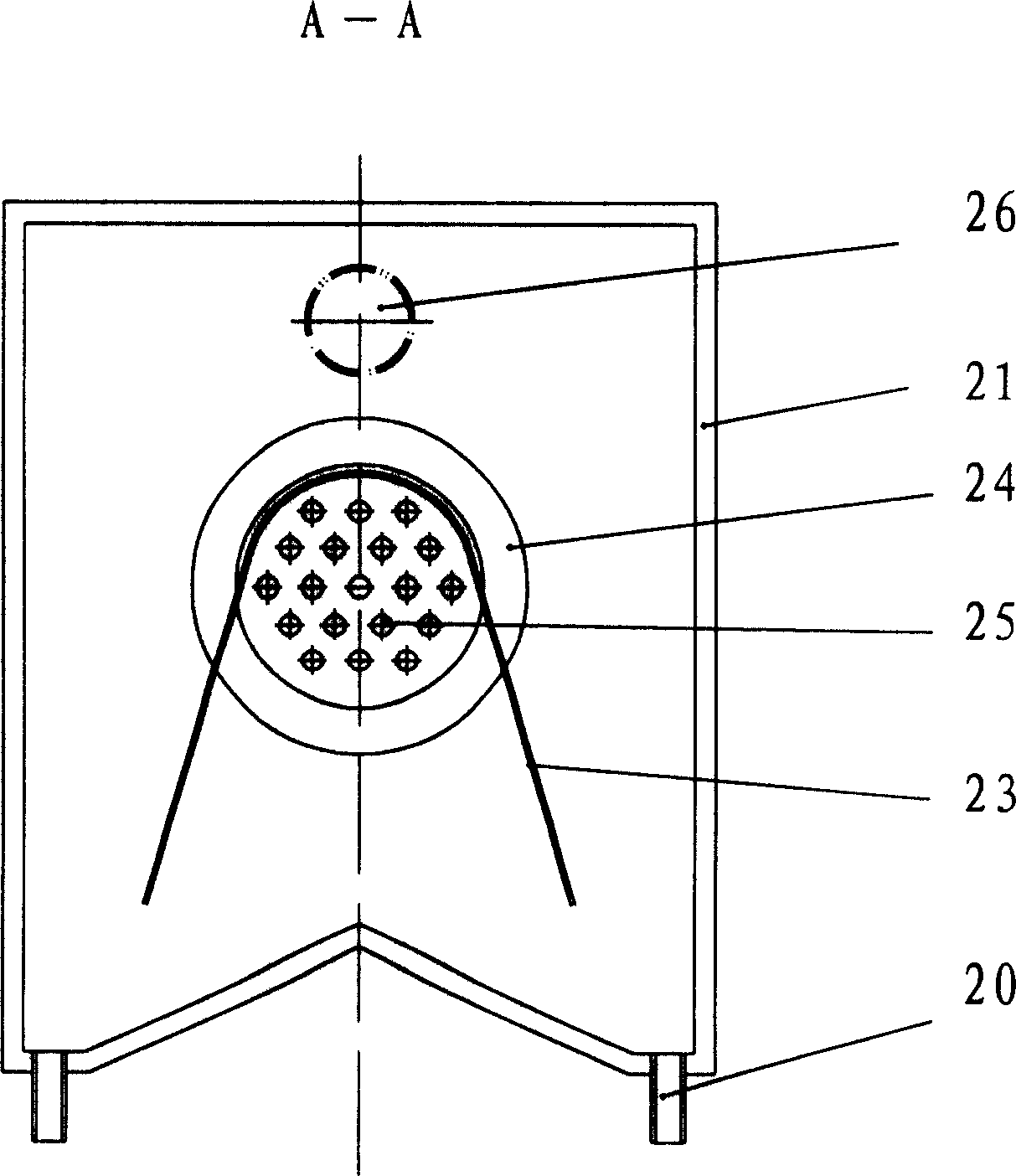

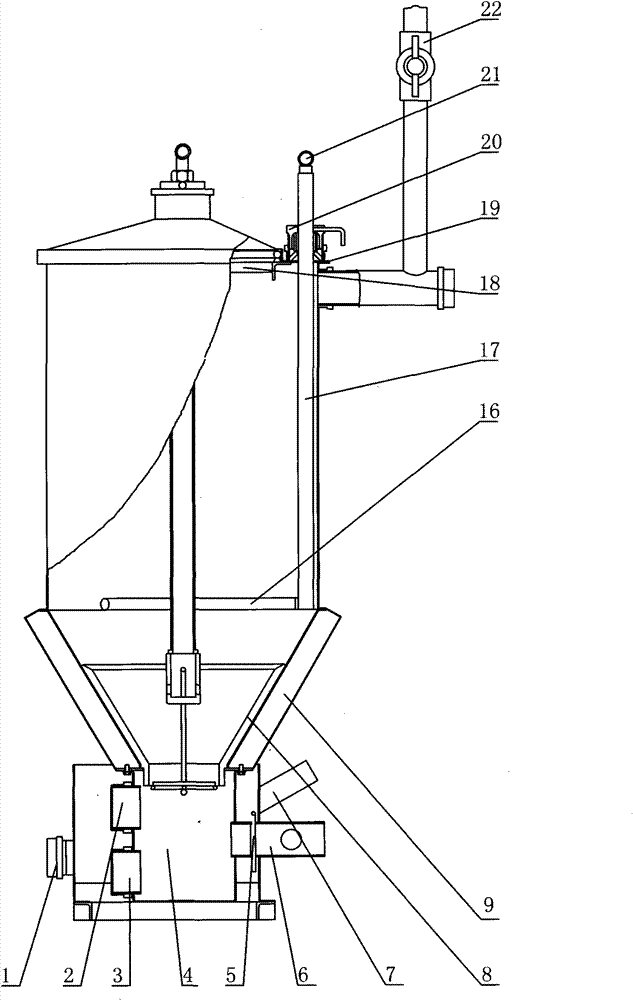

The invention discloses a gas burner capable of adjusting gas to be self-recycling. The gas burner capable of adjusting the gas to be self-recycling comprises a center fuel pipe, a primary rotational-flow air duct, a secondary direct-flow air duct and an ejector, wherein the center fuel pipe, the primary rotational-flow air duct, the secondary direct-flow air duct and the ejector are coaxial from inside to outside and sequentially embedded in a sleeved mode. A fuel nozzle is formed in the outlet segment of the center fuel pipe, an air cyclone and a pre-mixing chamber are arranged inside the primary rotational-flow air duct, the primary rotational-flow air duct and the pre-mixing chamber are communicated with the fuel nozzle, both an outlet of the pre-mixing chamber and the outlet end of the secondary direct flow air duct are arranged at the throat position of the ejector, a main flame burning area is formed at the throat position of the ejector, an electronic igniter is further arranged inside the primary rotational-flow air duct, one end of the electronic igniter penetrates through the air cyclone, the ignition electrode of the electronic igniter is arranged inside the pre-mixing chamber, the end surfaces, being connected with the head of the burner, of the ejector are of a sawtooth disk structure and meshed with each other, and linkage mechanisms are arranged at the positions of the sawtooth disk structures and fixed on the outer pipe wall of the secondary direct-flow air duct. The gas burner capable of adjusting the gas to be self-recycling has the advantages of being easy to manufacture, and capable of achieving the objective that the adapting range of fuel is wide, burning efficiency is high, burning is stable, and pollution is low.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

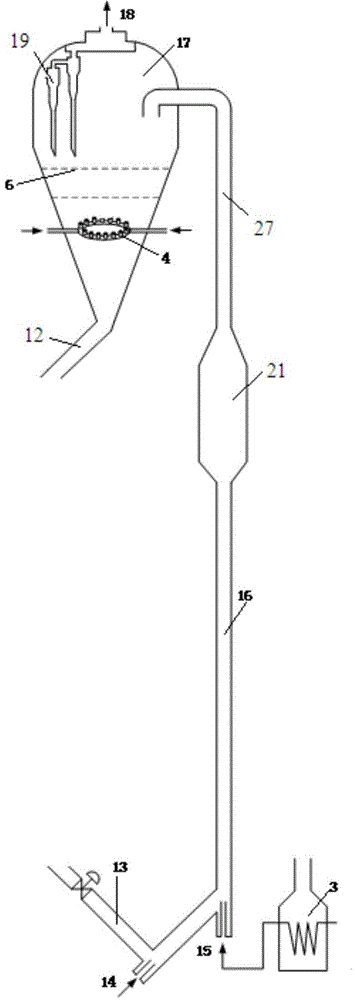

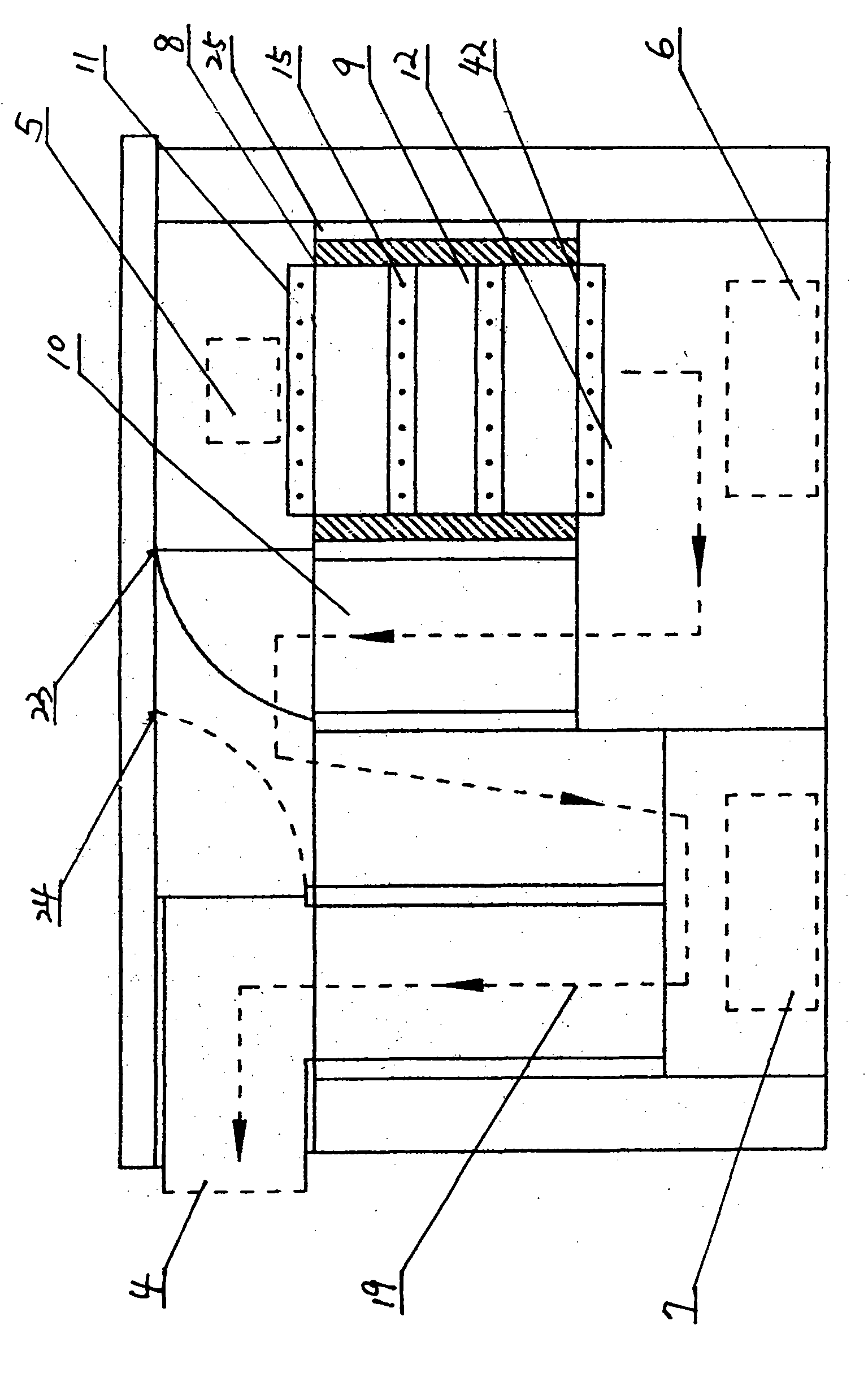

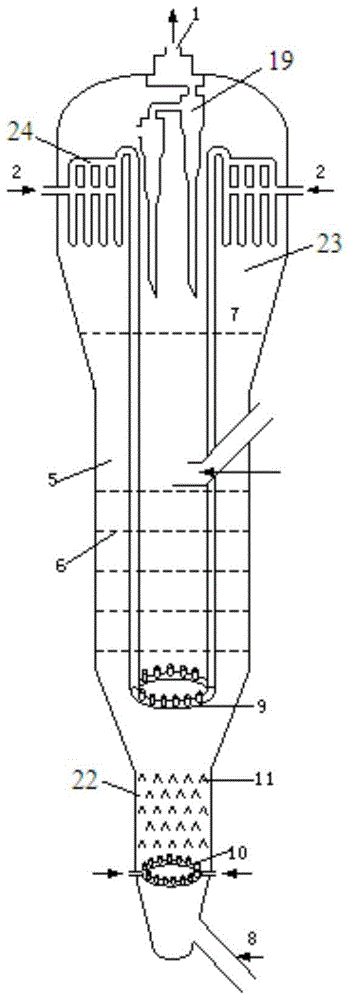

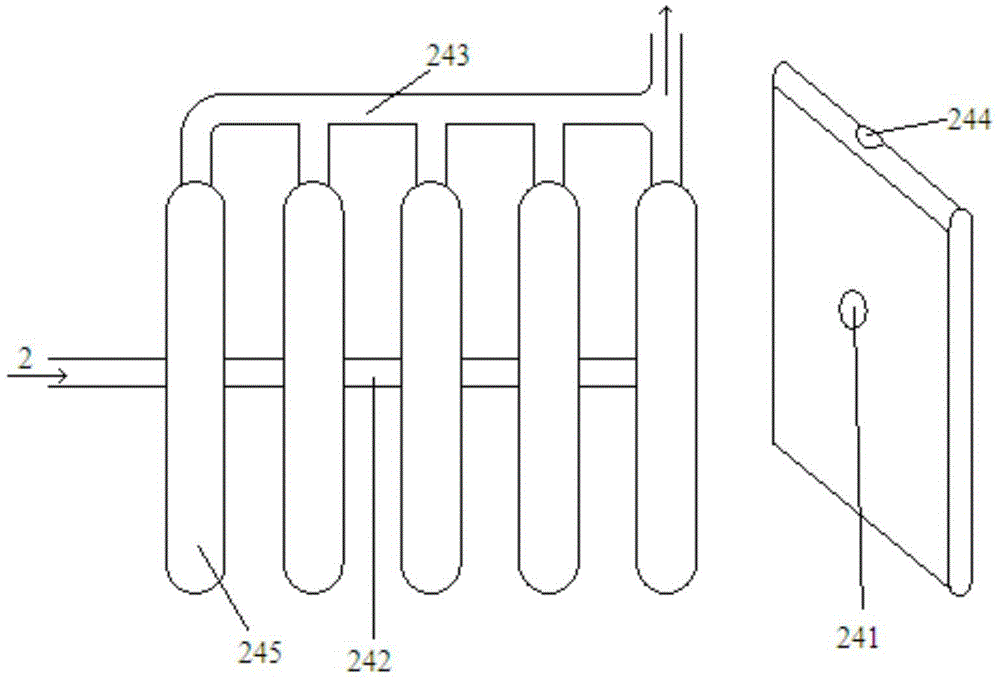

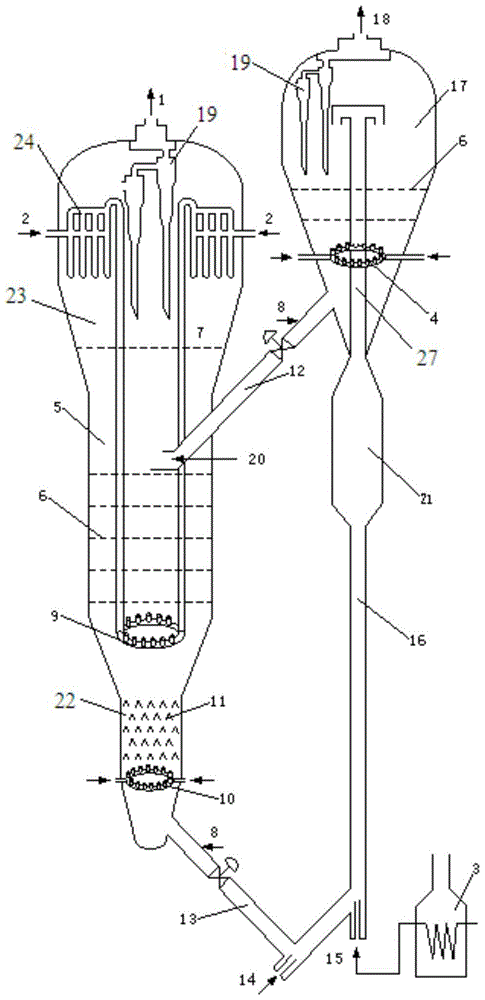

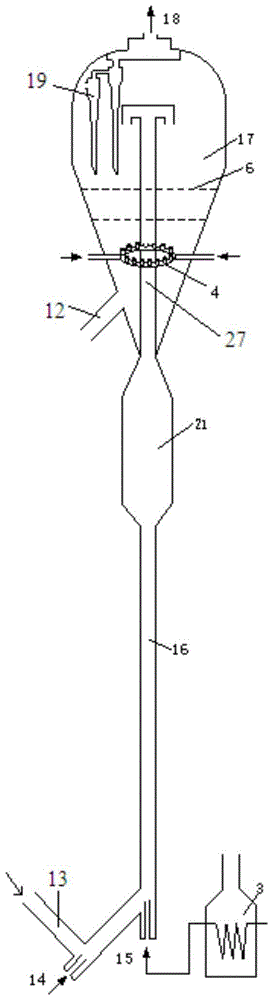

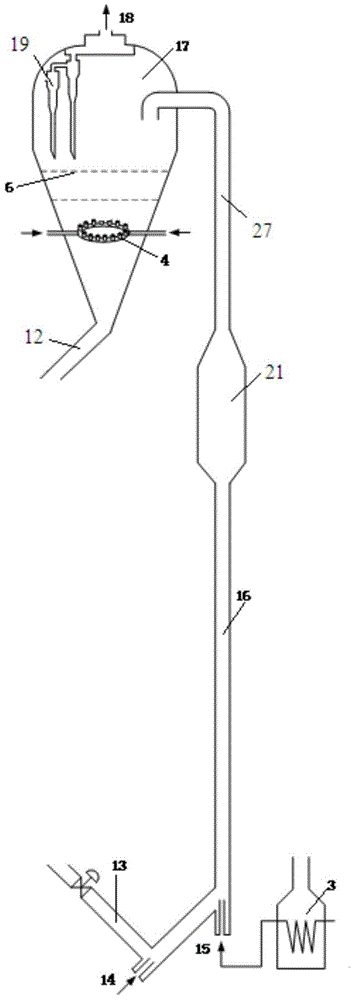

Circulating fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation

ActiveCN104549073AReduce polycondensation reactionResponse blockingHydrocarbonsChemical/physical processesThermal energyAlkane

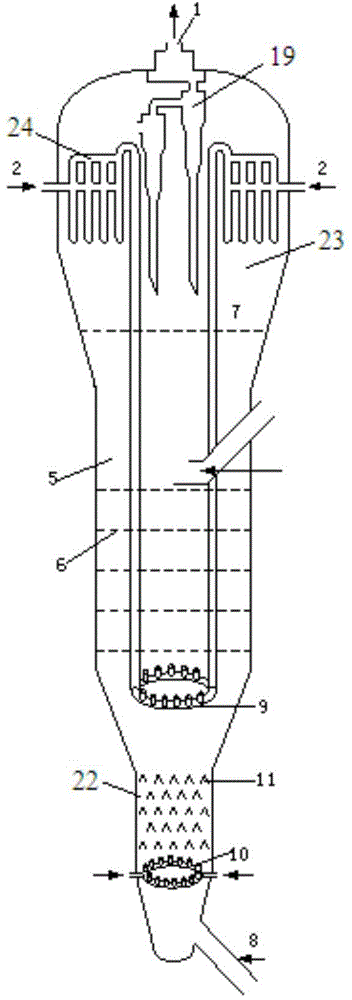

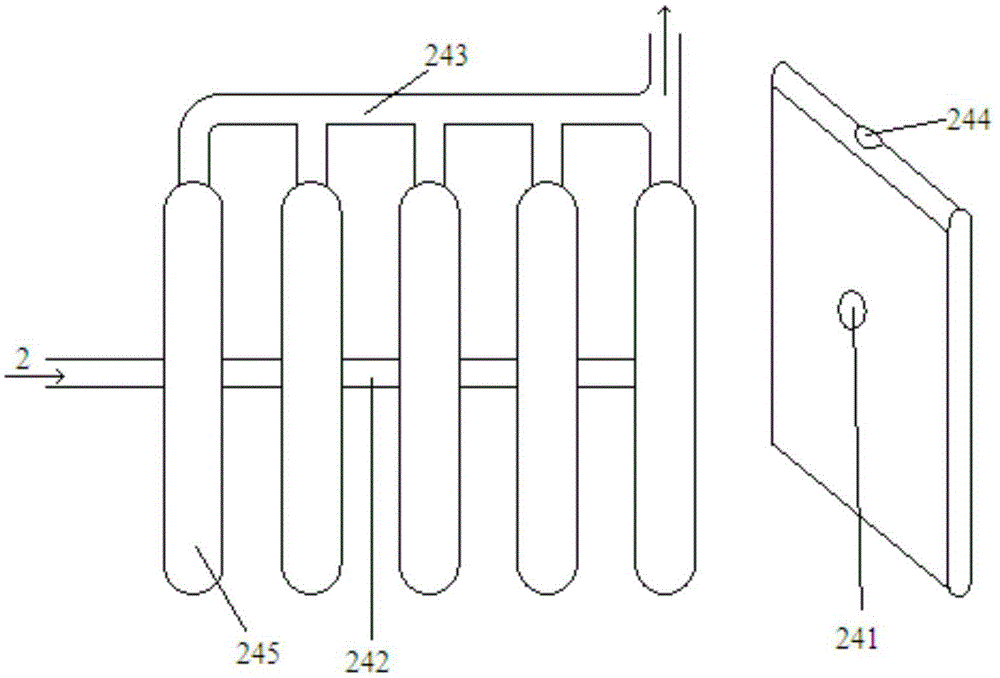

The invention discloses a fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation and a paraffin dehydrogenation method. The reaction device is a reducing tank body, and the tank body is divided into a gas stripping section, a reaction section and a catalyst settling section from bottom to top, wherein the diameter of the reaction section is larger than the diameter of the gas stripping section; and a heat exchanger is arranged in the settling section. According to the reaction device, raw materials and high-temperature oil gas are subjected to heat exchange in the reaction device, the raw materials are gasified and heated by utilizing the heat energy of the high-temperature oil gas, the high-temperature oil gas is cooled by virtue of heat exchange, the mutual energy is well utilized, coking of the reaction device due to high temperature is avoided, multiple effects are organically combined together, particularly a heat exchanger structure of connecting multiple heat exchange boxes in series together is adopted, the vibration caused by rapid gasification of the raw materials can be effectively avoided, and large temperature difference heat exchange can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

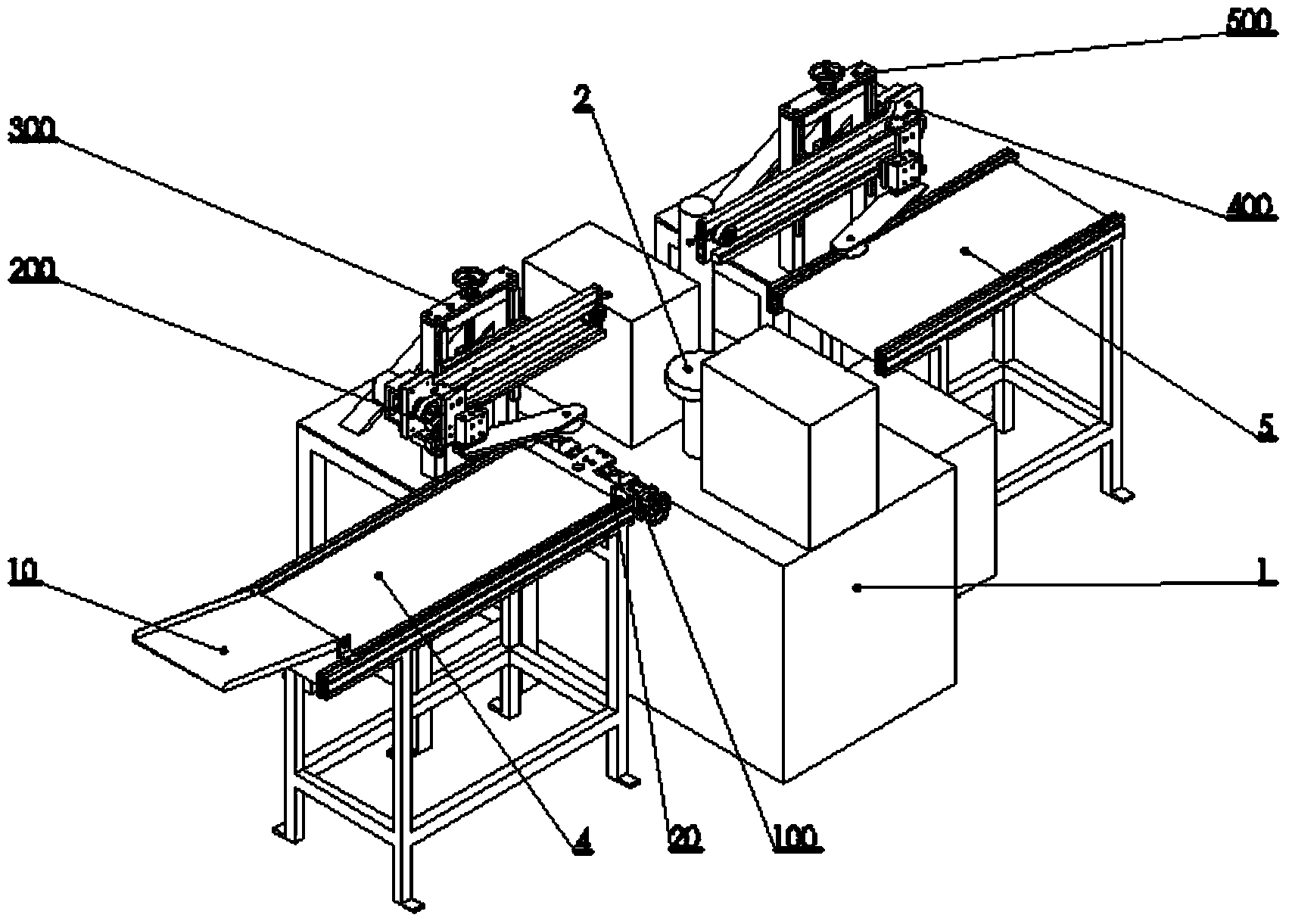

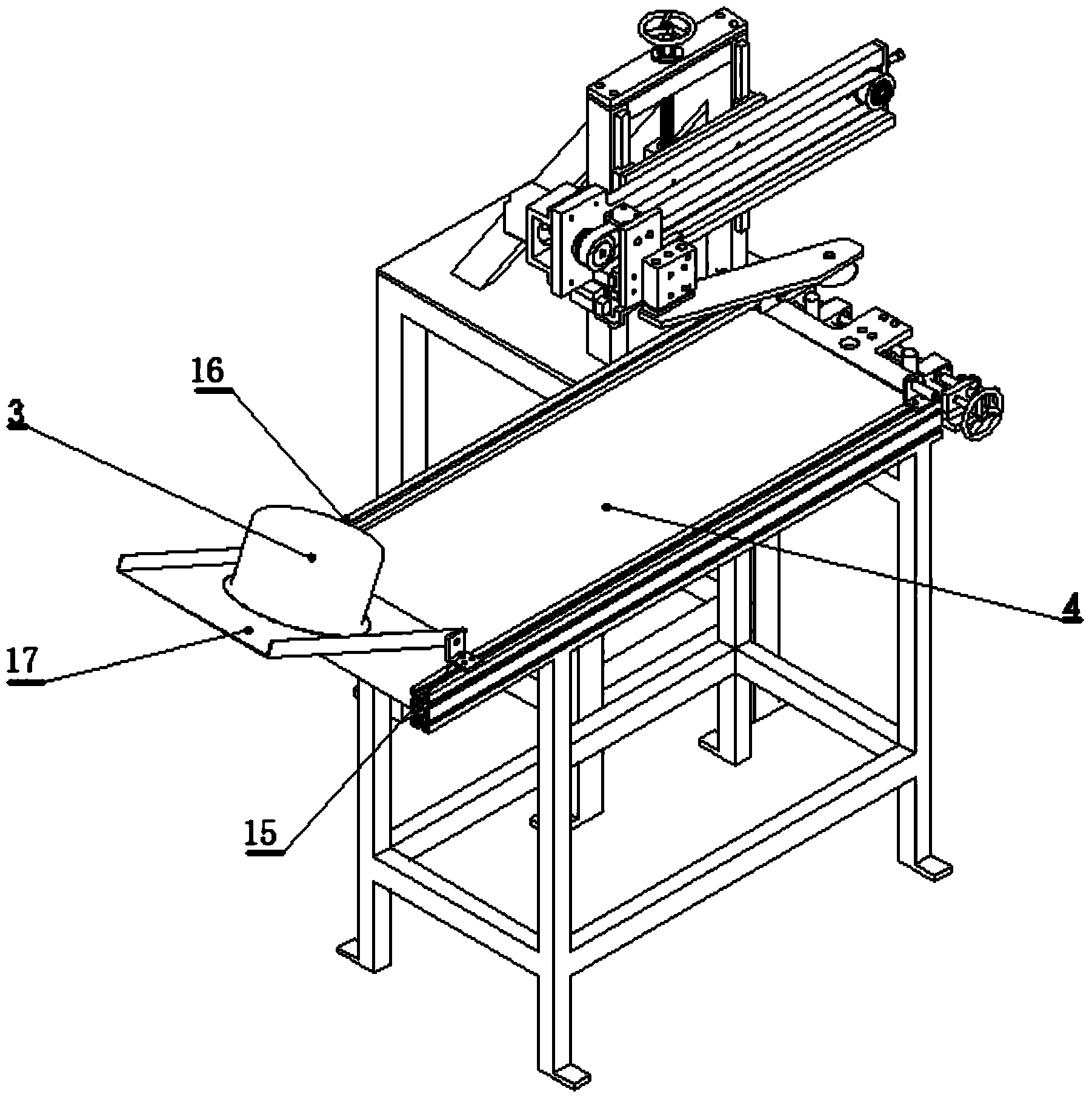

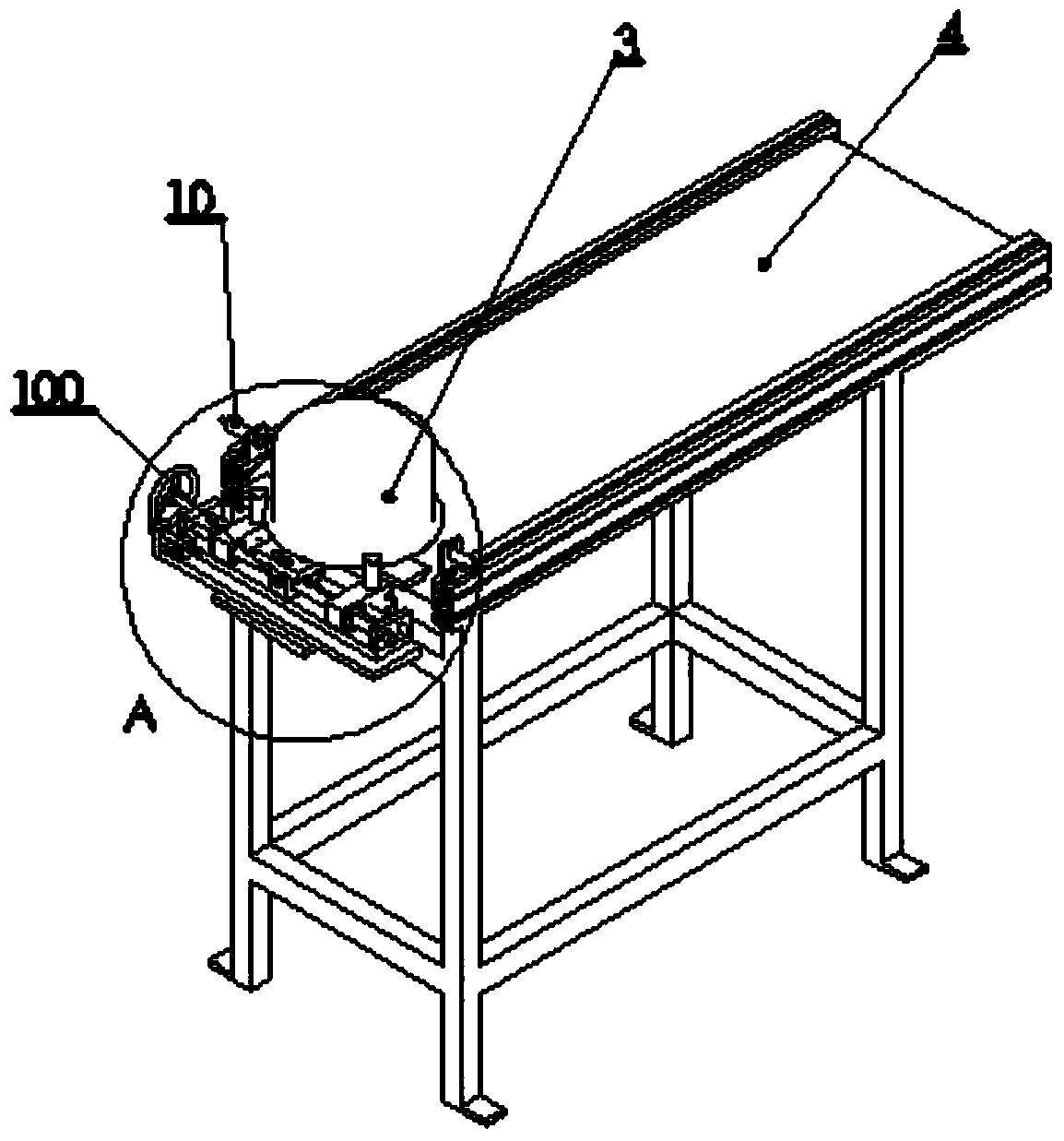

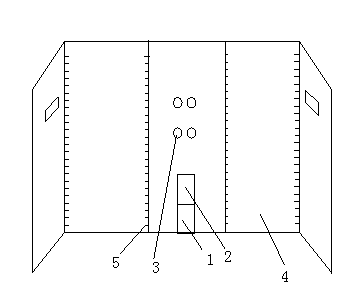

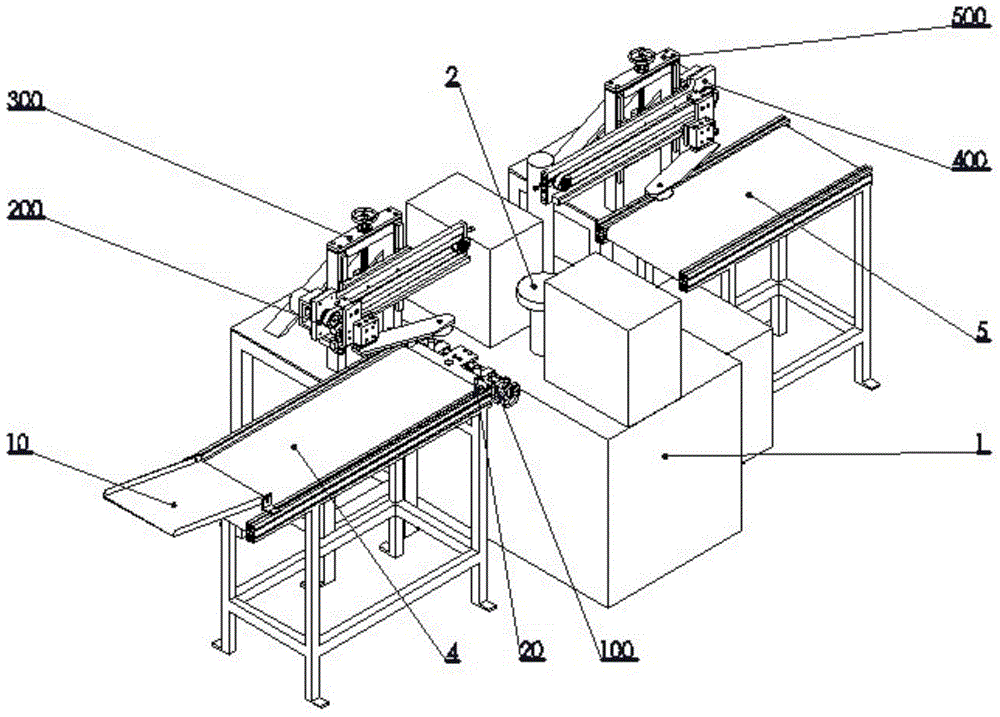

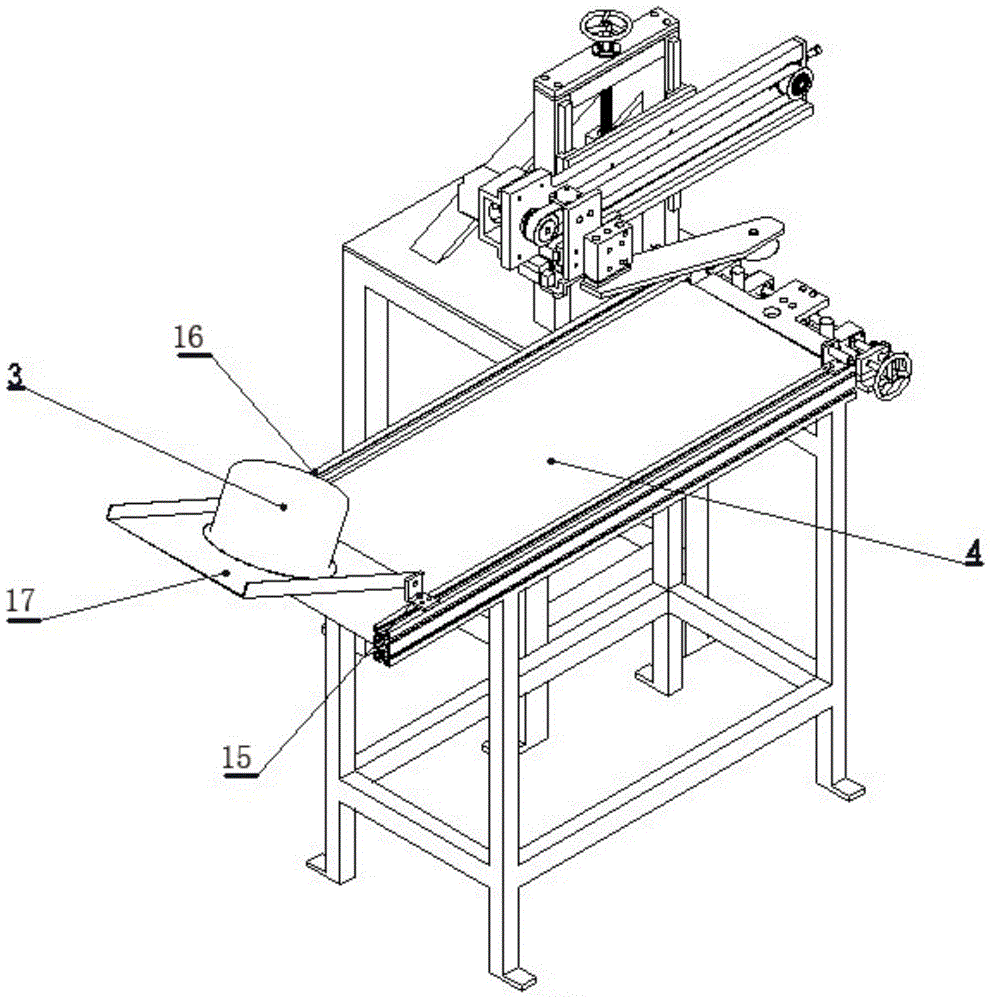

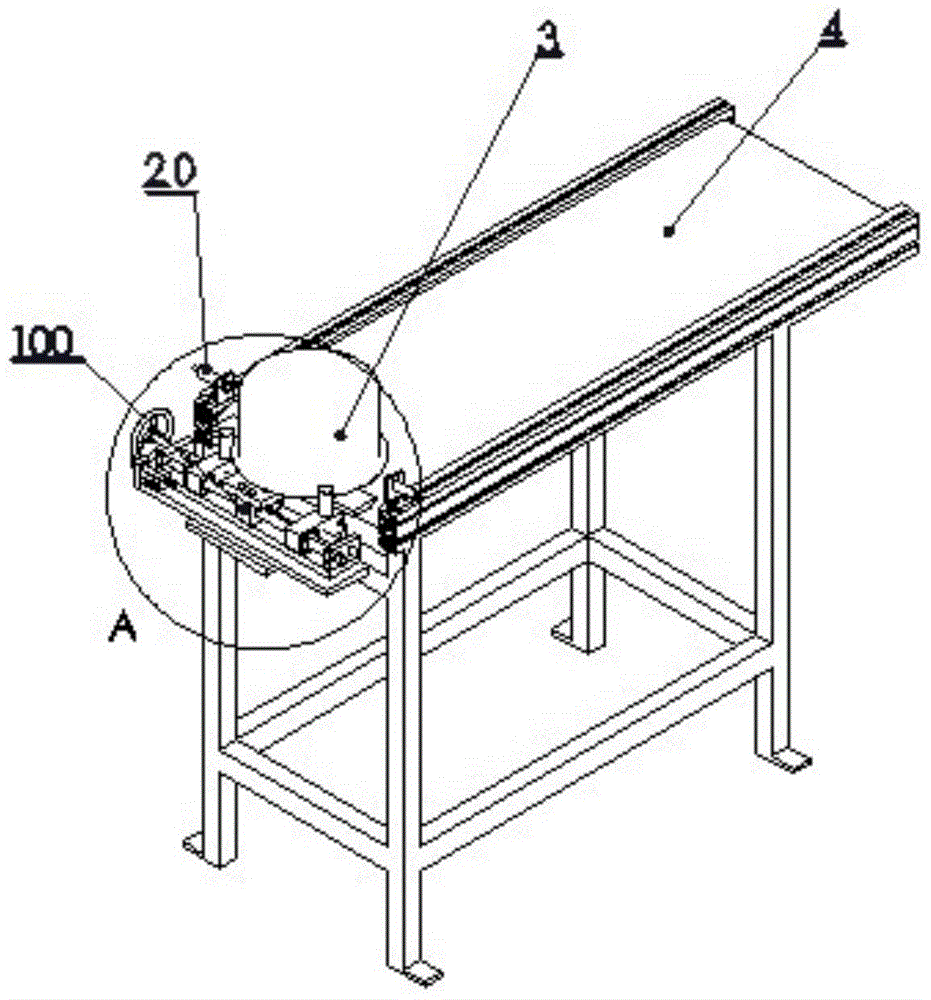

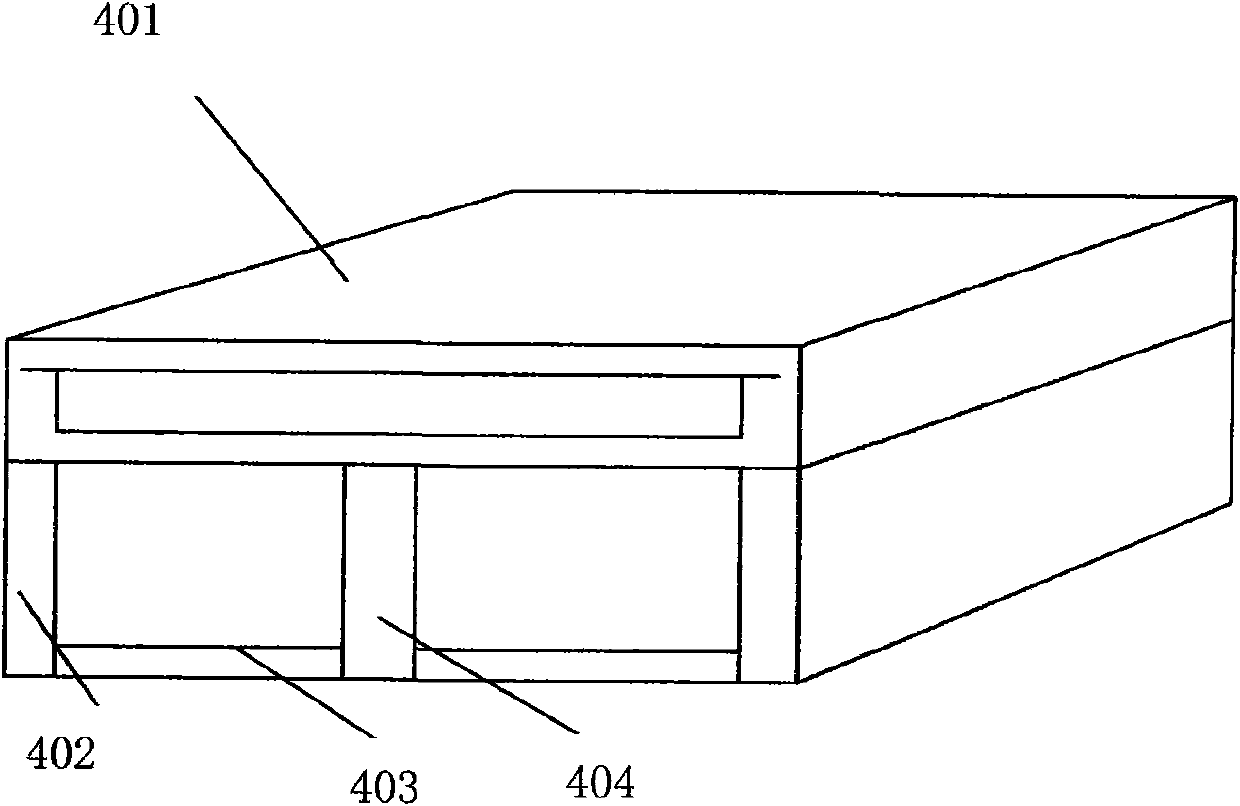

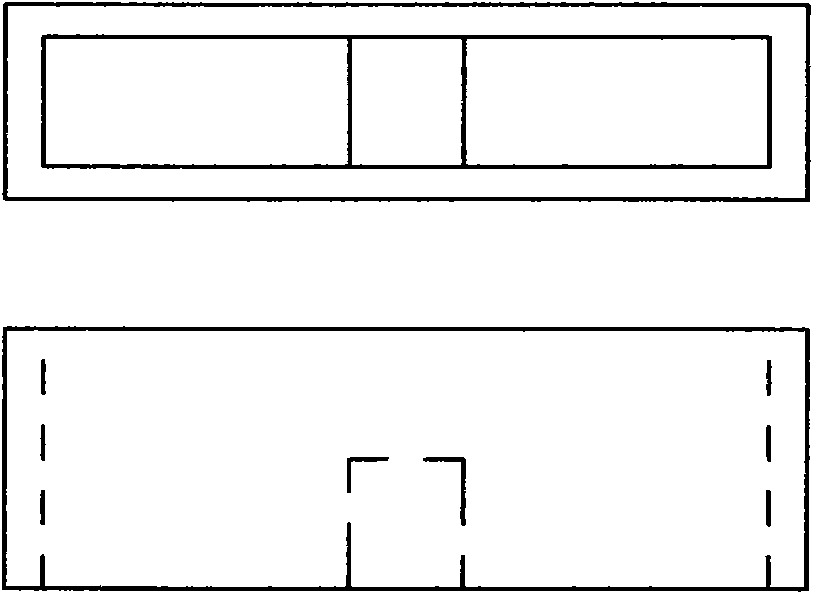

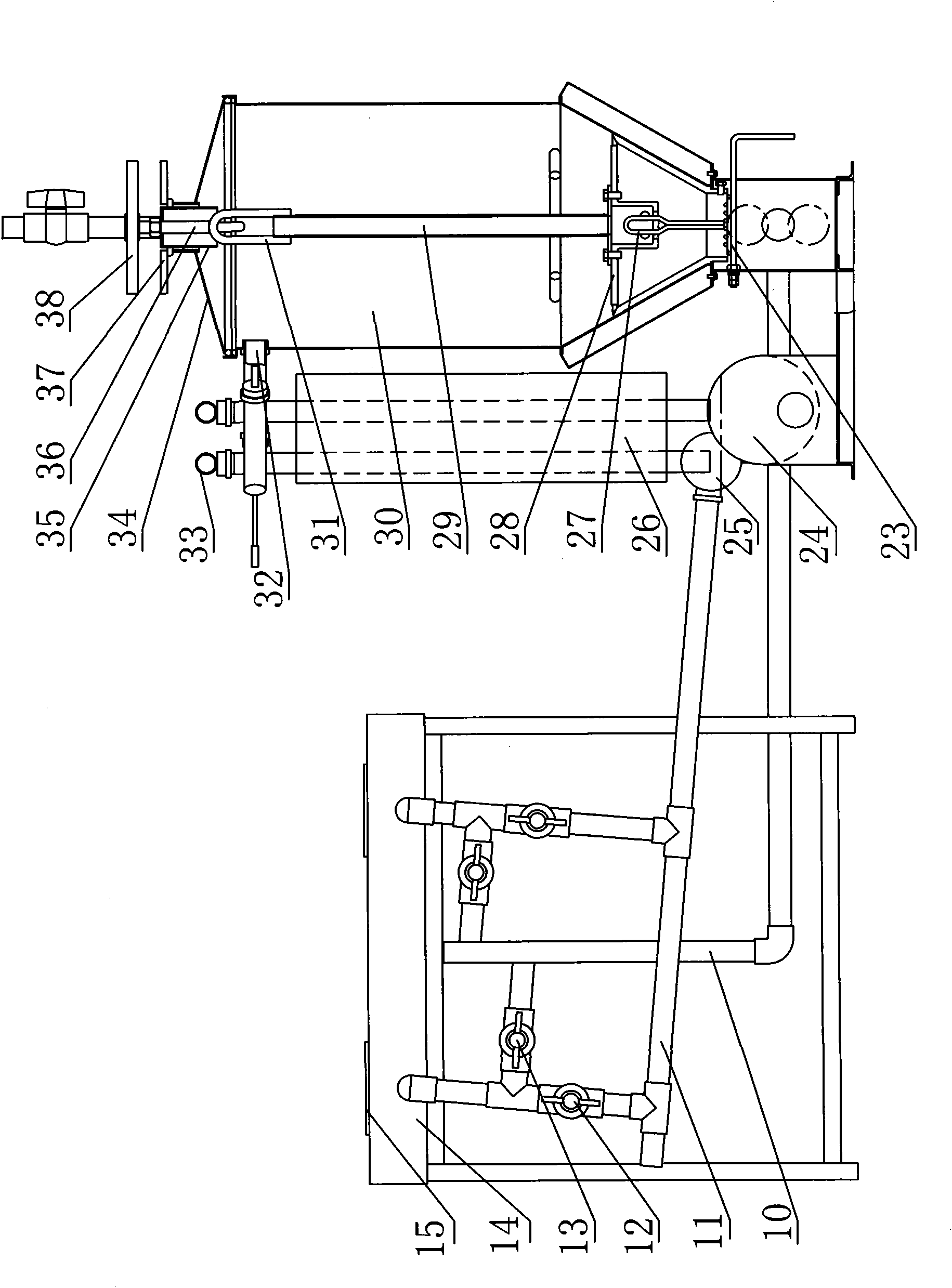

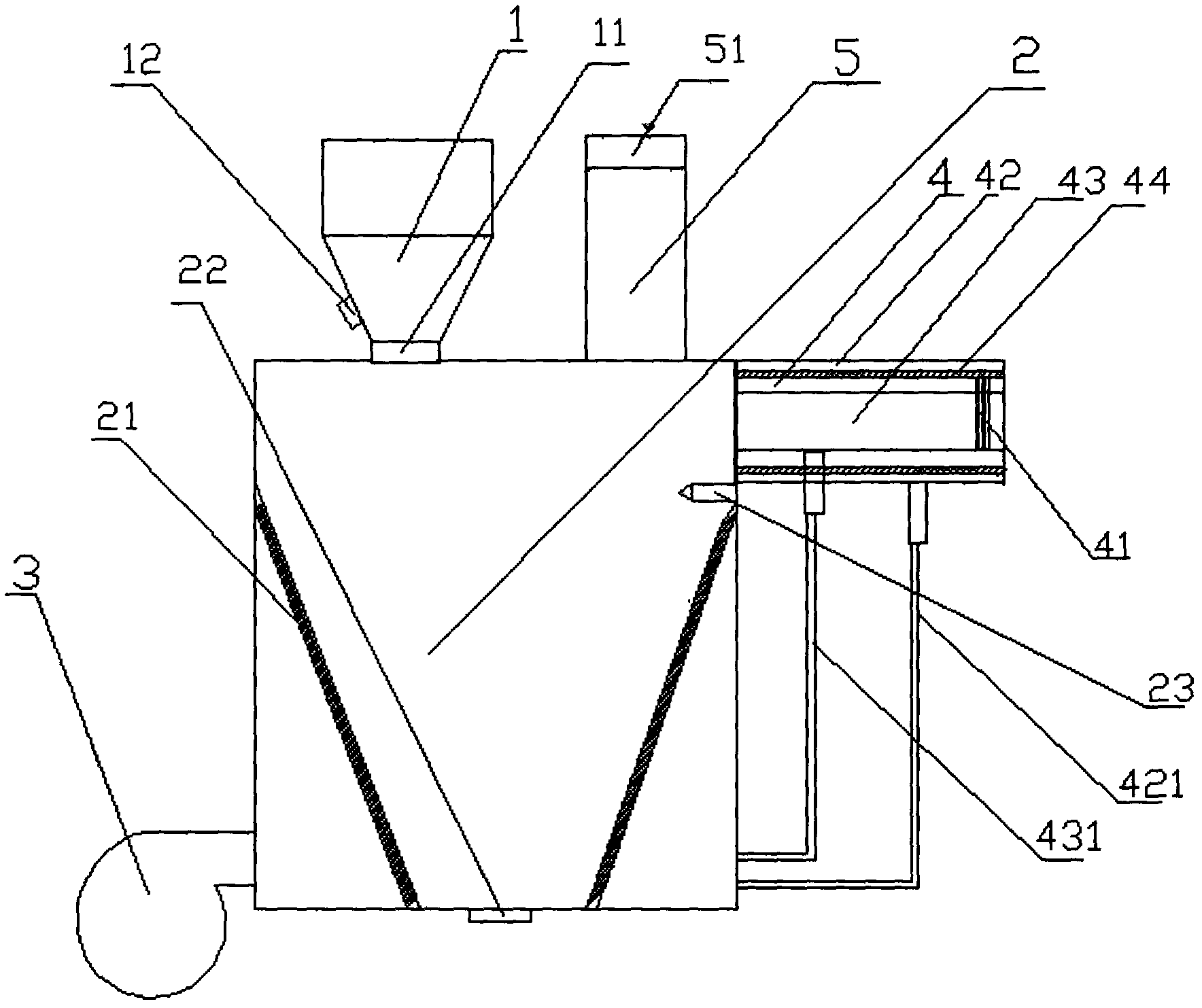

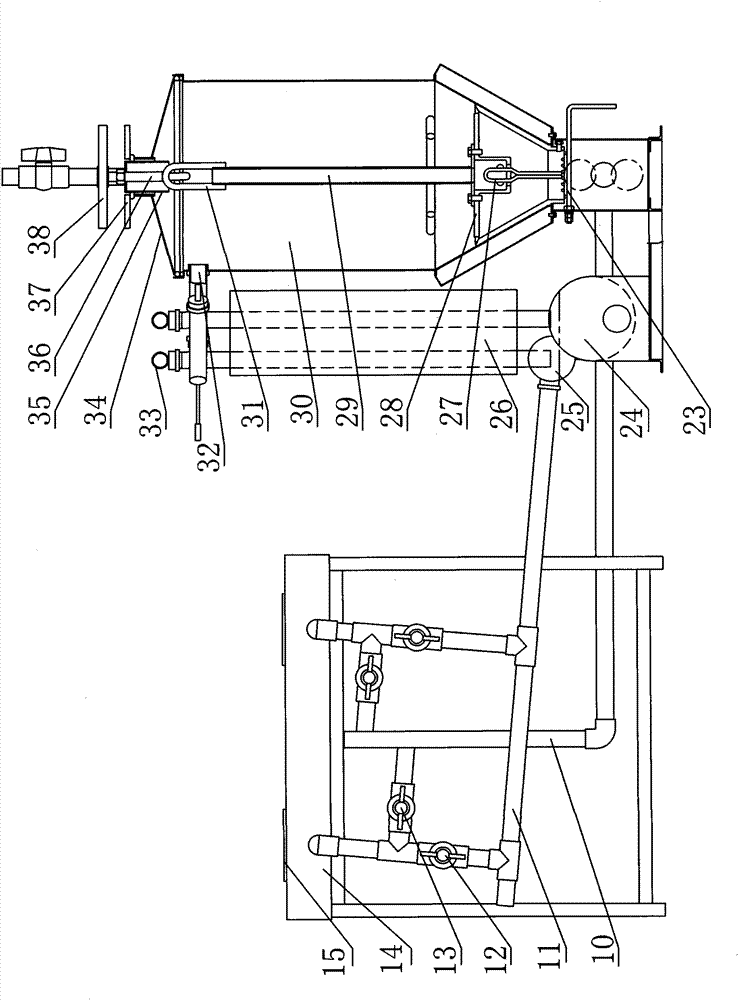

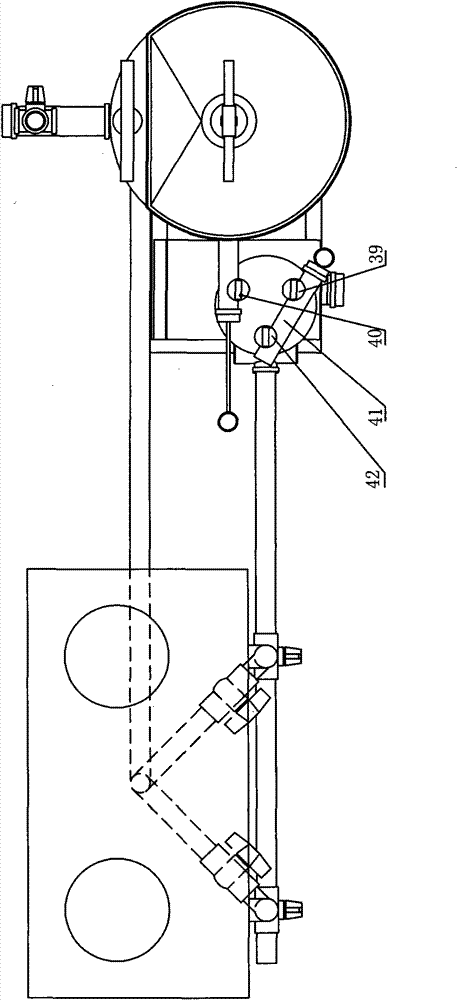

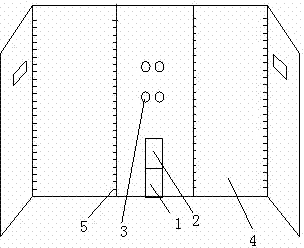

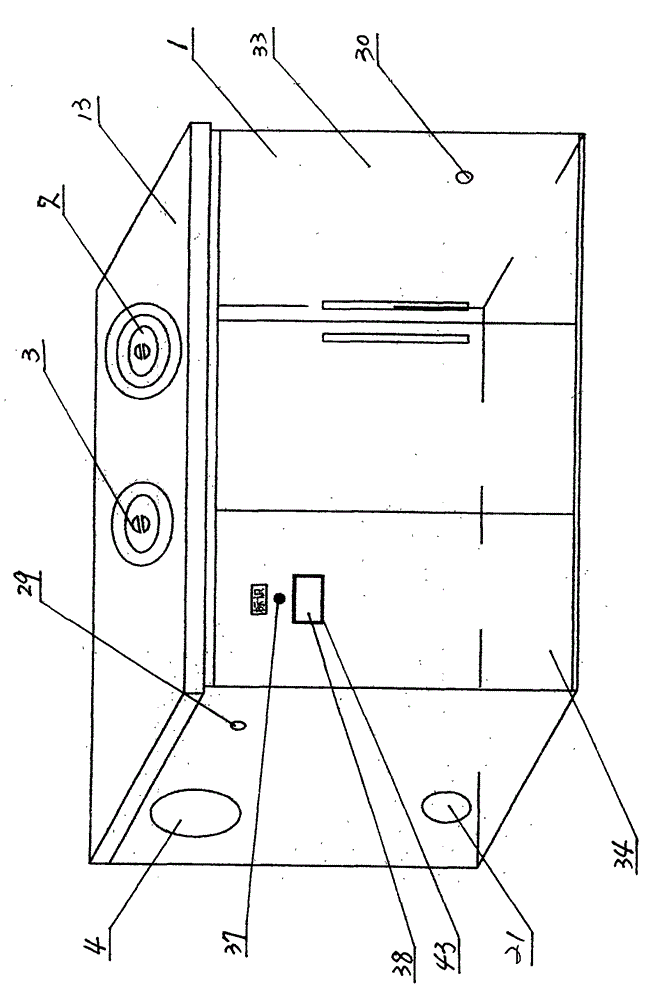

Automatic curling device for stainless steel pot

The invention discloses an automatic curling device for a stainless steel pot. The automatic curling device comprises a curling machine, a curling mold, a curling discharging mechanism, a feeding conveying mechanism, a positioning detecting mechanism, a feeding mechanical hand mechanism, a feeding mechanical hand lifting fixing mechanism, a material taking mechanical hand mechanism, a material taking mechanical hand lifting fixing mechanism and a material taking conveying mechanism, wherein the feeding conveying mechanism is connected with the curling machine through a positioning device, the positioning detecting mechanism is used for detecting whether the stainless steel pot is located at the designated position of the positioning device or not, the feeding mechanical hand mechanism is located above the feeding conveying mechanism and used for conveying the stainless steel pot from the designated position to the curling mold, the feeding mechanical hand lifting fixing mechanism is used for adjusting the height of the feeding mechanical hand mechanism, the material taking mechanical hand mechanism is used for taking the curled stainless steel pot out of the curling mold, the material taking mechanical hand lifting fixing mechanism is used for adjusting the height of the material taking mechanical hand mechanism, and the material taking conveying mechanism is used for conveying the curled stainless steel pot to the next working procedure. According to the automatic curling device, the contact ratio of sawtooth disc structures is adjusted through a linkage mechanism so as to control the recycling amount of fume, the application range of fuel is wide, and combustion is high in efficiency, stable and low in pollution.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

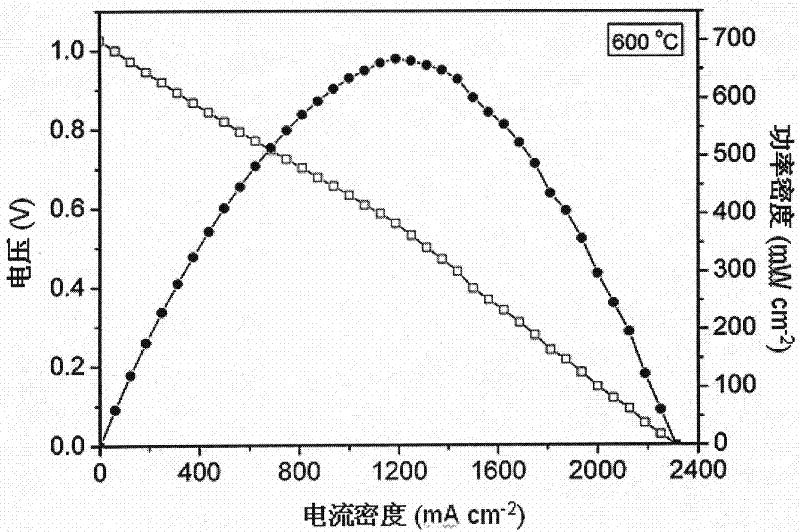

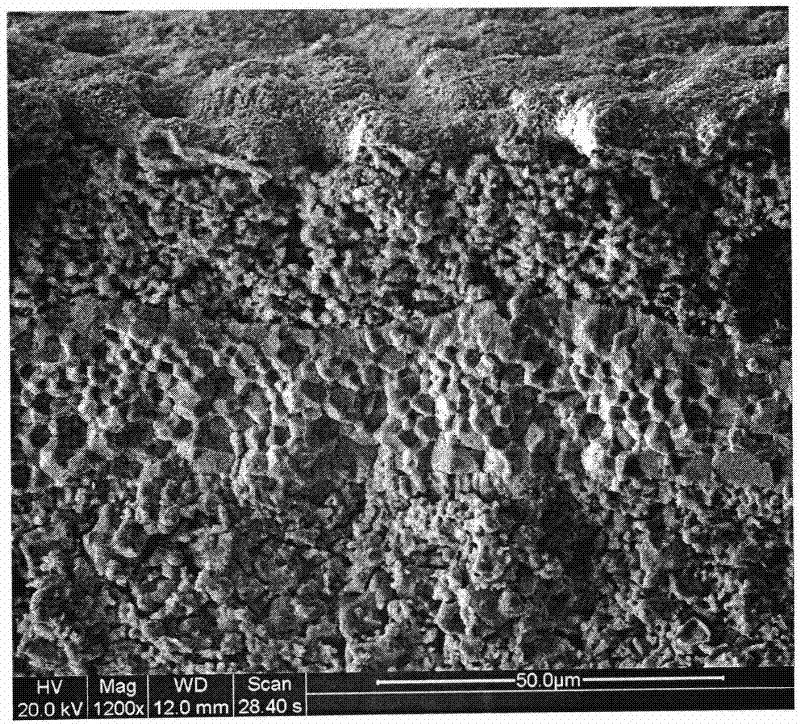

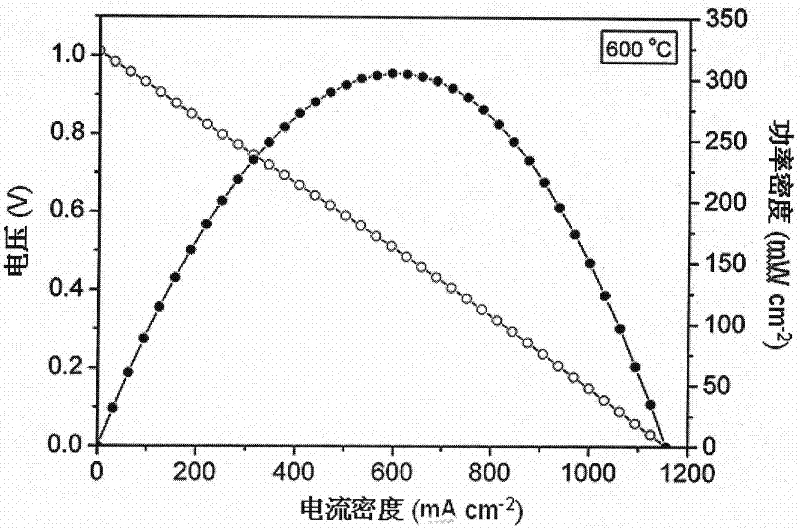

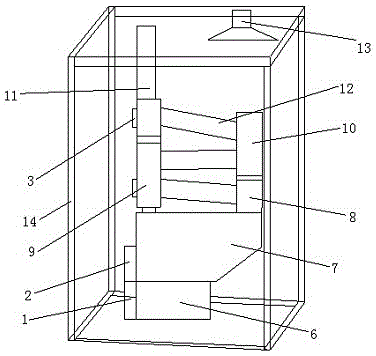

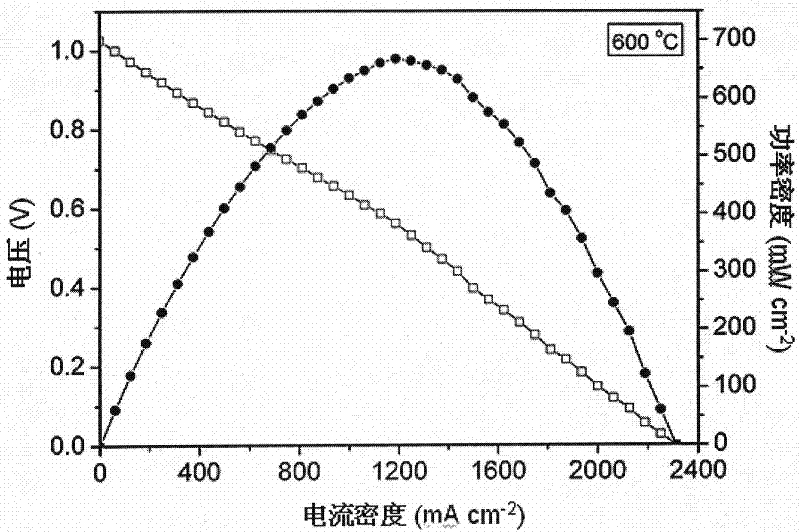

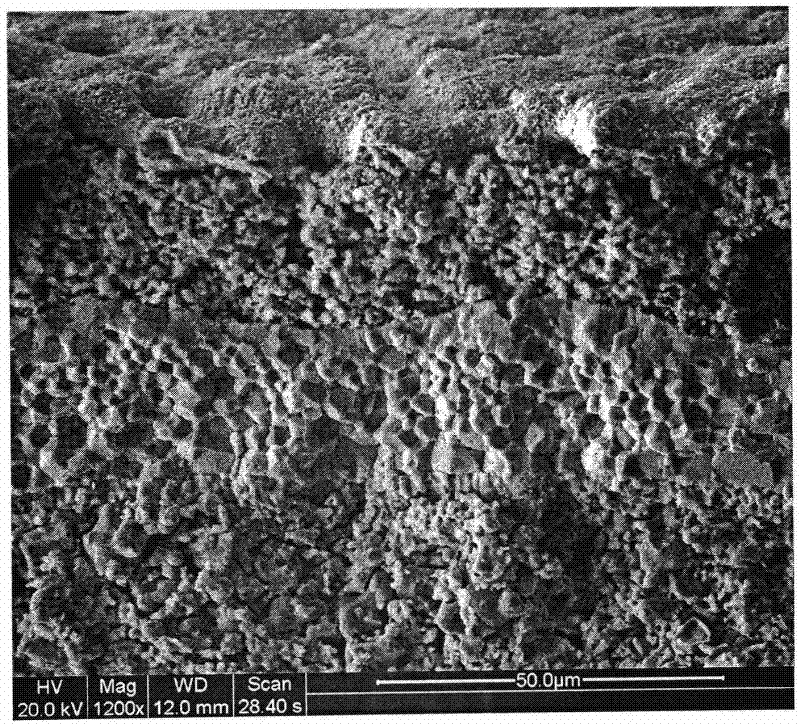

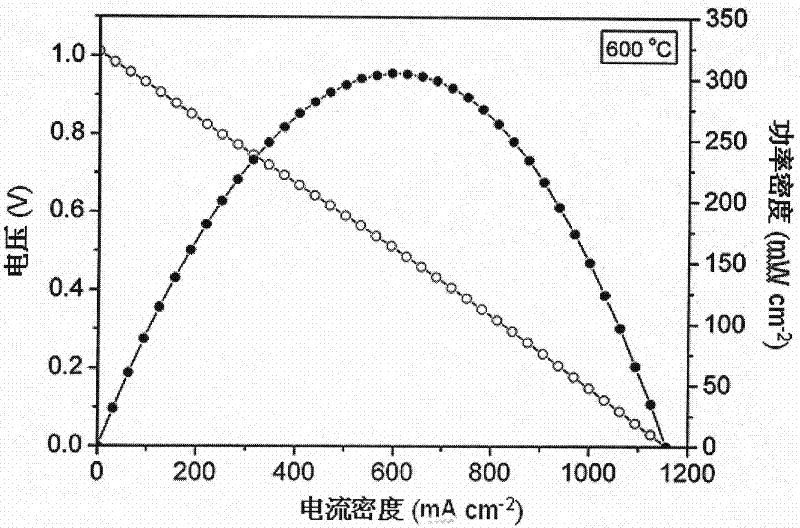

Solid oxide fuel battery system and preparation method thereof

ActiveCN101752585AWide range of fuelFinal product manufactureSolid electrolyte fuel cellsElectrical conductorOxygen ions

The invention relates to a solid oxide fuel battery system and a preparation method thereof. The electrolyte of the battery system adopts an oxygen ion conductor oxide; the anode is a metal-ceramic composite anode, wherein the ceramic material is a proton conductor oxide or a mixture of the proton conductor oxide and the oxygen ion conductor oxide; and the cathode material is at least one of noble metal and perovskite type oxides or a mixture of the electrolyte and at least one of the noble metal and perovskite type oxides. A battery with the structure has a wide operating temperature range which is between 300 and 1,000 DEG C, high power density and open circuit voltage and very good operational stability. The system and the method make a great contribution to the development of fuel batteries, particularly intermediate and low-temperature solid oxide fuel batteries.

Owner:福赛尔科技集团有限公司

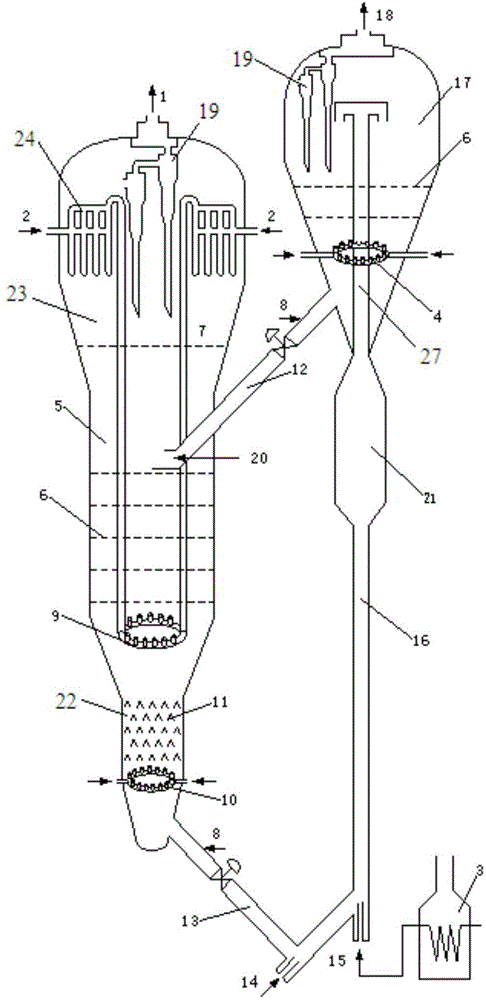

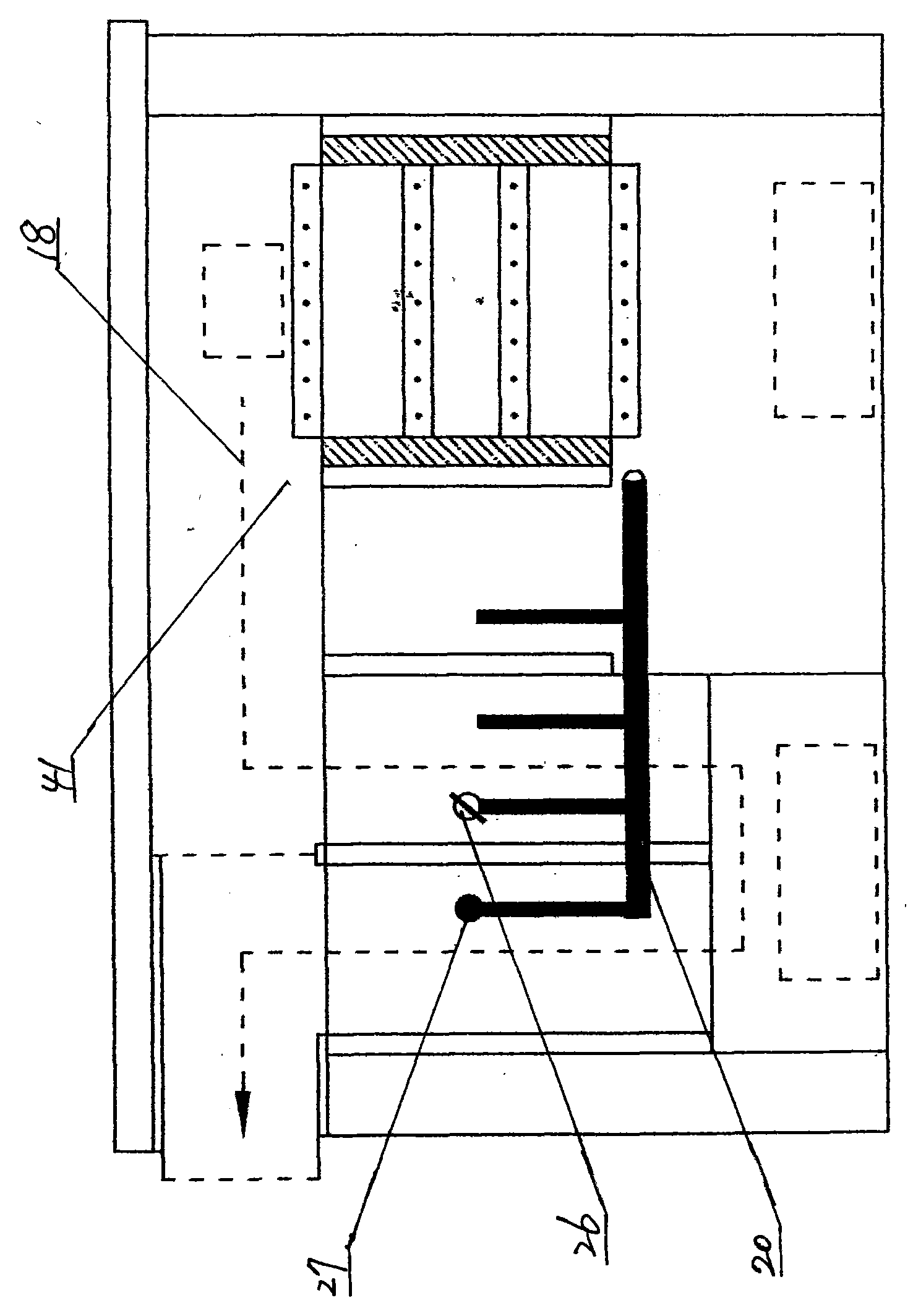

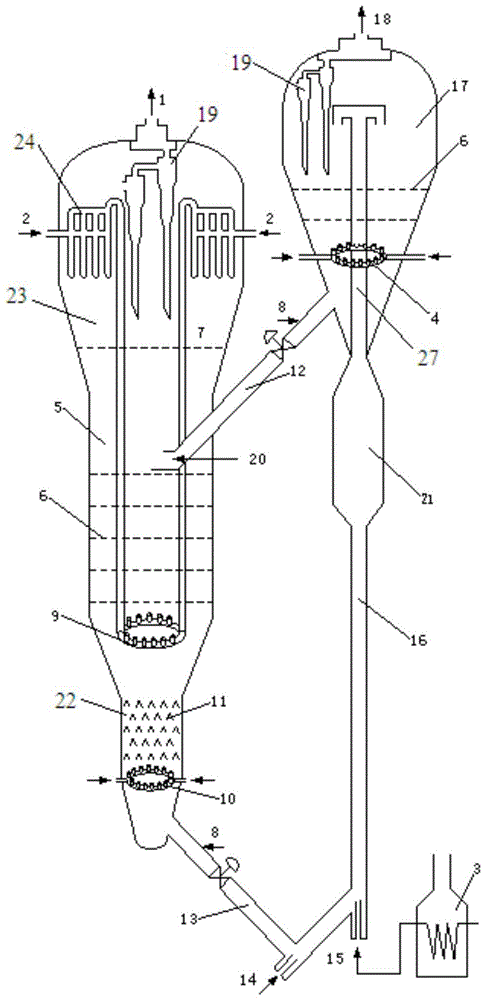

Regenerator and regeneration method of dehydrogenation catalyst

ActiveCN104525278AReduce polycondensation reactionResponse blockingCatalyst regeneration/reactivationPollutantProduct gas

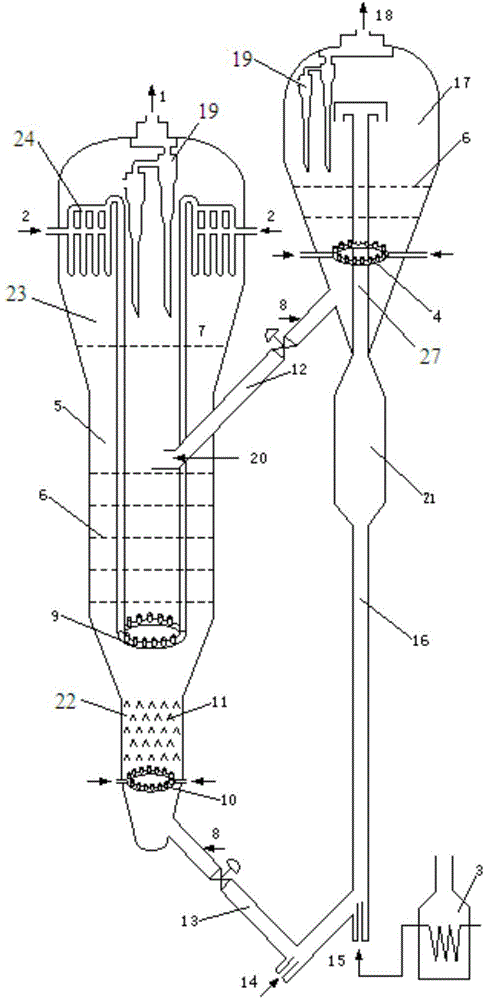

The invention provides a regenerator and a regeneration method of a dehydrogenation catalyst. The regenerator of the dehydrogenation catalyst comprises a regeneration section and a sedimentation section. The regeneration section sequentially comprises a lower lifting pipe section, an expanding dense-phase section and an upper lifting pipe section from bottom to top, and the upper lifting pipe section is connected with the sedimentation section. According to the regeneration method of the dehydrogenation catalyst, preheated air, the catalyst to be generated and fuel are combusted in a dilute-phase transport bed of the lower lifting pipe section; then, combusted high-temperature flue gas exchanges heat with the dense-phase section of the catalyst, and therefore the catalyst is fully scorched, the temperature difference between the flue gas and the catalyst is reduced, and the utilization rate of energy is increased; the flue gas leaving the dense-phase section and the catalyst enter the upper lifting pipe section, combustible gas such as CO is fully combusted in the dilute-phase transport process, and therefore energy is released, and pollutant discharge is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

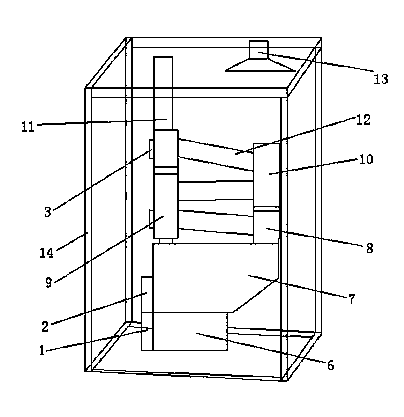

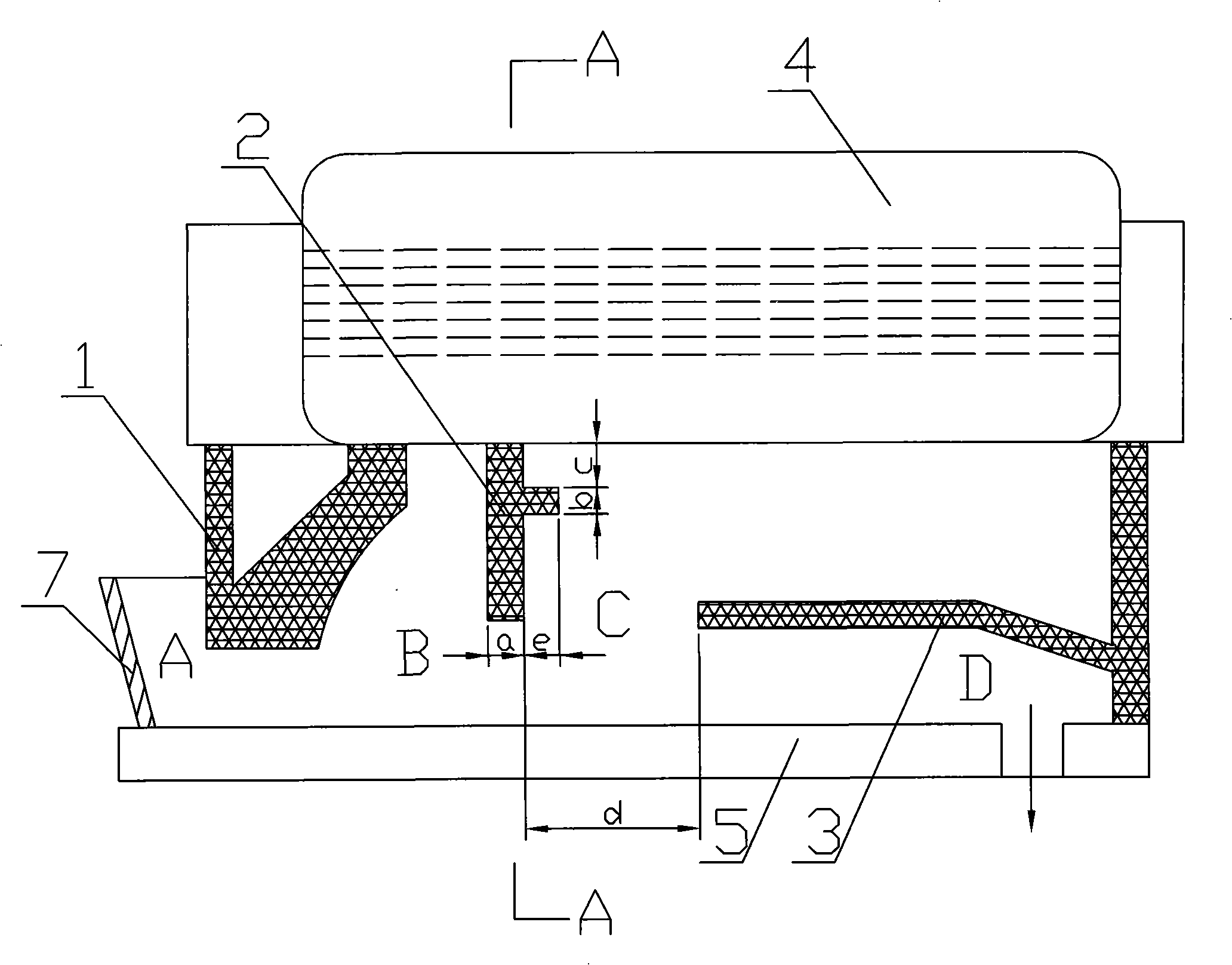

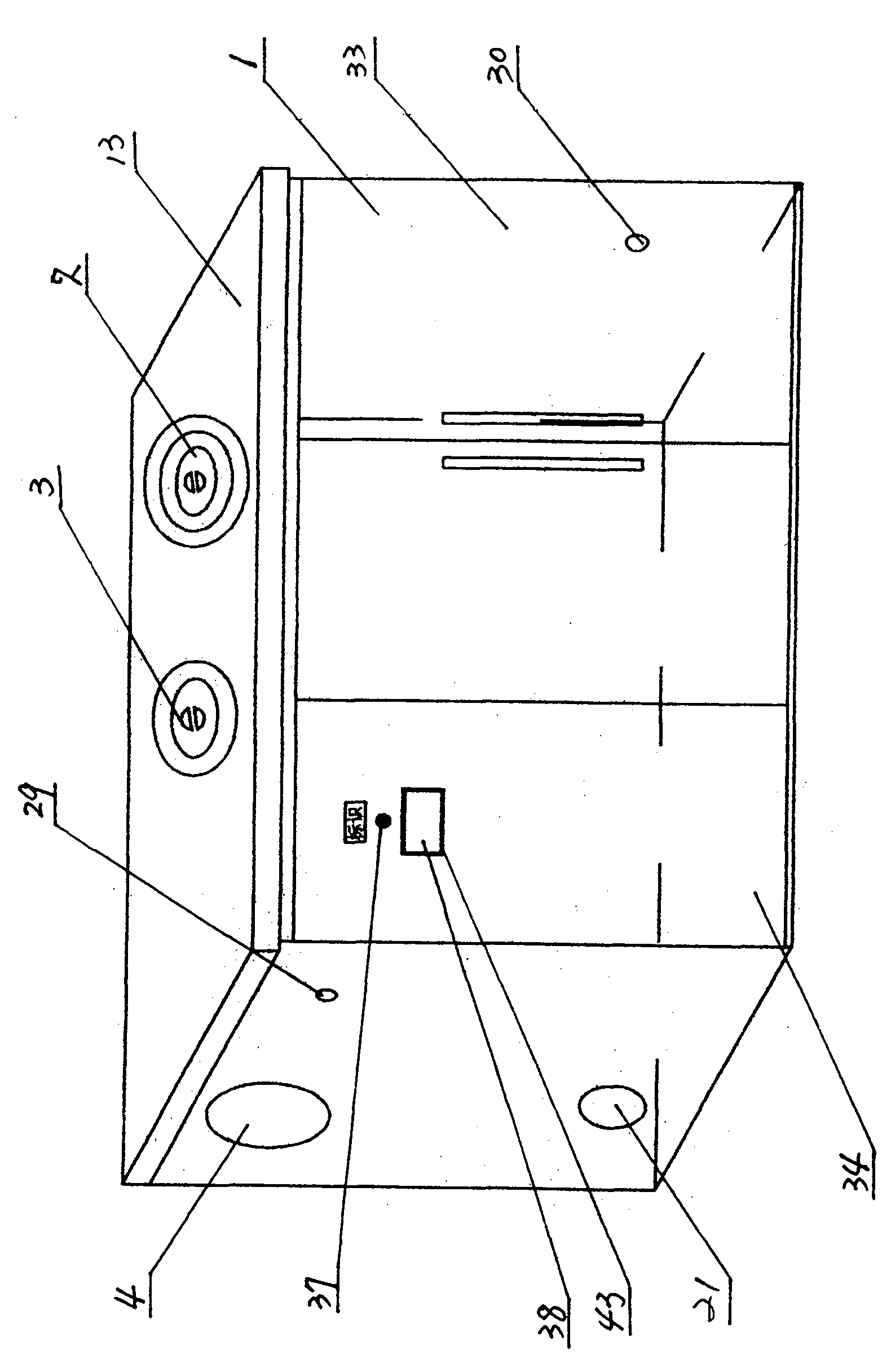

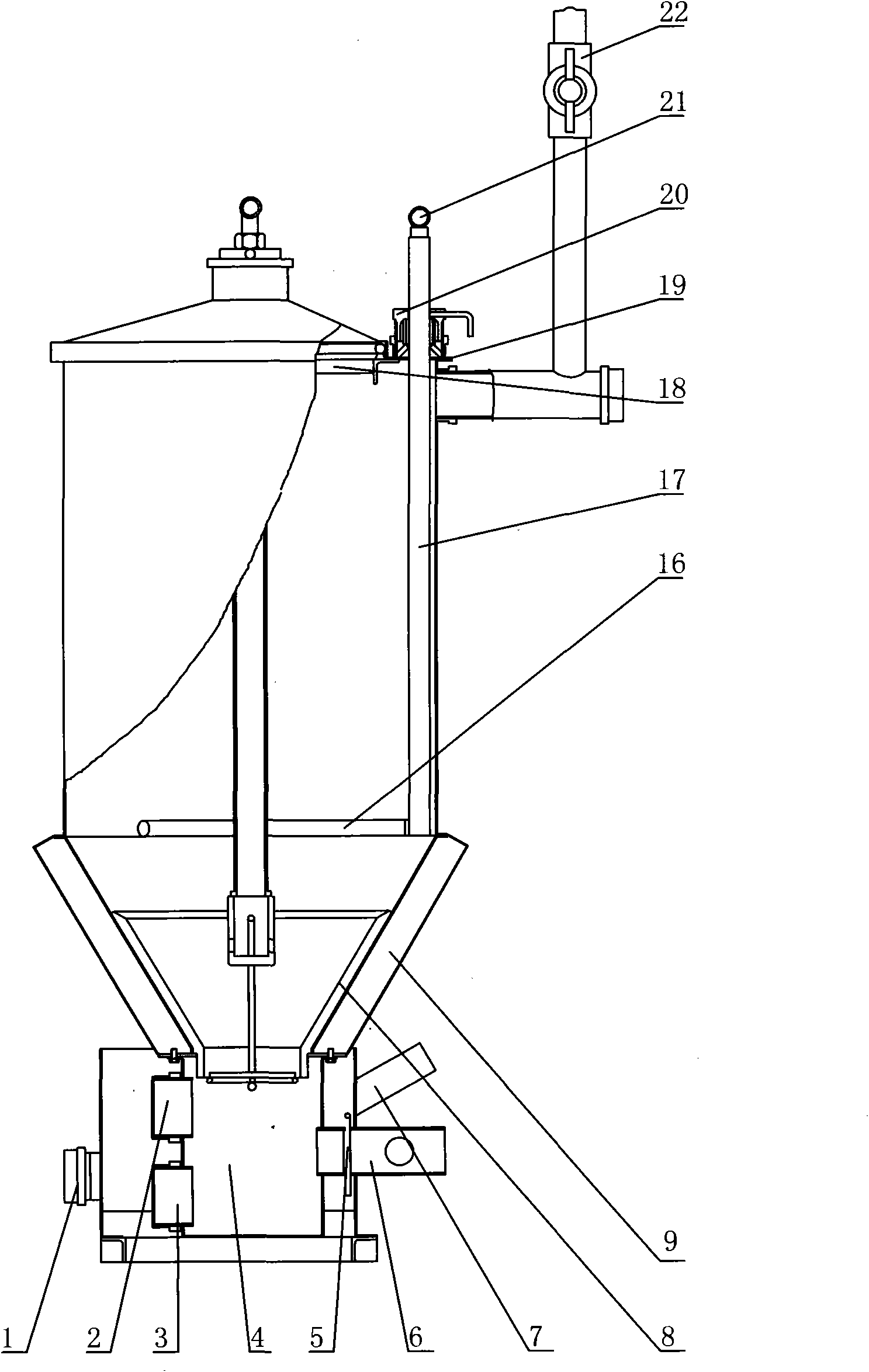

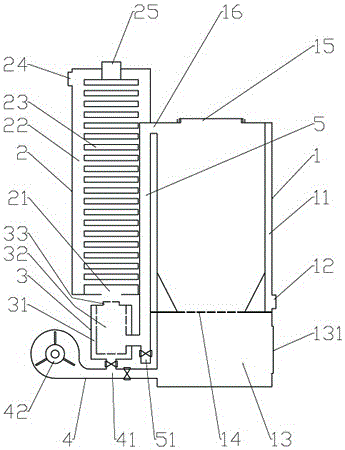

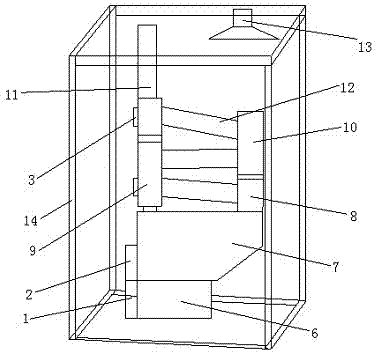

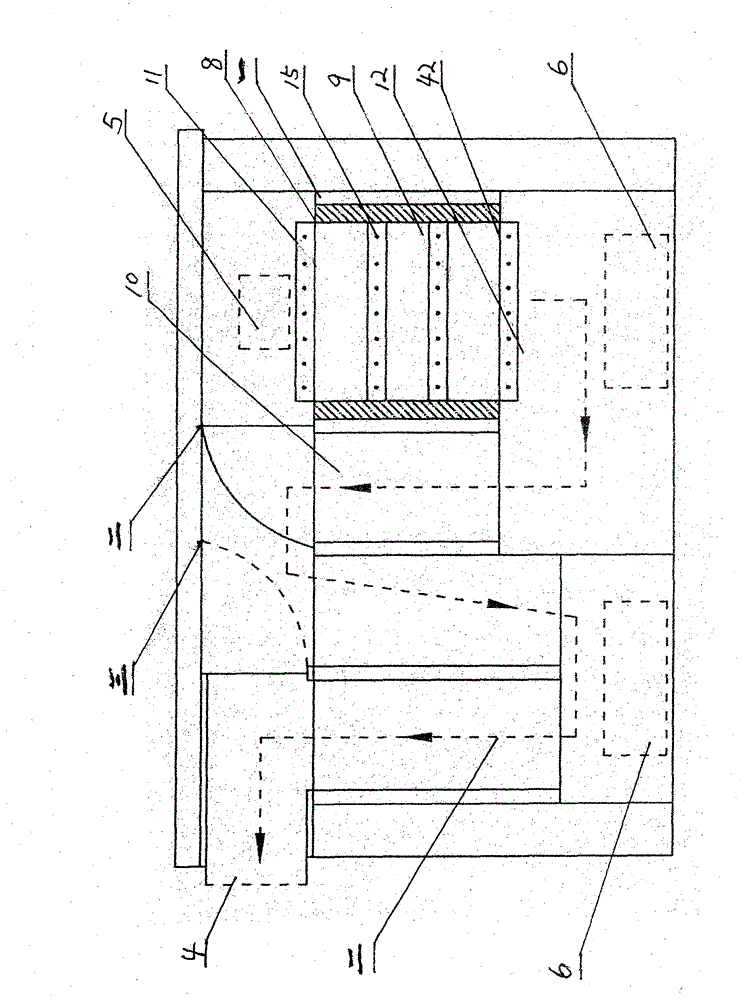

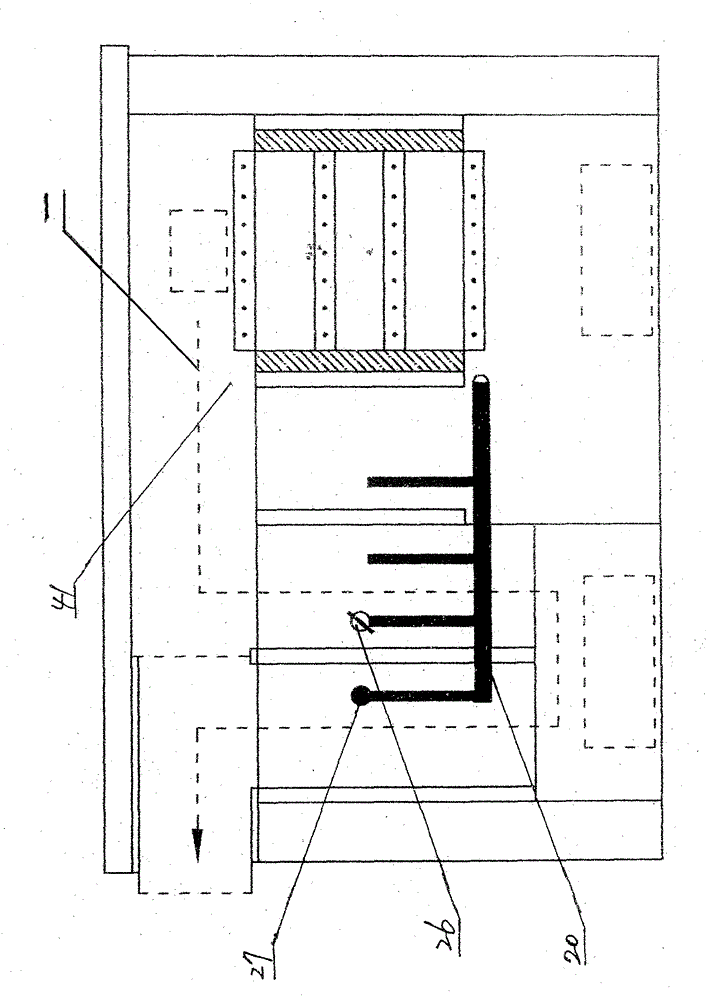

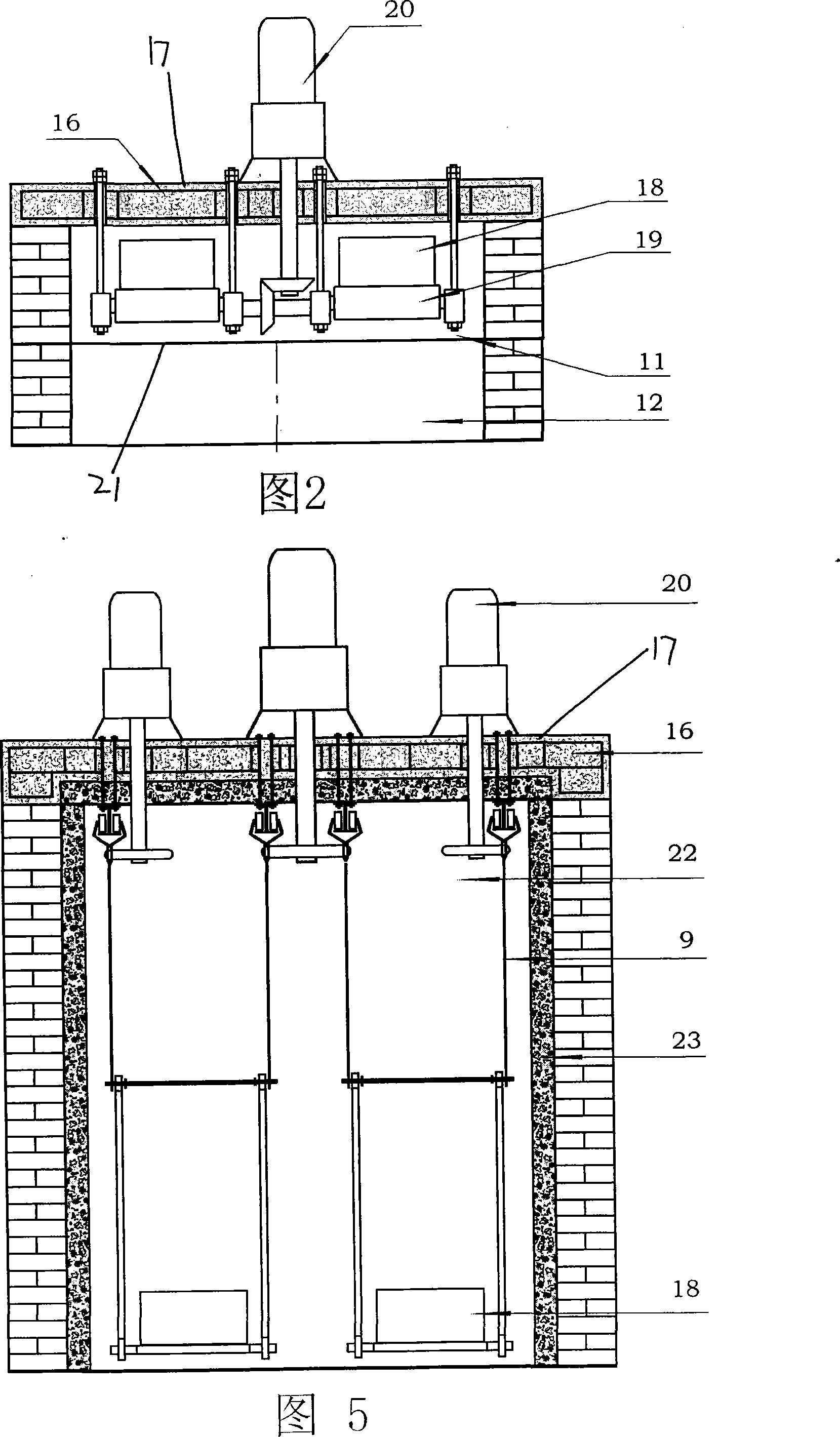

Processing method of dried lily bulb and drying device thereof

ActiveCN103719776ASimple processing methodEasy to operateFood thermal treatmentFood processingPolymer scienceHearth

The invention discloses a processing method of dried lily bulb and a drying device thereof. The processing method disclosed by the invention comprises the following steps: (1) selecting materials and cleaning the materials; (2) carrying out delaminating and color-protecting treatment on the obtained objects; (3) carrying out enzyme deactivation treatment on the obtained objects by hot ironing; (4) rinsing the obtained objects by using cold water; (5) drying the obtained products by using hot air. The drying device disclosed by the invention comprises a heating device and vertical drying chambers, wherein the vertical drying chambers are arranged on both sides of the heating device, the heating device, from top to bottom, is sequentially provided with an air chamber with an air inlet, a heating hearth with a fuel inlet, an air distributor and a smoke tube, a hot air circulating fan fixedly connected to a rack is arranged above the heating device, a moisture removal hole and at least four layers of shelves for placing trays are arranged in each vertical drying chamber, and a heater is arranged in the heating hearth. The processing method disclosed by the invention is simple and easy to operate, and good in drying effect, and the rate of finished products is 99.9%; the drying device disclosed by the invention is flexible and movable; the heating hearth is separated from the vertical drying chambers, and air feeding is performed in an isolated mode, so that clean air is fed into the drying chambers, therefore, fire hazards can be avoided; the fuel is wide.

Owner:LONGSHAN SHUNTIAN BIOTECH DEV

Gas burner capable of adjusting gas to be self-recycling

InactiveCN103277795BWide range of fuelImprove combustion efficiencyGaseous fuel burnerCycloneSpray nozzle

The invention discloses a gas burner capable of adjusting gas to be self-recycling. The gas burner capable of adjusting the gas to be self-recycling comprises a center fuel pipe, a primary rotational-flow air duct, a secondary direct-flow air duct and an ejector, wherein the center fuel pipe, the primary rotational-flow air duct, the secondary direct-flow air duct and the ejector are coaxial from inside to outside and sequentially embedded in a sleeved mode. A fuel nozzle is formed in the outlet segment of the center fuel pipe, an air cyclone and a pre-mixing chamber are arranged inside the primary rotational-flow air duct, the primary rotational-flow air duct and the pre-mixing chamber are communicated with the fuel nozzle, both an outlet of the pre-mixing chamber and the outlet end of the secondary direct flow air duct are arranged at the throat position of the ejector, a main flame burning area is formed at the throat position of the ejector, an electronic igniter is further arranged inside the primary rotational-flow air duct, one end of the electronic igniter penetrates through the air cyclone, the ignition electrode of the electronic igniter is arranged inside the pre-mixing chamber, the end surfaces, being connected with the head of the burner, of the ejector are of a sawtooth disk structure and meshed with each other, and linkage mechanisms are arranged at the positions of the sawtooth disk structures and fixed on the outer pipe wall of the secondary direct-flow air duct. The gas burner capable of adjusting the gas to be self-recycling has the advantages of being easy to manufacture, and capable of achieving the objective that the adapting range of fuel is wide, burning efficiency is high, burning is stable, and pollution is low.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Engine using quicklime as fuel

InactiveCN101694188BNo pollution in the processPollution is notHot gas positive displacement engine plantsCalcium hydroxideChemical reaction

The invention discloses an engine using quicklime as fuel, which adopts a piston type internal combustion engine. The internal combustion engine finishes the two processes of a working stroke and a discharge stroke; and in the working stroke, quicklime and water which are used as fuel are sprayed into a cylinder to perform chemical reaction so as to generate calcium hydroxide; and gas in the cylinder is expanded under the action of a plurality of heat discharged during the chemical reaction to generate high pressure for pushing a piston to do work, and the chemical reaction formula is CaO+H2O=Ca(HO)2+Q(heat); in the discharge stroke, the piston discharges the reaction product which is the calcium hydroxide from a lower dead point to an upper dead point by the inertia of a flywheel. The invention has the characteristics of reasonable structural design, wide application range and energy saving.

Owner:SHAOXING UNIVERSITY

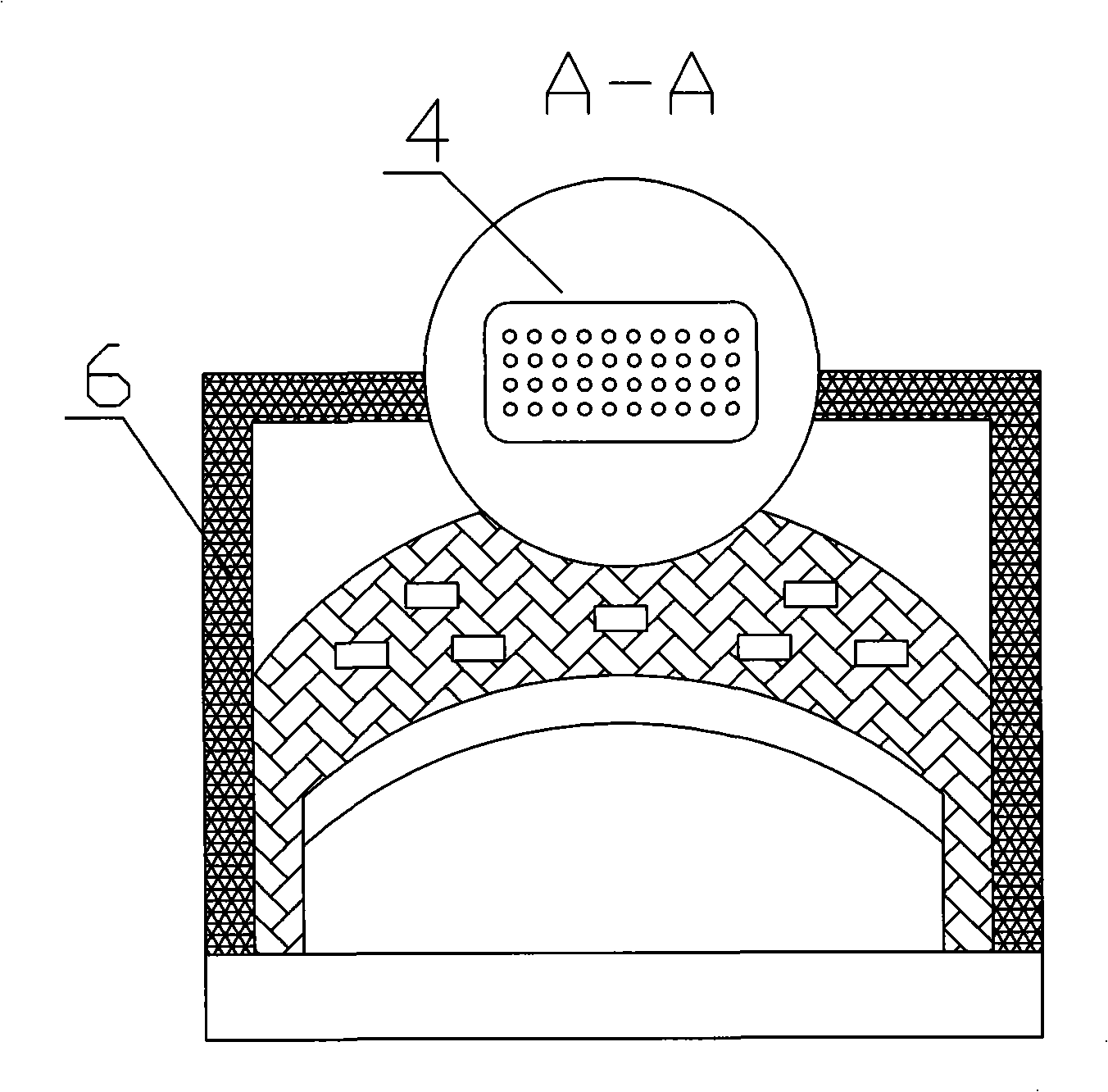

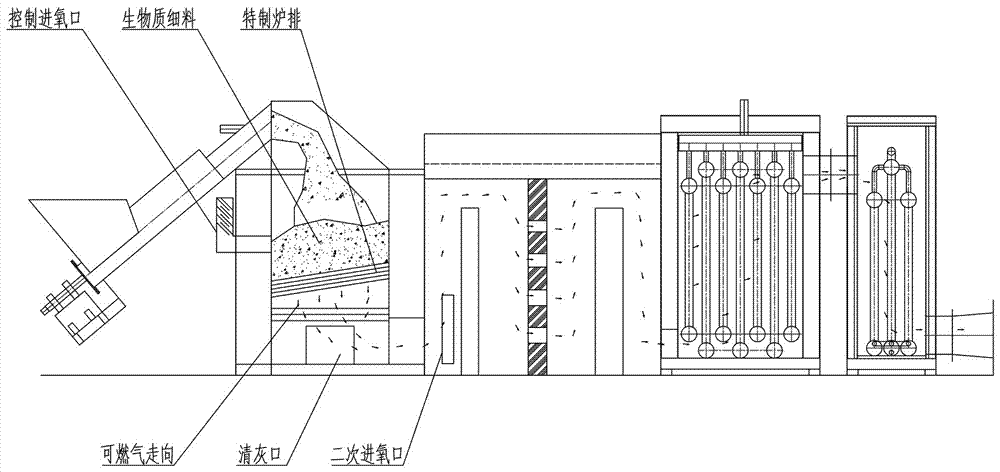

Biomass combustion special furnace

The invention relates to a novel biomass combustion special furnace arch taking biomass materials as raw materials and belonging to the technical field of combustion furnaces. The novel biomass combustion special furnace arch has a structure that a furnace body is internally provided with a front arch, a middle arch and a rear arch, wherein a feed zone is formed between the front arch and a hopper, a volatilization oxidation reduction zone is formed between the front arch and the middle arch, and a main combustion zone is formed between the middle arch and the rear arch; the shape of the rear arch is a fold line structure, and the shape of the front section of the rear arch is a level straight line structure; the middle arch is positioned between the front arch and the rear arch and in a single row wall body structure, the upper end of the middle arch is connected with a water containing boiler, the middle of the lower end of the middle arch is provided with a combustion passage, and the middle section of the inner side of the middle arch is provided with a bump which is positioned at the outer side above the rear arch. The invention relates to the novel biomass combustion special furnace arch which is beneficial to the sufficient combustion of biomass fuel, has long flame flow path, high heat efficiency, energy saving, smoke elimination, good environmental protection property, high temperature raising speed of water inside a the water containing boiler, and the like.

Owner:许元凯

Biomass straw gas furnace

InactiveCN102135278AHigh thermal efficiencySimple and fast operationLighting and heating apparatusStove/ranges for heating waterAutomatic controlMetallurgy

The invention relates to a biomass straw gas furnace and belongs to the technical field of environmentally-friendly and energy-saving multifunctional gas furnaces. The biomass straw gas furnace mainly comprises a furnace body; the upper part of the furnace body is provided with a discharge flue and a charging door; the lower part of the furnace body is provide with an ash removal hopper; a furnace pipe is arranged in the furnace body; a grate is arranged in the furnace pipe; the furnace pipe is communicated with the charging door; the furnace body consists of a combustion system, an oxygen supply system, a heating system, a heat conduction system and a control system; the upper part of the furnace body is provided with a mirror surface white steel plate table board; the front of the furnace body is provided with a mould pressing door and a fixing door; the mirror surface white steel plate table board is provided with a big pot range and a small pot range; the fixing door is provided with a manual fan switch, a temperature controller, a hot wind oxygen supply system, and a quick heating system; an automatic control system improves the heat efficiency; rural cauldrons and various cookers are actually used for cooking; heat is supplied by devices such as a heated kang, a heating unit, a geothermal system and the like at large power; the biomass straw gas furnace is convenient and easy to operate; the source of the fuels is wide, biomass straw particle blocks are used as main fuels, and moulded coal, fungus waste, and xylon all can be used as fuels; the biomass straw gas furnace has high calorific value, large water capacity, and short heating time, has the functions of stopping and keeping fire, and saving energy, is clean and environmentally-friendly, discharge no combustible gas, and leaks no tar; and smoke, odor and dust are avoided during operation.

Owner:BAISAN ZHENYUAN BIOMASS ENERGY TECH

Automatic crimping device for stainless steel pot

The invention discloses an automatic curling device for a stainless steel pot. The automatic curling device comprises a curling machine, a curling mold, a curling discharging mechanism, a feeding conveying mechanism, a positioning detecting mechanism, a feeding mechanical hand mechanism, a feeding mechanical hand lifting fixing mechanism, a material taking mechanical hand mechanism, a material taking mechanical hand lifting fixing mechanism and a material taking conveying mechanism, wherein the feeding conveying mechanism is connected with the curling machine through a positioning device, the positioning detecting mechanism is used for detecting whether the stainless steel pot is located at the designated position of the positioning device or not, the feeding mechanical hand mechanism is located above the feeding conveying mechanism and used for conveying the stainless steel pot from the designated position to the curling mold, the feeding mechanical hand lifting fixing mechanism is used for adjusting the height of the feeding mechanical hand mechanism, the material taking mechanical hand mechanism is used for taking the curled stainless steel pot out of the curling mold, the material taking mechanical hand lifting fixing mechanism is used for adjusting the height of the material taking mechanical hand mechanism, and the material taking conveying mechanism is used for conveying the curled stainless steel pot to the next working procedure. According to the automatic curling device, the contact ratio of sawtooth disc structures is adjusted through a linkage mechanism so as to control the recycling amount of fume, the application range of fuel is wide, and combustion is high in efficiency, stable and low in pollution.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

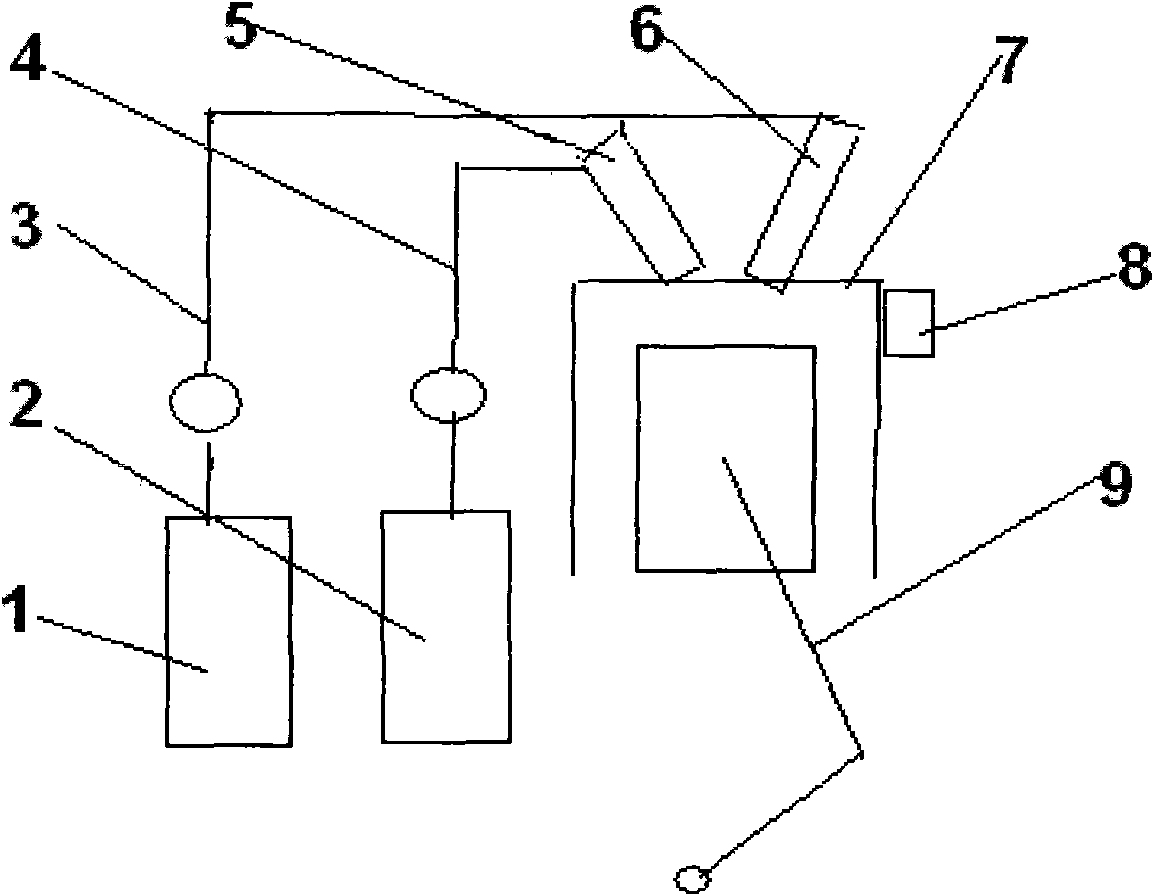

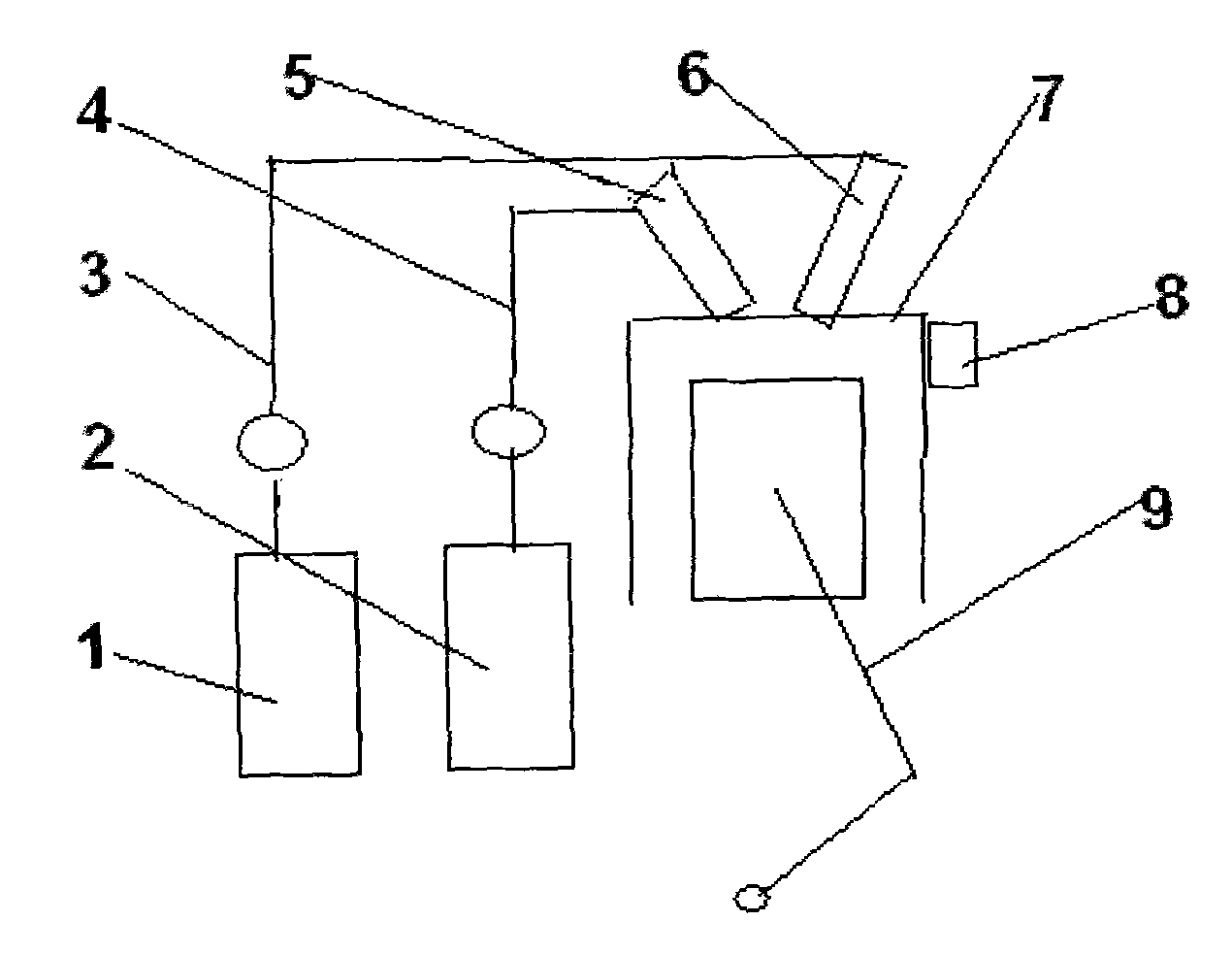

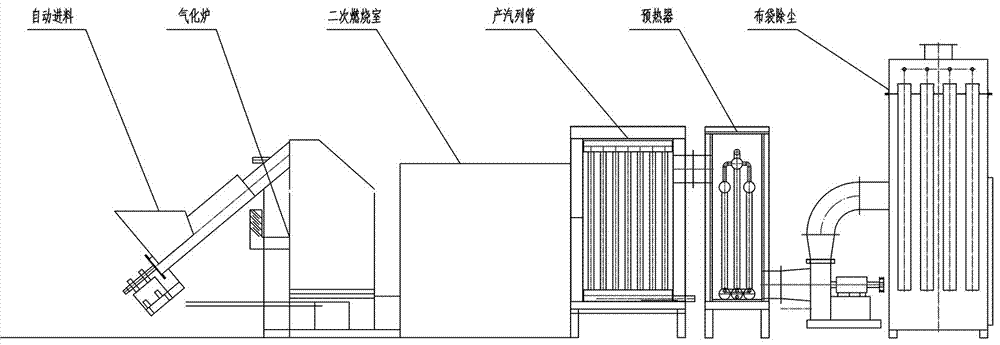

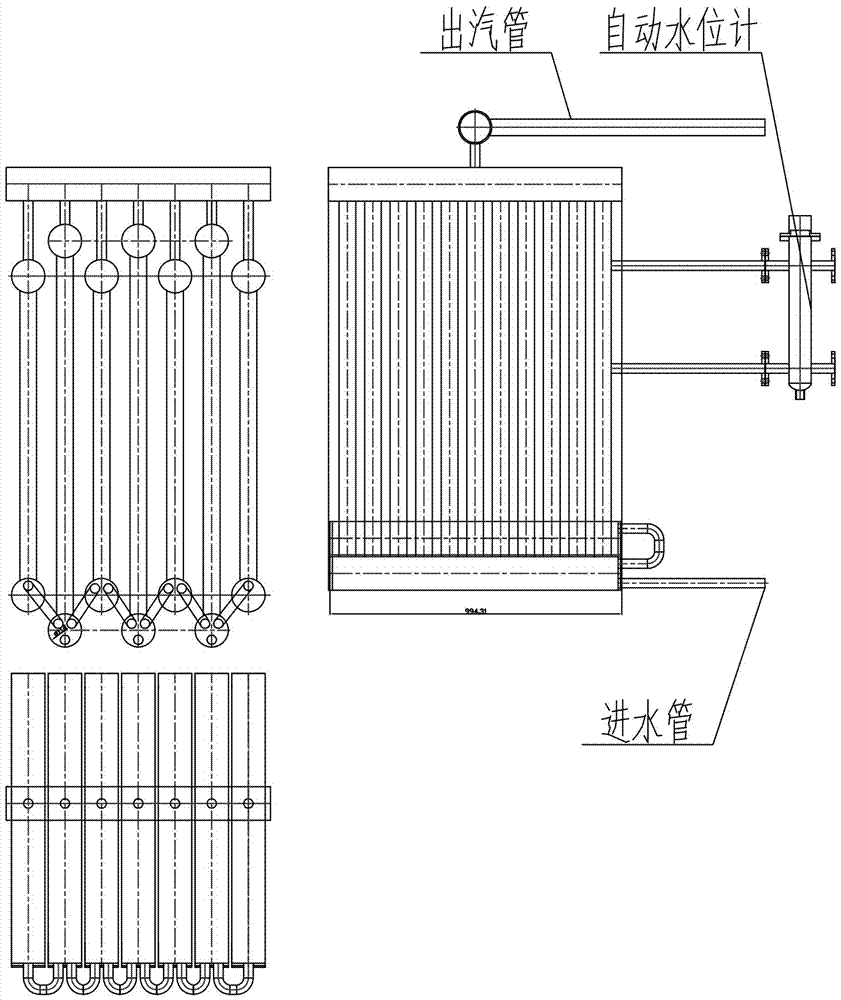

Novel biomass gasification steam generator

InactiveCN107366892AWide range of fuelHigh gasification combustion temperatureEnergy inputGasification processes detailsCombustion chamberCombustible gas

The invention provides a novel biomass gasification steam generator. The novel biomass gasification steam generator structurally comprises an automatic feeding system, a gasifier, a secondary combustion chamber, steam generation tube banks, a water preheating system and a bag-type dust collector, wherein the automatic feeding system is connected with a gasifier; the gasifier is connected with the secondary combustion chamber; the secondary combustion chamber is connected with the steam generation tube banks; the steam generation tube banks are connected with the water preheating system; and the water preheating system is connected with the bag-type dust collector. The novel biomass gasification steam generator has the following advantages: the provided novel biomass gasification steam generator is not a boiler, the tube banks are heated to produce steam for later use by virtue of combustion of a combustible gas generated after biomass gasification, and tail gas generated by combustion preheats cold water in inlets in the tube banks and is cooled down, so that the heat utilization ratio is high; bag-type pulse dust collection is performed to further reduce dust in the tail gas, so that the environmental emission demand is met; and the novel biomass gasification steam generator overcomes the adversity that enterprises need steam.

Owner:NANJING FORESTRY UNIV +1

A circulating fluidized bed reaction device for alkane dehydrogenation to olefins

ActiveCN104549073BAvoid cokingAvoid vibrationHydrocarbonsChemical/physical processesThermal energyAlkane

A circulating fluidized bed reaction device for alkane dehydrogenation to olefins and a method for alkane dehydrogenation, the reaction device is a tank body with variable diameter, and the tank body is divided into a gas stripping section, a reaction section and a catalyst settling section from bottom to top , wherein the diameter of the reaction section is larger than that of the stripping section, and a heat exchanger is provided in the settling section. The reaction device exchanges heat between the raw material and high-temperature oil and gas in the reaction device. The raw material is vaporized and heated by the heat energy of the high-temperature oil and gas. Coking due to high temperature, several effects are organically combined, especially the heat exchanger structure that connects multiple heat exchange boxes in series, which can effectively avoid vibration caused by rapid gasification of raw materials, and can realize heat exchange with large temperature difference .

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Composite heat carrier generator for high viscosity oil

ActiveCN107461179BAvoid easy cloggingWide range of fuelInsulationFluid removalRadiative heat lossHeat carrier

The invention discloses a composite heat carrier generating device suitable for high-viscosity oil. The composite heat carrier generating device comprises a shell, the shell is formed through integration of a circular cone section and a cylinder section, a cooling casing pipe is arranged in an inner cavity of the shell in a penetrating mode, and the cooling casing pipe is provided with a closed end and an open end. The closed end of the cooling casing pipe extends to and abuts against the conoid inner wall of the circular cone section, and the open end of the cooling casing pipe extends in the axial direction of the shell and penetrates out of the cylinder section to be plugged with a head body arranged at the end of the cylinder section. A cylindrical air register arranged to be opposite to the head body is arranged in an inner cavity, close to the open end, of the cooling casing pipe, and a whirlcone arranged on an external ring of the end of the head body in a sleeving mode is arranged in the middle of the air register. According to the composite heat carrier generating device, heavy oil or crude oil with the high viscosity can be burned in an atomizing mode so that the gas injection cost can be lowered, the radiation heat loss in a burning chamber is reduced at the same time, the scaling phenomenon happening in a cooling water flow pass is relieved, and the energy utilization ratio of the composite heat carrier generating device can be increased, and the operation stability of the composite heat carrier generating device are improved.

Owner:WUHAN YUANFANG SCI & TECH CO LTD OF CHINA SANJIANG SPACE GRP

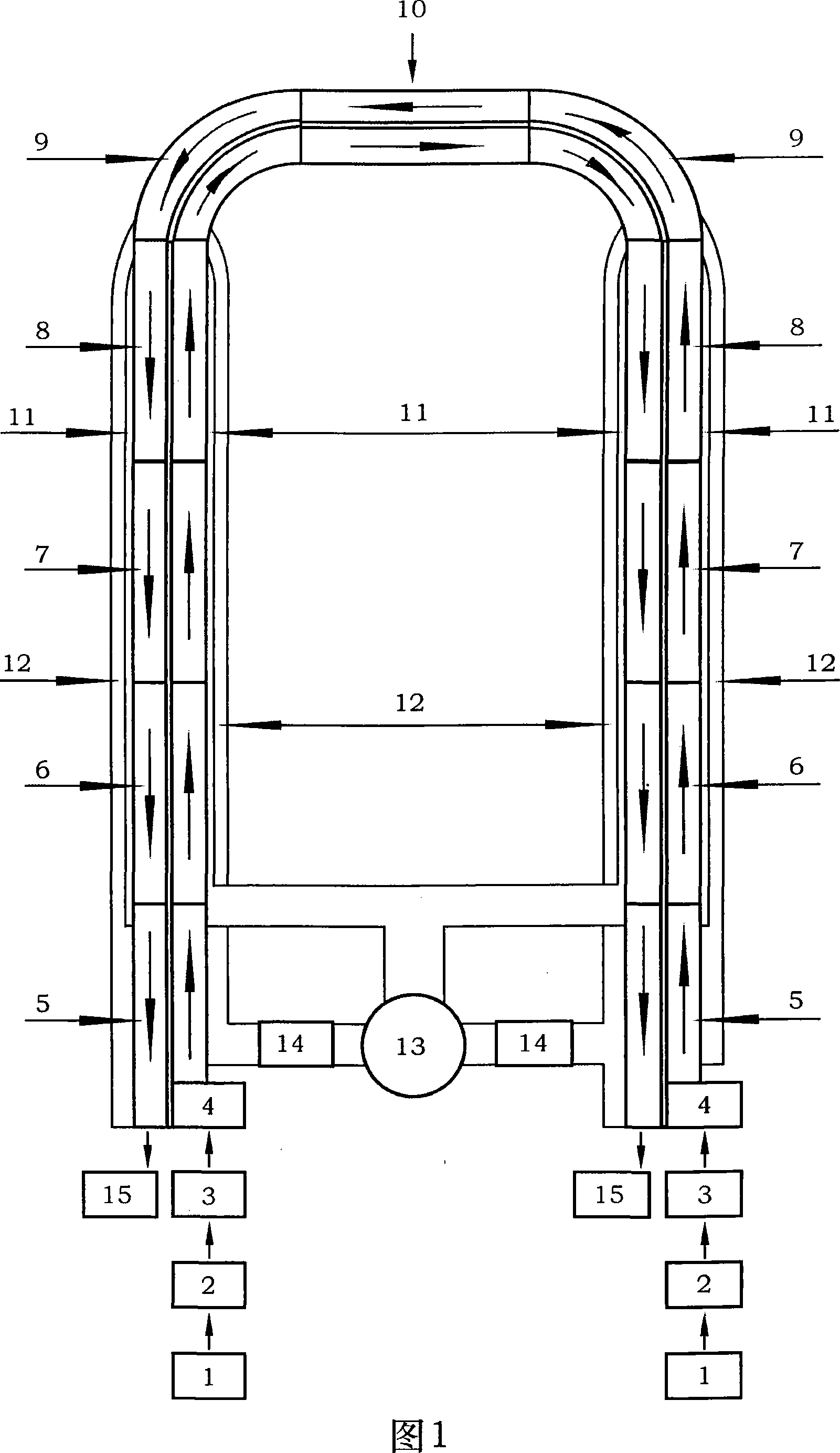

Waste heating device

InactiveCN101907306AWide range of fuelLow costStoves/ranges with convection heatingLighting and heating apparatusCombustion chamberOxygen supply

The invention discloses a waste heating device comprising a generator, a distributor (1), a distributor (2), a heat radiating pipeline and an air feeding pipeline, wherein a mixed air outlet of the generator is sequentially communicated with the distributor (1), the distributor (2) and the heat radiating pipeline; an air outlet of a heat storage tank is communicated with the air feeding pipeline; an oxygen collecting chamber, the heat storage tank, an air collecting chamber and an U-shaped combustion chamber are arranged in the generator; the front part of the heat storage tank is provided with an air inlet, and the rear part of the heat storage tank is provided with the air outlet communicated with the outer part of a housing; the lower part of the heat storage tank is provided with the oxygen collecting chamber, and the front part of the oxygen collecting chamber is provided with two oxygen supply ports communicated with the outer part of the housing; the air collecting chamber is provided with a mixed air outlet communicated with the outer part of the housing; the upper part of the air collecting chamber is provided with a movable upper cover; the side wall of the U-shaped combustion chamber is provided with a fire-resistant insulating layer, the front part of the combustion chamber is provided with two ash outlets and two observation holes, which are respectively communicated with the outer part of the housing; the side wall of the lower bottom of the oxygen collecting chamber is provided with a plurality of oxygen supply holes; and the distributor (1), the distributor (2) and the heat radiating pipeline are prefabricated by concrete. The waste heating device has the advantages of wide used fuel, low cost and simple structure, and due to the set of the heat storage tank in the combustion chamber, the waste heating device can fully utilize heat sources, thereby having obvious effect of energy saving.

Owner:董国峰

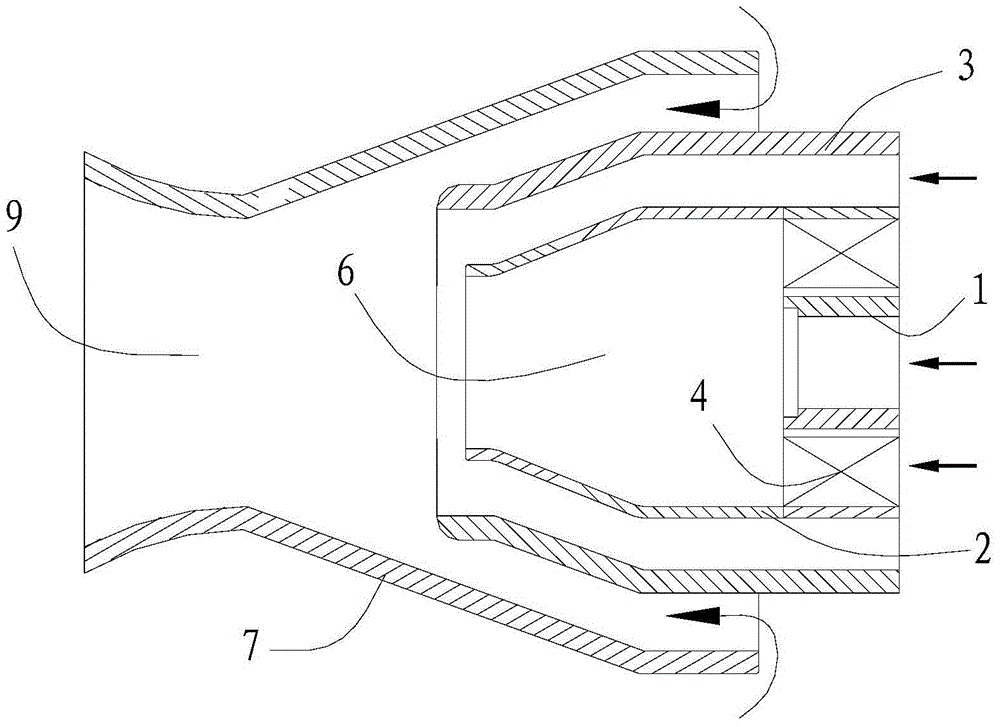

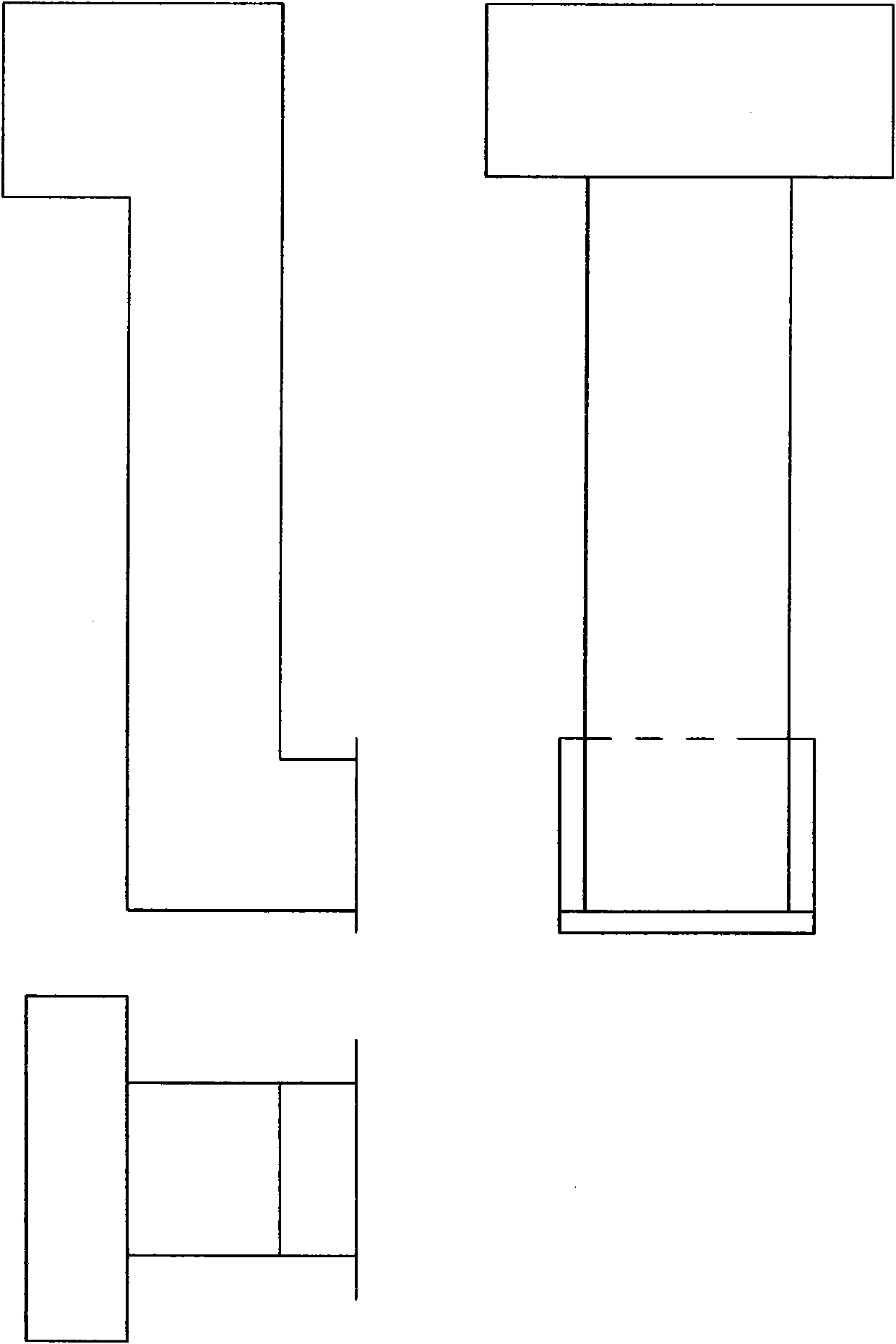

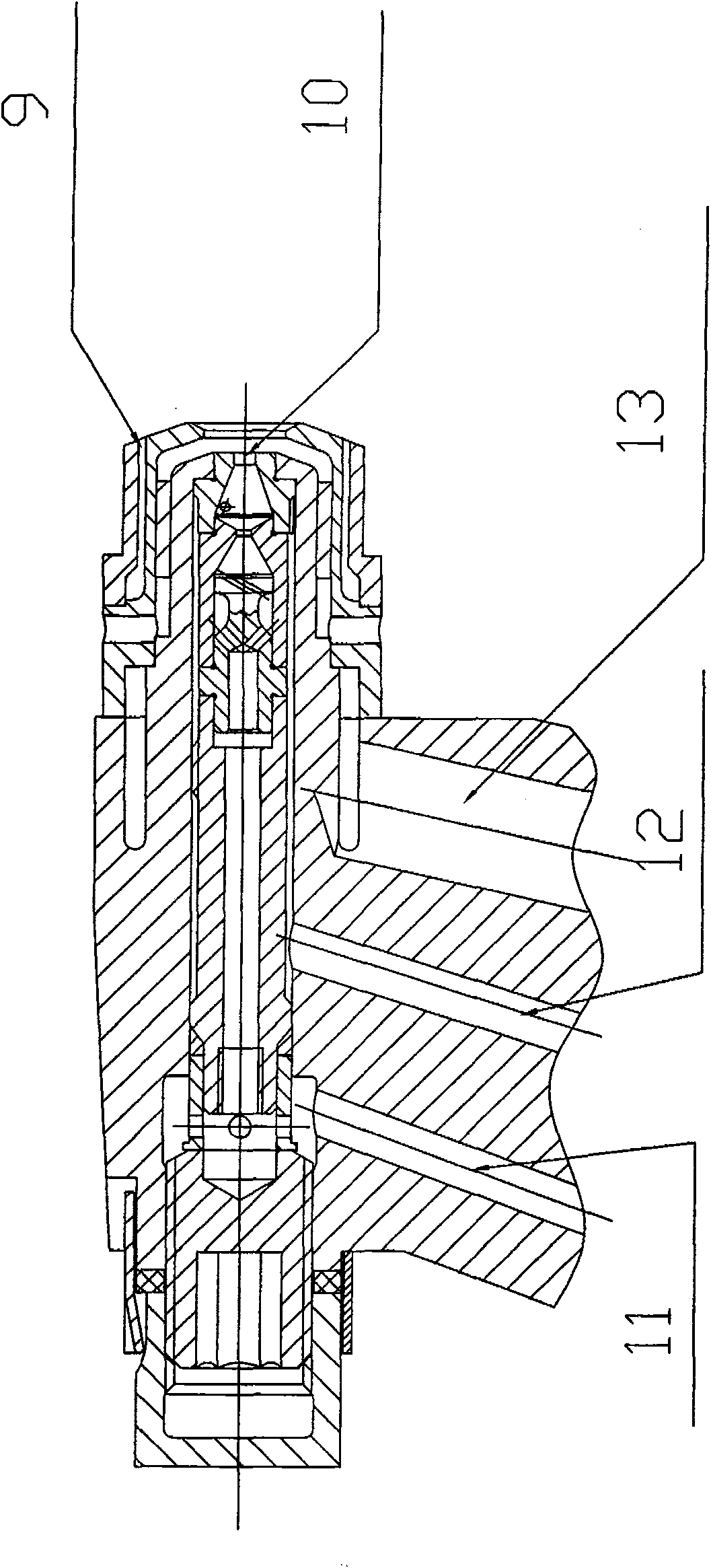

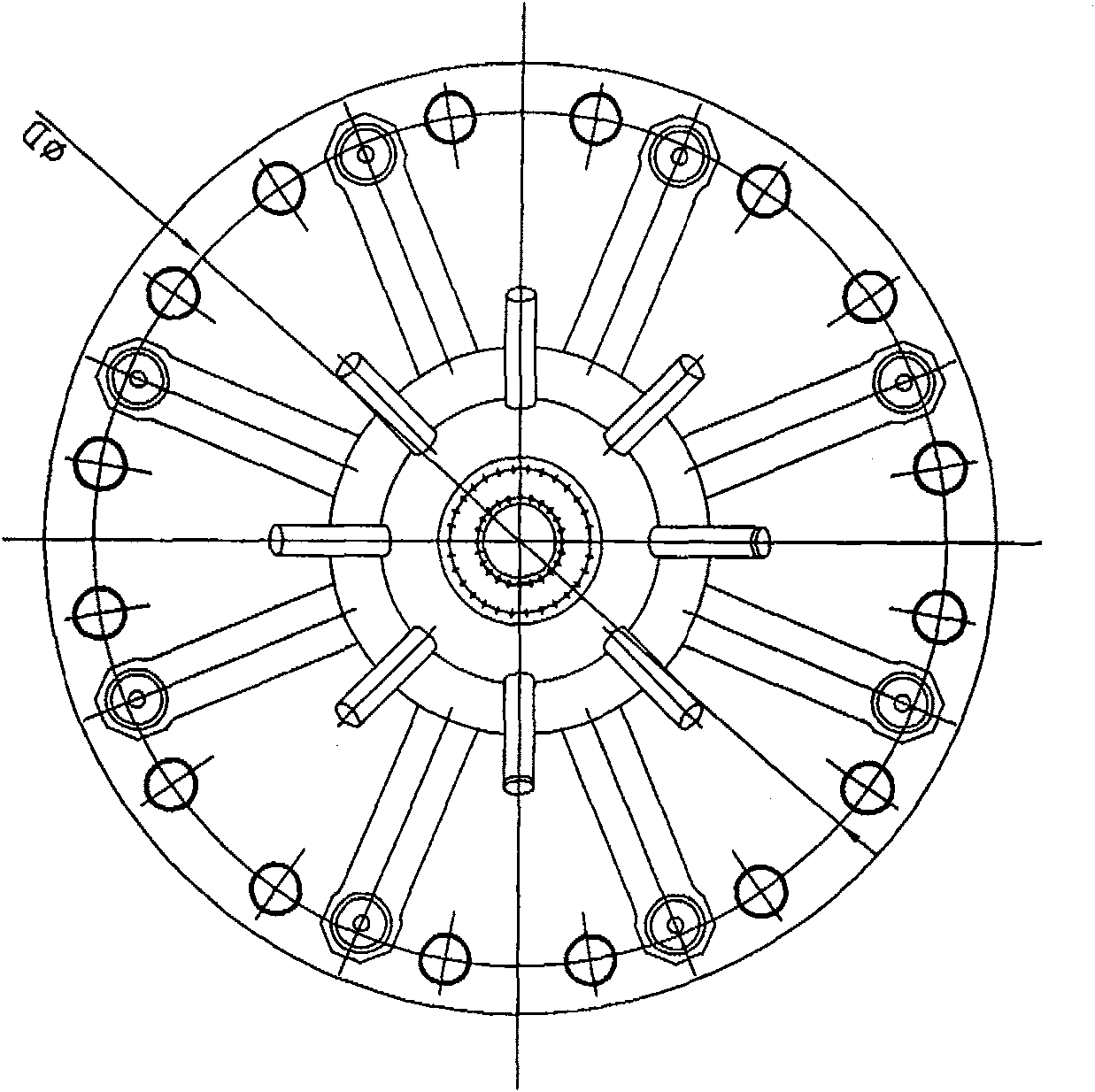

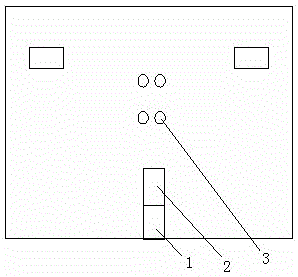

Multi-head double-fuel combined nozzle

InactiveCN100590360CImprove atomization effectEmission reductionBurnersLiquid spraying apparatusCombustion chamberLiquid fuel

The invention relates to a multi-head dual fuel combined nozzle. The multi-head dual fuel combined nozzle is characterized by comprising a head nozzle 1, a center nozzle group 2, a nozzle mounting side 3, a center liquid fuel nozzle mounting side 4 and a nozzle casing body 5; the nozzle casing body 5 comprises a head nozzle casing body 6 and a center nozzle casing body 7; the center nozzle group 2comprises a gas fuel nozzle, a pilot nozzle 9 and a center liquid fuel nozzle10; the multi-head dual fuel combined nozzle has the advantages that the traditional mechanical structure is improved, thecombustion efficiency of the combustion chamber is enhanced, and the annihilation performance of the combustion chamber is improved. The multi-head dual fuel combined nozzle can be applied to the combustion turbine combustion chambers which are operated by adopting liquid fuel and gas fuel.

Owner:SHENYANG ENGINE DESIGN RES INST CHINA AVIATION IND CORP I

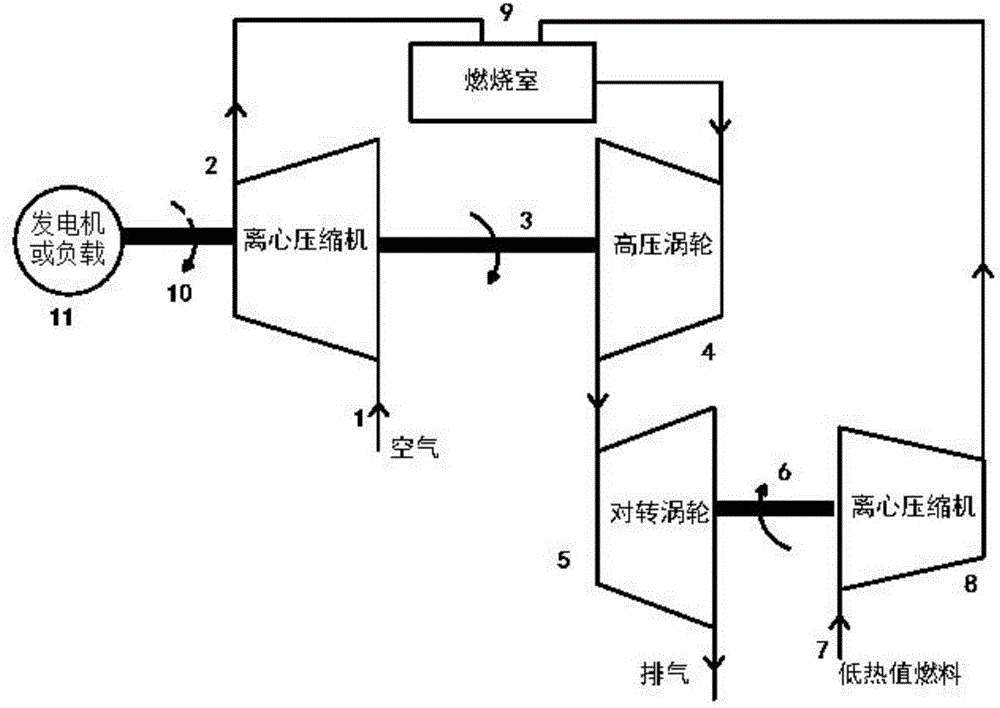

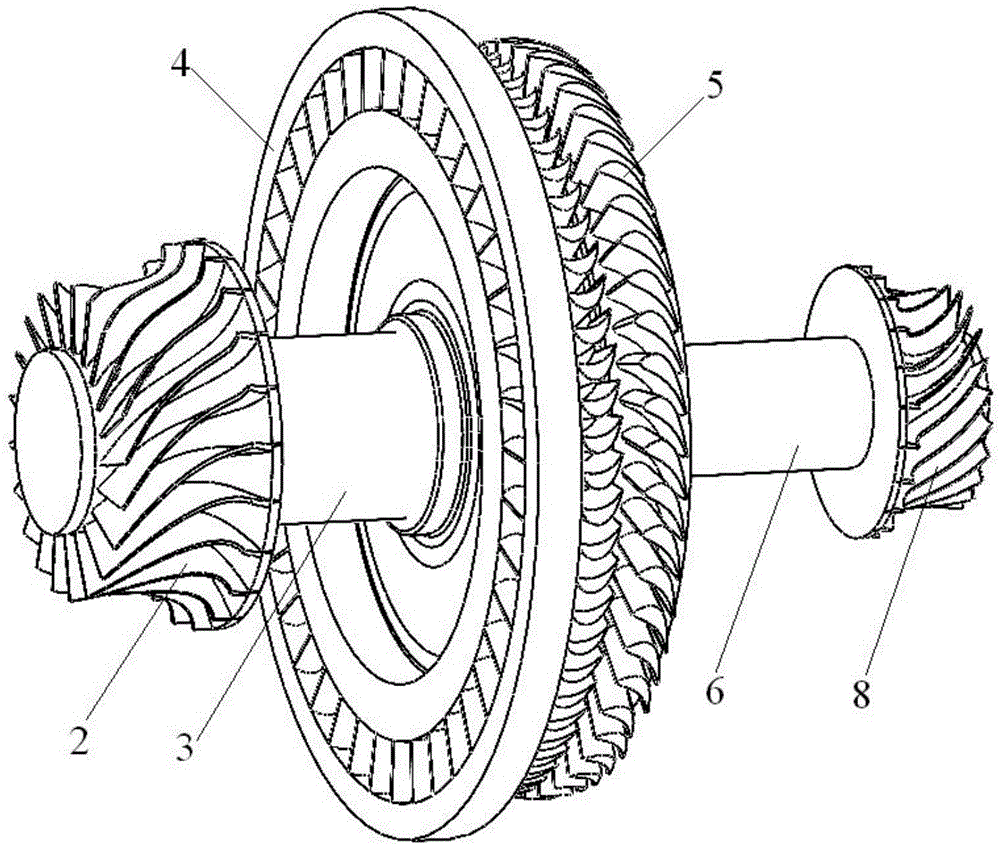

A compact gas turbine device using gaseous fuel with low combustion value

ActiveCN104533620BImprove power-to-weight ratioAlleviate shortagesGas turbine plantsCombustion chamberProduct gas

Disclosed is a compact gas turbine device adopting low-combustion value gas fuel. An air inlet way and a compression air outlet way are arranged on an air centrifugal compressor, and a low-combustion value gas fuel air inlet way and a low-combustion value gas fuel air outlet way are arranged on a low-combustion value gas fuel centrifugal compressor; the compression air and the low-combustion value gas fuel enters a combustion chamber through the compression air outlet way and the low-combustion value gas fuel air outlet way respectively to be combusted in a mixed manner; high-temperature and high-pressure gas generated by the combustion chamber drives a high-pressure turbine to rotate, and the high-pressure turbine drives the air centrifugal compressor to compress air through a high-pressure portion rotating shaft and drives an electric generator or a load to do work through a power output shaft; and the high-temperature high-pressure gas flowing out of a high-pressure turbine drives a contra rotating turbine to rotate, and the contra rotating turbine drives the low-combustion value gas fuel centrifugal compressor to compress the low-combustion value gas fuel through a low-pressure portion rotating shaft. The compact gas turbine device has the advantages of being high in pneumatic efficiency, small in size, compact and small in consumable and saving cost, and has the extreme wide market prospect.

Owner:XI AN JIAOTONG UNIV

Pressure-converging internal circulation multi-fuel engine

InactiveCN102003275AWide range of fuelSimple structureInternal combustion piston enginesFuel supply apparatusSolid fuelInlet valve

The invention relates to a pressure-converging internal circulation multi-fuel engine which has small volume and wide fuel range, and especially can use rural methane and solid fuel. A pressure-converging evaporating chamber has small internal storage space and large heating surface, and realizes quick ignition without idle start-up; a top steam outlet pipe of the pressure-converging evaporating chamber is communicated with a center hole of a movable valve sleeve; a left hole and a right hole at the opposite sides of the center hole are communicated with the left side and the right side of a cylinder sleeve through steam pipes; when two small pistons of a movable valve are in a left position or a right position, the center hole can be communicated with one of the left hole and the right hole; an oblong opening is arranged in the middle of the cylinder sleeve; the two pistons are put into the cylinder sleeve and connected by connecting rods; a rocker arm is installed on a fulcrum; the lower end of the rocker arm is between two blocking pieces of the piston connecting rods; the upper end of a pendulum rod is connected with the upper end of the rocker arm; a hollow damping part is installed on the right connecting rod of the two small pistons of the movable valve; a frame is arranged at the right end of the connecting rod; two springs are installed in the frame; the lower part of the pendulum rod is between the two springs; a one-way outlet valve is installed on a guide pipe of a plunger sleeve and communicated with the pressure-converging evaporating chamber; another guide pipe is inserted into an inner pipe orifice of circulating liquid and provided with a one-way inlet valve; and a plunger tappet is connected with the lower end of the pendulum rod.

Owner:范明合

A kind of processing method of dried lily

ActiveCN103719776BSimple processing methodEasy to operateFood thermal treatmentFood processingPolymer scienceHearth

The invention discloses a processing method of dried lily bulb and a drying device thereof. The processing method disclosed by the invention comprises the following steps: (1) selecting materials and cleaning the materials; (2) carrying out delaminating and color-protecting treatment on the obtained objects; (3) carrying out enzyme deactivation treatment on the obtained objects by hot ironing; (4) rinsing the obtained objects by using cold water; (5) drying the obtained products by using hot air. The drying device disclosed by the invention comprises a heating device and vertical drying chambers, wherein the vertical drying chambers are arranged on both sides of the heating device, the heating device, from top to bottom, is sequentially provided with an air chamber with an air inlet, a heating hearth with a fuel inlet, an air distributor and a smoke tube, a hot air circulating fan fixedly connected to a rack is arranged above the heating device, a moisture removal hole and at least four layers of shelves for placing trays are arranged in each vertical drying chamber, and a heater is arranged in the heating hearth. The processing method disclosed by the invention is simple and easy to operate, and good in drying effect, and the rate of finished products is 99.9%; the drying device disclosed by the invention is flexible and movable; the heating hearth is separated from the vertical drying chambers, and air feeding is performed in an isolated mode, so that clean air is fed into the drying chambers, therefore, fire hazards can be avoided; the fuel is wide.

Owner:LONGSHAN SHUNTIAN BIOTECH DEV

Solid oxide fuel battery system and preparation method thereof

ActiveCN101752585BWide range of fuelFinal product manufactureSolid electrolyte fuel cellsElectrical conductorOxygen ions

The invention relates to a solid oxide fuel battery system and a preparation method thereof. The electrolyte of the battery system adopts an oxygen ion conductor oxide; the anode is a metal-ceramic composite anode, wherein the ceramic material is a proton conductor oxide or a mixture of the proton conductor oxide and the oxygen ion conductor oxide; and the cathode material is at least one of noble metal and perovskite type oxides or a mixture of the electrolyte and at least one of the noble metal and perovskite type oxides. A battery with the structure has a wide operating temperature range which is between 300 and 1,000 DEG C, high power density and open circuit voltage and very good operational stability. The system and the method make a great contribution to the development of fuel batteries, particularly intermediate and low-temperature solid oxide fuel batteries.

Owner:福赛尔科技集团有限公司

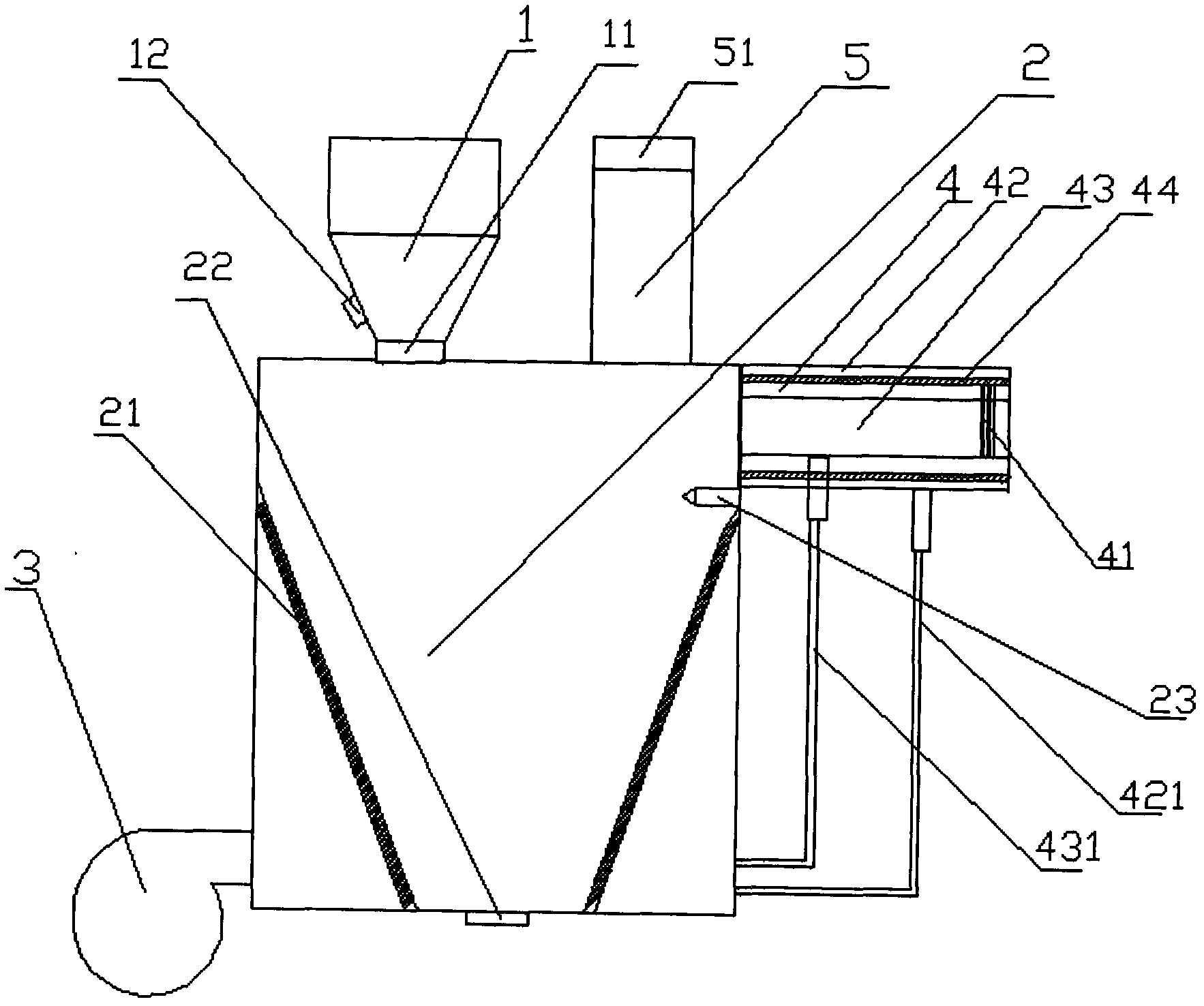

Gasifier stirring and pushing adjustment and composite gas-taking method and device

InactiveCN102062419ANo leakageNo harmful effectsDomestic stoves or rangesLighting and heating apparatusThermodynamicsCombustible gas

The invention relates to a gasifier stirring and pushing adjustment and composite gas-taking method and a gasifier stirring and pushing adjustment and composite gas-taking device, and aims to solve the problems that gas is generated unstably and is easy to burn partially and burn in a mixed way, the burning state is difficult to adjust, the mixture of tar, water and dust cannot be treated in a centralized way, materials have low adaptability and low continuity, the gas and the tar at the outlet cannot be completely burnt, pots, kettles and the environment can be polluted, and the like in the conventional gasifier. Combustible gas is obtained in two ways. A composite stirring and pushing gasifier consists of a fuel generating and adjusting device, a water tank, tar, dust and water purifying and centralizing device and a gas combustion and conversion device. By the method and the device, the problem of partial burn is solved, the continuous workability of the gasifier is guaranteed, full oxidation and material discharge are facilitated, gas temperature is reduced and afterheat is fully utilized. A fuel conveniently and reliably flows; combustion is stable; harmful gases such as the tar and the like are not discharged; and a furnace end is not blocked.

Owner:徐克

Biomass combustion special furnace

The invention relates to a novel biomass combustion special furnace arch taking biomass materials as raw materials and belonging to the technical field of combustion furnaces. The novel biomass combustion special furnace arch has a structure that a furnace body is internally provided with a front arch, a middle arch and a rear arch, wherein a feed zone is formed between the front arch and a hopper, a volatilization oxidation reduction zone is formed between the front arch and the middle arch, and a main combustion zone is formed between the middle arch and the rear arch; the shape of the reararch is a fold line structure, and the shape of the front section of the rear arch is a level straight line structure; the middle arch is positioned between the front arch and the rear arch and in a single row wall body structure, the upper end of the middle arch is connected with a water containing boiler, the middle of the lower end of the middle arch is provided with a combustion passage, and the middle section of the inner side of the middle arch is provided with a bump which is positioned at the outer side above the rear arch. The invention relates to the novel biomass combustion specialfurnace arch which is beneficial to the sufficient combustion of biomass fuel, has long flame flow path, high heat efficiency, energy saving, smoke elimination, good environmental protection property, high temperature raising speed of water inside a the water containing boiler, and the like.

Owner:许元凯

Biomass fuel cracker

InactiveCN102533307APrevent backfirePrevent smoke leakageLiquid hydrocarbon mixture productionBio-feedstockThermal energyTar

The invention discloses a biomass fuel cracker. The biomass fuel cracker comprises a feeding device, an air blower, a cracking chamber and a fire cylinder, wherein the feeding device is arranged at the upper end of the cracking chamber and communicated with the cracking chamber; the air blower is respectively connected with the cracking chamber and the fire cylinder; an air locking feeding device is arranged on the lower side of the feeding device and driven by a motor mounted on the feeding device; an emergency discharging device is additionally arranged at the upper end of the cracking chamber and communicated with the cracking chamber; a tangential swirl flow guide device is additionally arranged on the mouth part of the fire cylinder; and the fire cylinder is also connected with a primary air tube and a secondary air tube which are communicated with the air blower. According to the invention, tempering and smoke spillage phenomenons of the feeding device can be prevented, the cracking efficiency is increased, the generation of tar is reduced, the thermal energy consumption is reduced, burnout ratio is increased, the use cost of the equipment is reduced, and the really high-temperature pyrolysis is made by using the cracker; and the biomass fuel cracker disclosed by the invention has the advantages of higher safety factor, wider fuel range, very strong practicability, convenience in operation and simple using procedure.

Owner:郭丰亮

A dehydrogenation catalyst regenerator and regeneration method

ActiveCN104525278BAvoid cokingAvoid vibrationCatalyst regeneration/reactivationFlue gasDehydrogenation

A dehydrogenation catalyst regenerator and catalyst catalytic regeneration method, the catalyst regenerator includes a regeneration section and a settling section, and the regeneration section is the lower section of the riser, the dense phase section of the enlarged diameter and the upper section of the riser in sequence from bottom to top , the upper section of the riser is connected with the settling section. In the dehydrogenation catalyst regenerator of the present invention, the preheated air, the catalyst to be generated and the fuel are combusted in the dilute-phase conveying bed at the lower section of the riser; subsequently, the high-temperature flue gas after combustion exchanges heat with the catalyst in a dense phase to ensure that the catalyst is fully burnt, Reduce the temperature difference between the flue gas and the catalyst and improve the utilization rate of energy; the flue gas and catalyst that leave the dense phase section enter the upper section of the riser, so that combustible gases such as CO can be fully burned during the dilute phase transportation process, releasing energy and reducing pollution emissions.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Boiler capable of burning inferior fuel

The boiler capable of burning inferior fuel has inside reflecting board, heating board and guide board, and is divided into pre-burning region, burning region, heat exchange region and slag discharging channel. The subsequent fuel is heated via absorbing the radiated heat from the burning region without covering the burning layer, so that it does not disturb the burning state of the burning region and does not lower the temperature of the burning region and the fuel in the burning region can burn stably in full hot state. Inflammable gas produced in preheating is ignited by the high temperature flame in the burning region, dust in fume is separated and exhausted in the heat exchange region and smoke collecting box. The boiler can burn coal with lower heat and other inferior fuel as well as their mixture while meeting the environment protecting standard.

Owner:韩枫

Gasifier stirring and pushing adjustment and composite gas-taking method and device

InactiveCN102062419BSolve the problem of uncovering and compacting materialsNo leakageDomestic stoves or rangesLighting and heating apparatusThermodynamicsCombustible gas

The invention relates to a gasifier stirring and pushing adjustment and composite gas-taking method and a gasifier stirring and pushing adjustment and composite gas-taking device, and aims to solve the problems that gas is generated unstably and is easy to burn partially and burn in a mixed way, the burning state is difficult to adjust, the mixture of tar, water and dust cannot be treated in a centralized way, materials have low adaptability and low continuity, the gas and the tar at the outlet cannot be completely burnt, pots, kettles and the environment can be polluted, and the like in the conventional gasifier. Combustible gas is obtained in two ways. A composite stirring and pushing gasifier consists of a fuel generating and adjusting device, a water tank, tar, dust and water purifying and centralizing device and a gas combustion and conversion device. By the method and the device, the problem of partial burn is solved, the continuous workability of the gasifier is guaranteed, full oxidation and material discharge are facilitated, gas temperature is reduced and afterheat is fully utilized. A fuel conveniently and reliably flows; combustion is stable; harmful gases such as the tar and the like are not discharged; and a furnace end is not blocked.

Owner:徐克

Heating double-layer gasifier

InactiveCN105114942AEasy to cleanTake advantage ofChemical industryAir heatersRural areaFuel gasification

The invention belongs to a stove transforming plants, coal dust and other combustible into combustible gas to be combusted for indirect heating, and particularly relates to a heating double-layer gasifier used for cooking and heating in winter. An existing gasifier is generally limited to be used in a single home, combustible gas generated in a gasifier body is directly used for cooking and heating, the purity of the generated combustible gas is not high enough, and combustion is not powerful; and a smoking phenomenon still exists, and the health of family members is influenced. The heating double-layer gasifier comprises a gasifier body, a heat supply device, a combustion device and a gas supply device. The gasifier body is communicated with the heat supply device through heating medium space and communicated with the combustion device through a gas pipe. The gas supply device is communicated with the combustion device and the gasifier body through an air supply pipe. A burner of the combustion device is aligned to a combustion space flame inlet of the heat supply device. The heating double-layer gasifier is reasonable in design, compact in structure, convenient to use, long in fuel gasification time, high in heat efficiency, suitable for vast rural areas in short of fuel resources, wide in fuel range and low in cost.

Owner:新疆吾孜坦国际商贸有限公司

Dried lily bulb drying equipment

InactiveCN104757699AAvoid "retting" phenomenonAvoid damageFood thermal treatmentFood processingPolymer scienceHearth

The invention discloses a processing method of dried lily bulb and a drying device thereof. The processing method disclosed by the invention comprises the following steps: (1) selecting materials and cleaning the materials; (2) carrying out delaminating and color-protecting treatment on the obtained objects; (3) carrying out enzyme deactivation treatment on the obtained objects by hot ironing; (4) rinsing the obtained objects by using cold water; (5) drying the obtained products by using hot air. The drying device disclosed by the invention comprises a heating device and vertical drying chambers, wherein the vertical drying chambers are arranged on both sides of the heating device, the heating device, from top to bottom, is sequentially provided with an air chamber with an air inlet, a heating hearth with a fuel inlet, an air distributor and a smoke tube, a hot air circulating fan fixedly connected to a rack is arranged above the heating device, a moisture removal hole and at least four layers of shelves for placing trays are arranged in each vertical drying chamber, and a heater is arranged in the heating hearth. The processing method disclosed by the invention is simple and easy to operate, and good in drying effect, and the rate of finished products is 99.9%; the drying device disclosed by the invention is flexible and movable; the heating hearth is separated from the vertical drying chambers, and air feeding is performed in an isolated mode, so that clean air is fed into the drying chambers, therefore, fire hazards can be avoided; the fuel is wide.

Owner:LONGSHAN SHUNTIAN BIOTECH DEV

Biomass straw gas furnace

InactiveCN102135278BHigh thermal efficiencySimple and fast operationLighting and heating apparatusStove/ranges for heating waterAutomatic controlHearth

The invention relates to a biomass straw gas furnace and belongs to the technical field of environmentally-friendly and energy-saving multifunctional gas furnaces. The biomass straw gas furnace mainly comprises a furnace body. The upper part of the furnace body is provided with a discharge flue and a charging door. The lower part of the furnace body is provide with two ash removal hoppers. A cylindrical furnace pipe is arranged in the furnace body. A grate is arranged in the cylindrical furnace pipe. The cylindrical furnace pipe is communicated with the charging door. The furnace body consists of a combustion system, an oxygen supply system, a heating system, a heat conduction system and a control system. The upper part of the furnace body is provided with a mirror surface white steel plate table board. The front of the furnace body is provided with a mould pressing door and a fixing door. The mirror surface white steel plate table board is provided with a big pot range and a small pot range. The fixing door is provided with a manual fan switch, a temperature controller, a hot wind oxygen supply system, and a quick heating system. An automatic control system improves the heat efficiency. Rural cauldrons and various cookers are actually used for cooking. Heat is supplied by devices such as a heated kang, a heating unit, a geothermal system and the like at large power. The biomass straw gas furnace is convenient and easy to operate. The source of the fuels is wide. Biomass straw particle blocks are used as main fuels, and moulded coal, fungus waste, and xylon all can be used as fuels. The biomass straw gas furnace has high calorific value, large water capacity and short heating time, which has the functions of fire stopping and keeping, and energy saving. The biomass straw gas furnace is clean and environmentally-friendly, which discharges no combustible gas, and leaks no tar. Meanwhile, smoke, odor and dust are avoided during operation.

Owner:BAISAN ZHENYUAN BIOMASS ENERGY TECH

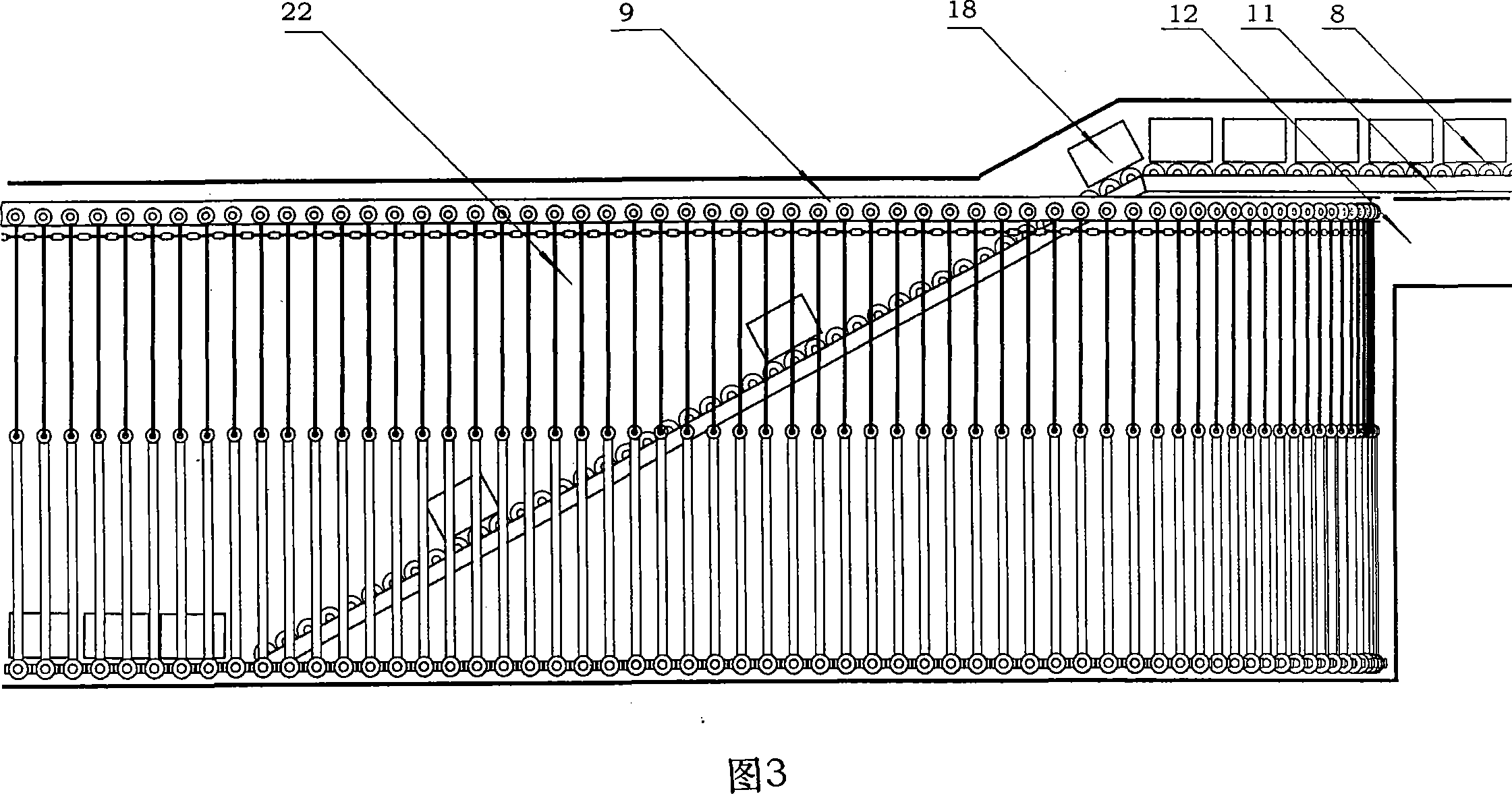

Cavity brick sintered production line

InactiveCN101158553AIncrease profitReduce energy consumptionCharge manipulationFurnace typesBrickWorking environment

The invention relates to a production line of sintering an air brick, comprises a welding furnace, a flue and a conveyor connected at the two ends of the welding furnace to be used for feeding and discharging, and is characterized in that the conveyor is a symmetrically arranged one-way driving delivering mechanism with a plurality of layers and can bear different temperature. The invention has the advantages of a high thermal utilizing rate, low energy cost, small labor intensity, sound working environment, small floor space, good sintering effect, low production cost, being applicable to sintering air bricks made of a variety of raw materials, and wide range of fuel, with burning not only anthracite, but also bituminous coal, gangue as well as straw.

Owner:张文彦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com