Gasifier stirring and pushing adjustment and composite gas-taking method and device

An adjustment device and a composite technology are applied in the field of biomass waste recycling and treatment devices, which can solve the problems of difficult adjustment of combustion state, unstable gas production of a fixed-bed gasifier, and low material adaptability, etc. Conducive to relatively fixed and uniform, convenient and reliable fuel flow, low sensitivity to dry and humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

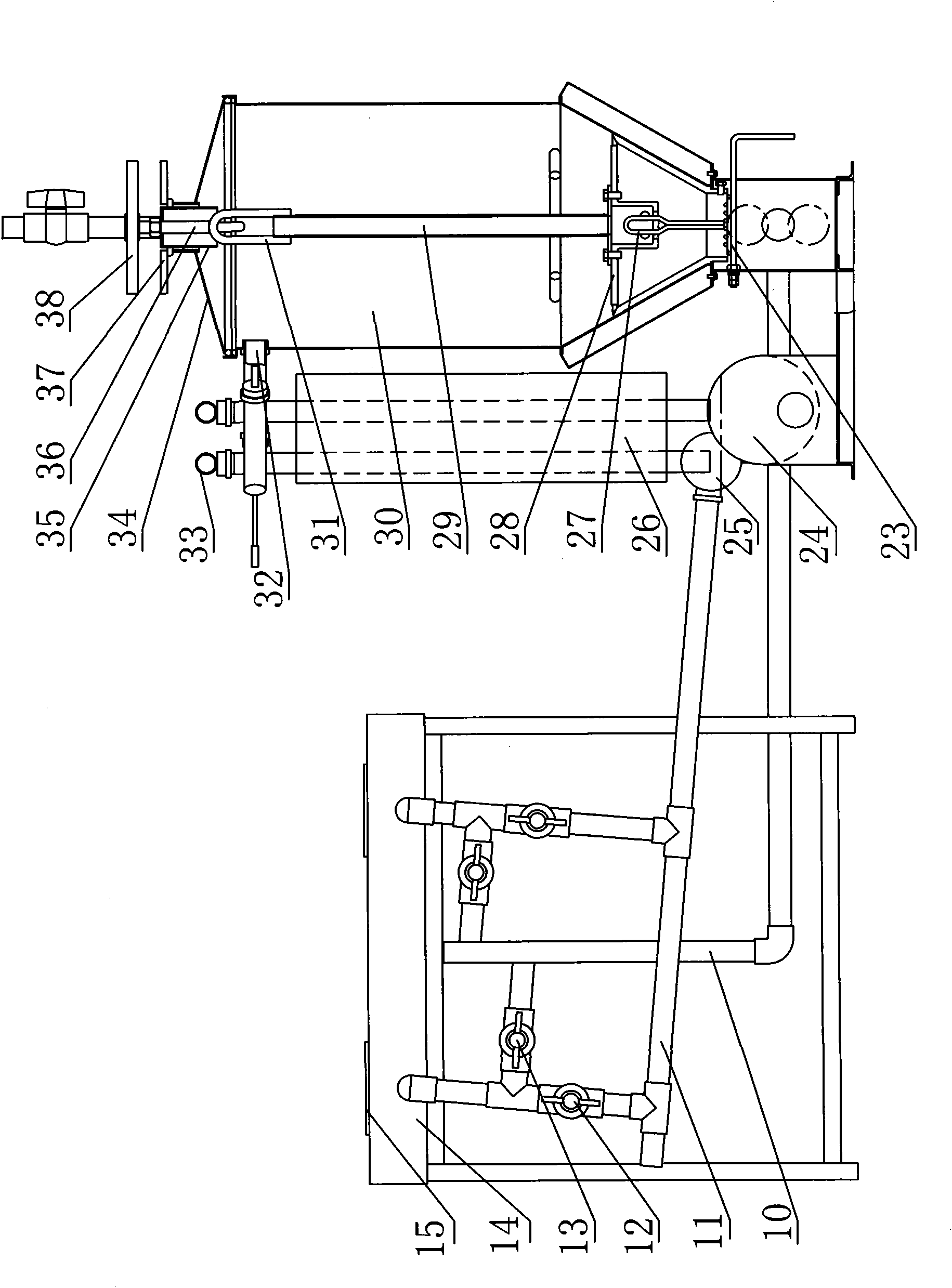

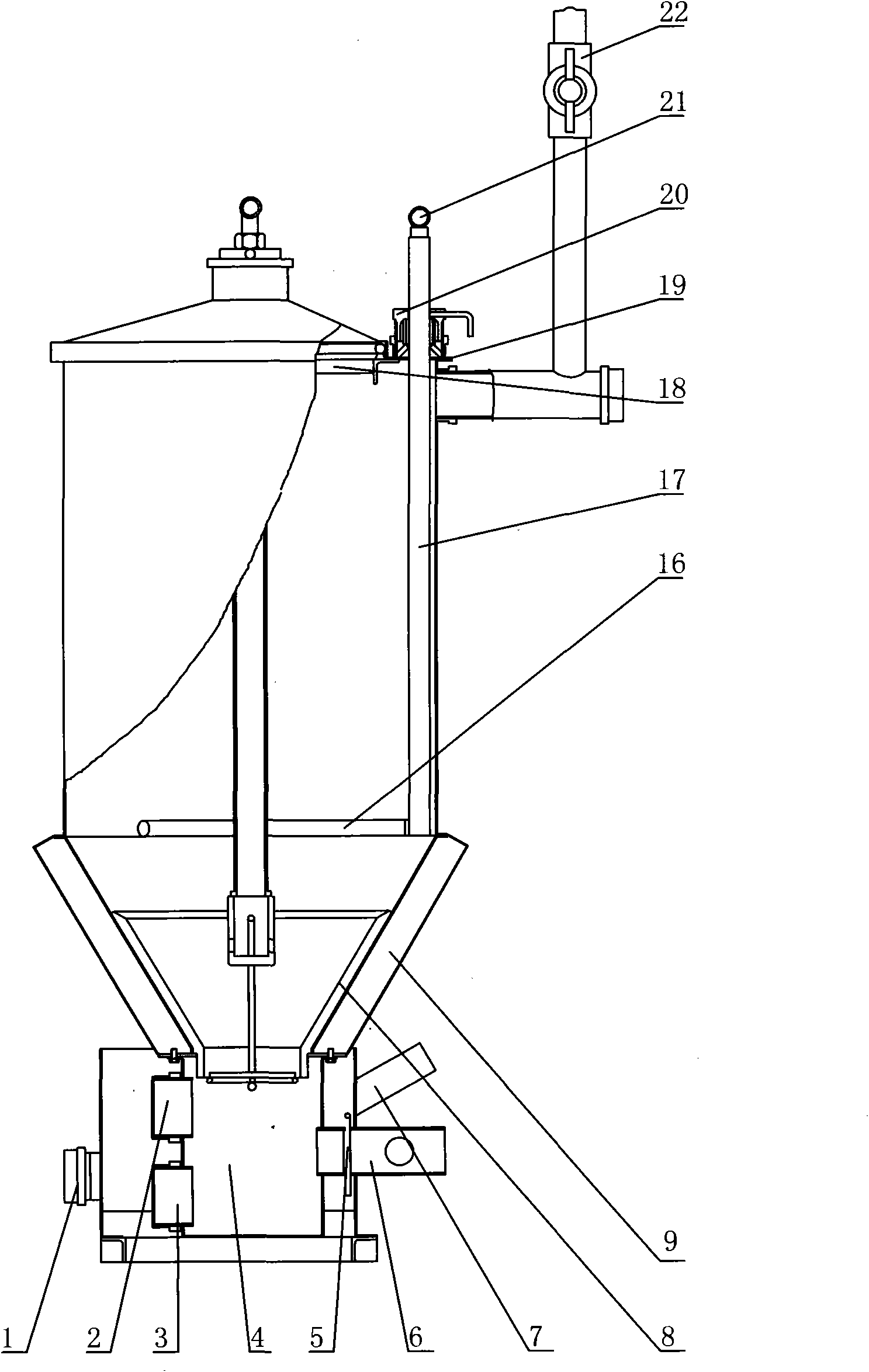

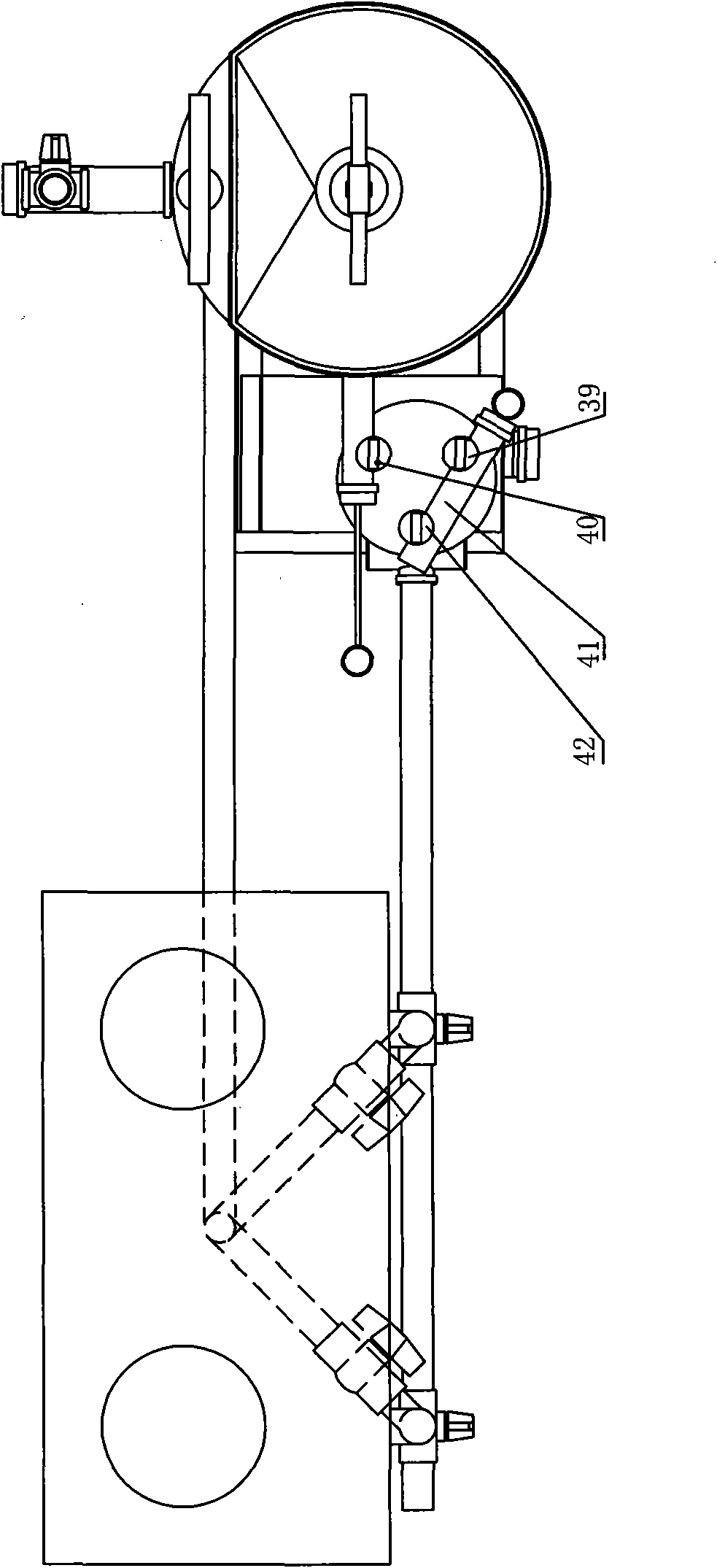

[0056] The composite stirring gasifier is composed of three parts: gas generation and adjustment device, water tank, coke, dust and water purification concentration device and gas combustion conversion device.

[0057] 1. Gas generation and adjustment device:

[0058] It is mainly divided into three parts: the lower part is the air inlet and ash storage pipe 4, the middle part is the furnace body 30, and the upper part is the furnace cover 34. The center of the furnace body 30 is connected with a high-temperature gas guide-rotary lifting and stirring device through the support arm 18.

[0059] See figure 2 , the air inlet and ash storage pipe 4 are vertical pipes, and the ignition door 2 is fixed in the vertical direction of the pipe wall, the ash door 3, and the air inlet pipe 6. The ignition door 2 and the ash outlet door 3 are provided with movable covers, and the air inlet valve 5 is arranged in the air inlet pipe 6; the bottom of the air inlet and ash storage pipe 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com