Biomass straw gas furnace

A technology of biomass straw and gas stoves, which is applied in household stoves/stoves, climate sustainability, solid heating fuels, etc. It can solve the problems of insufficient combustion of materials, inability to burn again, and stoves can only be used for cooking, etc., to achieve fuel efficiency. Broad, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

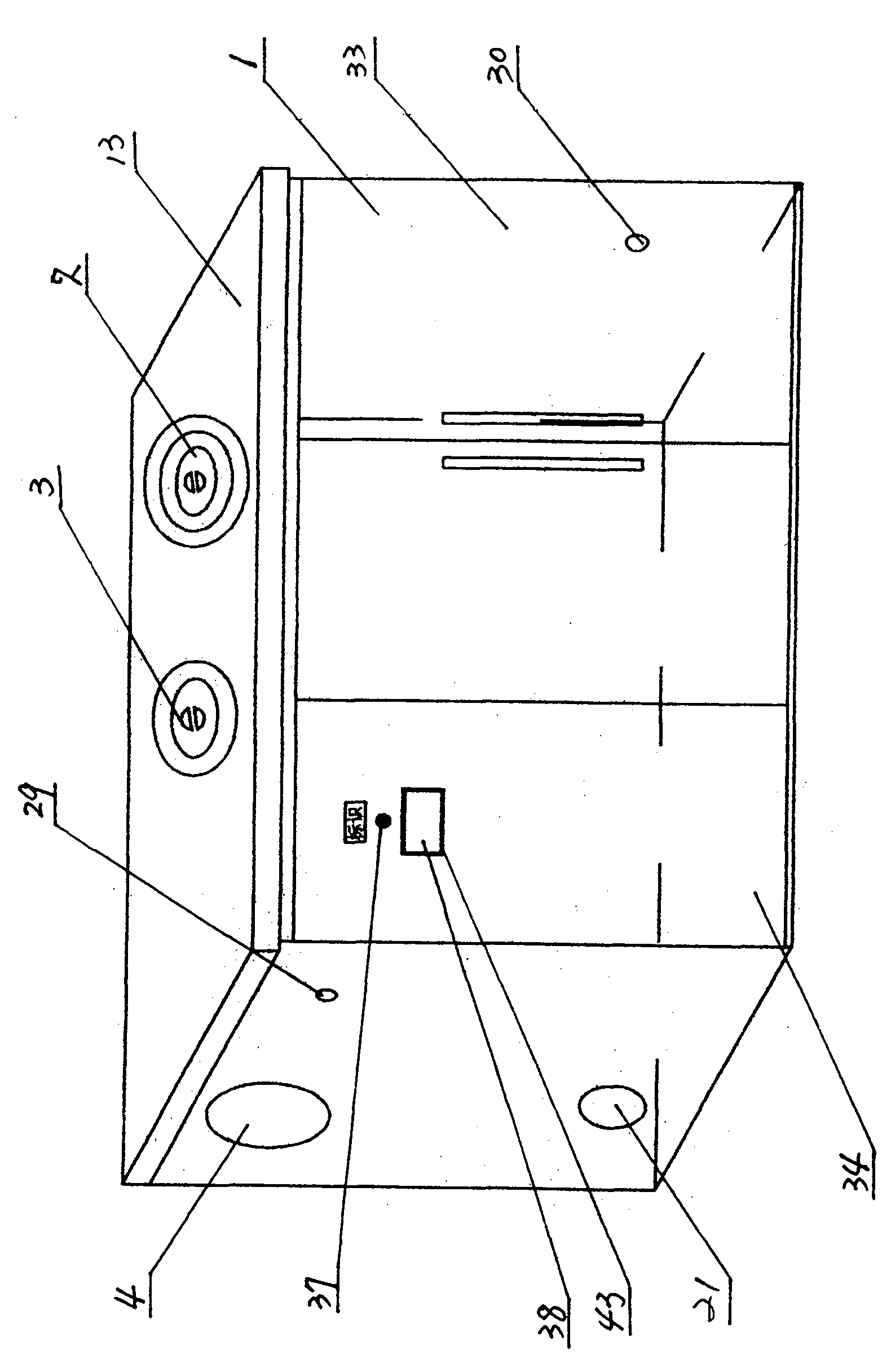

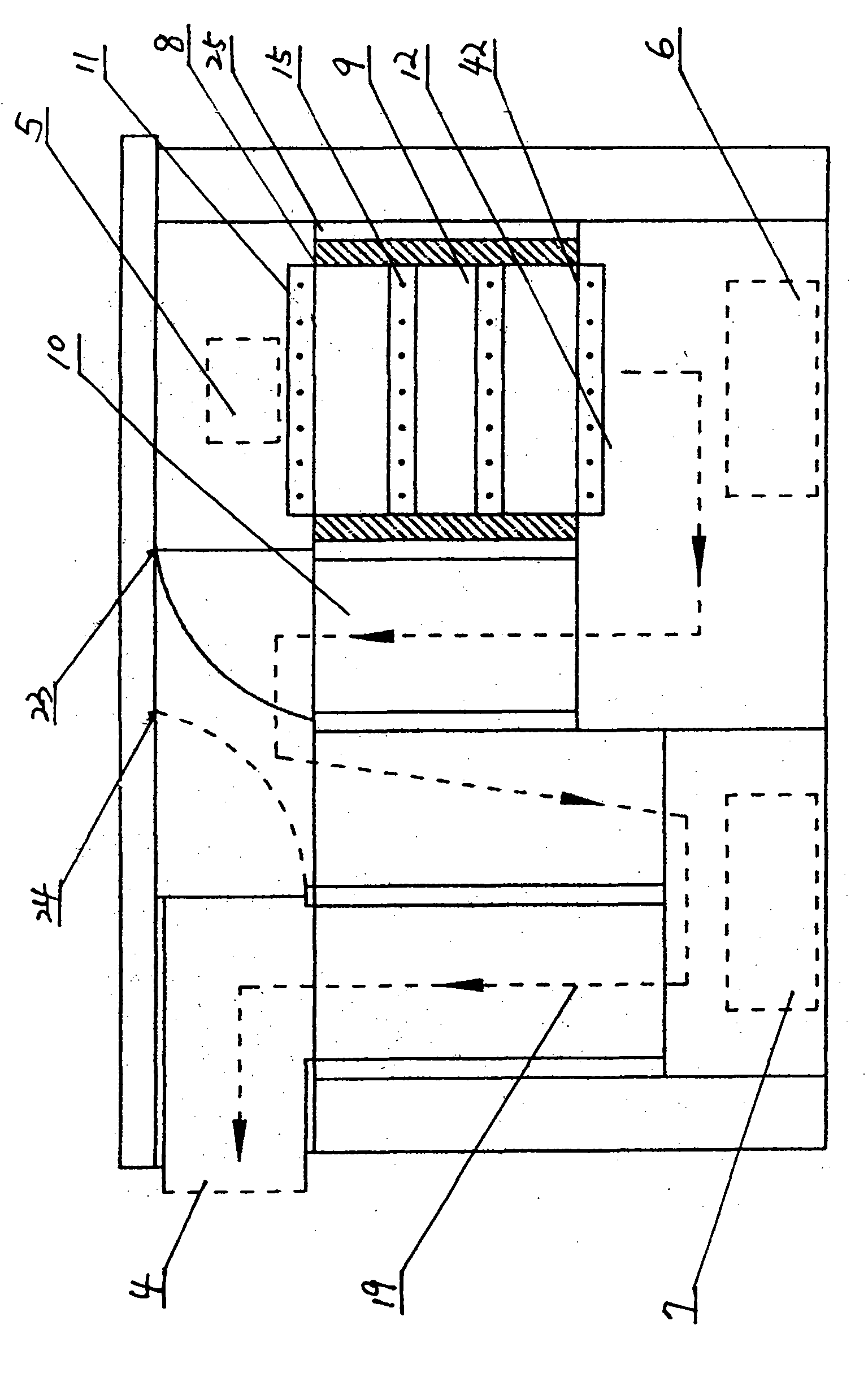

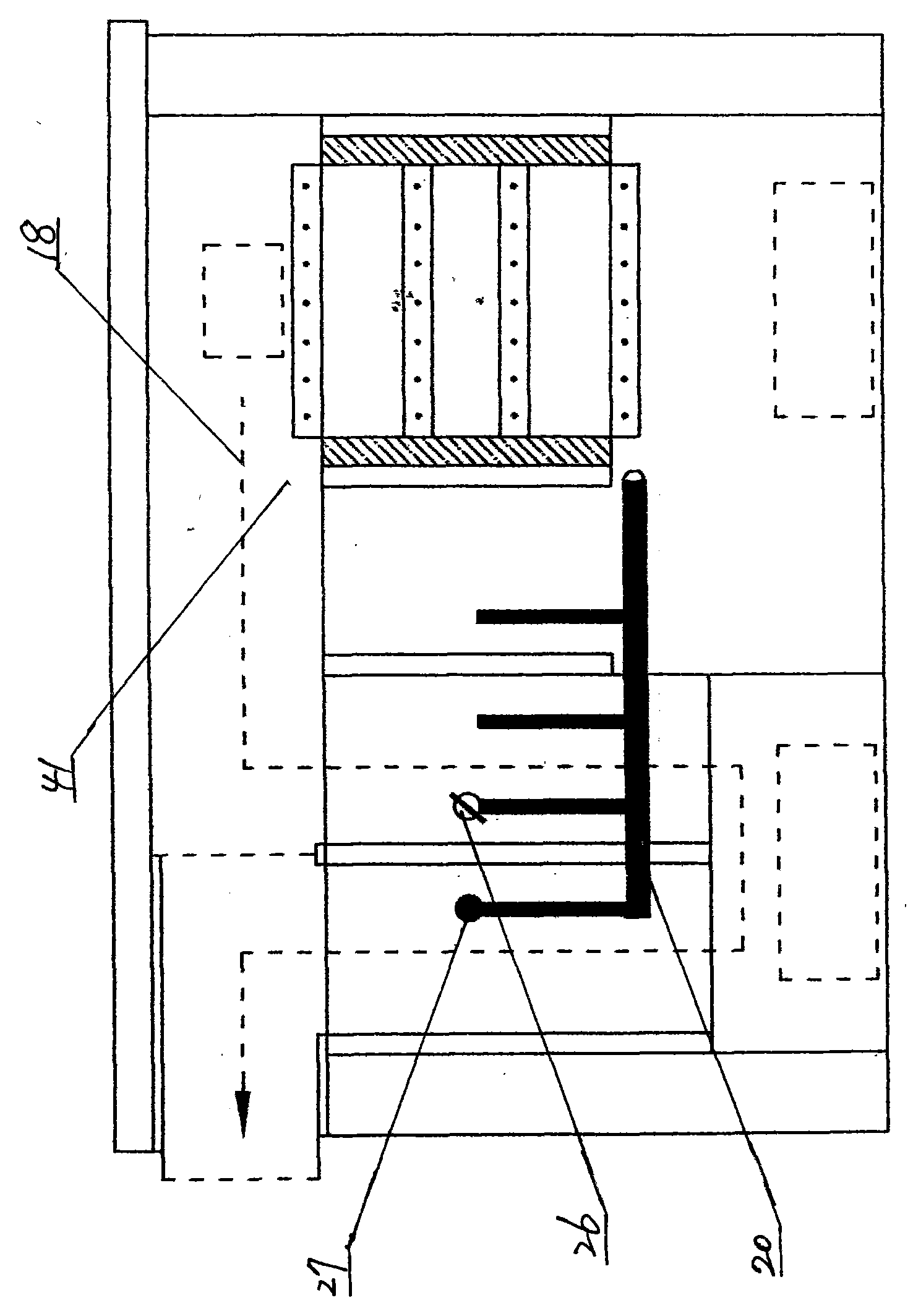

[0016] A biomass straw gas furnace, comprising a furnace body 1, the upper part of the furnace body 1 is provided with a flue gas exhaust 4, a charging door 5, the lower part of the furnace body 1 is provided with an ash removal hopper 6 and an ash removal hopper 7, and the furnace body 1 is provided with Furnace 8, cylindrical furnace 8 is composed of hot air duct 14 and refractory soil, furnace 8 is provided with grate 42, furnace 8 is communicated with charging door 5, and hot air duct 14 is evenly distributed from top to bottom. The vent 15, the main combustion chamber 9 and the upper gas chamber 11 and the lower gas chamber 12 pass through the furnace 8, the main combustion chamber 9 is provided with a choke door 25, the hot air duct 14 is connected with the oxygen supply regulation fan 16 and the natural air duct 17, and the upper The gas chamber 11 is communicated with the turn-back flue 18, the lower gas chamber 12 is communicated with the turn-back flue 19, the upper g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com