Composite heat carrier generator for high viscosity oil

A technology of composite heat carrier and generating device, which is applied in the directions of isolation device, production fluid, wellbore/well components, etc., can solve the problems of easy scaling of the cooling channel of the combustion chamber, weakening the heat transfer effect, blocking the water injection hole, etc. The effect of reducing the phenomenon of scaling and deposition, improving the combustion efficiency, and being less prone to clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

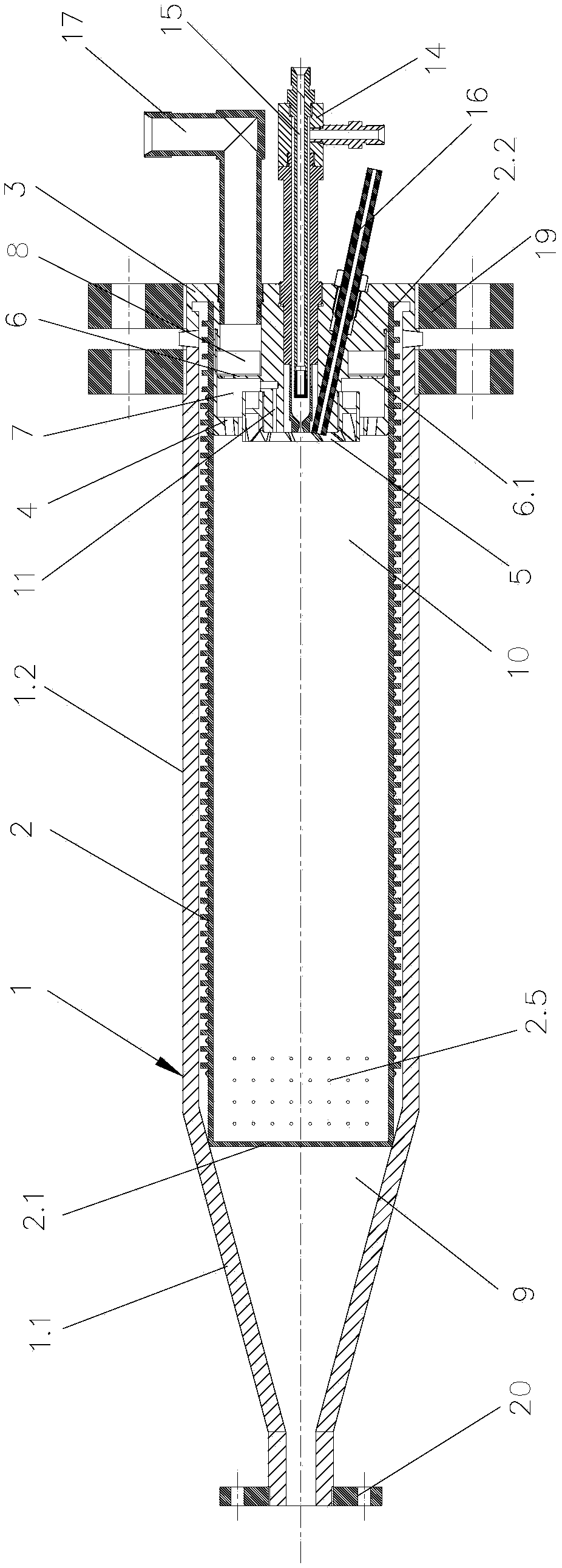

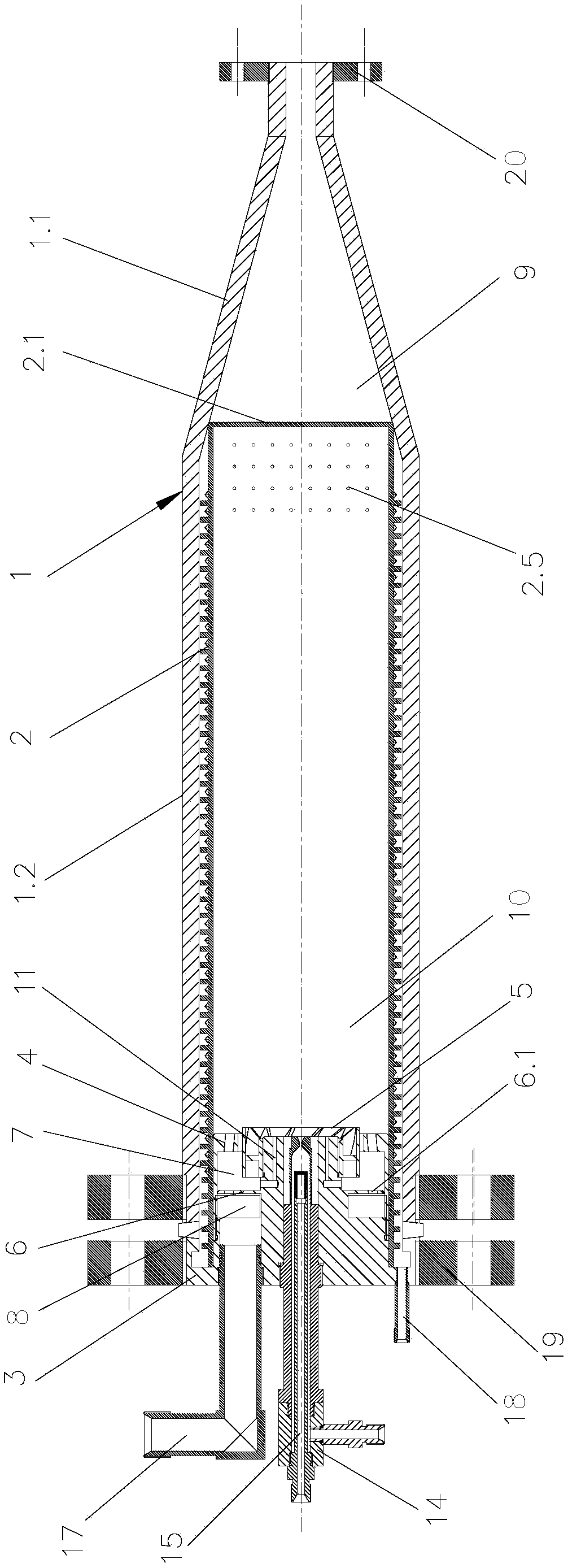

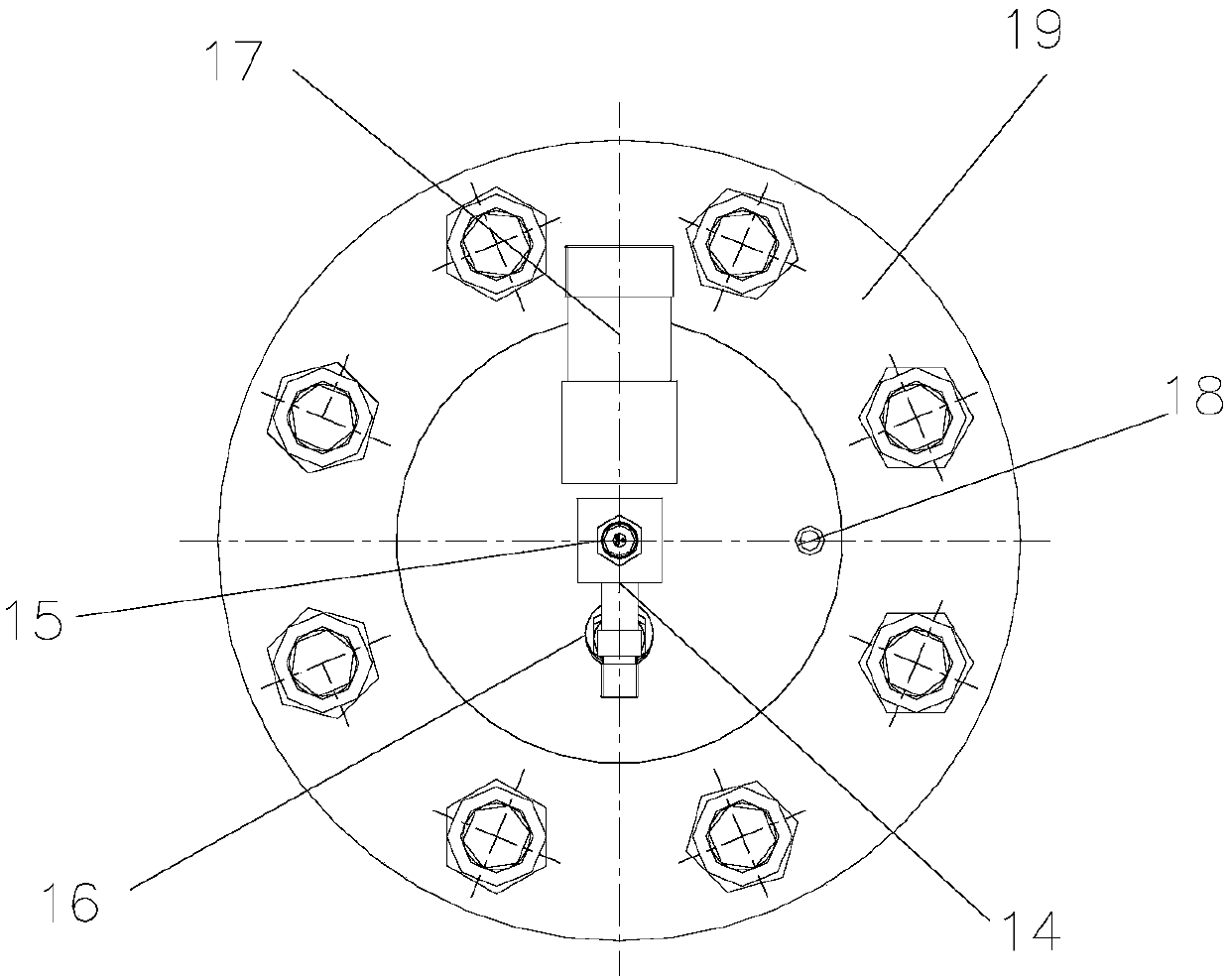

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0031] A composite heat carrier generating device suitable for high-viscosity oil shown in the figure includes a shell 1, which is integrally formed by a conical section 1.1 and a cylindrical section 1.2, and the inner wall of the shell 1 is covered with a high-temperature heat reflection layer , The outer wall of the housing 1 is covered with a high temperature heat insulation layer. The inner cavity of the housing 1 is pierced with a cooling jacket 2. The cooling jacket 2 has a closed end 2.1 and an open end 2.2. The outer wall of the cooling jacket 2 is provided with a spiral groove 2.3 extending along its axial direction. The spiral groove 2.3 The outer wall is provided with several vortex generators 2.4 staggered along its circumference, and the outer wall of the cooling jacket 2 near the closed end 2.1 is provided with several water inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com