Processing method of dried lily bulb and drying device thereof

A processing method and technology of drying equipment, which are applied in food processing, food preparation, food drying, etc., can solve the problems that agricultural product processing enterprises cannot bear, the heating method is limited, and cannot be popularized and used, so as to avoid fire hazards and process The method is simple and easy to operate, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

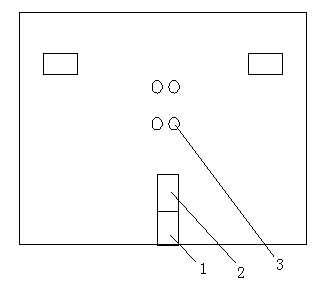

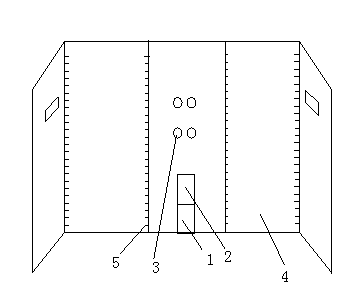

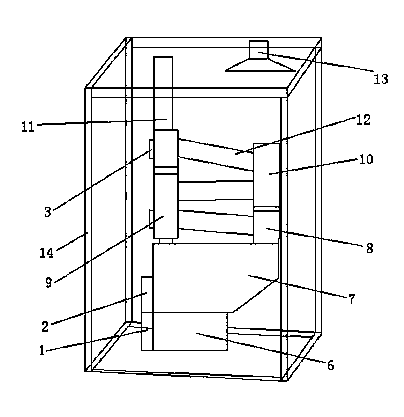

[0028] Embodiment 1: Device embodiment

[0029] Referring to the accompanying drawings, the embodiment of the dry lily processing and drying equipment of the present invention includes a heating device and vertical drying compartments 4 arranged on both sides of the heating device, and the heating device is successively provided with an air chamber 6 with an air inlet 1, Bring into the heating furnace 7 of the fuel port 2, the air flow distributor and the smoke pipe 11, the top of the heating device is provided with a hot air circulation fan 13 fixed on the frame 14, and the vertical drying compartment 4 is provided with a moisture discharge hole and Shelves 5 with four layers of pallets at equal intervals, high-efficiency and energy-saving biomass stove heaters are arranged in the heating furnace 7, and dry-humidity meters and thermometers are arranged on the inner arms of the upper and middle parts of the vertical drying chamber 4 to detect the temperature of the chamber. In...

Embodiment 2

[0034] Embodiment 2: method embodiment ①

[0035] The processing method of dried lily of the present invention comprises the following steps:

[0036] (1) Preliminary washing of material selection: select qualified fresh lilies, and use clean water to preliminarily wash away the sediment and impurities on the surface of fresh lily bulbs;

[0037] (2) Peeling, cleaning and color protection treatment: ①Peel the lily individual into scales; ②Clean the peeled lily scales; ③Put the lily scales into the color protection solution in time to protect the color, so as to prevent the scales from turning brown when exposed to sunlight ;

[0038] (3) Scalding to kill enzyme treatment: After the water in the tiltable stainless steel open pot is boiled, put the scales with the color protection in step (2) into the boiling water and mix well. The weight ratio of scales to water is 1:3.5; The blanching time is 5s; the operation of blanching to kill enzymes should be well mastered, if the bla...

Embodiment 3

[0041] Embodiment 3: method embodiment ②

[0042] The processing method of dried lily of the present invention comprises the following steps:

[0043] (1) Preliminary washing of material selection: select qualified fresh lilies, and use clean water to preliminarily wash away the sediment and impurities on the surface of fresh lily bulbs;

[0044] (2) Peeling, cleaning and color protection treatment: ①Peel the lily individual into scales; ②Clean the peeled lily scales; ③Put the lily scales into the color protection solution in time to protect the color, so as to prevent the scales from turning brown when exposed to sunlight ;

[0045] (3) Scalding to kill enzyme treatment: After the water in the tiltable stainless steel open pot is boiled, put the scales with the color protection in step (2) into the boiling water and mix well. The weight ratio of scales to water is 1: 4.5; The blanching time is 40s; the operation of blanching to kill enzymes must be mastered, if the blanchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com