Boiler capable of burning inferior fuel

A low-quality fuel and boiler technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as low calorific value, and achieve stable output, easy adjustment, and a wide range of fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

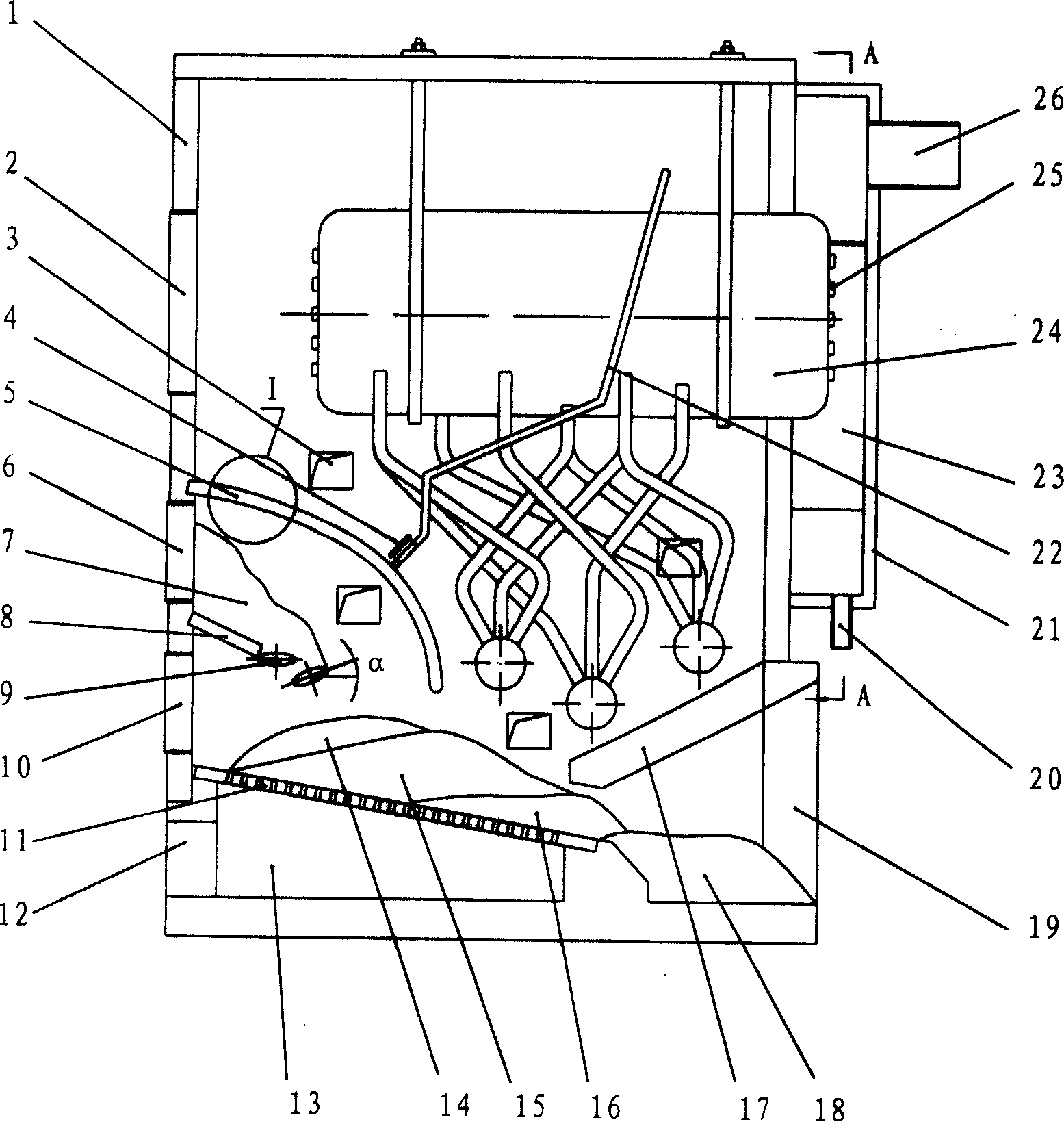

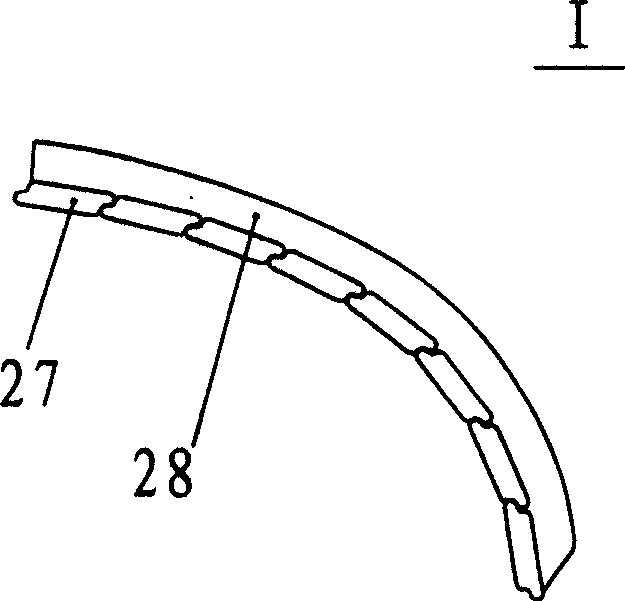

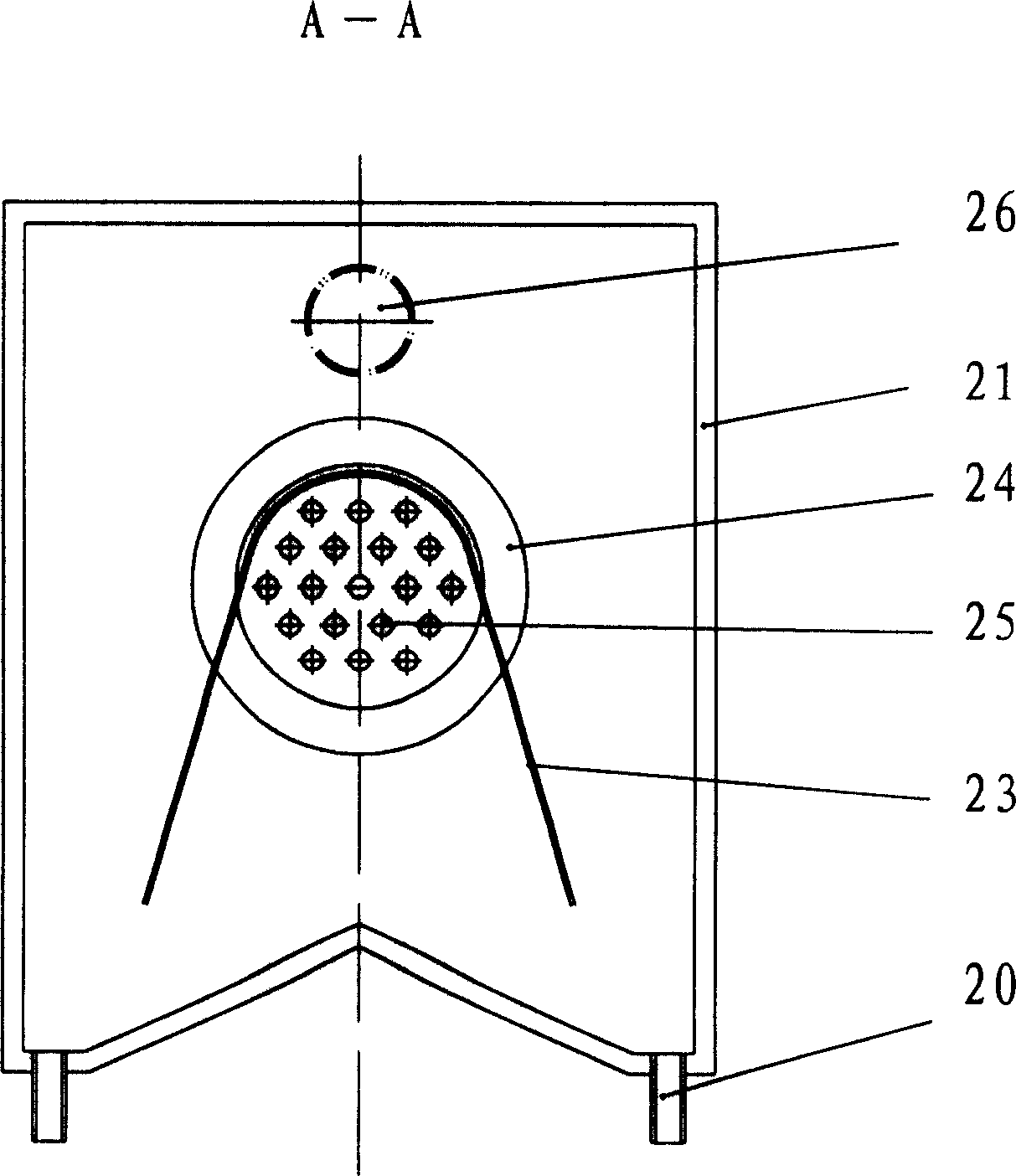

[0026] A boiler capable of burning low-quality fuel is composed of a furnace body 1, a grate 11, a combustion area, a heat exchange area, and a smoke collection box 21; the combustion area is divided into a pre-combustion area, a front accumulation combustion area, and a rear accumulation combustion area. area and suspended combustion heat exchange area; the pre-combustion area is composed of heating plate 8, rotating heating plate 9, reflector plate 5, furnace body 1 and material inlet 6; the stacking combustion area is composed of heating plate 8, rotating heating plate 9, Port 10, grate 11, slag outlet 19, and furnace arch 18. The front part of the vertical line along the lower edge of the reflector is the front accumulation combustion area, and the rear part of the vertical line is the rear accumulation combustion area; the heat exchange area is divided into dust removal and heat exchange areas. And the suspended combustion heat exchange area, the dust removal heat exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com