Cavity brick sintered production line

A technology of production line and hollow brick, applied in the field of hollow brick sintering production line, can solve the problems of low heat energy utilization rate, high production cost, high labor intensity, etc., and achieve the effect of high heat energy utilization rate, low cost and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

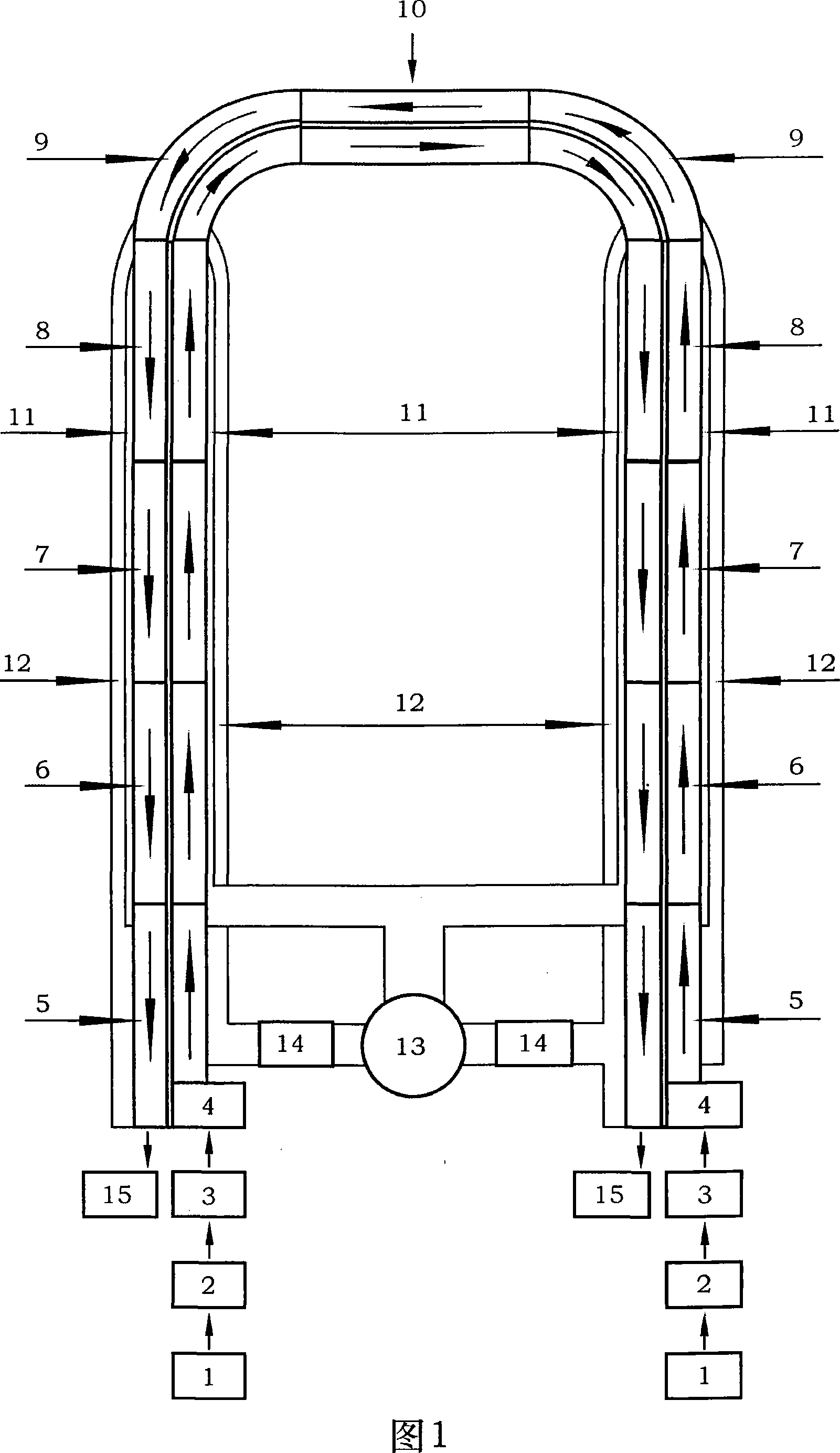

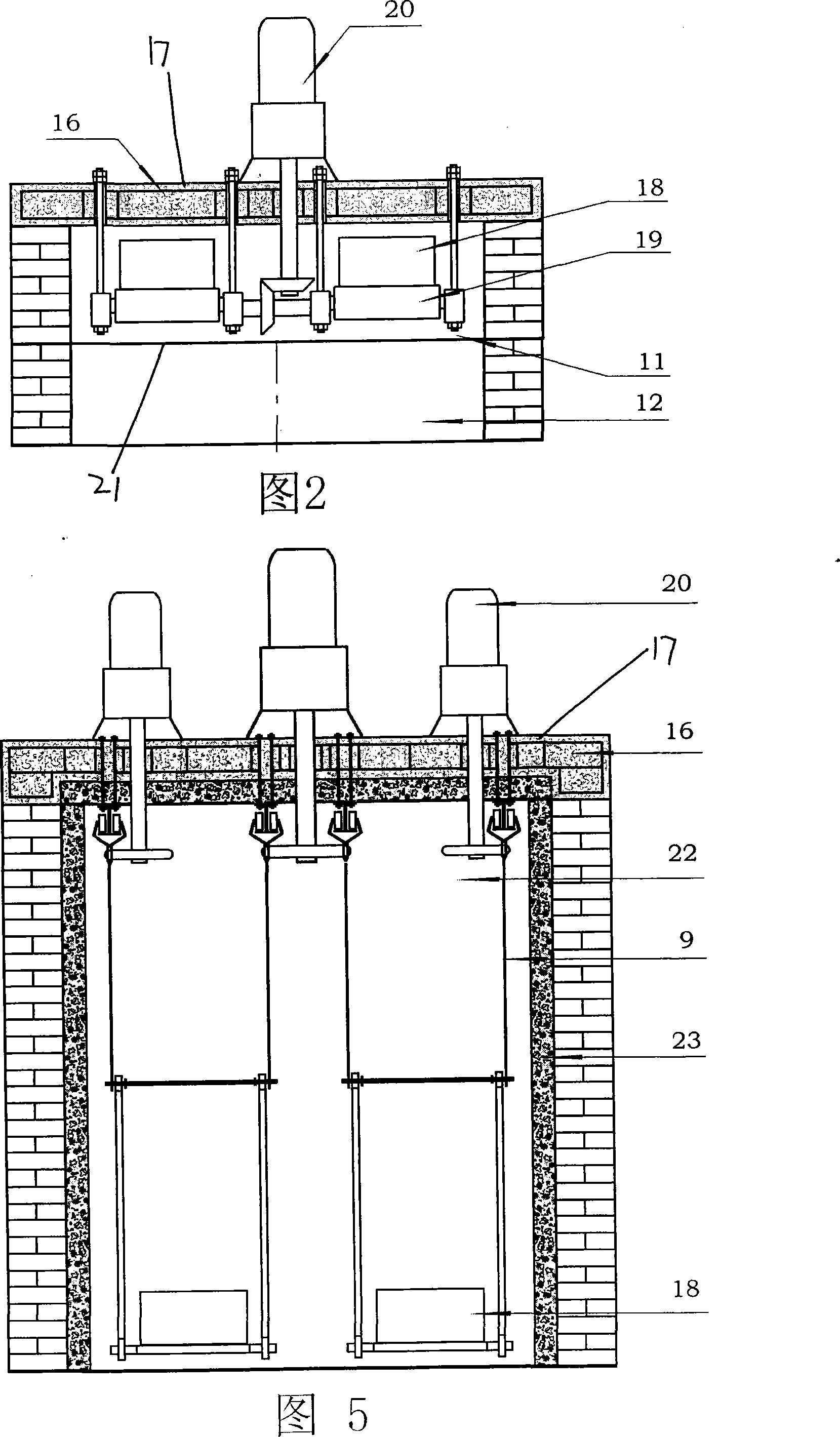

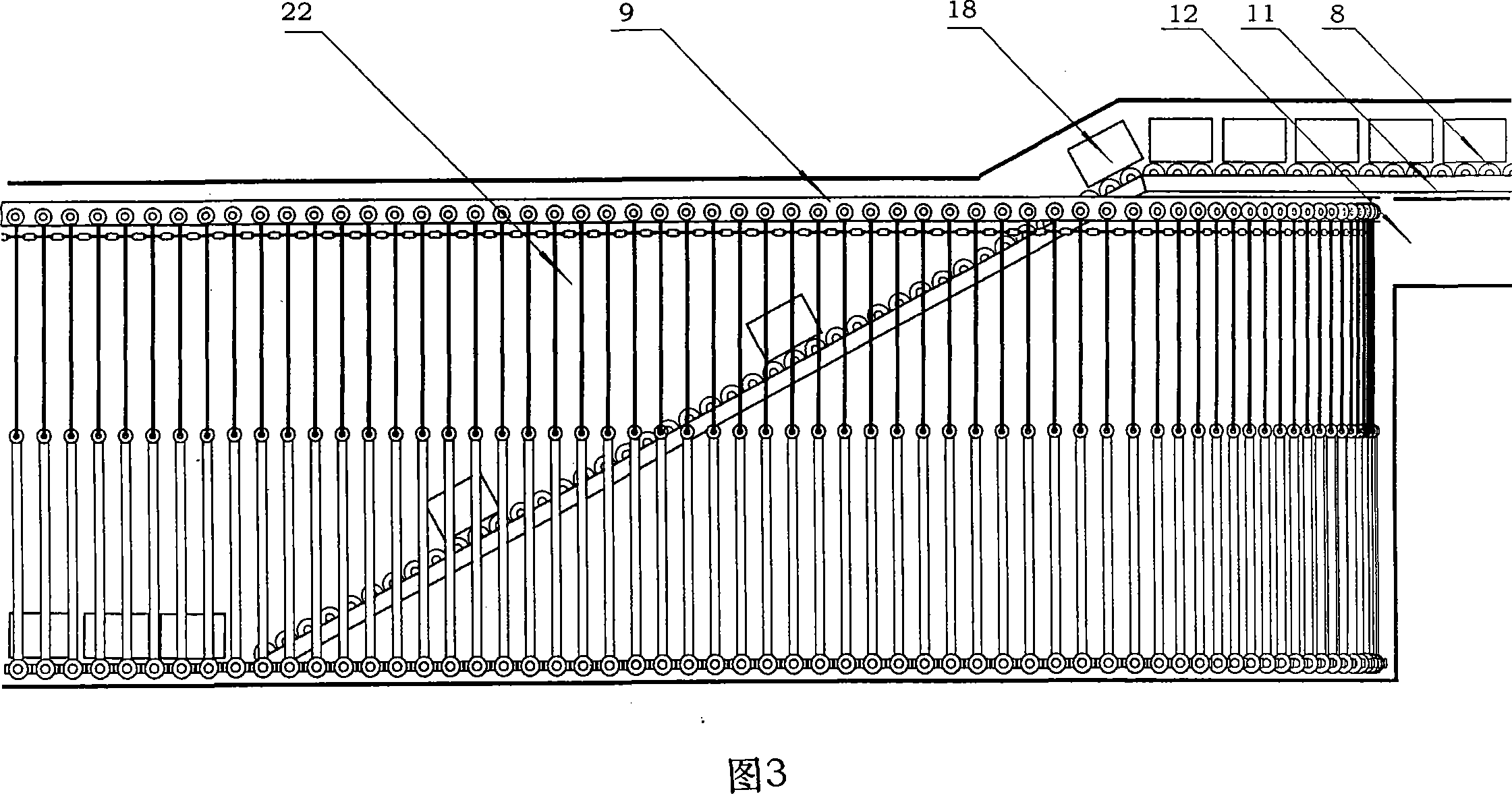

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

[0018] The brick firing production line of the present invention includes a sintering furnace, a flue, and a conveyor connected to both ends of the sintering furnace for feeding and discharging, and the conveyors are several-stage transmission mechanisms that withstand different temperatures in one-way transmission, and arranged symmetrically. The conveyor includes a five-level transmission mechanism, from high temperature to low temperature, it is a high-temperature-resistant suspension chain conveyor, a high-temperature-resistant roller conveyor, an ordinary roller conveyor, a high-temperature-resistant mesh belt conveyor, and an ordinary mesh belt conveyor. The high-temperature suspension chain conveyor runs through both ends of the sintering furnace, and the ordinary mesh belt conveyor is docked with the brick making machine or brick unloading equipment. The high temperature resistant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com