Solid oxide fuel battery system and preparation method thereof

A fuel cell system and solid oxide technology, applied in solid electrolyte fuel cells, fuel cells, circuits, etc., can solve the problems of low battery electromotive force and low power density, and achieve the effect of wide range of fuels and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

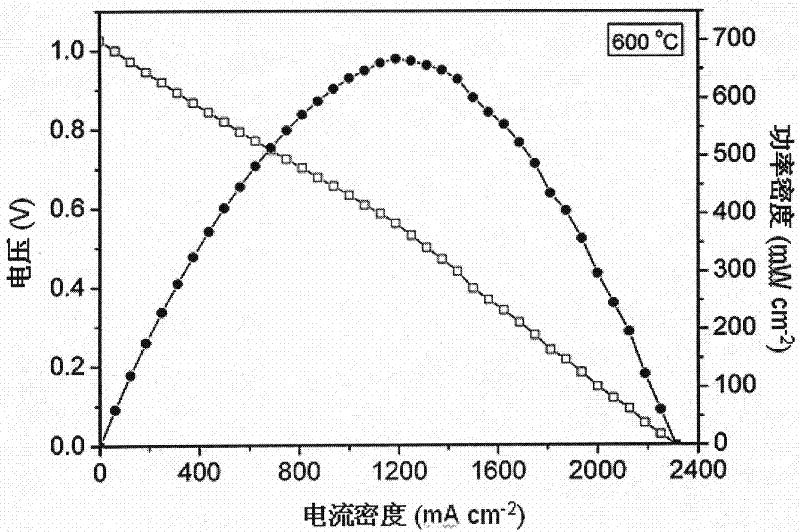

[0031] Example 1: Preparation and performance test of Ni-BZCY|SDC|BSCF single cell

[0032] First, weigh 30g of NiO, 20g of BZCY powder and 3g of polyvinyl butyral, add 100ml of ethanol to mix by ball mill, take it out after 24h, keep it constant at 80°C, and keep stirring to dry the formed mixture slurry, then pass Grinding and sieving by hand to finally form an anode powder, weigh 0.35 g of the powder, and pass through a mold to prepare an anode green body.

[0033] Then, 0.02 g of electrolyte powder SDC was weighed again, evenly distributed on the anode green body just prepared, and pressed again. The anode-supported electrolyte double-layer body prepared above was calcined at 1450° C. for 5 hours, and the heating rate was 5° C. / min.

[0034] Next, weigh 2 g of BSCF, pipette 20 ml of isopropanol, 5 ml of ethylene glycol, and 1.5 ml of glycerol, add them together into a high-energy ball mill jar, and ball mill at 400 rpm for 30 minutes to prepare cathode slurry. Utilize th...

Embodiment 2

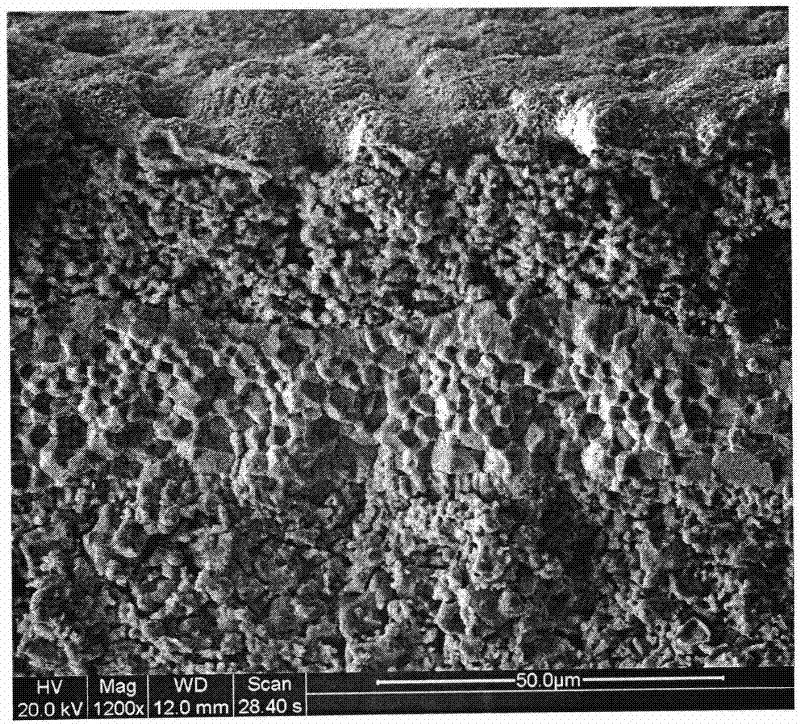

[0036] Example 2: Preparation and performance test of Ni-BZCY|YDC|BSCF single cell

[0037] First, weigh 70g of NiO, 30g of BZCY powder, 4g of starch and 3g of polyvinylpyrrolidone, add 300ml of acetone, add them together into a stainless steel ball mill jar, mix them for 24 hours, take them out, stir and dry the formed mixture slurry at a constant 60°C, and then pass Grind and sieve by hand to finally form anode powder, weigh 0.4g of the powder, and make an anode body through a mold, and send the body to a high-temperature furnace for heat treatment at 1000°C for 2 hours, with a heating rate of 5°C / min .

[0038] Then, weigh 10 g of electrolyte powder YDC, pipette 80 ml of isopropanol, 10 ml of ethylene glycol and 10 ml of toluene into a high-energy ball mill jar, and ball mill at 500 rpm for 2 hours to prepare electrolyte slurry. The slurry is sprayed on the above-mentioned anode blank by using an ultrasonic sprayer. During the spraying process, the constant temperature of ...

Embodiment 3

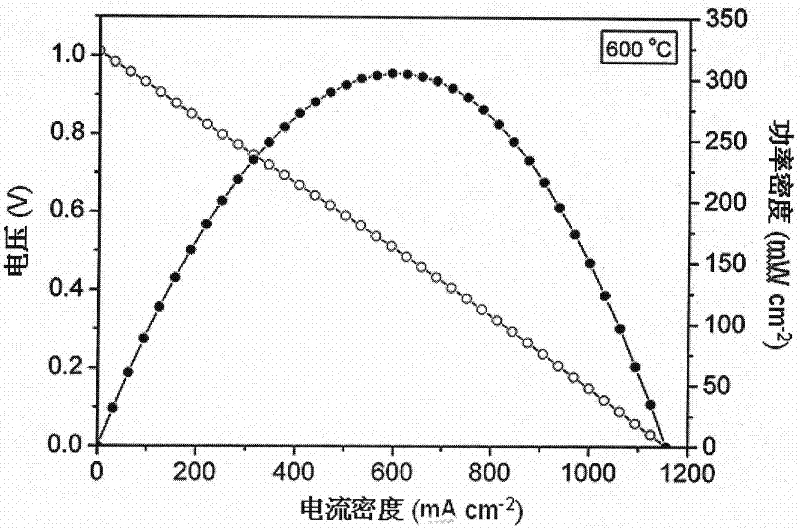

[0041] Example 3: Preparation and performance test of Ni-BCY|YSZ|LSM+YSZ single cell

[0042] First, weigh 55g of NiO, 45g of BCY powder, 8g of graphite and 2g of polyvinyl butyral, add 500ml of ethanol and xylene as solvents, add them together into a stainless steel ball mill jar, mix them for 24 hours, take them out, and pass the slurry through a small degassing Machine degassing for 40 minutes to obtain casting slurry, and the anode green body was prepared through a casting machine, and the green body was sent to a high-temperature furnace for heat treatment at 900°C for 5 hours, and the heating rate was 2°C / min.

[0043] Then, weigh 2g of electrolyte powder YSZ, pipette 20ml of isopropanol, 5ml of ethylene glycol and 2ml of toluene into a high-energy ball mill jar, and ball mill at 400rmp for 1 hour to prepare an electrolyte slurry. Use a spray gun to spray the slurry on the above-mentioned anode body. During the spraying process, the anode body is kept at a constant tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com