Pressure-converging internal circulation multi-fuel engine

An internal circulation and engine technology, applied to internal combustion piston engines, combustion engines, engine components, etc., can solve the problems of internal combustion engines that cannot burn, pollute the environment, and limit the use of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

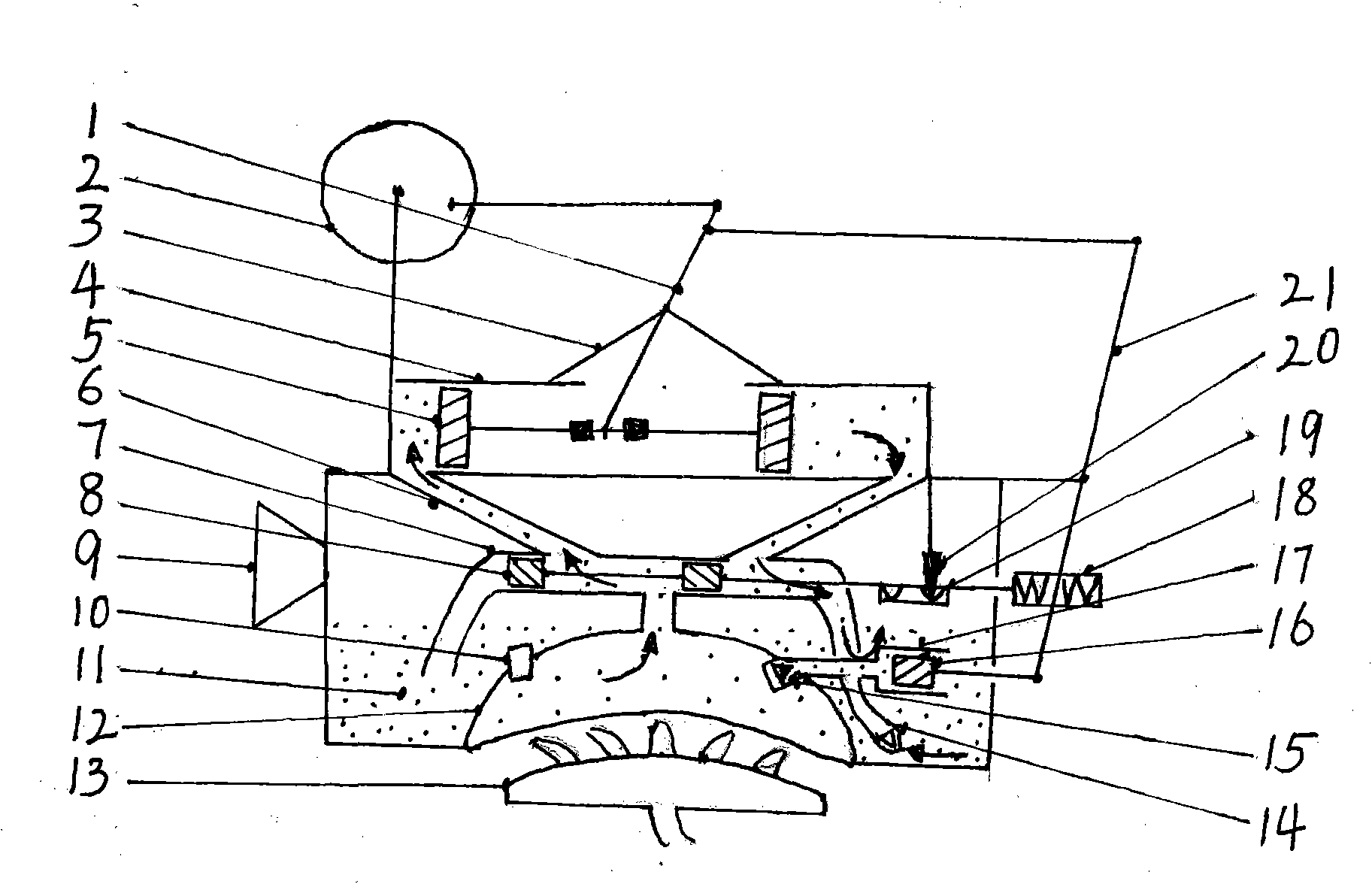

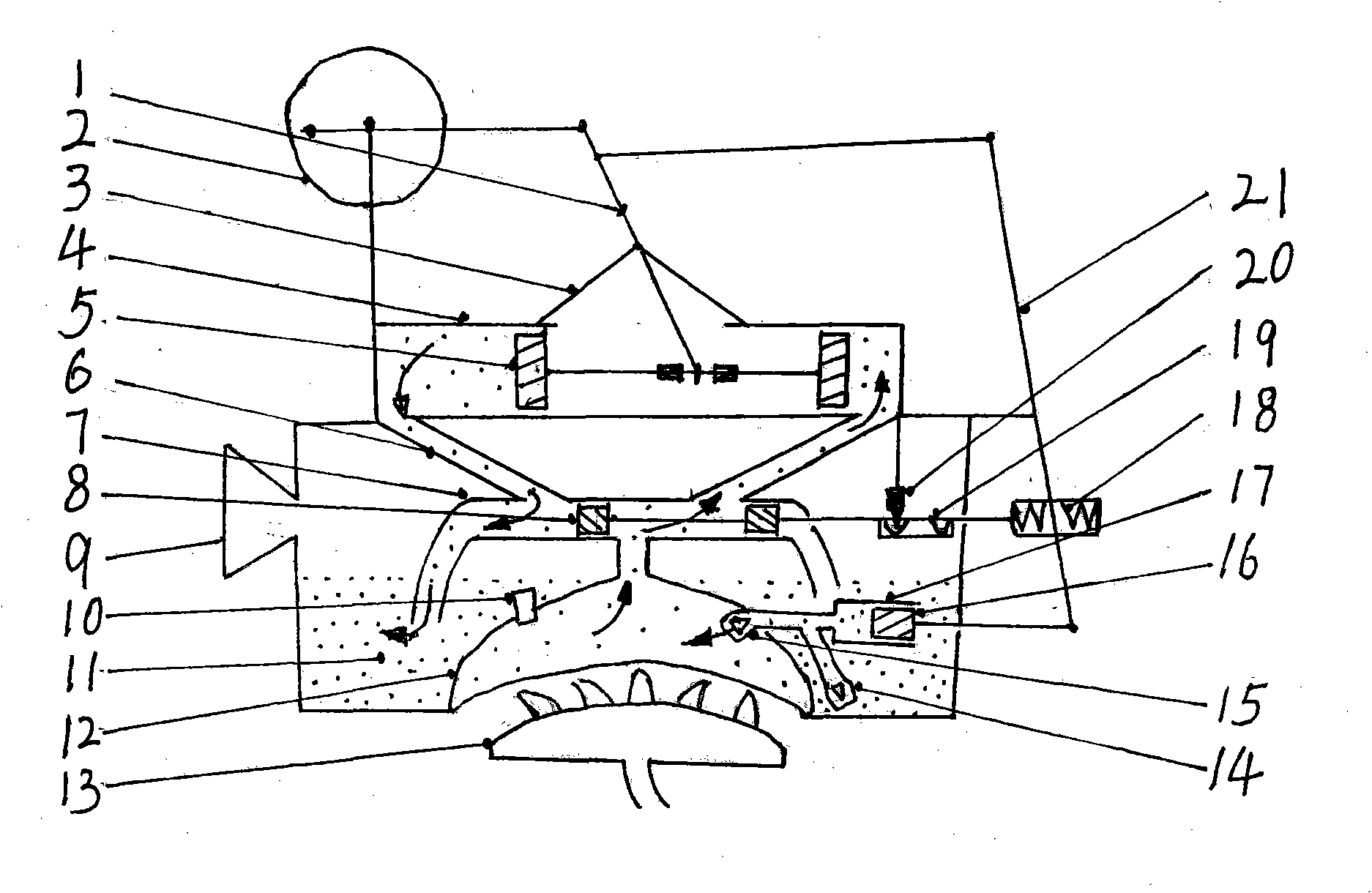

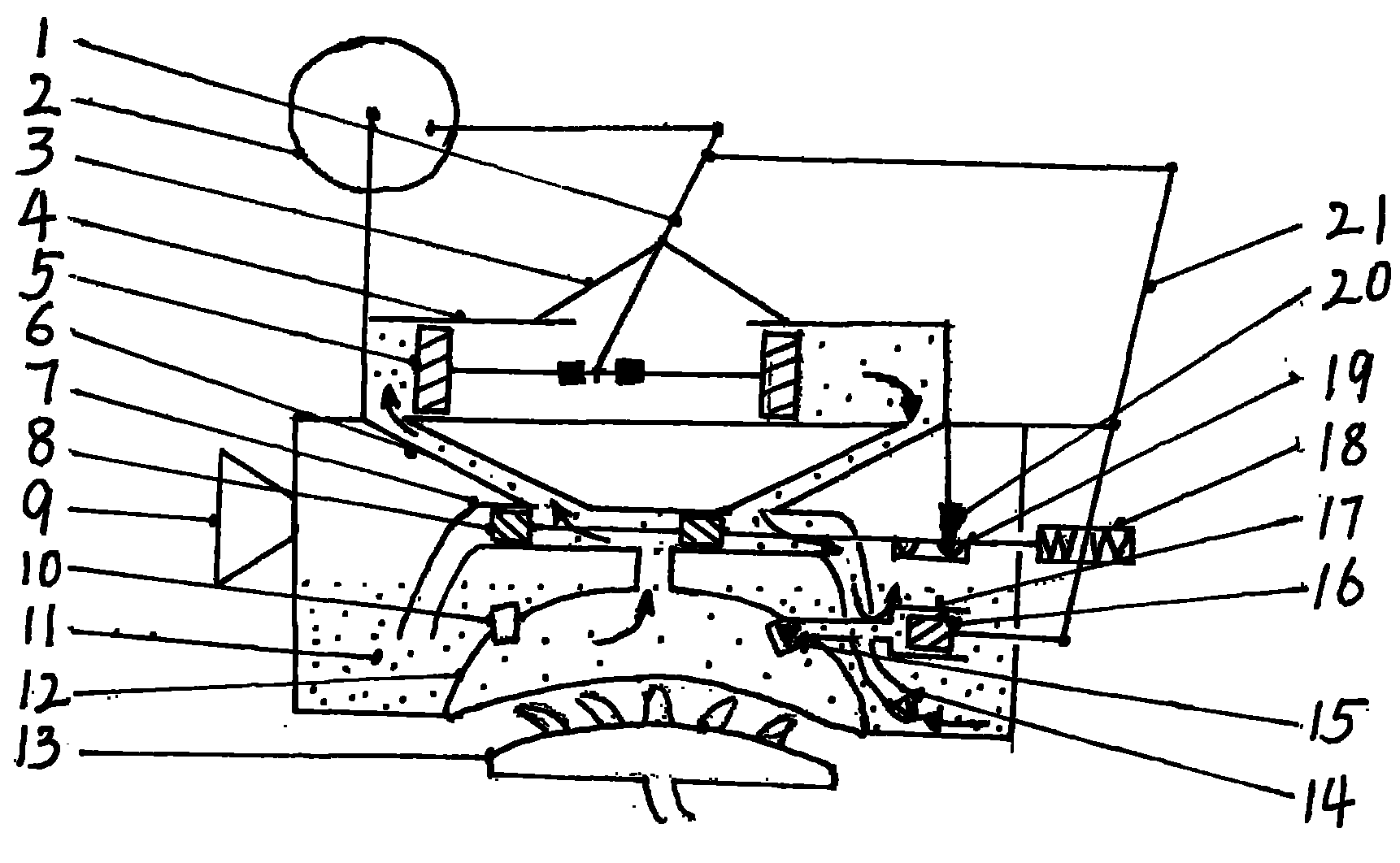

[0009] exist figure 1 In the process, make a pressure-gathering evaporation chamber (12) with a large heating bottom area and a small memory space. A pressure-stabilizing valve (10) is installed on the pressure-gathering evaporation chamber (12), and the steam outlet at the upper end of the pressure-gathering evaporation chamber (12) is connected. Valve sleeve (7) center hole, there is a left hole and a right hole respectively on the opposite side of movable valve sleeve (7) center hole. Connect the right side in the cylinder liner (4) with a steam pipe, connect the two small pistons (8) of the movable valve with a connecting rod and put them into the movable valve sleeve (7), and the central hole of the movable valve sleeve (7) is always on the Between the two small pistons (8), the two small pistons (8) of the movable valve can only lead to the center hole and the left hole when they are in the left position, and they can only lead to the center hole and the right hole when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com