Gas burner capable of adjusting gas to be self-recycling

A gas burner and recirculation technology, which is applied to gas fuel burners, burners, and combustion methods, can solve problems such as slagging, reduced combustion efficiency, and corrosion, and achieve high combustion efficiency, stable combustion, and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

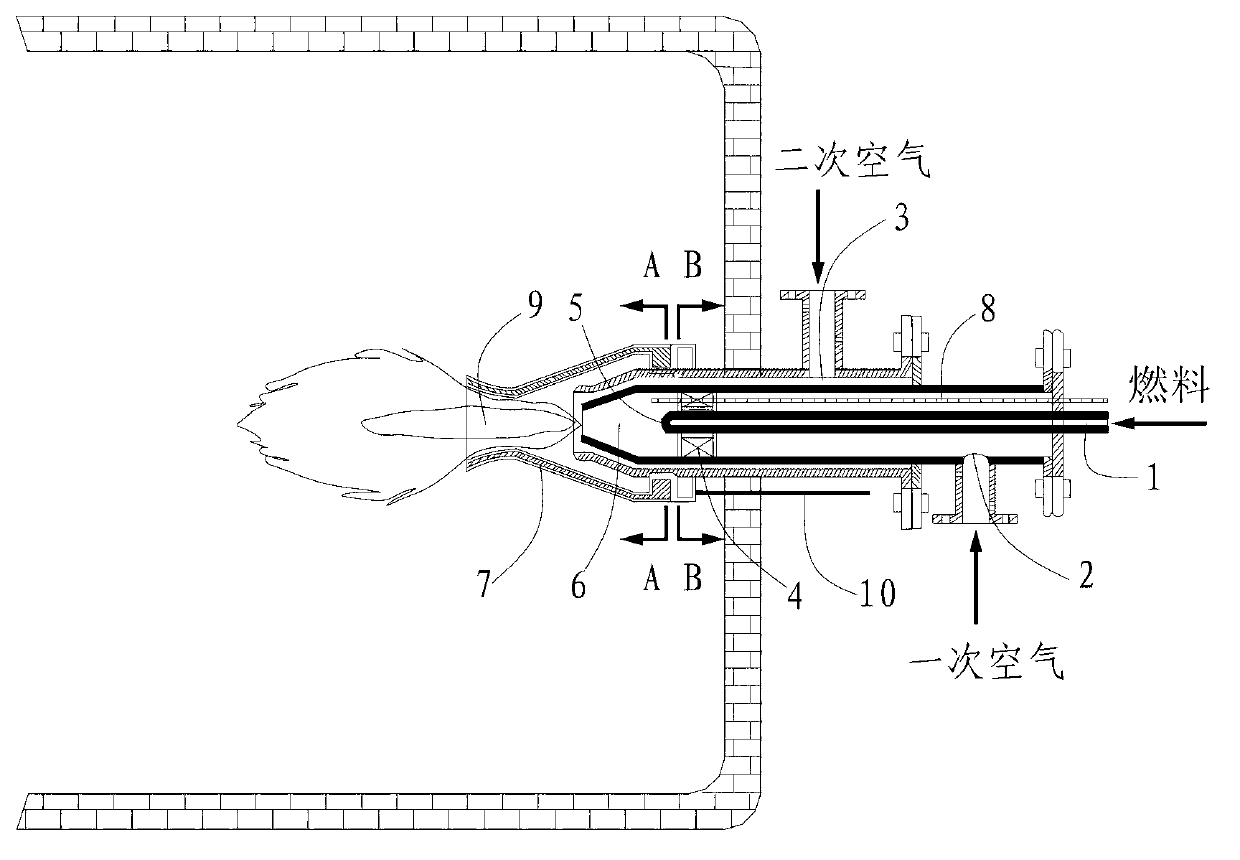

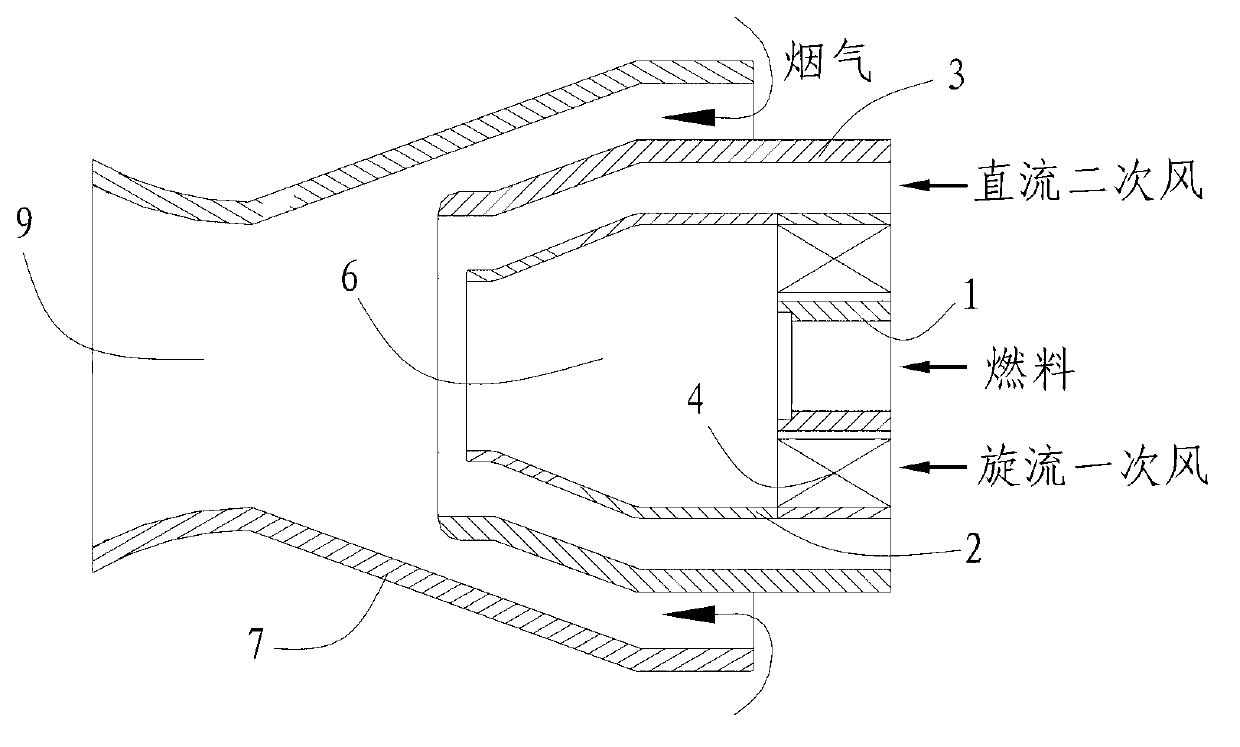

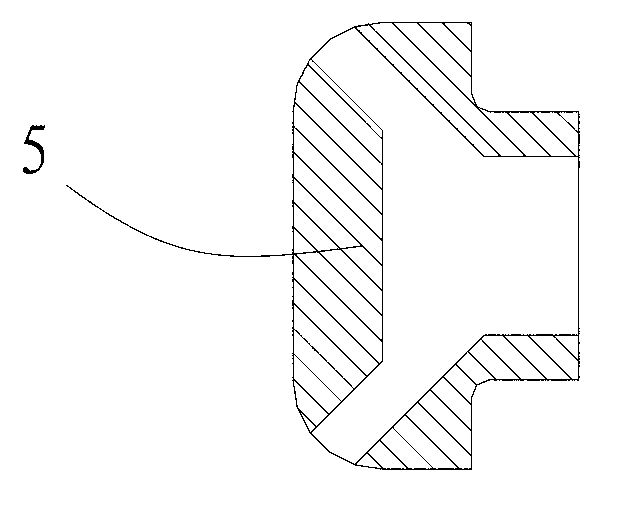

[0022] refer to Figure 1 to Figure 5 , the arrow shows the flow direction of fuel or air, an adjustable flue gas self-recirculation gas burner, including a central fuel pipe 1 coaxial and nested in sequence from the inside to the outside, a primary swirl air pipe 2, a secondary The direct air duct 3 and the ejector 7, the outlet section of the central fuel pipe 1 is provided with a fuel nozzle 5, the primary swirl air duct 2 is provided with an air swirler 4 and a premixing chamber 6, and the primary swirl air The pipe 2 and the premixing chamber 6 communicate with the fuel nozzle 5, and the outlet of the premixing chamber 6 and the outlet end of the secondary straight air pipe 3 are located at the throat of the ejector 7, where the main flame combustion zone 9 is formed. An electronic igniter 8 is also provided in the primary swirl air duct 2, and one end of the electronic igniter 8 passes through the air swirler 4, and its ignition electrode is located in the premixing cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com