Biomass combustion special furnace

A biomass fuel and biomass technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of waste of biological resources, lack of combustion devices, and the inability to widely use biomass fuels, etc., to achieve a wide range of fuels, improve The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

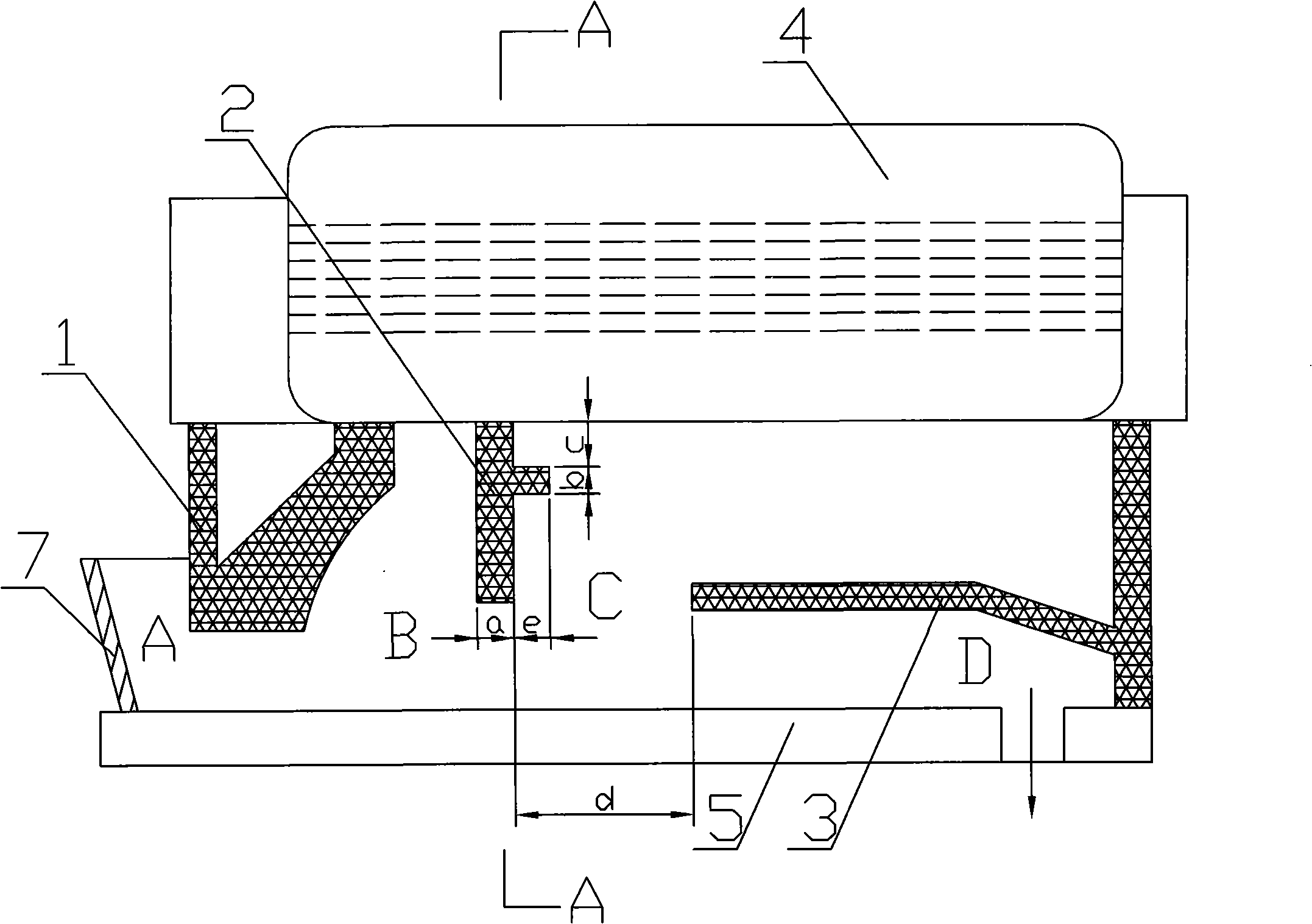

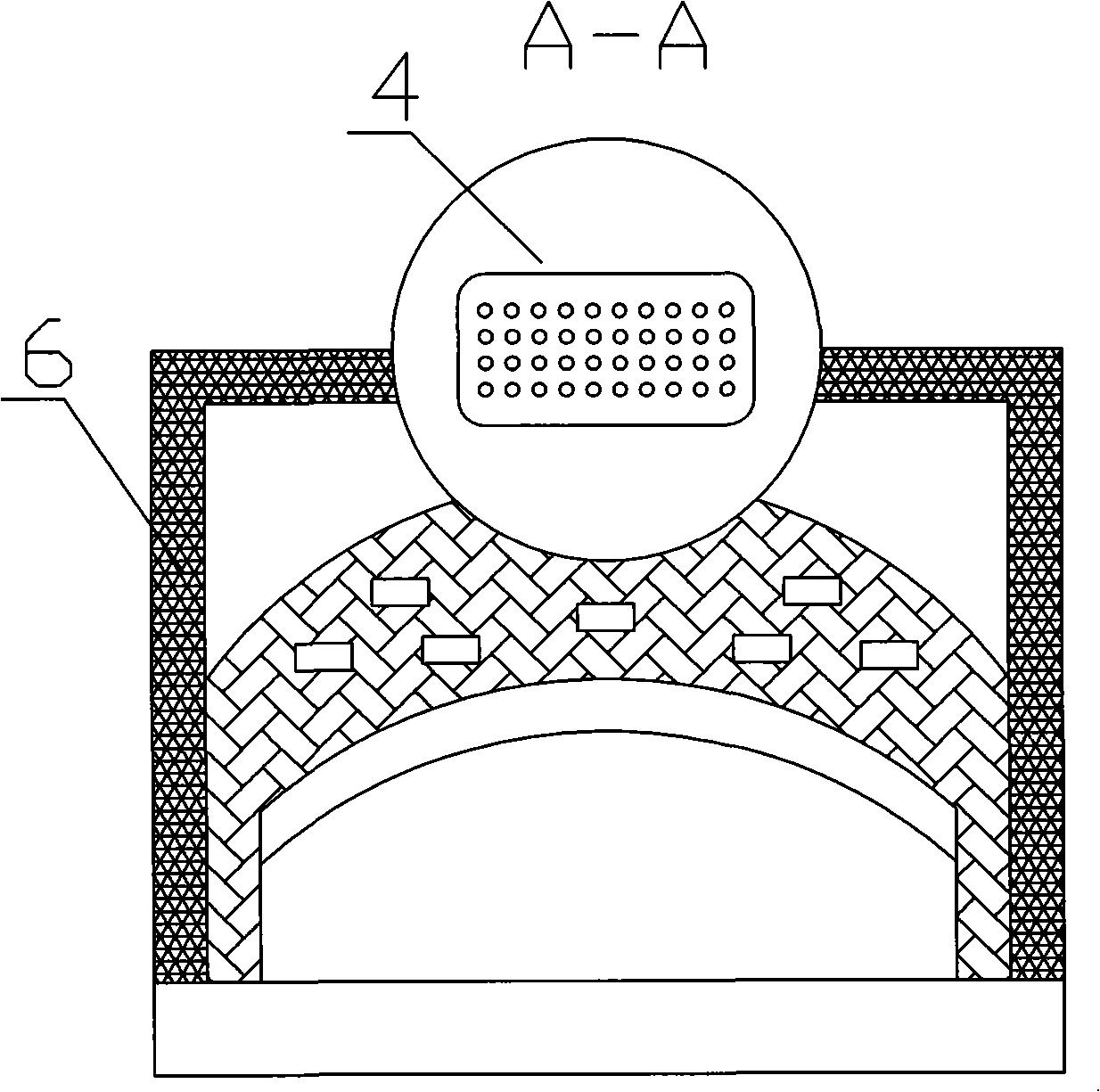

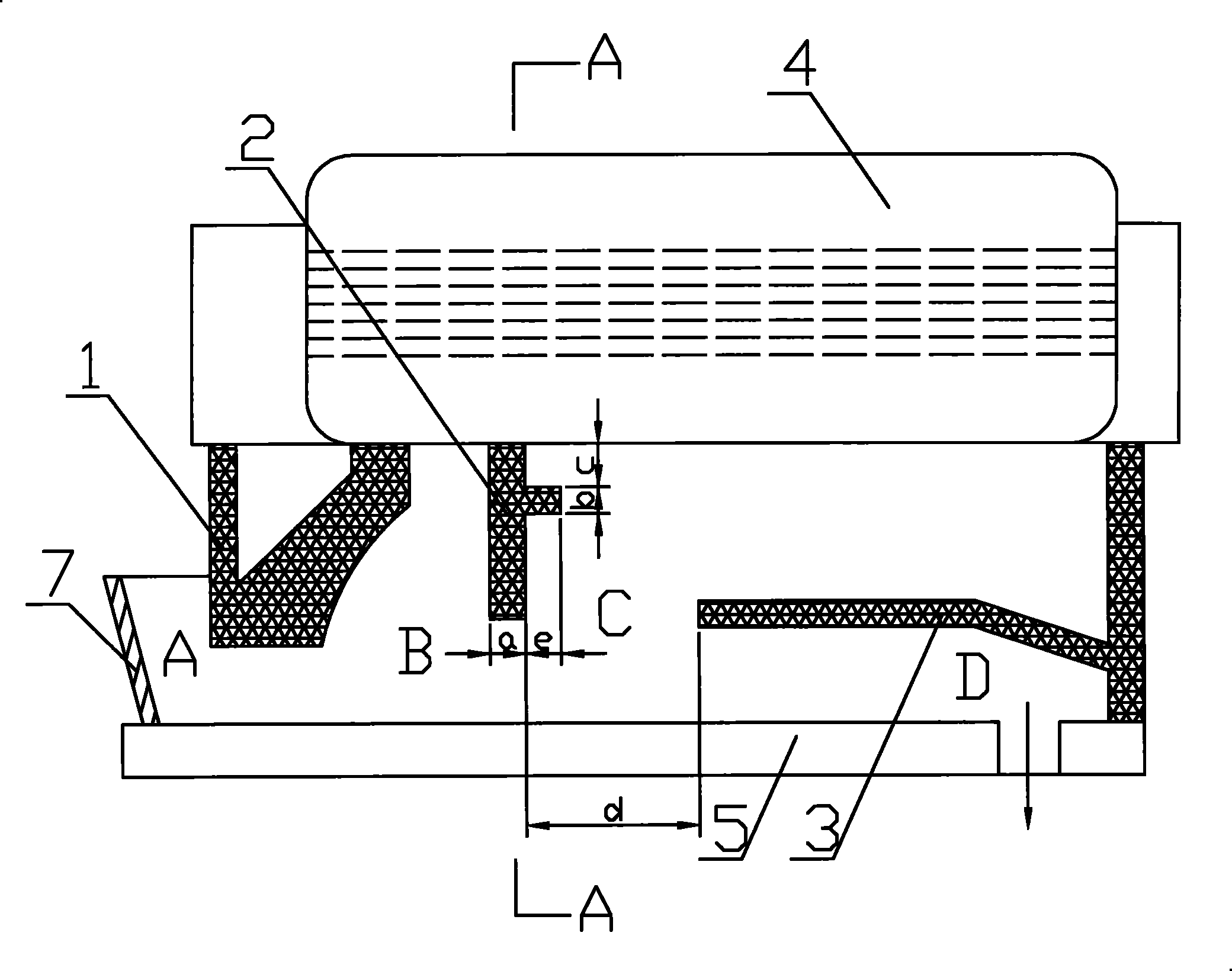

[0018] The specific implementation method of the present invention is as shown in the drawings: the present invention has three arch walls in the furnace body 6 of the boiler, which are respectively the front arch 1, the middle arch 2 and the rear arch 3. There is a mechanical transmission fire grate 5 at the lower end of the three arch walls; a hopper 7 that can be loaded with biomass fuel is installed at the front end of the front arch 1 and the mechanical transmission fire grate 5 . A feed area A is formed between the front arch 1 and the hopper 7, a volatile redox area B is formed between the front arch 1 and the middle arch 2, and a main combustion area C is formed between the middle arch 2 and the rear arch 3. The middle section inside the middle arch 2 has a protruding part; the shape of the back arch 3 is a broken line structure, the front section of the back arch 3 is in the shape of a horizontal straight line, and the rear section is in the shape of a broken line stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com