Waste heating device

A heating device and waste technology, applied in the field of heating devices, can solve problems such as insufficient utilization of energy, potential safety hazards, inability to burn, etc., and achieve the effects of low cost, fast heating speed, and no hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

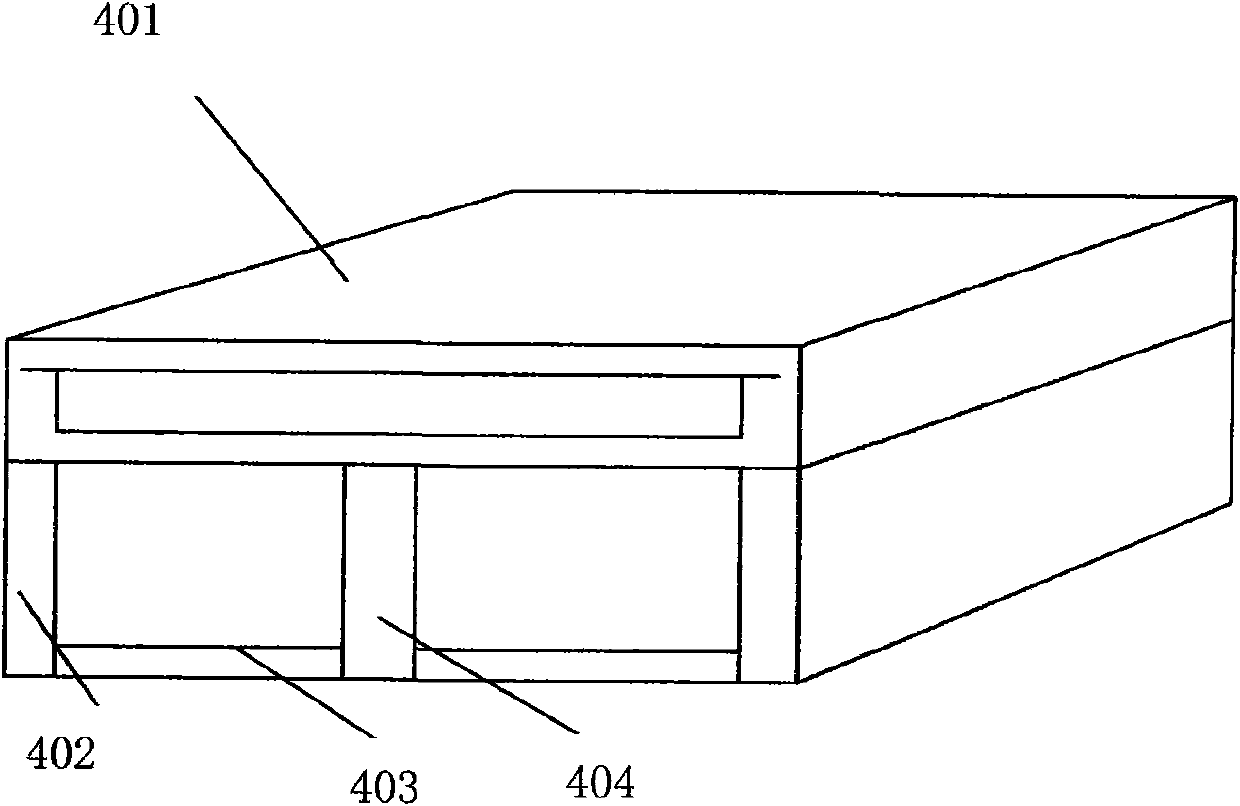

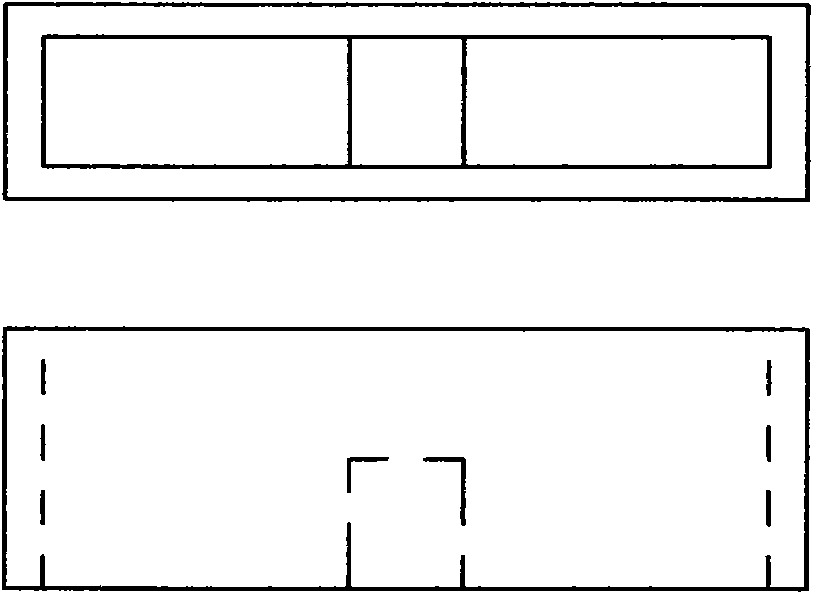

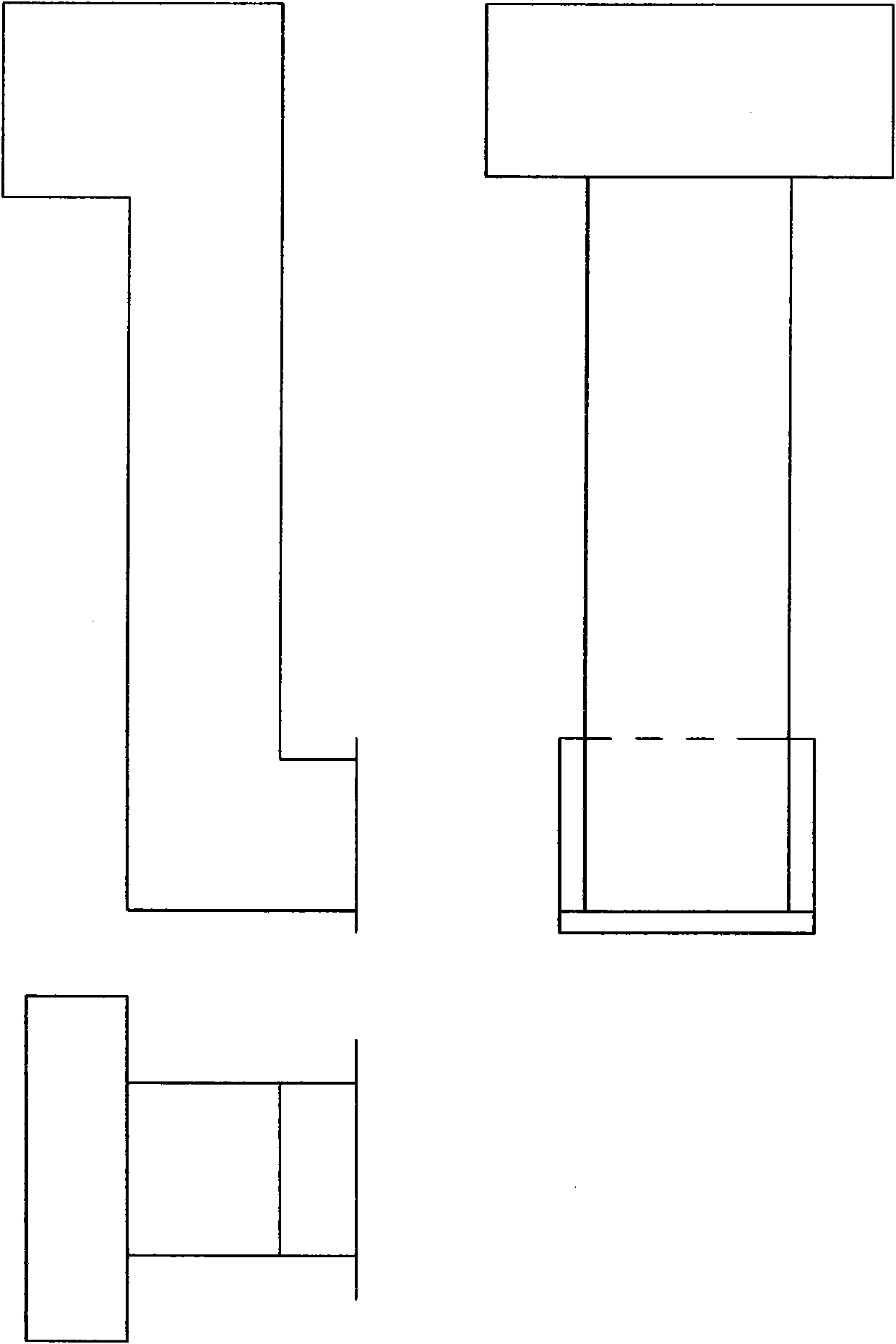

[0025] Such as Figure 1 to Figure 8 As shown, the waste heating device of the present invention includes a generator 100 , a distributor (1) 200 , a distributor (2) 300 , a heat dissipation pipe 400 , and an air supply pipe 500 . The generator 100 is arranged outdoors, and the mixed gas outlet 103 on the generator is connected with the distributor (1) 200; the distributor (1) 200 is connected with the distributor (2) 300; the distributor (2) 300 is connected with the cooling pipe 400 are connected; the heat dissipation pipe 400 is connected with the chimney 600; the air supply pipe 500 is connected with the air outlet 102 of the heat storage tank; a heating system is formed. The upper part of the generator 100 is provided with a movable upper cover 104 and a feeding port 105 . A gas collection chamber 111 is provided in the generator 100 to communicate with the U-shaped combustion chamber, and a mixed gas outlet 103 is opened outside the gas collection chamber 111 to communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com