Automatic crimping device for stainless steel pot

A stainless steel pot and crimping device technology, which is applied in the field of auxiliary automation devices, can solve the problems of low flexibility level of the production line, reduced production efficiency, and high maintenance requirements in the later stage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

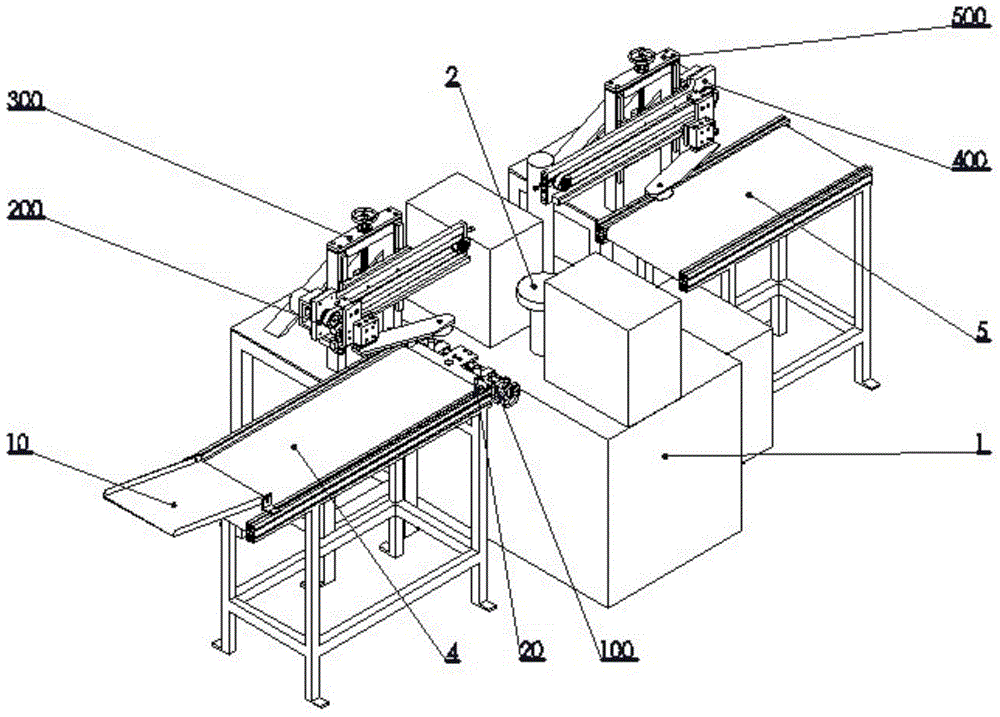

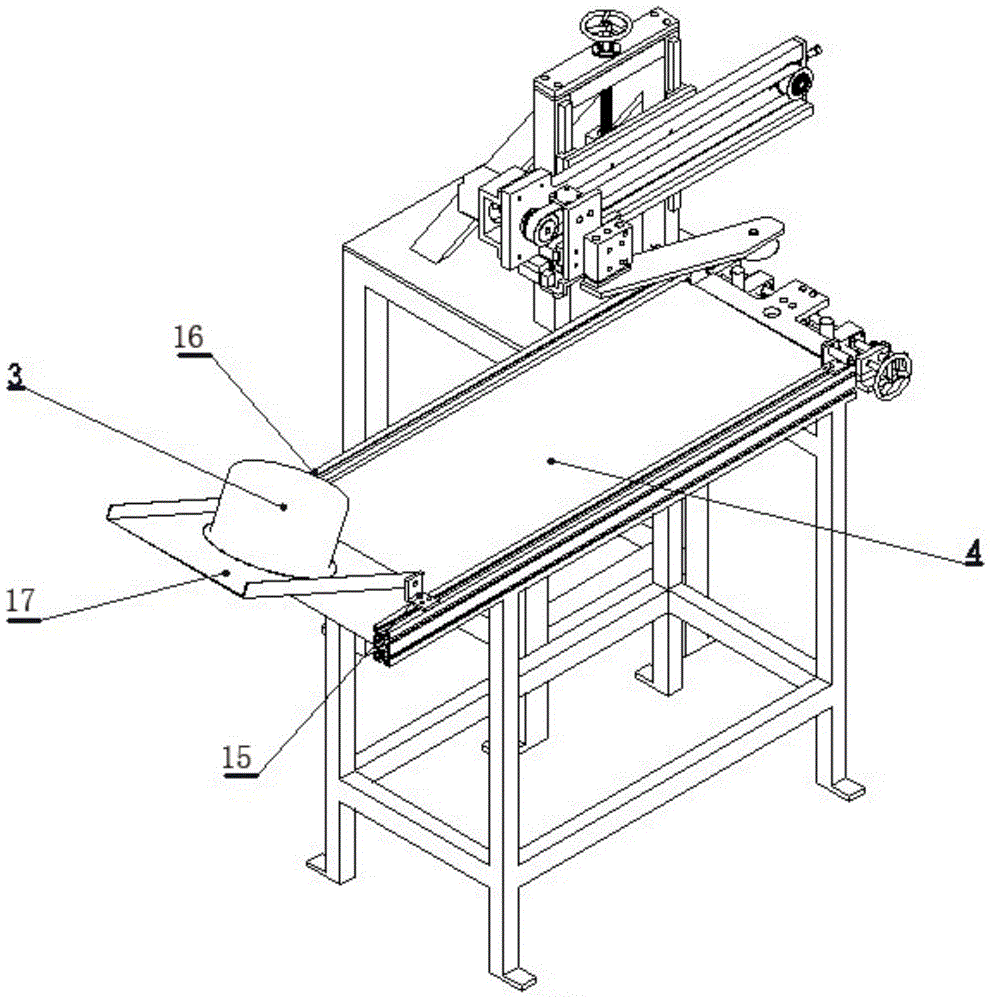

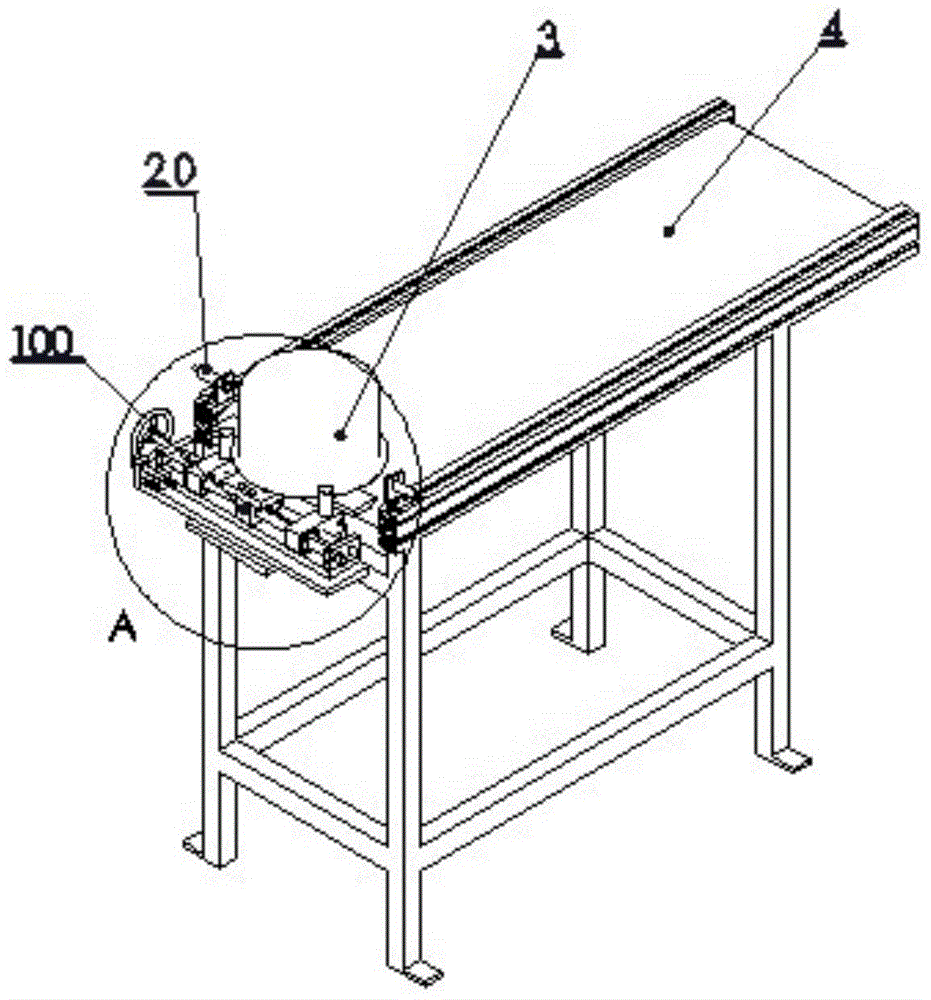

[0058] In this embodiment, the direction from the crimping and discharging mechanism 10 to the retrieving and conveying mechanism 5 is the front-rear direction, the crimping and discharging mechanism 10 is the front, the retrieving and conveying mechanism 5 is the rear, and the direction perpendicular to the front-rear direction is the left-right direction The stainless steel pot enters the crimping discharge mechanism 10 from the previous process and is called the workpiece 3 to be processed, and is called the crimping completion workpiece 6 after the crimping mold 2 operations, and thus unfolds the description.

[0059] refer to figure 1 , an automatic crimping device for a stainless steel pot, comprising a crimping machine 1 and a crimping mold 2 arranged on the crimping machine 1, and also includes:

[0060] Crimping discharge mechanism 10, the crimping discharge mechanism 10 is connected with the equipment of the previous process, and is used to transfer the stainless ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com