Novel biomass gasification steam generator

A steam generator and biomass technology, applied in the field of mechanical processing, can solve the problems of increasing large investment, black smoke and dust, and increasing production costs of enterprises, so as to save electric energy and labor, high combustion temperature and low equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

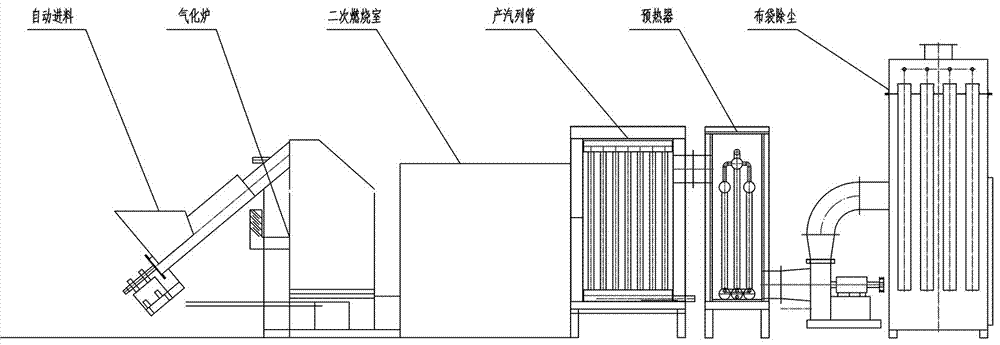

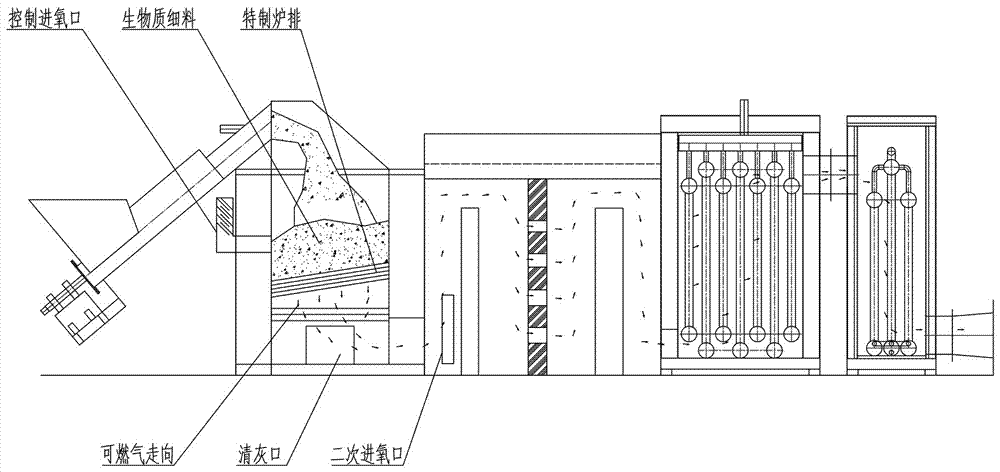

[0033] Example 1, a novel biomass gasification steam generator that produces 1 ton of steam per hour, the main parts consist of:

[0034] (1) The diameter of the screw conveyor is 200mm, and the rated power of the motor is 1.5kw;

[0035] (2) The internal length of the gasifier is 860mm, the width is 860mm, and the height is 1380mm;

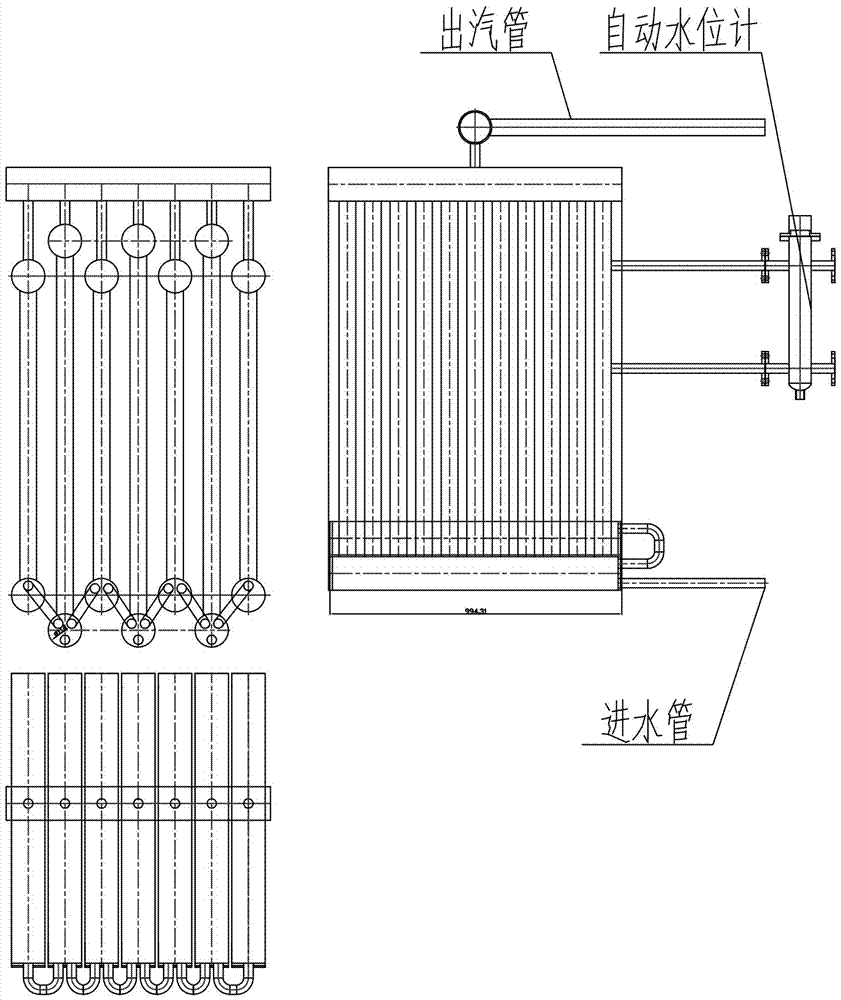

[0036] (3) The tube diameter is 70mm, the length is 1000mm, and the quantity is 77 pieces;

[0037] (4) The water pump power of the water preheating system is 0.75kw;

[0038] (5) The bag filter is 1400mm long, 1000mm wide and 2900mm high.

Embodiment 2

[0039] Example 2, a novel biomass gasification steam generator that produces 2 tons of steam per hour, the main parts consist of:

[0040] (1) The diameter of the screw conveyor is 300mm, and the motor power is 2.2kw;

[0041] (2) The internal length of the gasifier is 400mm, the width is 1200mm, and the height is 1700mm;

[0042] (3) The tube diameter is 80mm, the length is 1500mm, and the quantity is 90 pieces;

[0043] (4) The water pump power of the water preheating system is 1.1kw;

[0044] (5) The dust collector is 2000mm long, 1600mm wide and 3000mm high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com