Patents

Literature

54results about "Simultaneous control of electric and non-electric variables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

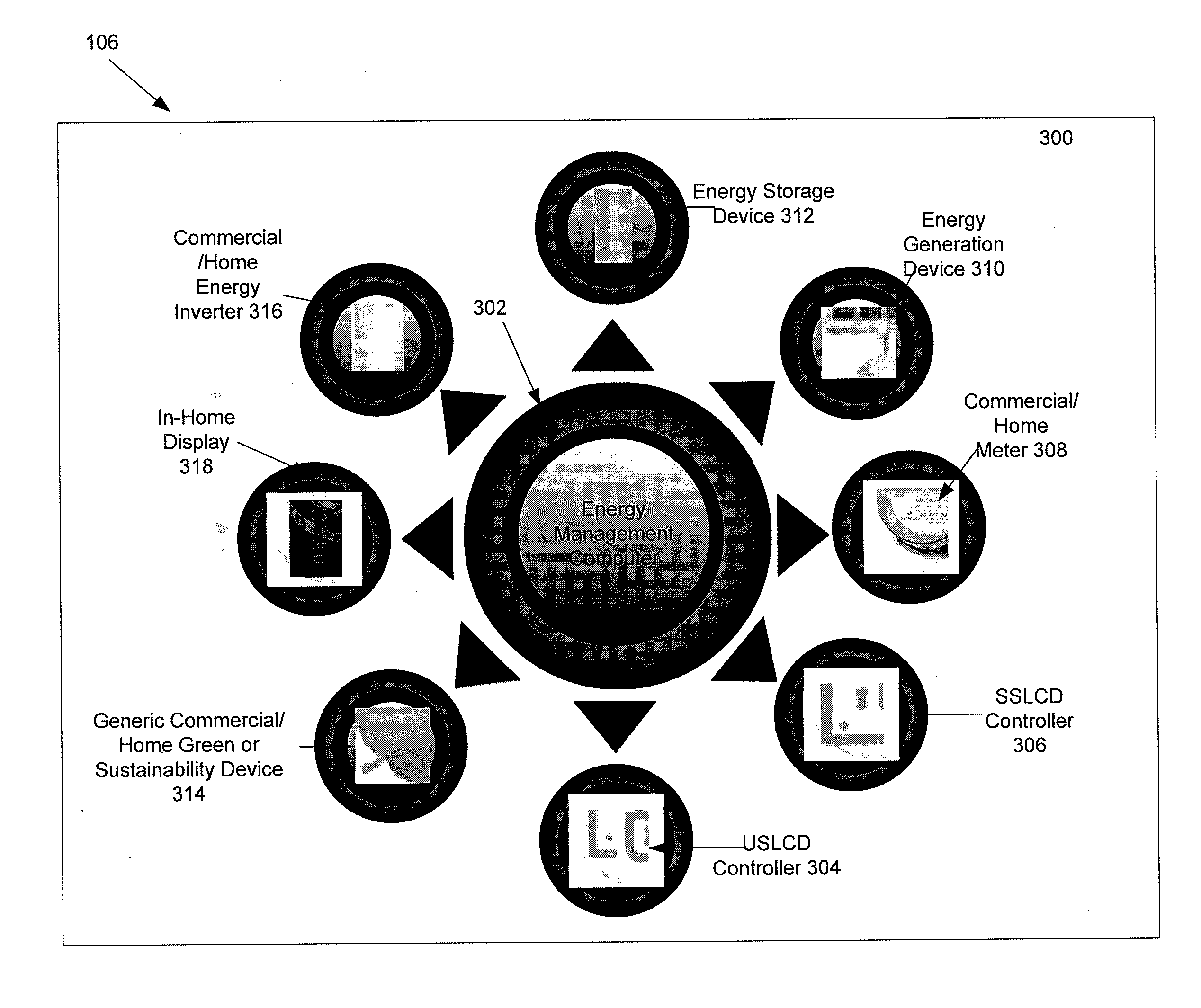

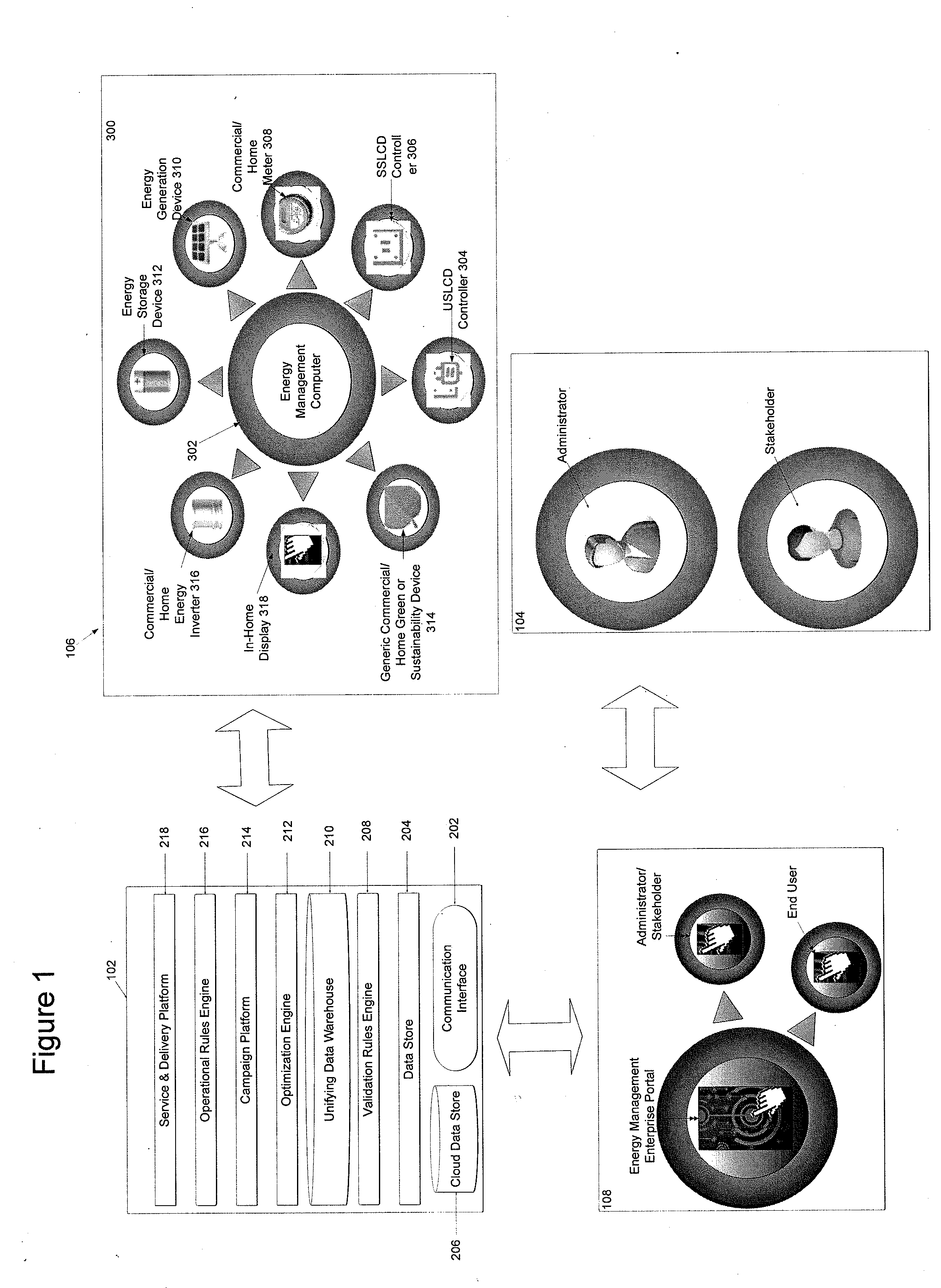

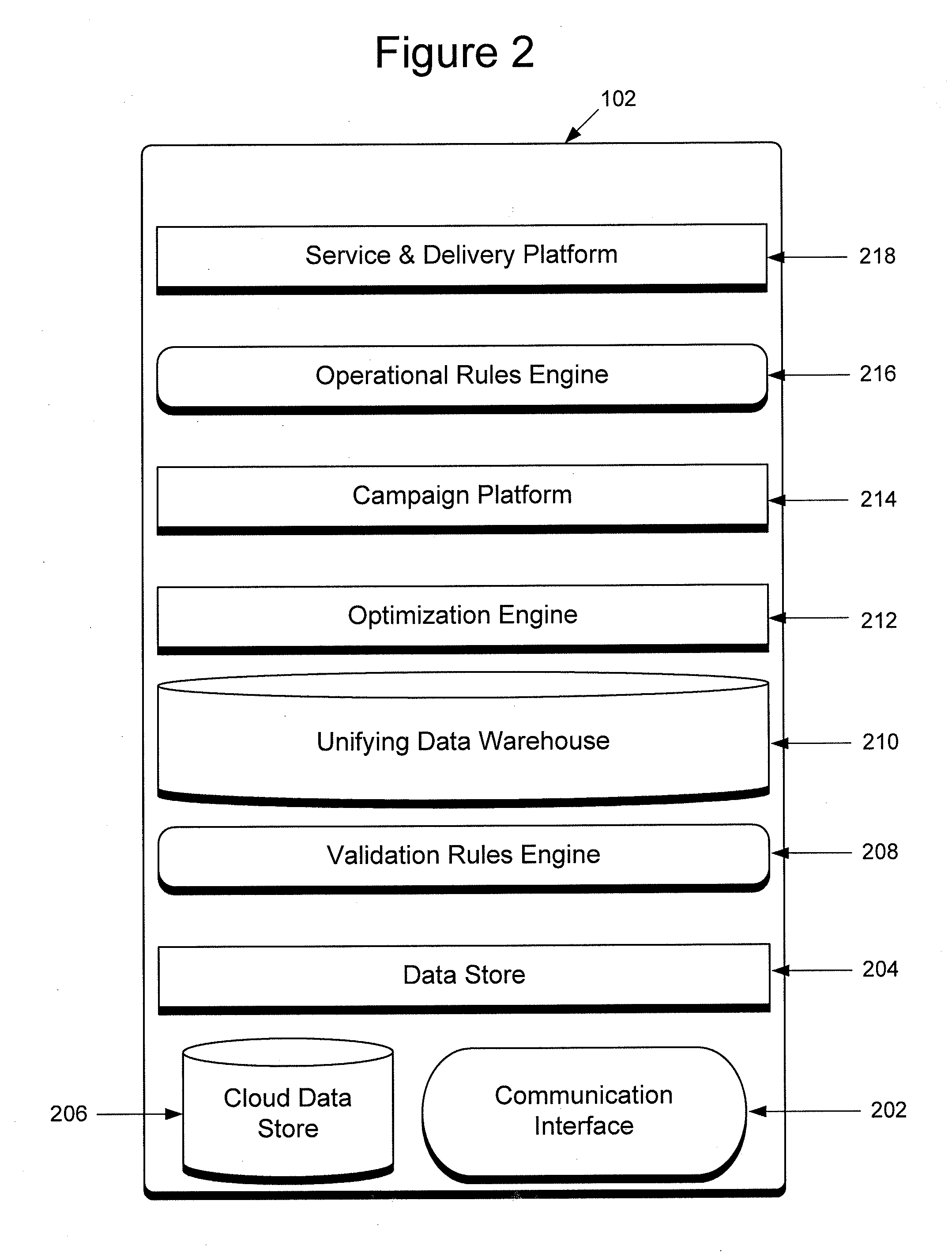

System and method for energy consumption management

InactiveUS20100262313A1Low costEliminate energy wasteProgramme controlMechanical power/torque controlProcess engineeringEnergy expenditure

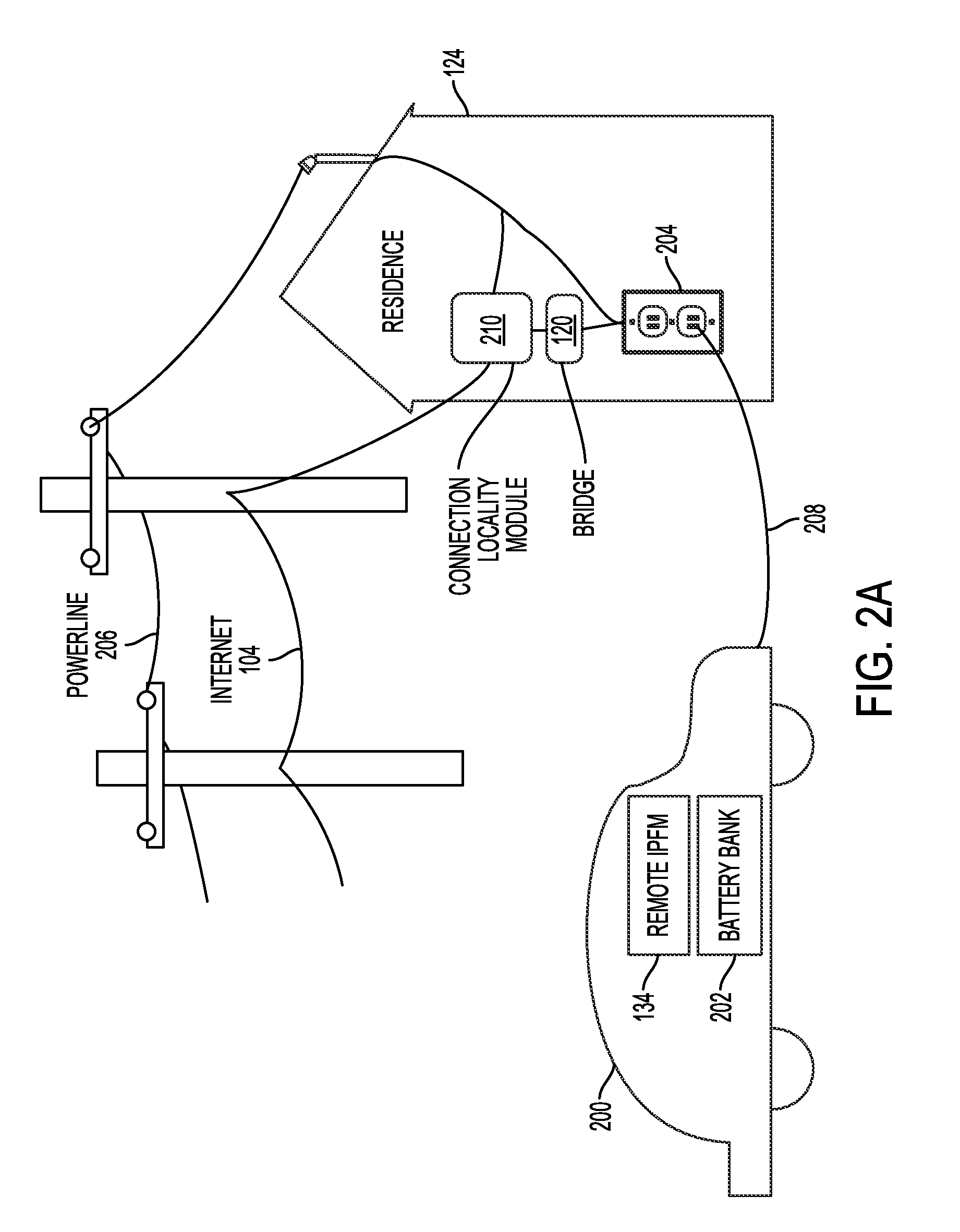

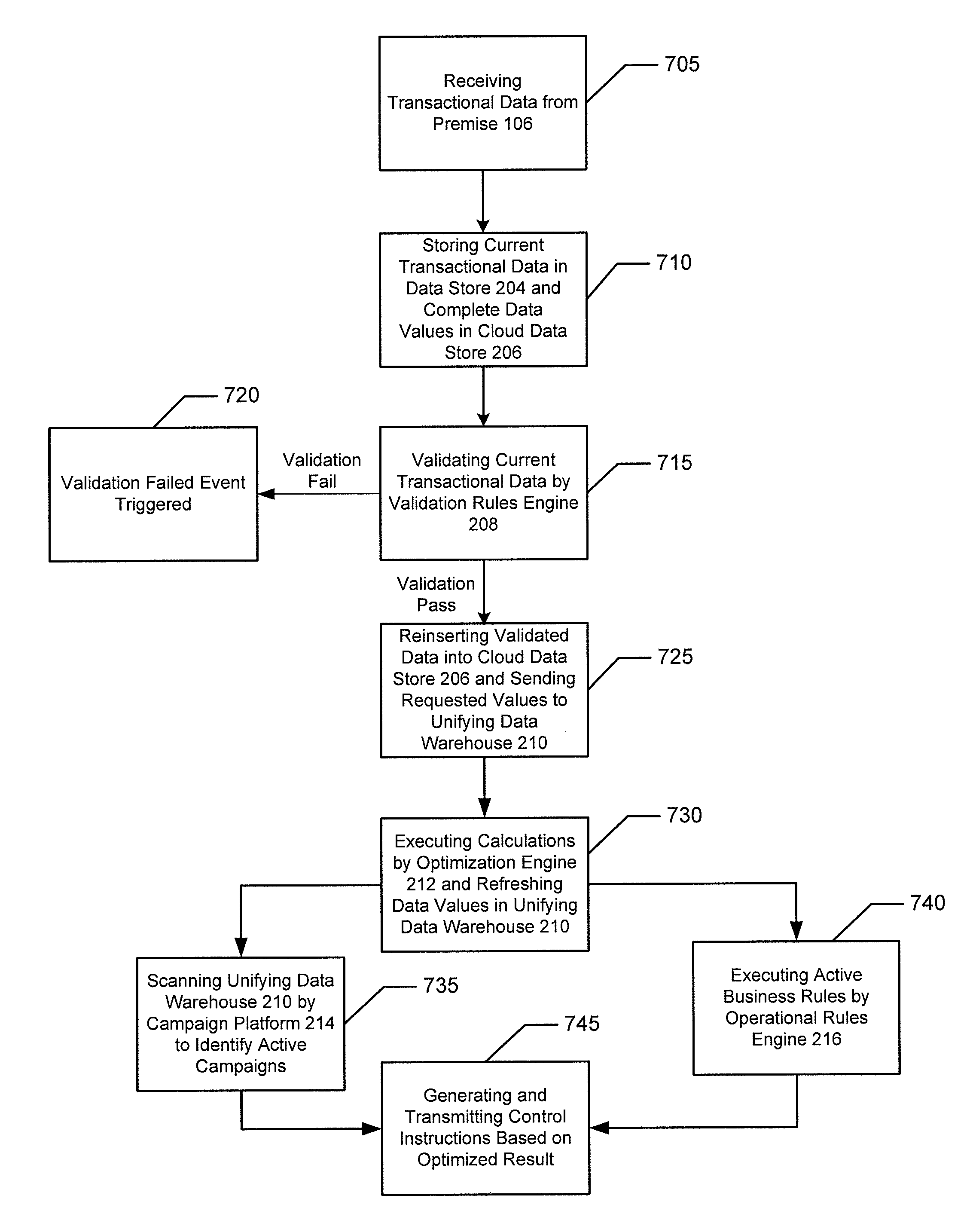

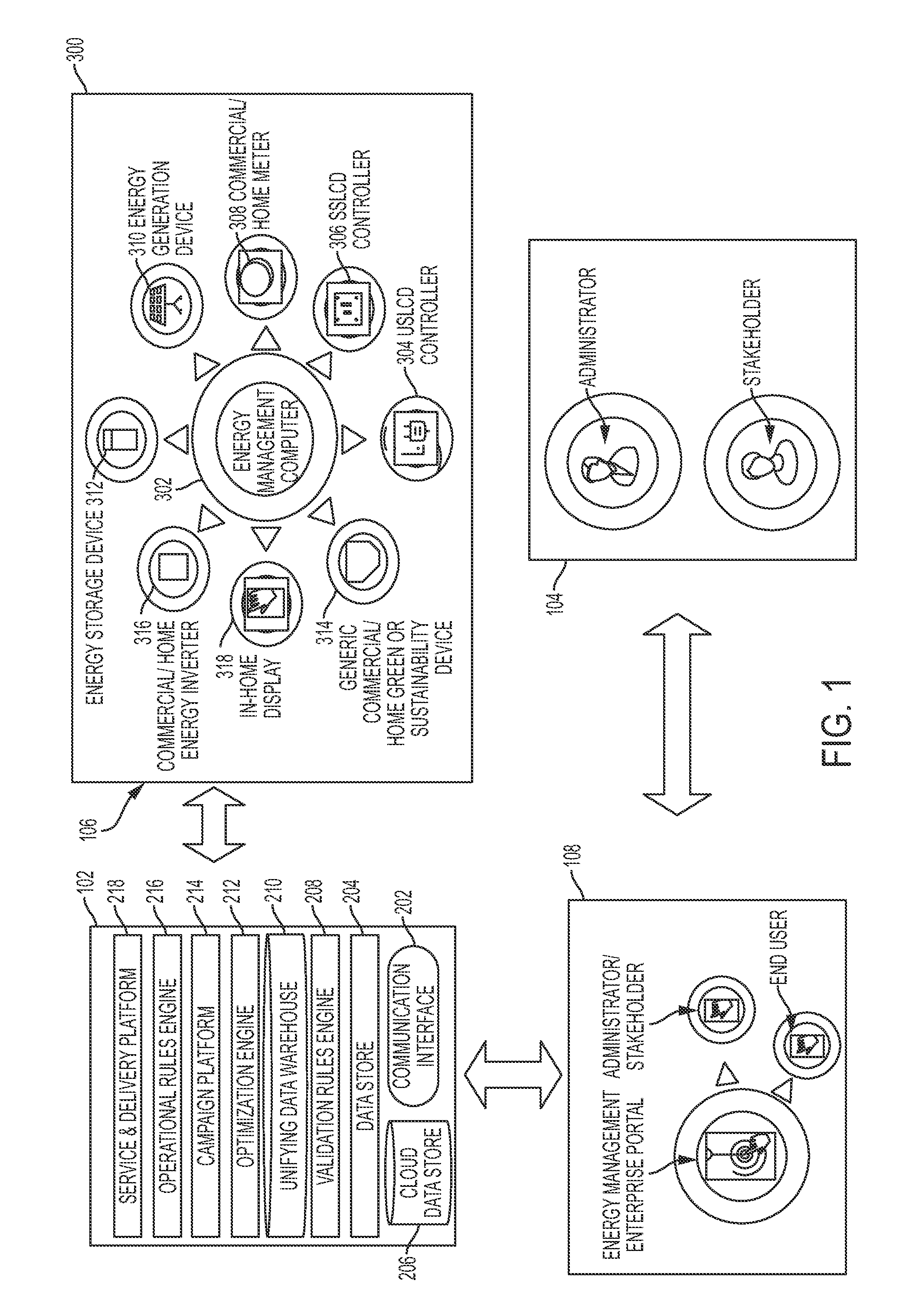

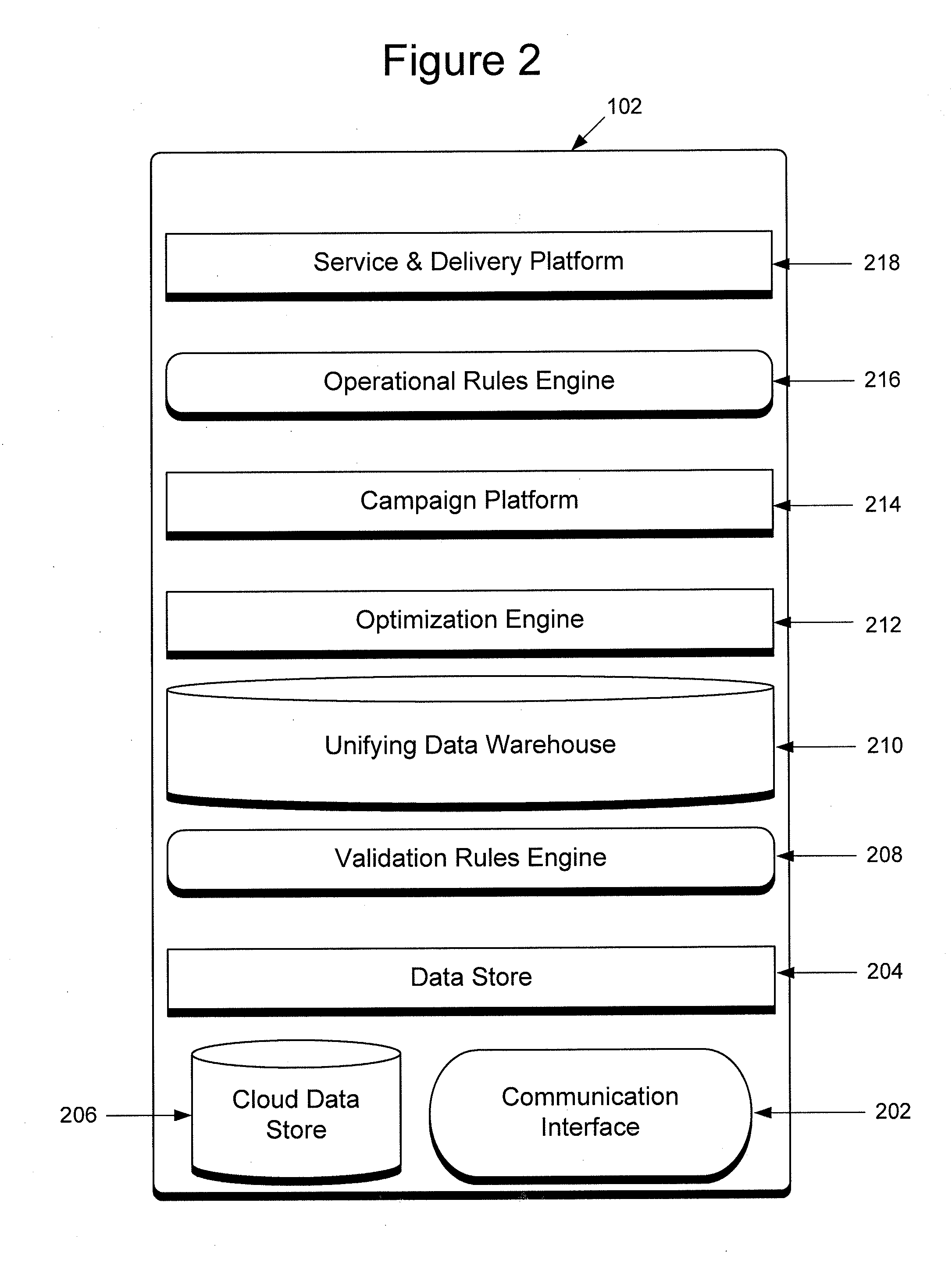

An energy management system and method providing a holistic premise energy optimization and energy efficiency reclamation system comprised of an interconnected system of software, analytics and automated process that optimizes the energy generation and storage technologies, energy consumption, energy demand and energy utilization of energy consuming assets within a premise.

Owner:INTELLIGENT ENERGY SOLUTIONS

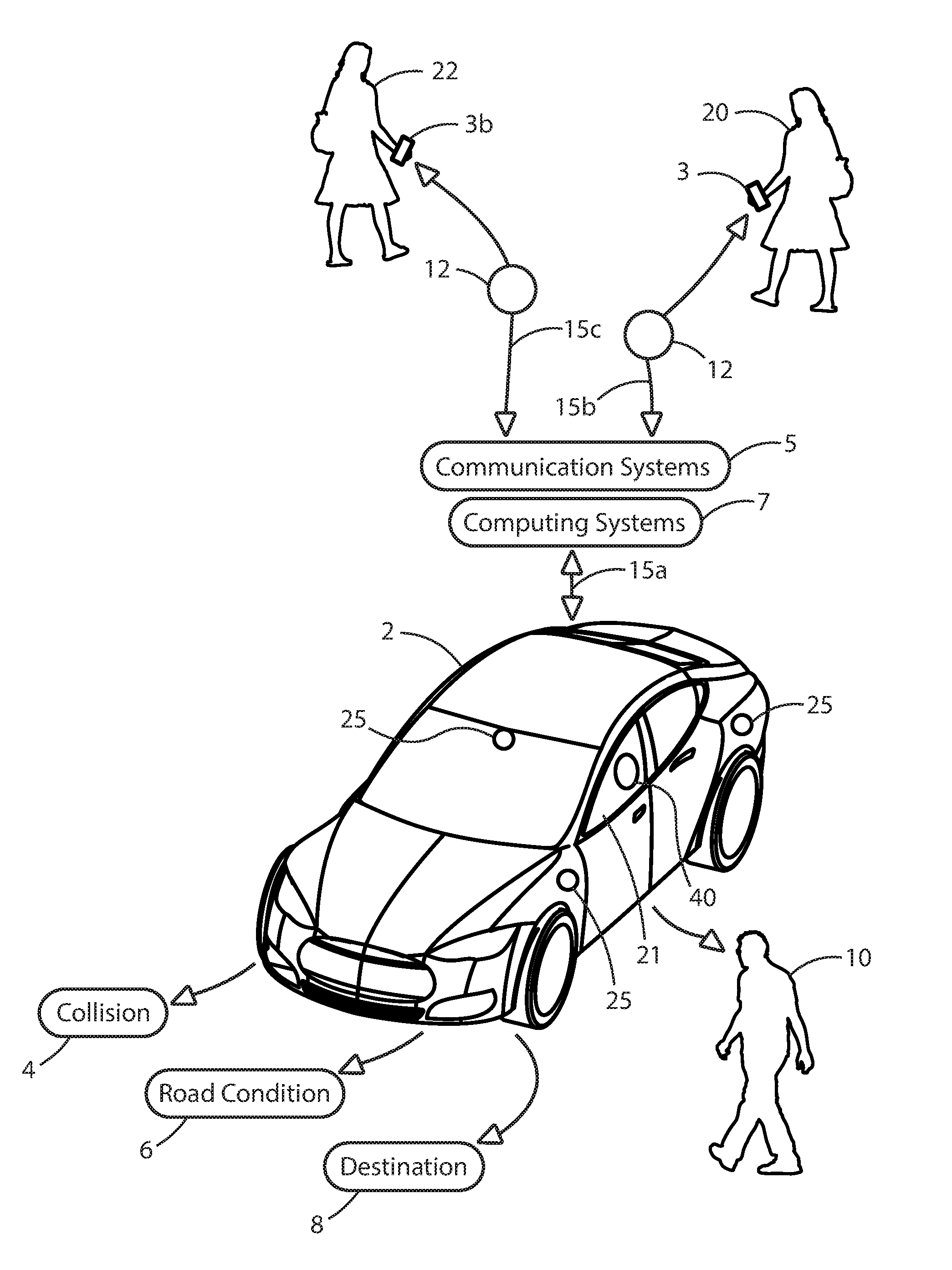

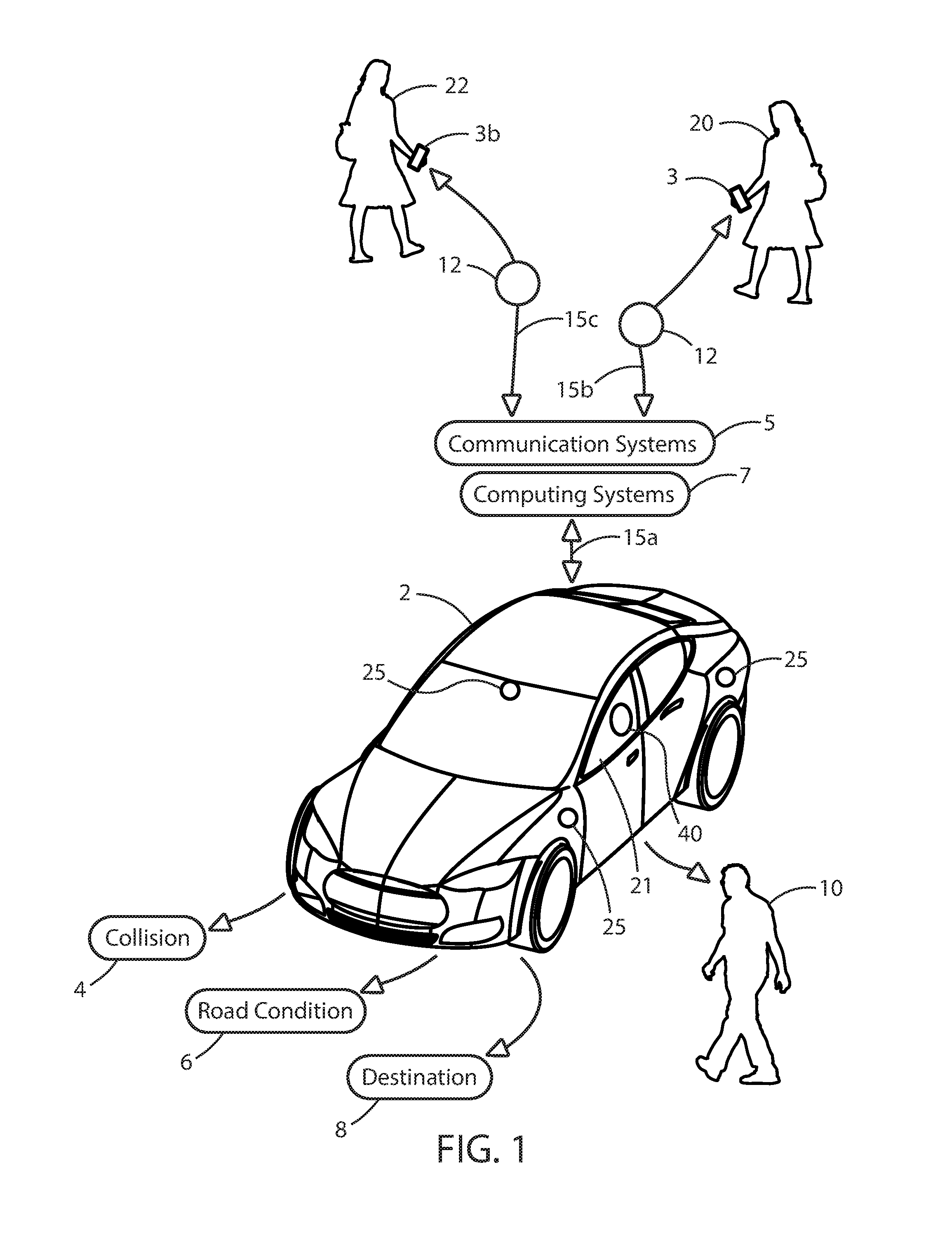

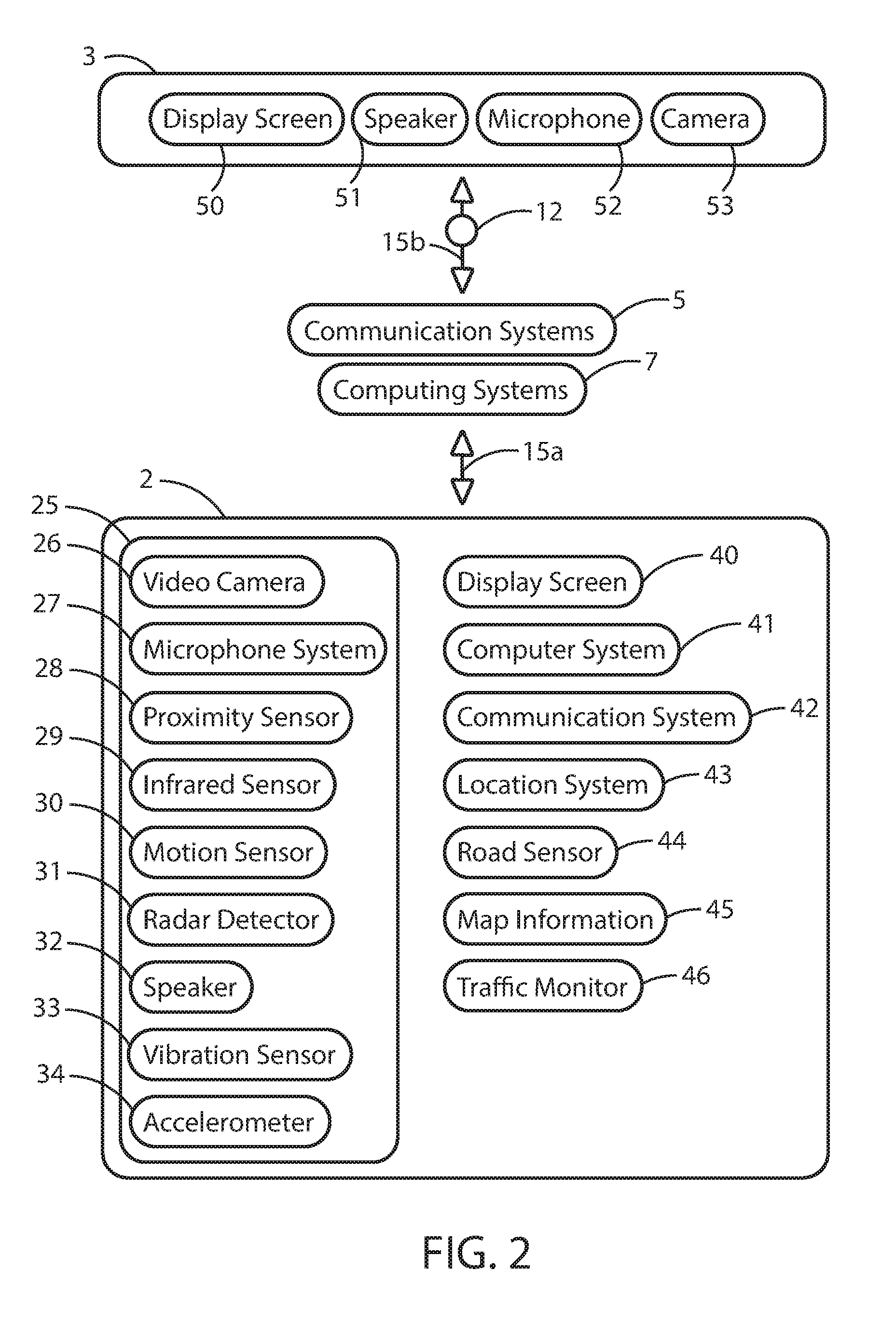

Self-driving vehicle systems and methods

ActiveUS9429947B1Unlimited attention spanAbility of self-driving vehicles to save lives is so impressiveAutonomous decision making processSimultaneous control of electric and non-electric variablesHuman interactionHybrid approach

Although self-driving vehicles excel under “normal” driving conditions, they sometimes struggle with new situations that often would not be overly difficult for a person. Several embodiments described herein enable a hybrid approach that leverages the exceptional abilities of self-driving vehicles while soliciting human interaction in select situations. The resulting combination of machine intelligence and human intelligence significantly enlarges the potential of self-driving vehicles in a manner that will enable self-driving vehicles to become widespread much faster than would otherwise be the case.

Owner:DRIVENT LLC

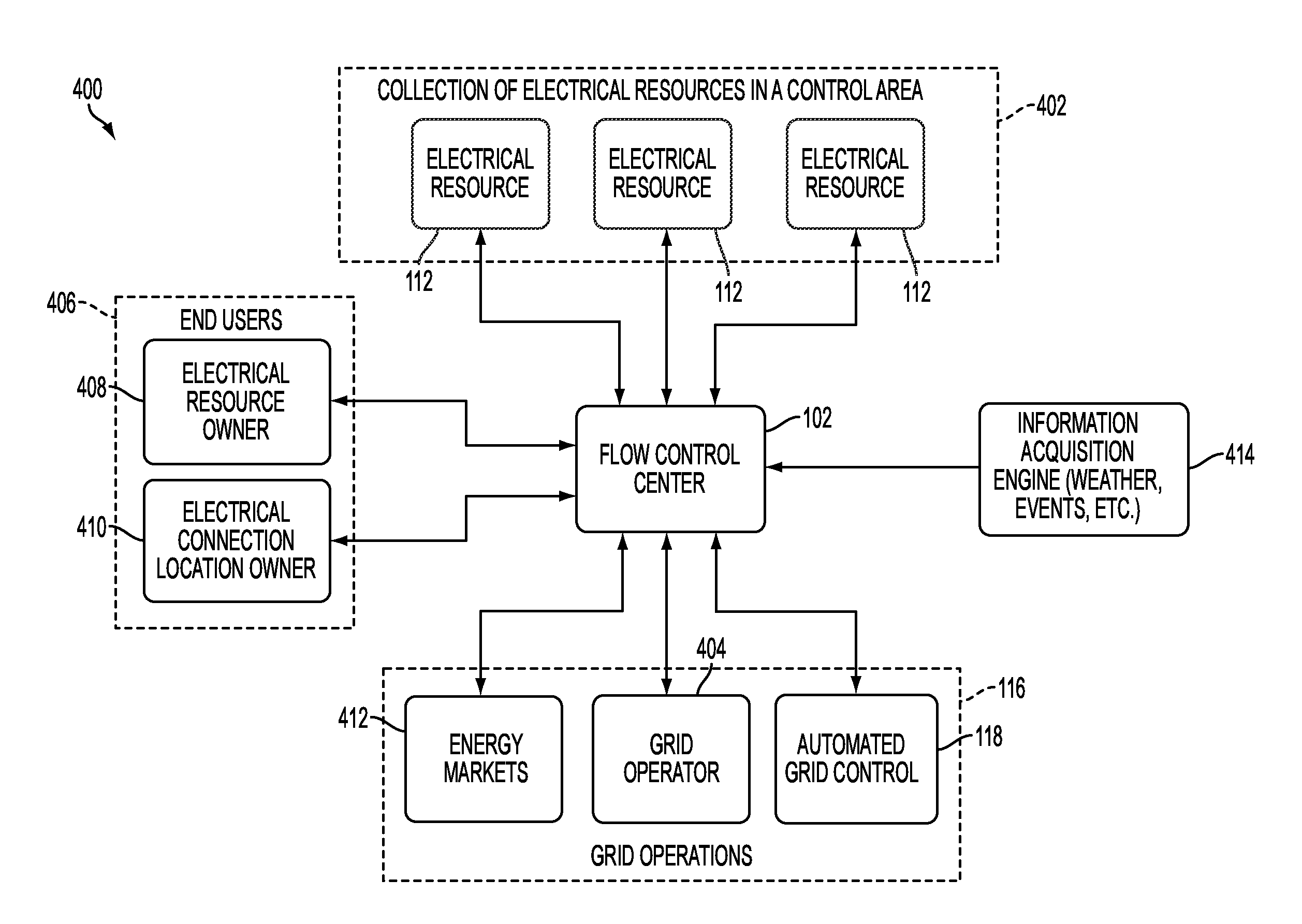

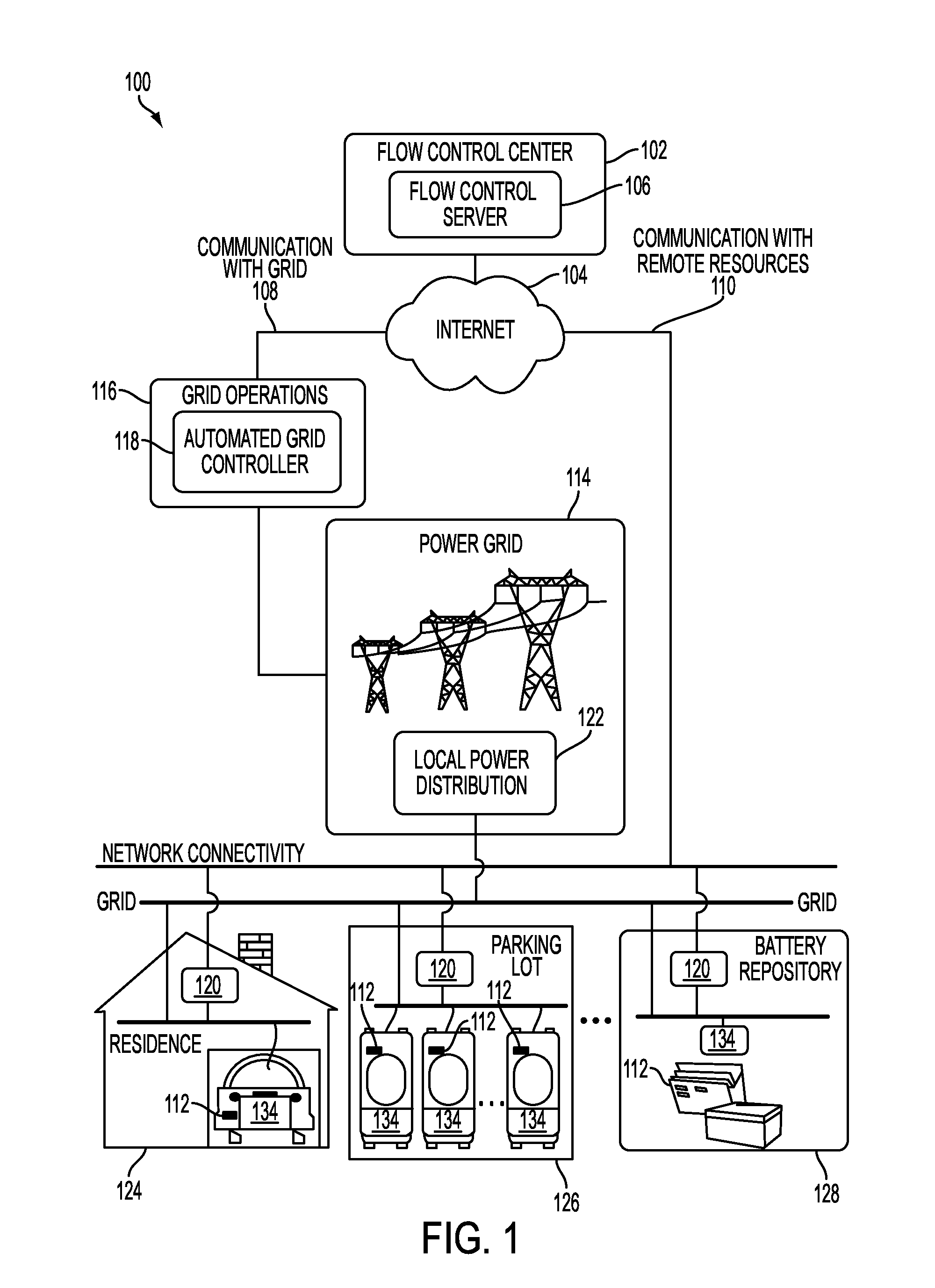

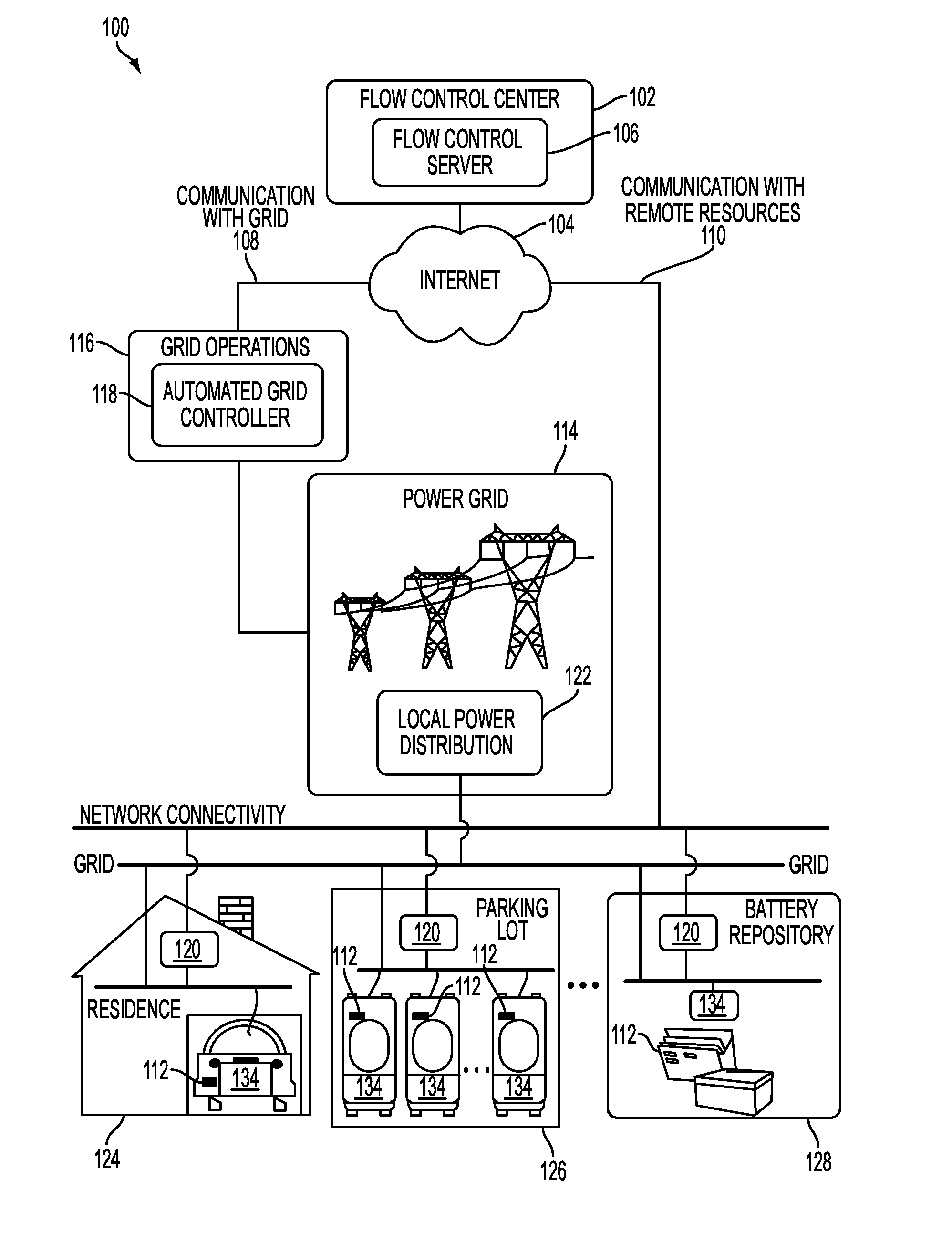

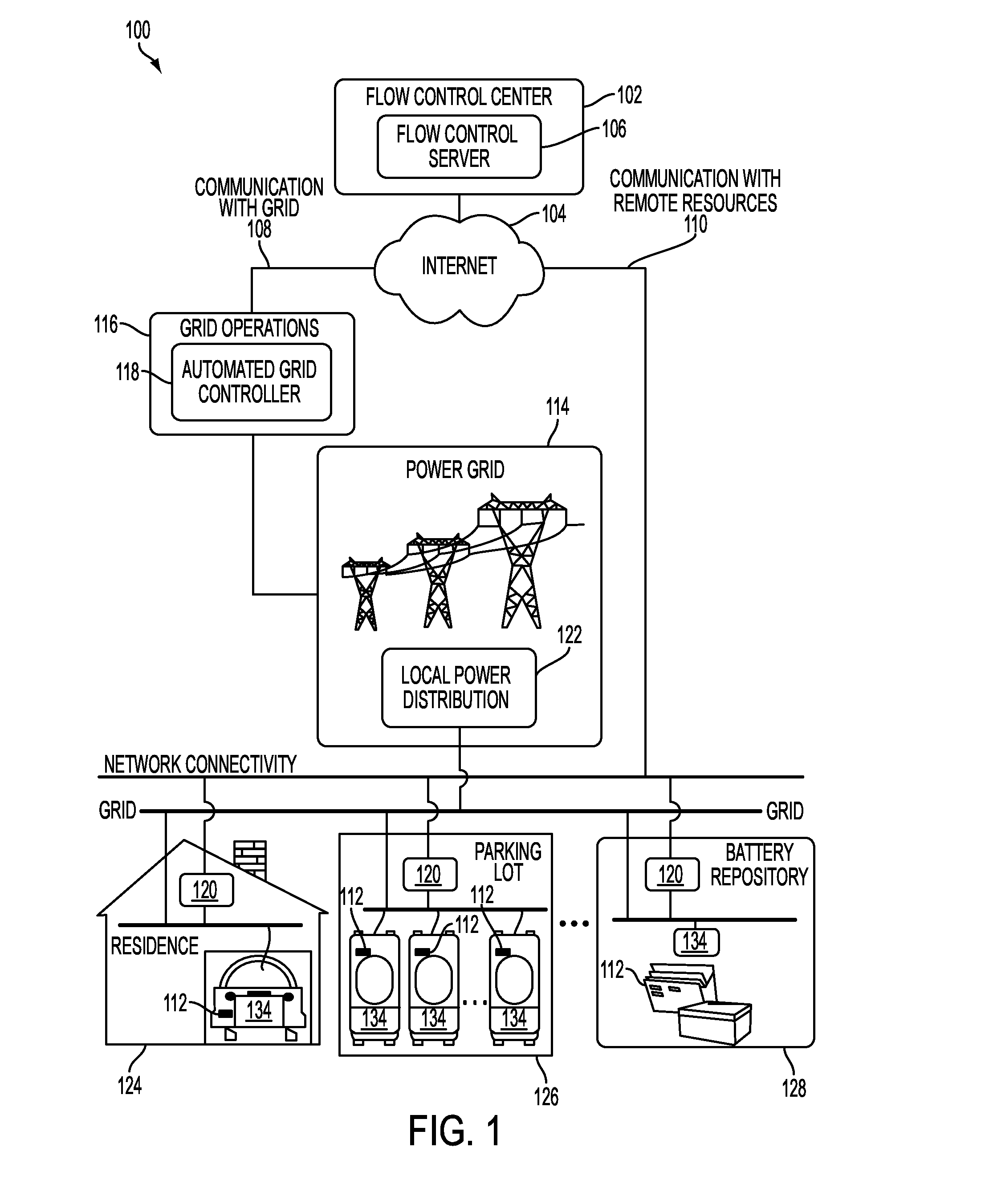

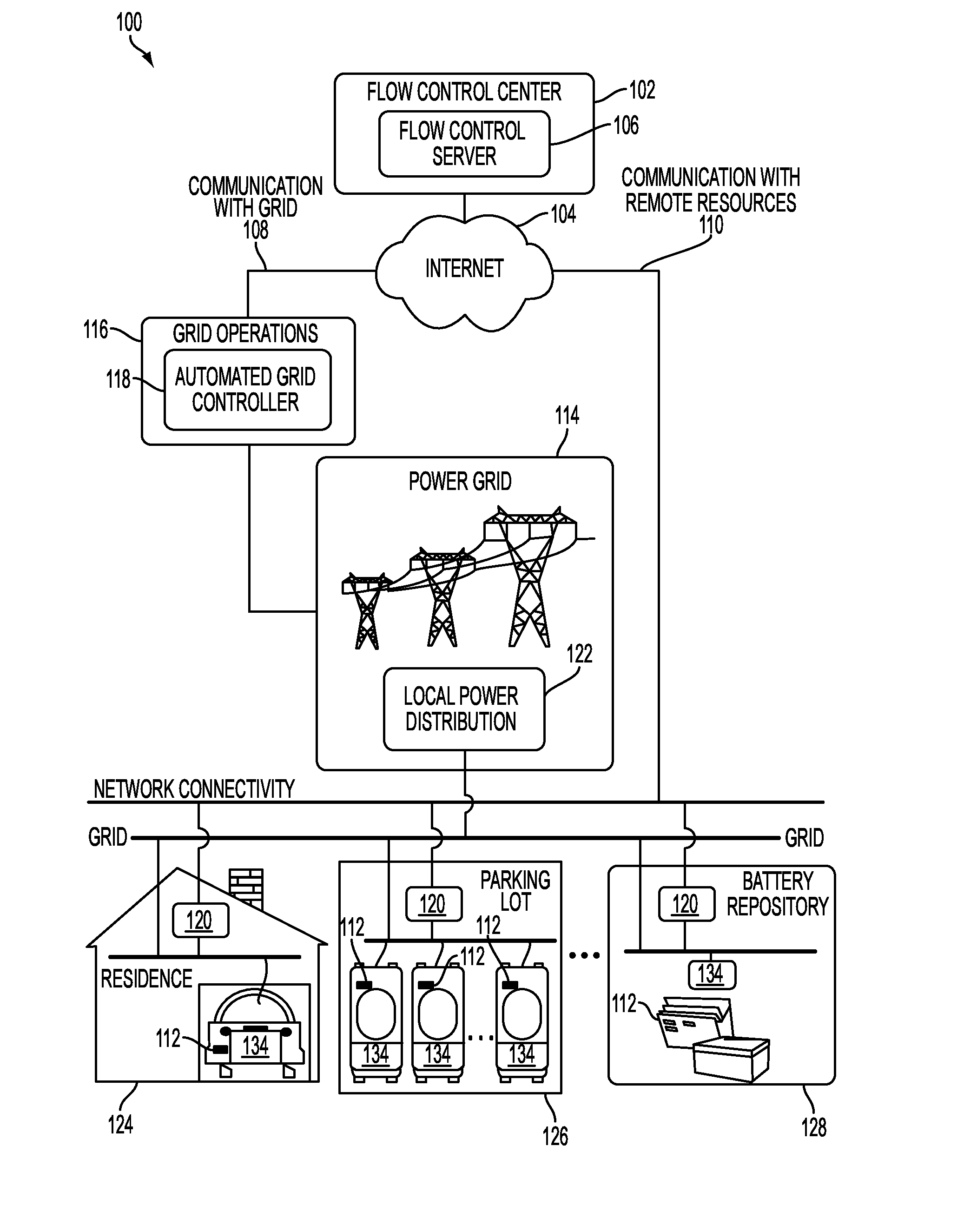

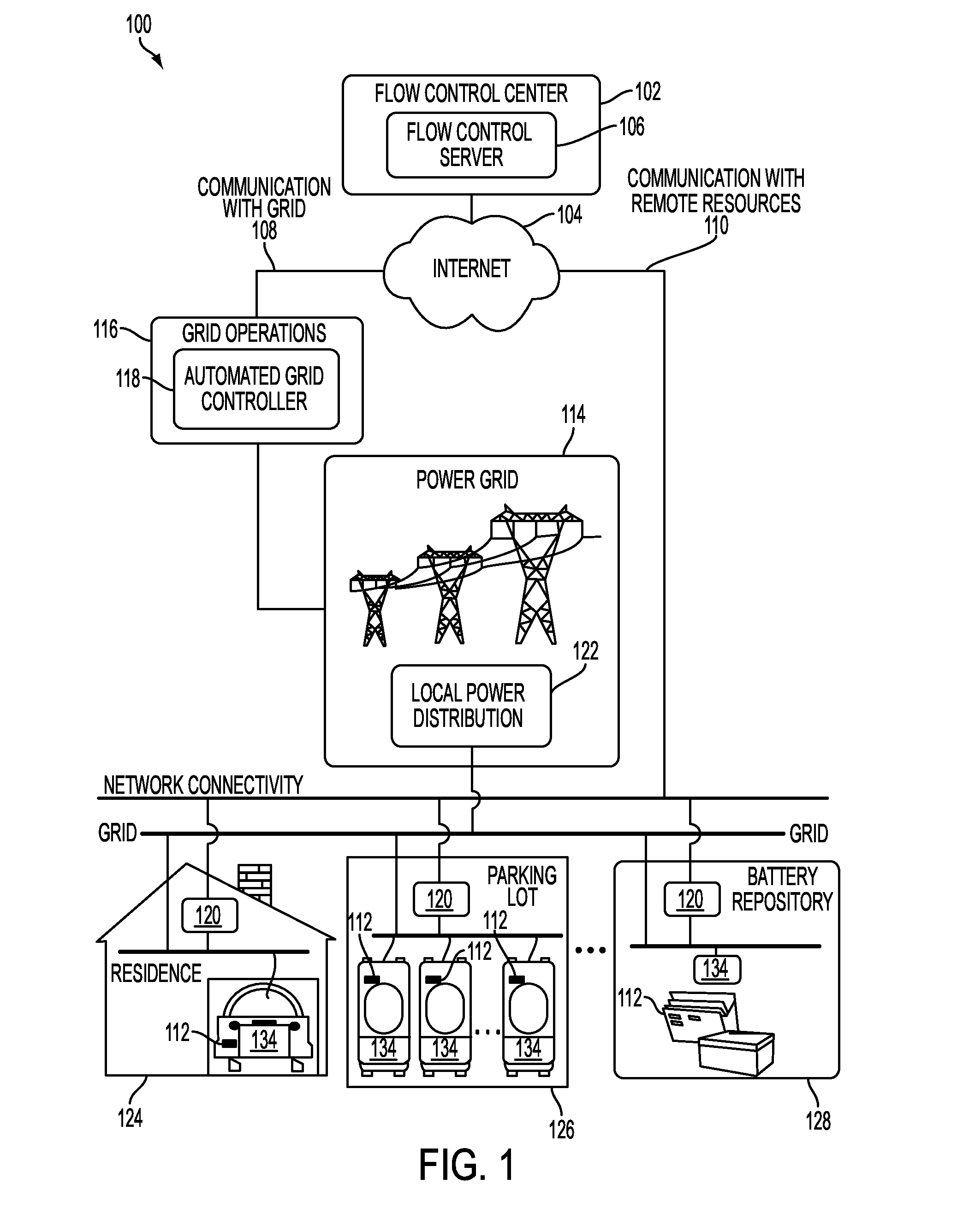

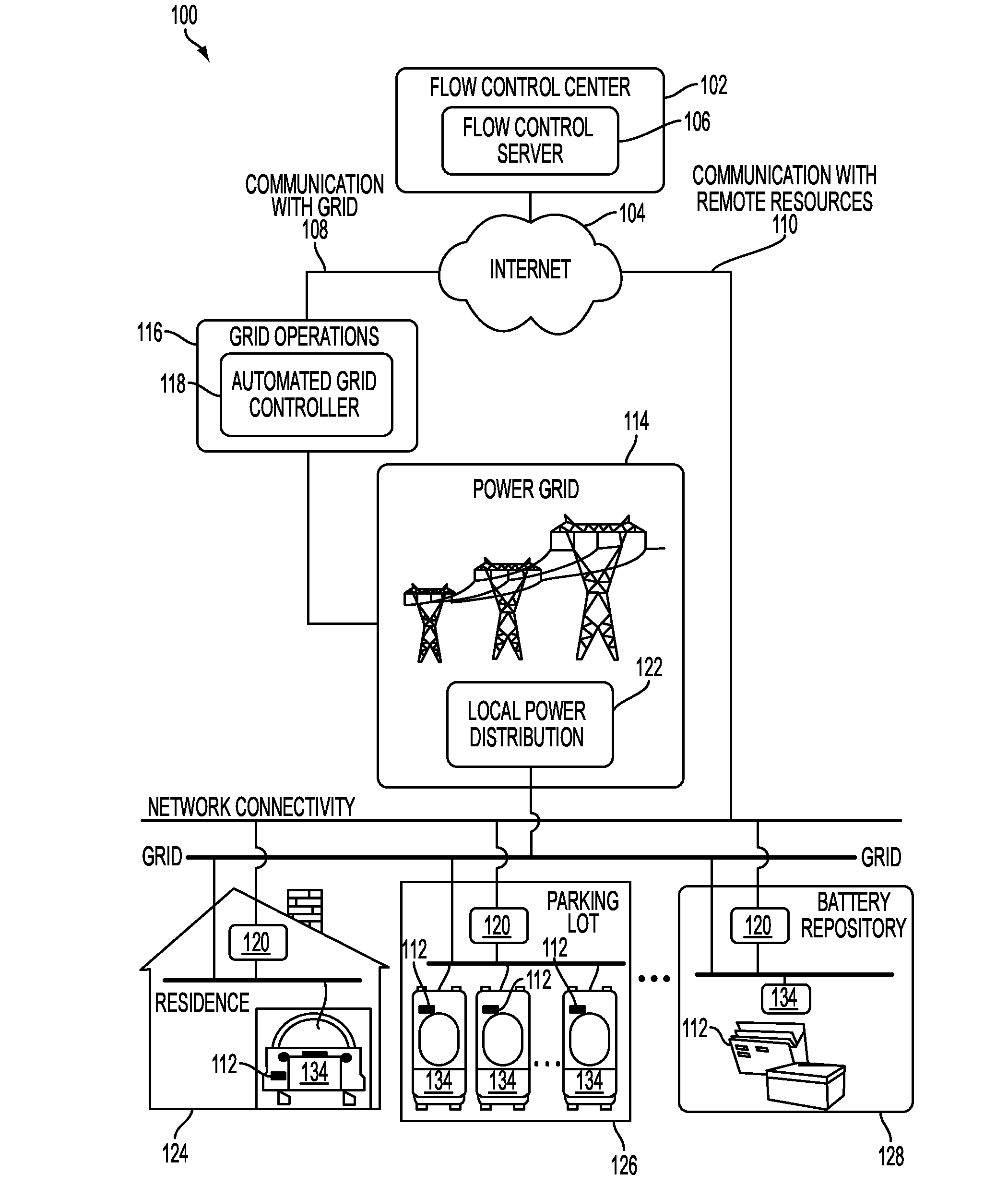

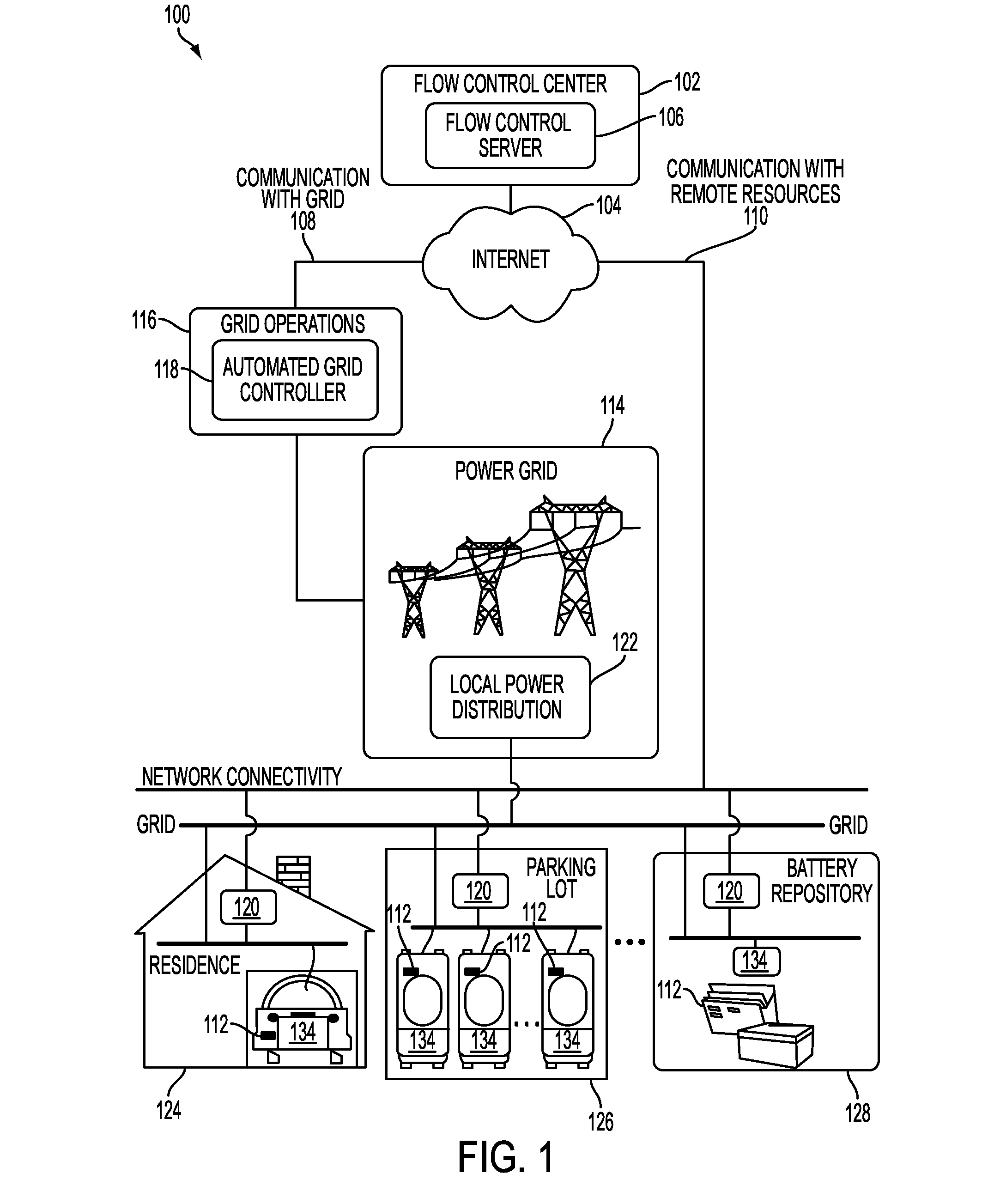

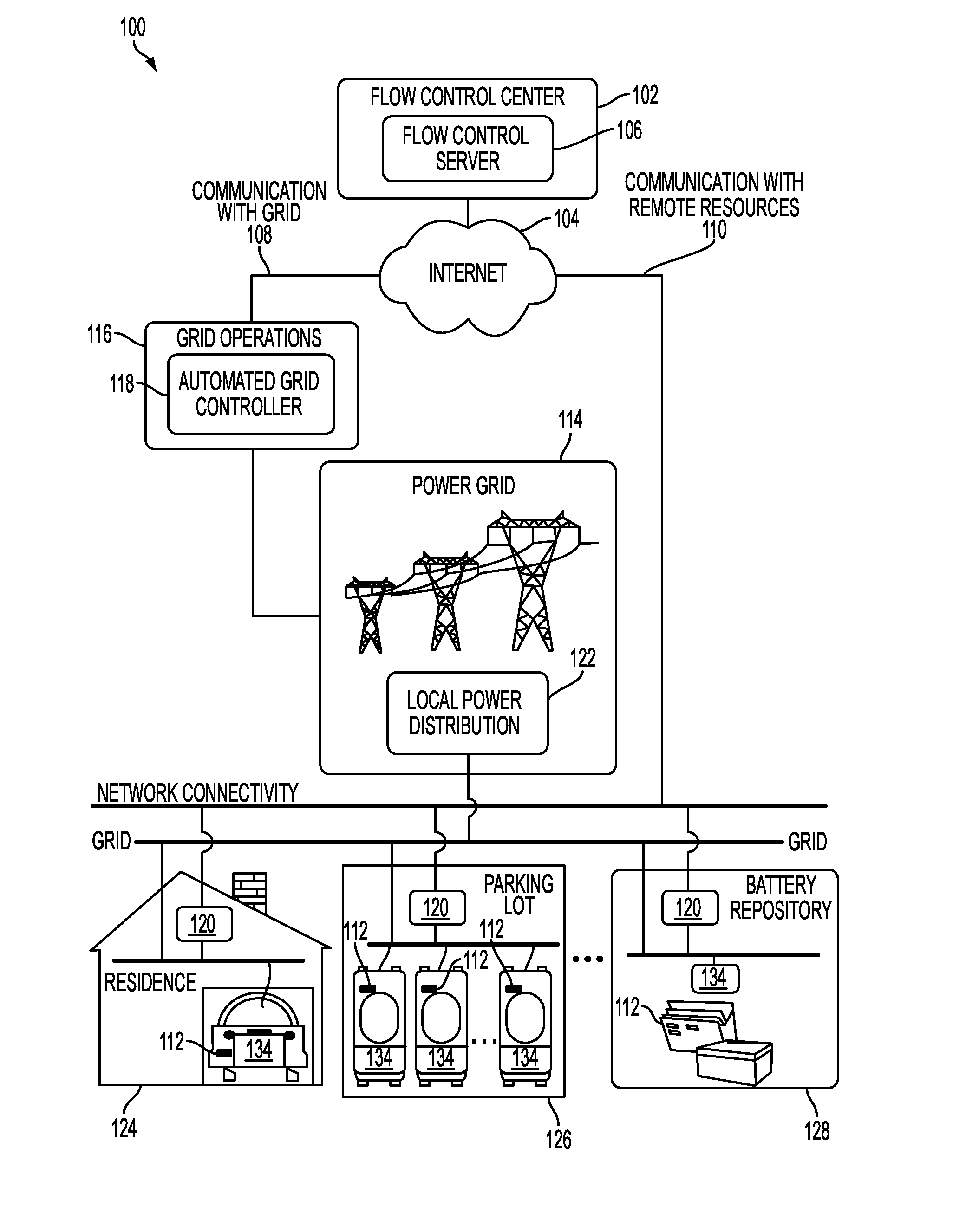

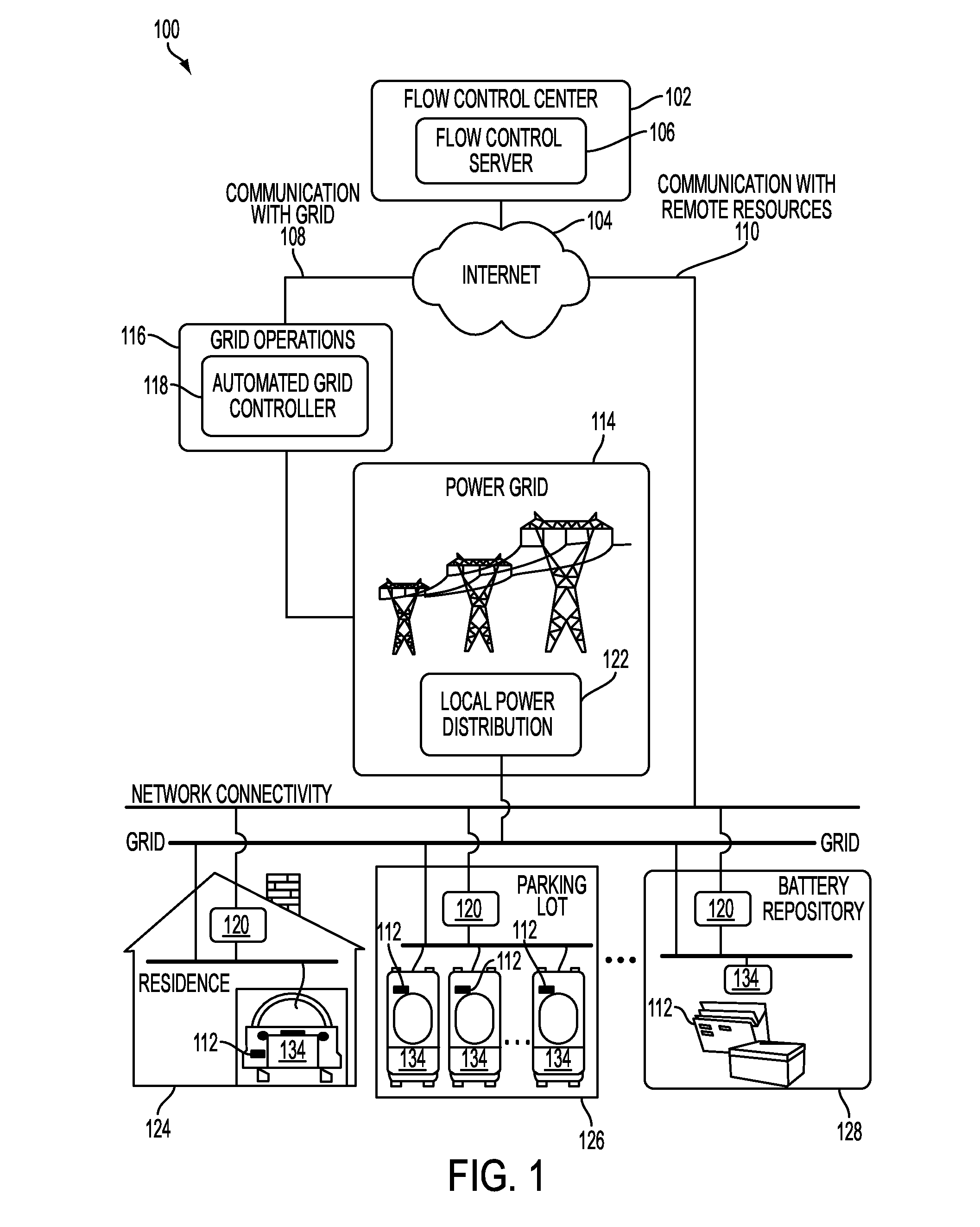

Systems and methods for electric vehicle grid stabilization

InactiveUS20110001356A1Fairness to the power resourcesMaximizing abilityBatteries circuit arrangementsSimultaneous control of electric and non-electric variablesControl powerPower flow

A system and methods that enables power flow management using AGC commands to control power resources. Power regulation can be apportioned to the power resources. An AGC command requesting an apportioned amount of the power regulation may be transmitted to a power resource. The power flow manager can determine a power regulation range for a power resource, and transmit an AGC command based on the power regulation range. In addition, a power flow management system can detect a change in an intermittent power flow and implement a power flow strategy in response to the change in the intermittent power flow. The power flow strategy may be a smoothing strategy or a leveling strategy.

Owner:GRIDPOINT

System and method for energy consumption management

InactiveUS9146548B2Save energyReduce carbon emissionsProgramme controlMechanical power/torque controlProcess engineeringEnergy management system

An energy management system and method providing a holistic premise energy optimization and energy efficiency reclamation system comprised of an interconnected system of software, analytics and automated process that optimizes the energy generation and storage technologies, energy consumption, energy demand and energy utilization of energy consuming assets within a premise.

Owner:INTELLIGENT ENERGY SOLUTIONS

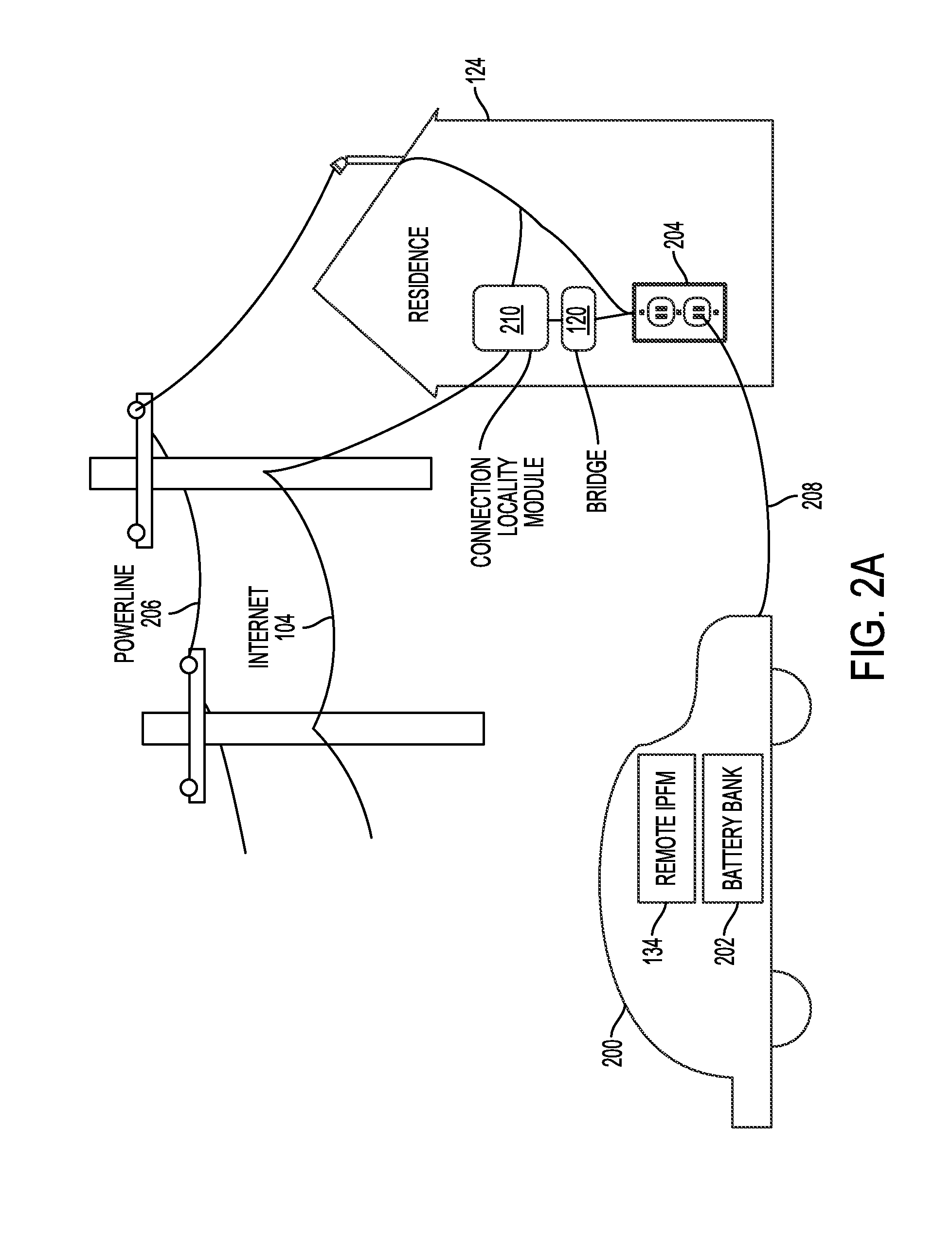

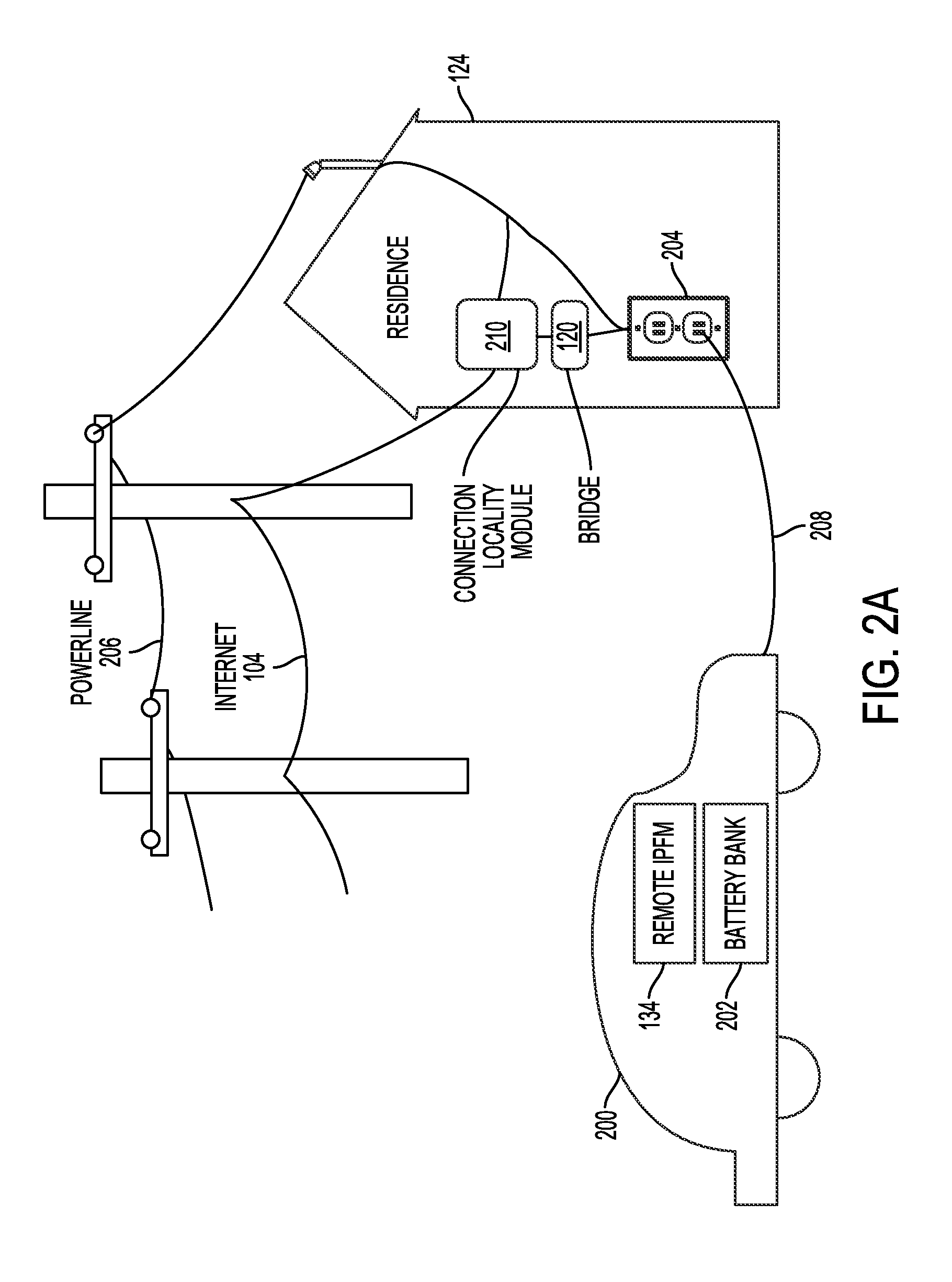

Systems and methods for electric vehicle power flow management

InactiveUS20110004358A1Low costBatteries circuit arrangementsLevel controlPower flowElectrical devices

Owner:GRIDPOINT

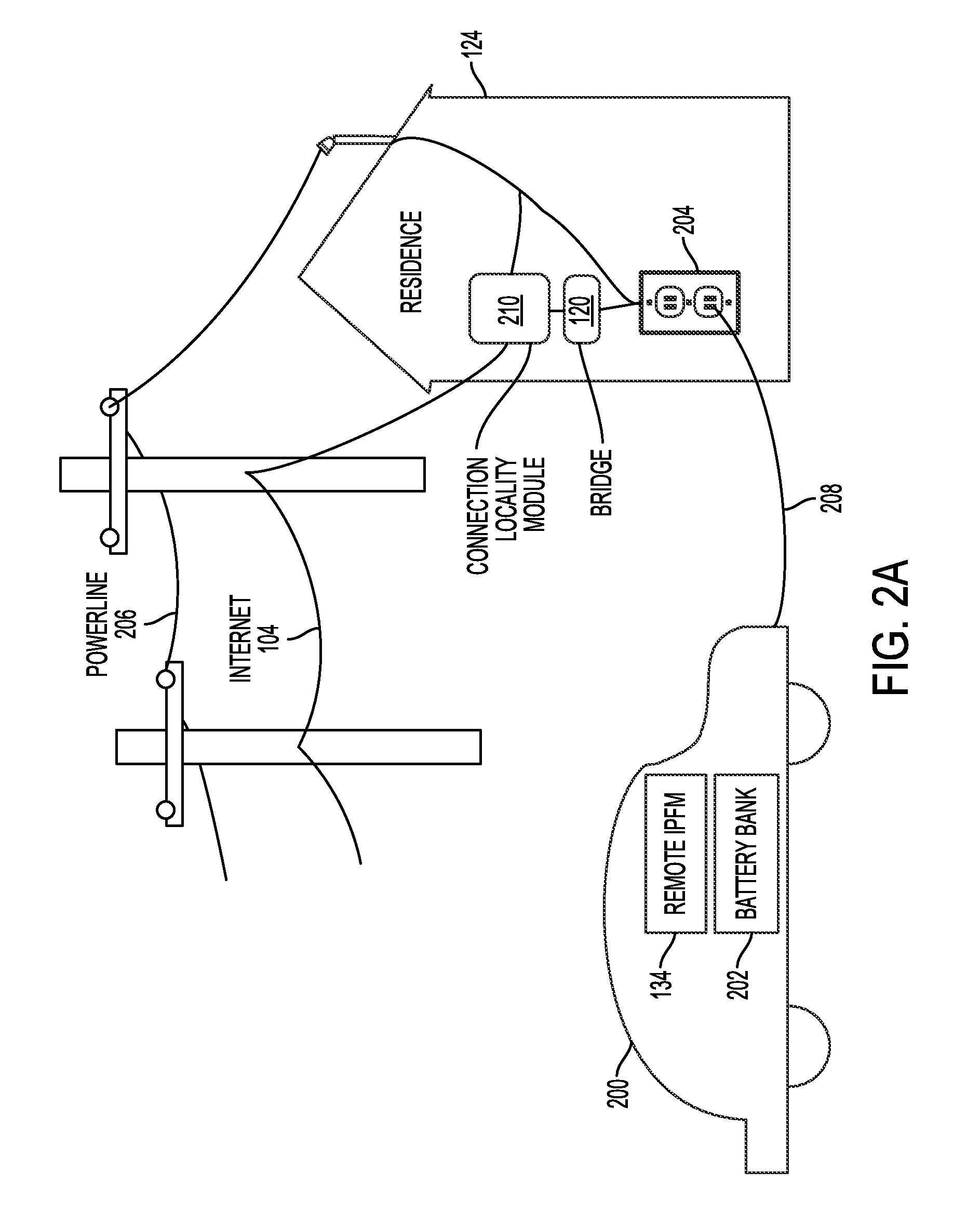

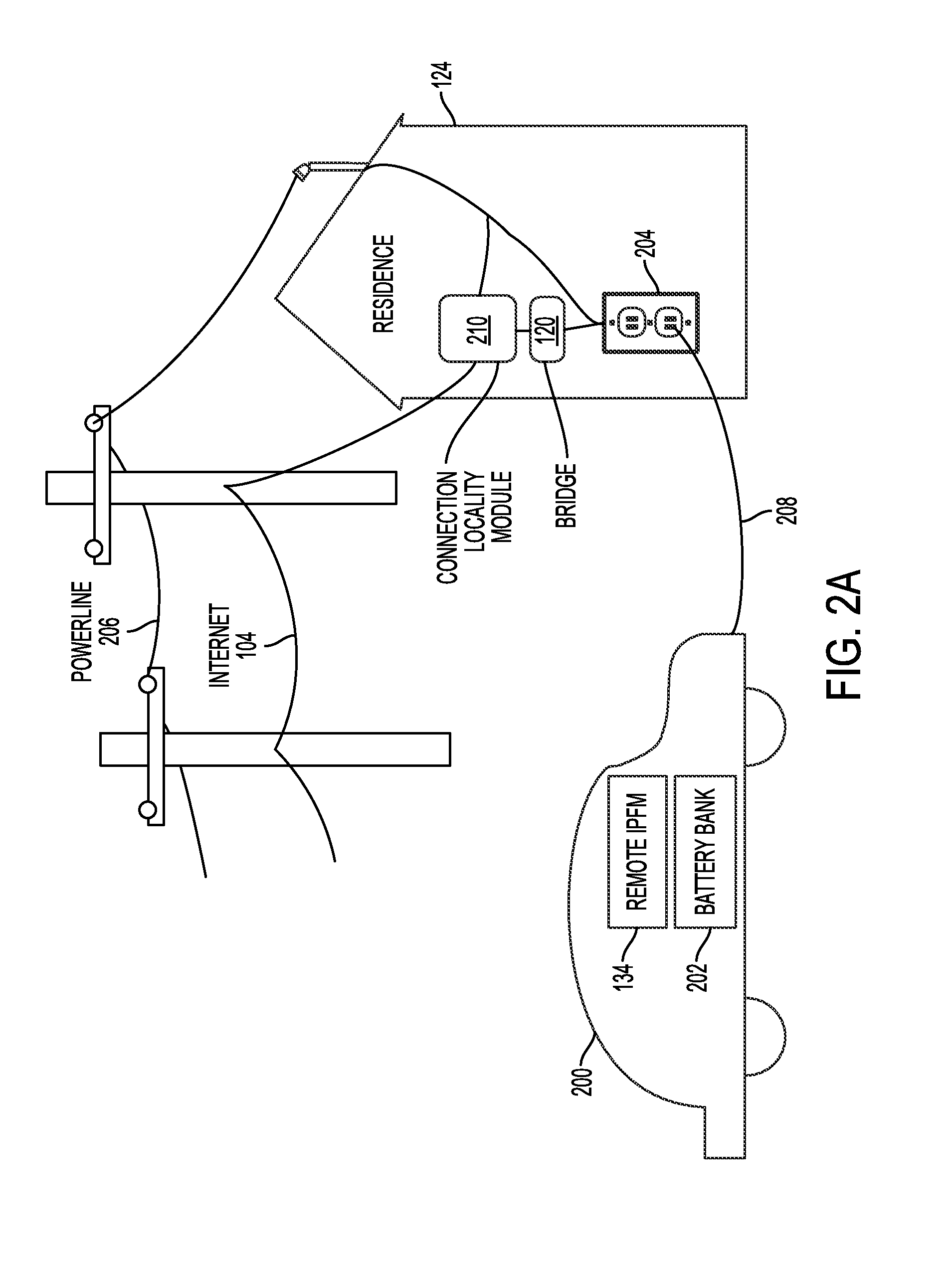

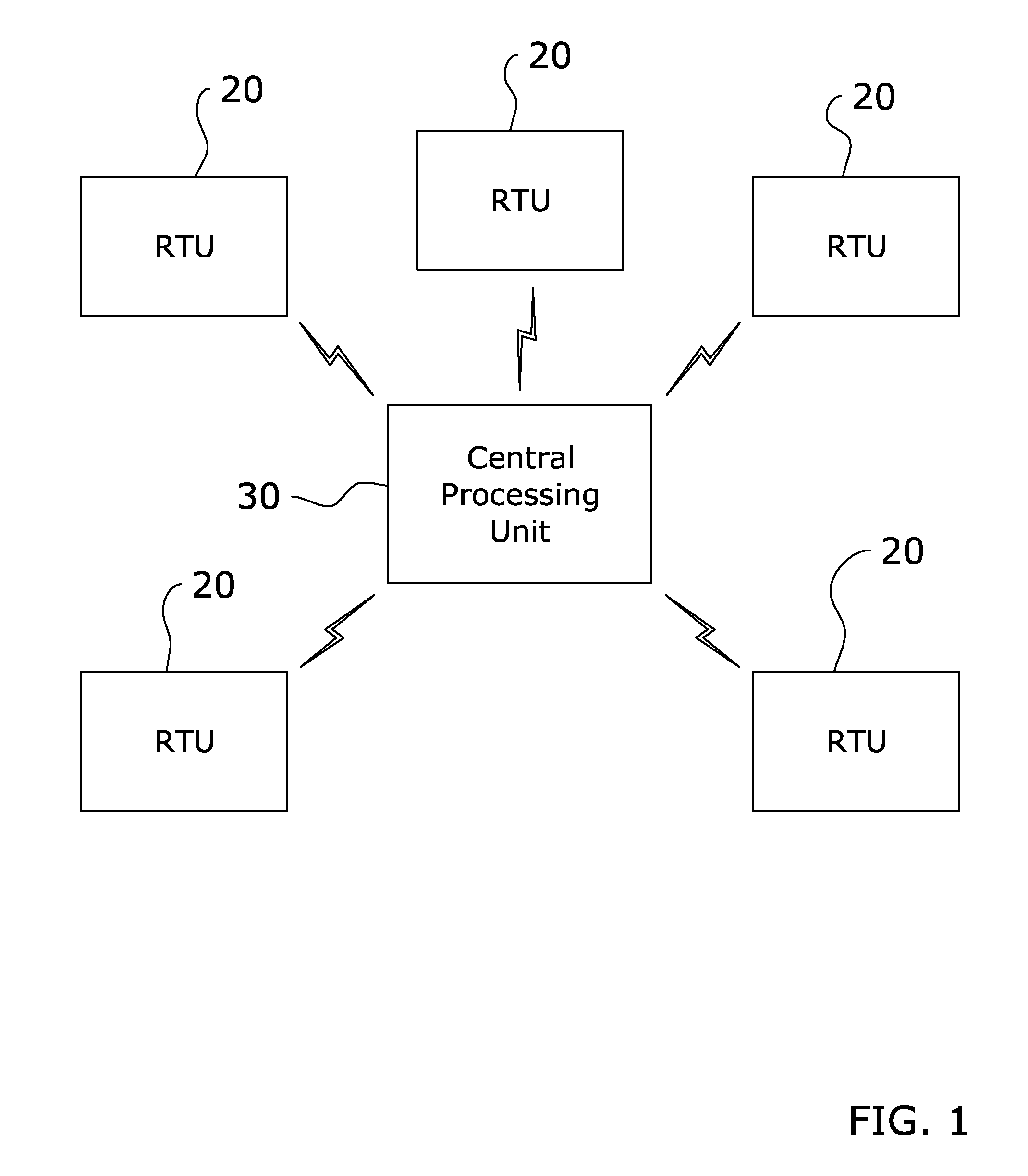

Vehicle communication systems and methods for electric vehicle power management

InactiveUS20110010043A1Reduce power consumptionModerate electrical loadVehicle testingBatteries circuit arrangementsElectric power transmissionExtensibility

A system and methods that enables enhanced vehicle communications for electric vehicle power management. In an embodiment, a system provides for communications in a power flow management system utilizing existing hardware including a smart charging module. In another embodiment, a communications module provides communication services to vehicle subsystems including a central processing unit in a vehicle and a CAN-bus transceiver. In yet another embodiment, an interface enables the installation of a charge controller for a control extensibility system including a physical interface to a vehicle's CAN-bus comprising an electrical contact plug. In an embodiment, an interface enables an electric vehicle to communicate with an electric power supply device without specific hardware by modulating the power transfer between the electrical load and an electric power supply. In another embodiment, a system provides for arbitrating a smart chargepoint includes a first smart charging module implemented on equipment located inside a vehicle.

Owner:GRIDPOINT

System communication systems and methods for electric vehicle power management

InactiveUS20110007824A1Reduce consumptionBatteries circuit arrangementsSimultaneous control of electric and non-electric variablesCommunications systemInternet traffic

Owner:GRIDPOINT

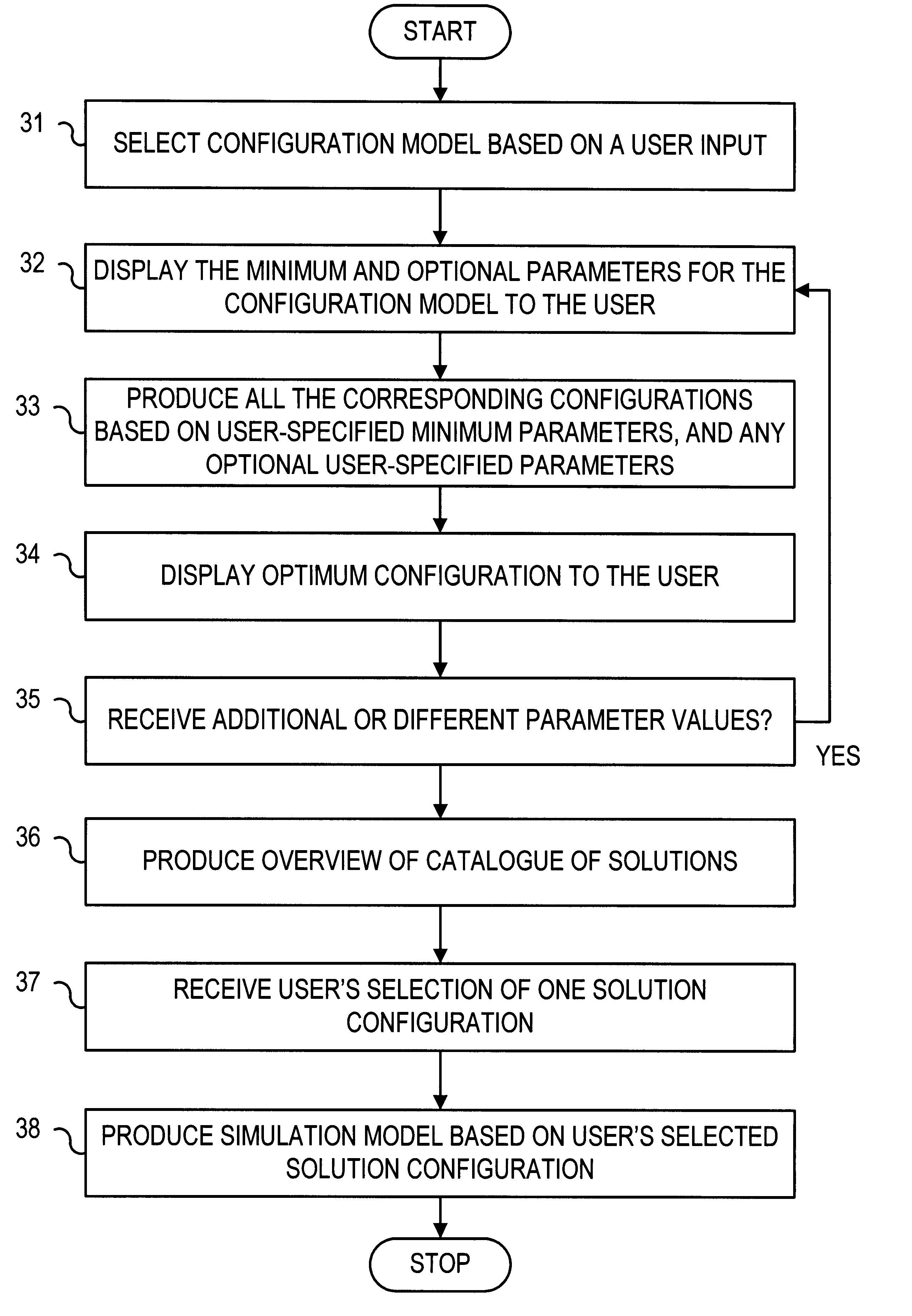

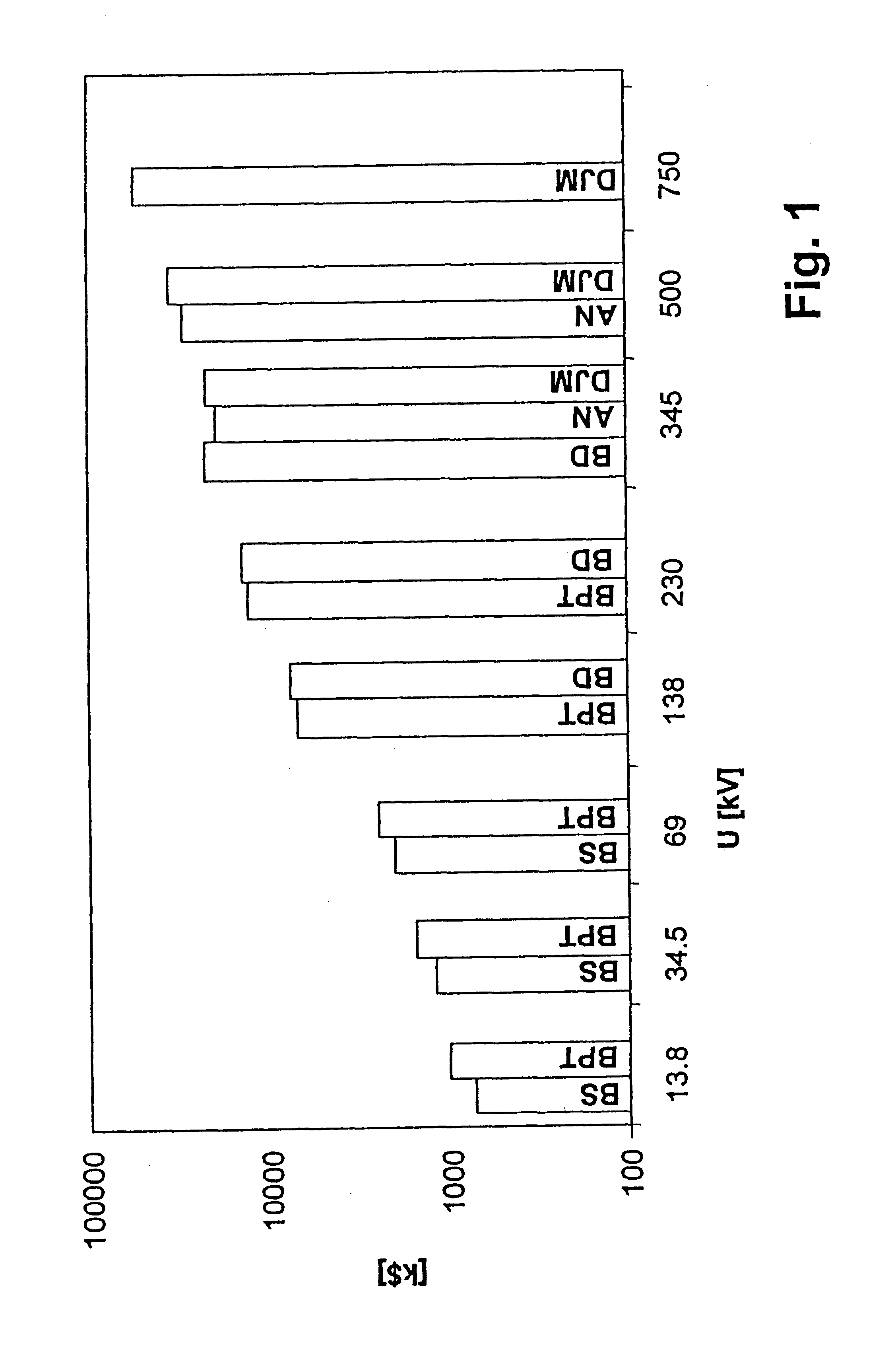

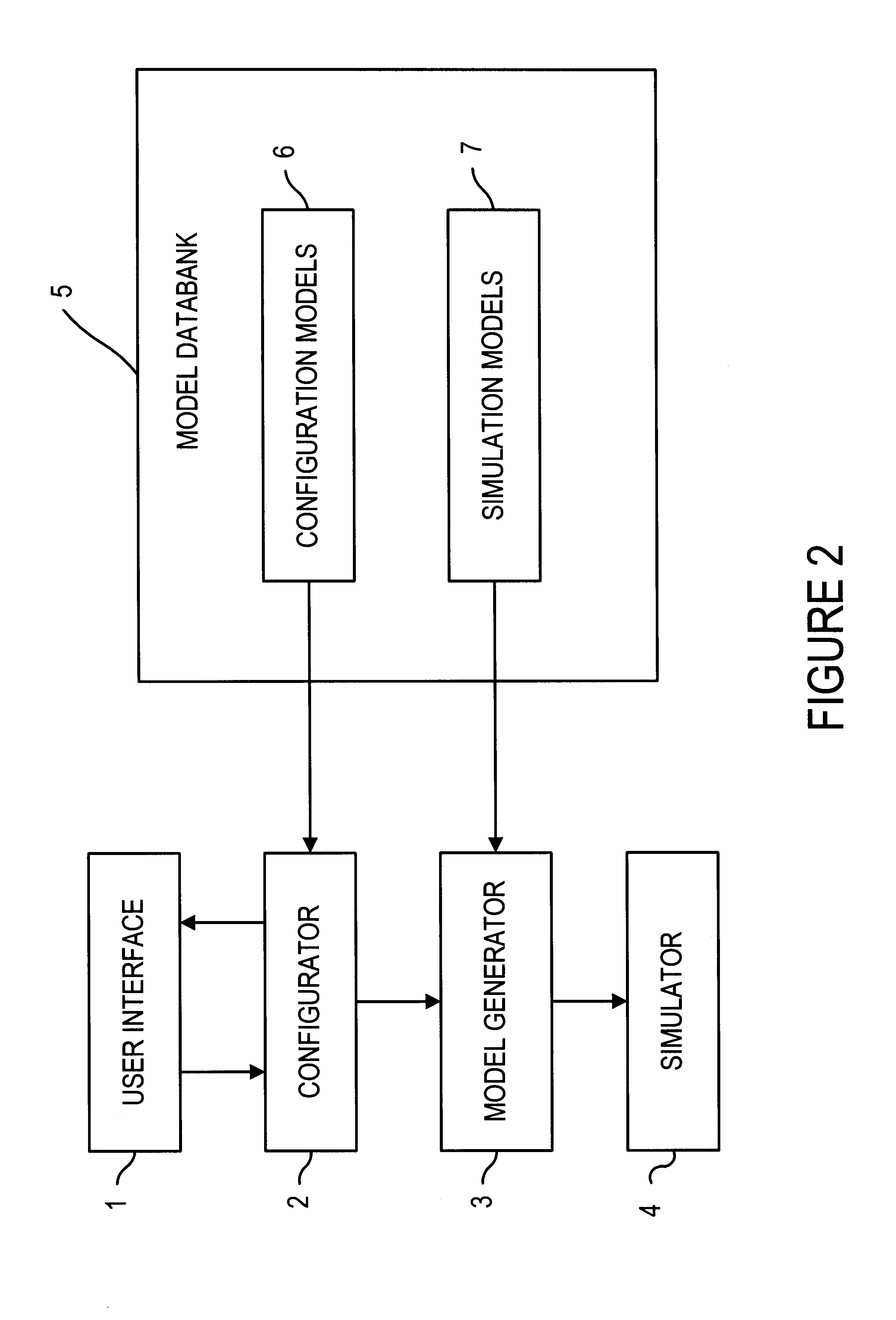

Configuration of a part of an electrical power distribution network

InactiveUS6885915B2Automatic productionSearch is limitedMechanical power/torque controlLevel controlSimulationElectric distribution network

The method according to the invention is based on a configuration model of a part of an electrical power distribution network, describing a totality of possible configurations of appliances. The configuration model is used to systematically produce (2) all the possible configurations which satisfy a predetermined set of functional requirements, in which case each possible configuration may have at least one associated characteristic value, and a solution configuration is defined which optimizes this characteristic value. It is thus possible to produce an optimum configuration automatically, without any need for expert knowledge about the appliances used in the configuration. In one preferred embodiment of the invention, a simulation model for simulation of a technical response of the solution configuration is produced automatically (3). It is thus possible to test one or more solution configurations by simulations (4), without any need for expert knowledge about the characteristics and simulation models of the appliances used in the solution configuration.

Owner:ABB RES LTD +1

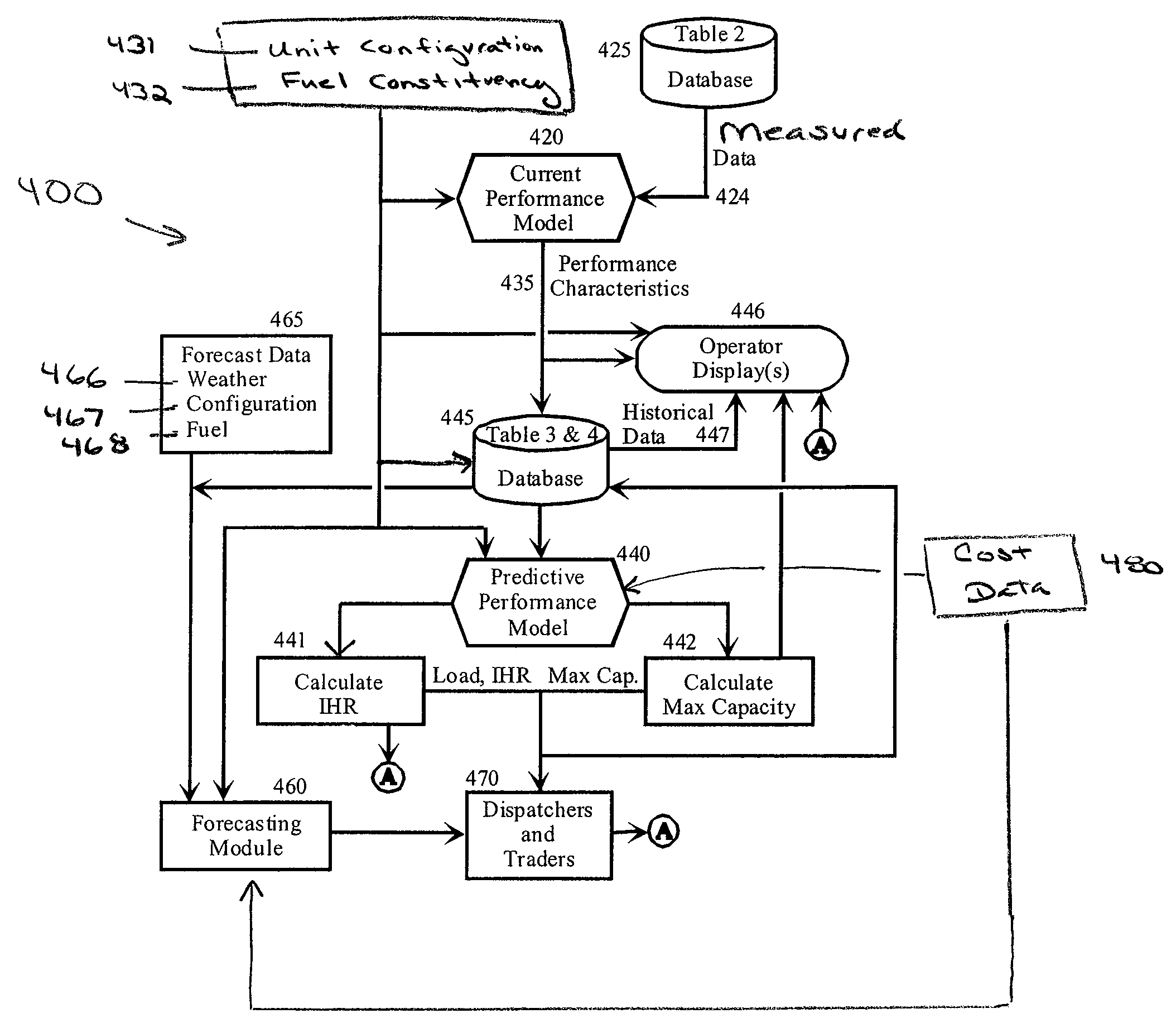

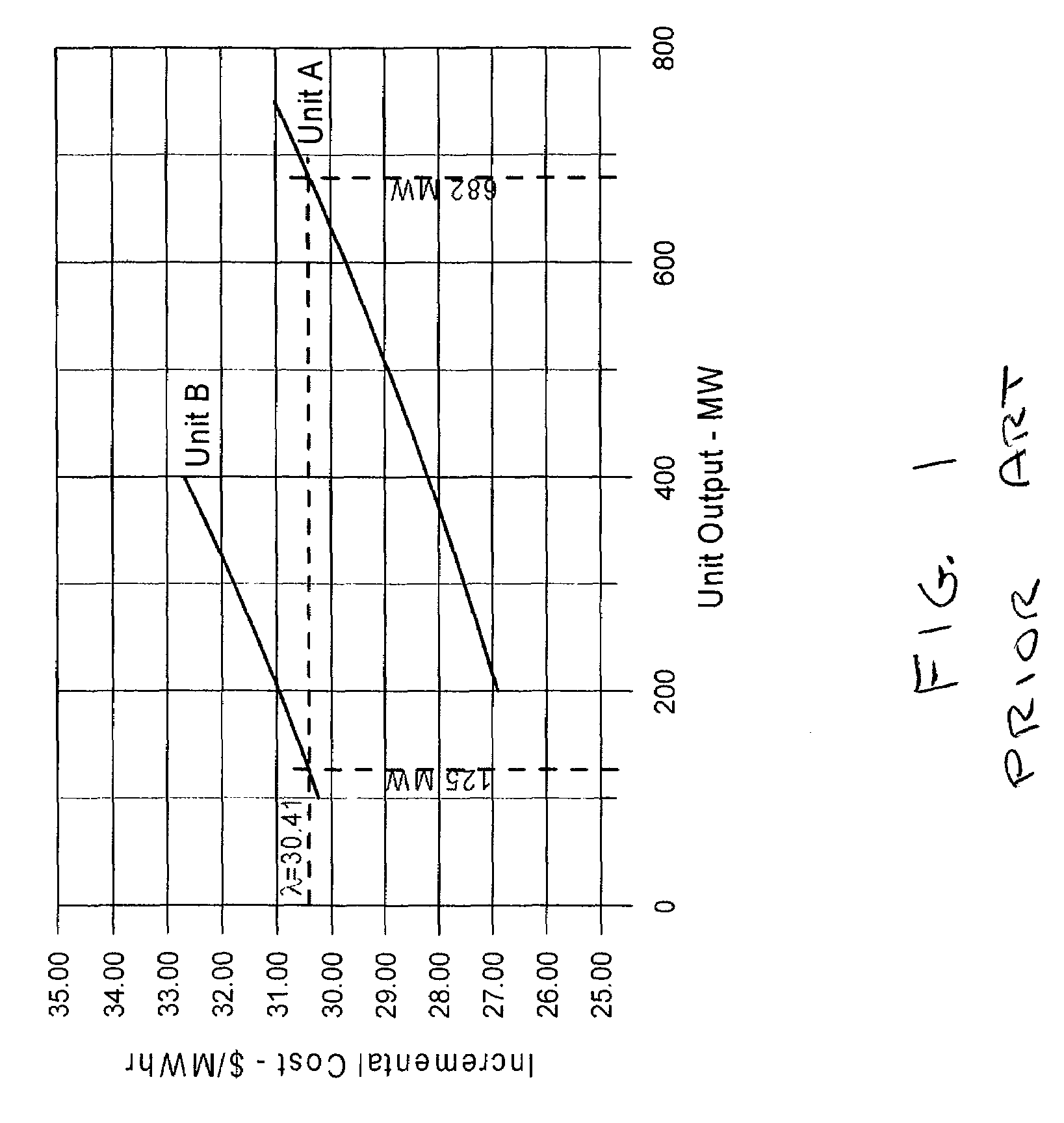

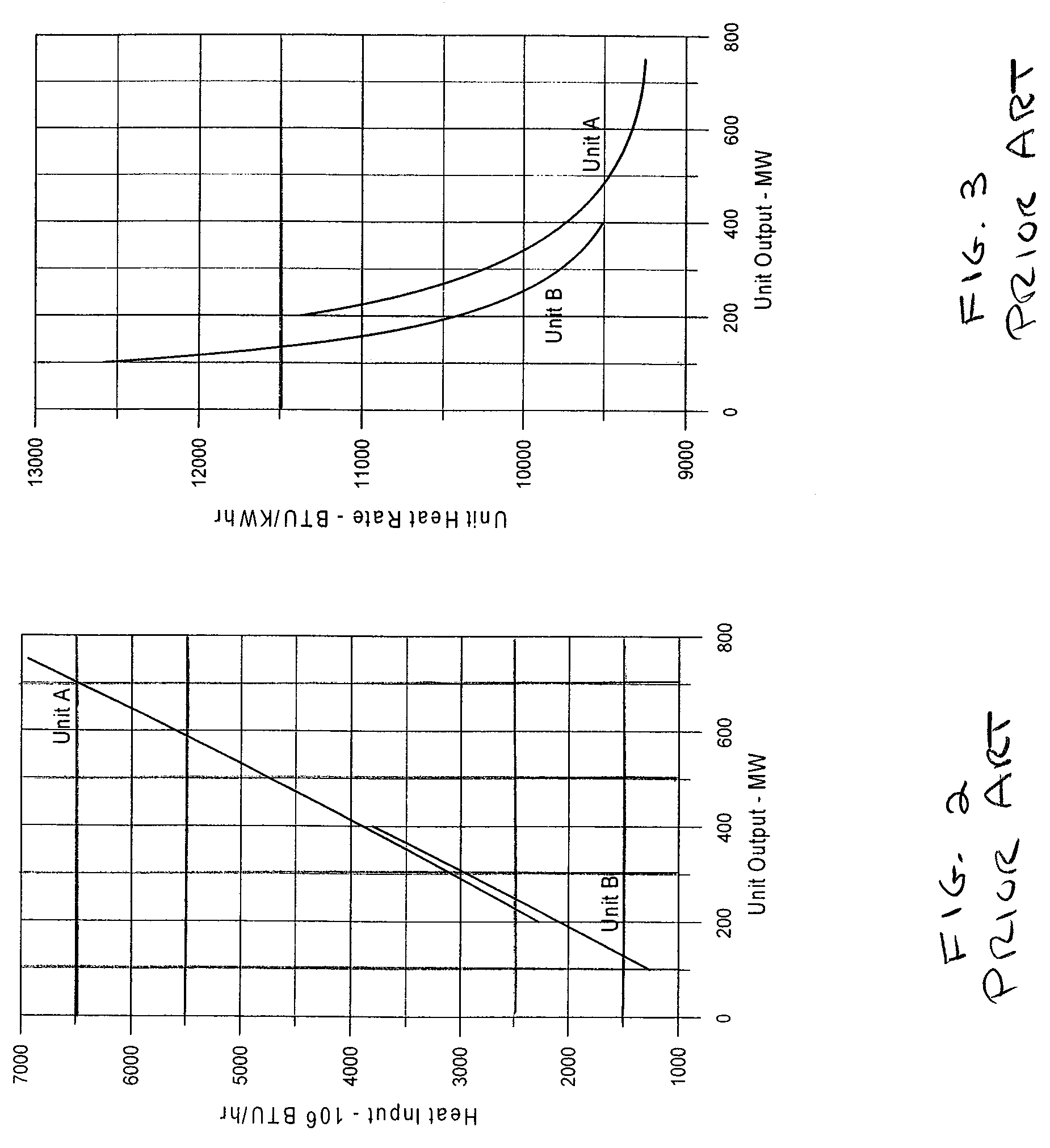

Systems and methods for calculating and predicting near term production cost, incremental heat rate, capacity and emissions of electric generation power plants based on current operating and, optionally, atmospheric conditions

Systems and methods for calculating and predicting performance characteristics, incremental heat rate, capacity, incremental costs, production cost and emissions, for electric power generation plants, and in particular, those that use steam and gas-turbine prime movers. The system includes models and modules for calculating current unit performance and predicting unit performance, including the incremental heat rate and maximum capacity, using unit operating parameters, unit configuration data, and fuel constituency data. The system further includes a module for forecasting or predicting unit performance and cost information, by allowing the user to alter unit configuration and fuel constituency data to model planned maintenance and projected fuel changes, and to account for anticipated atmospheric conditions.

Owner:FEHR STEPHEN L +1

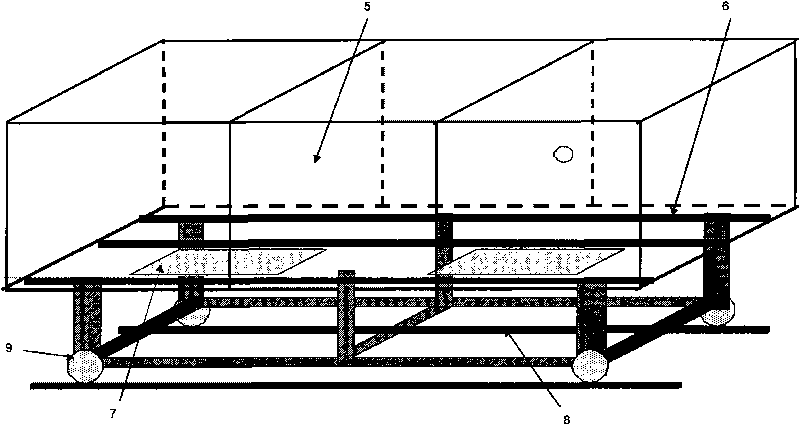

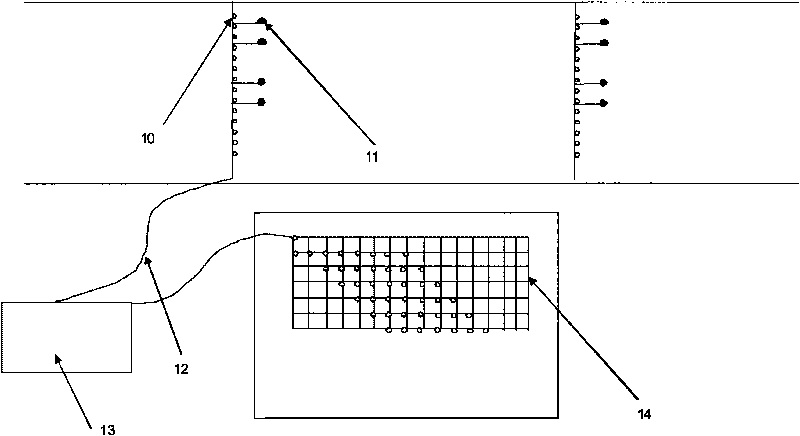

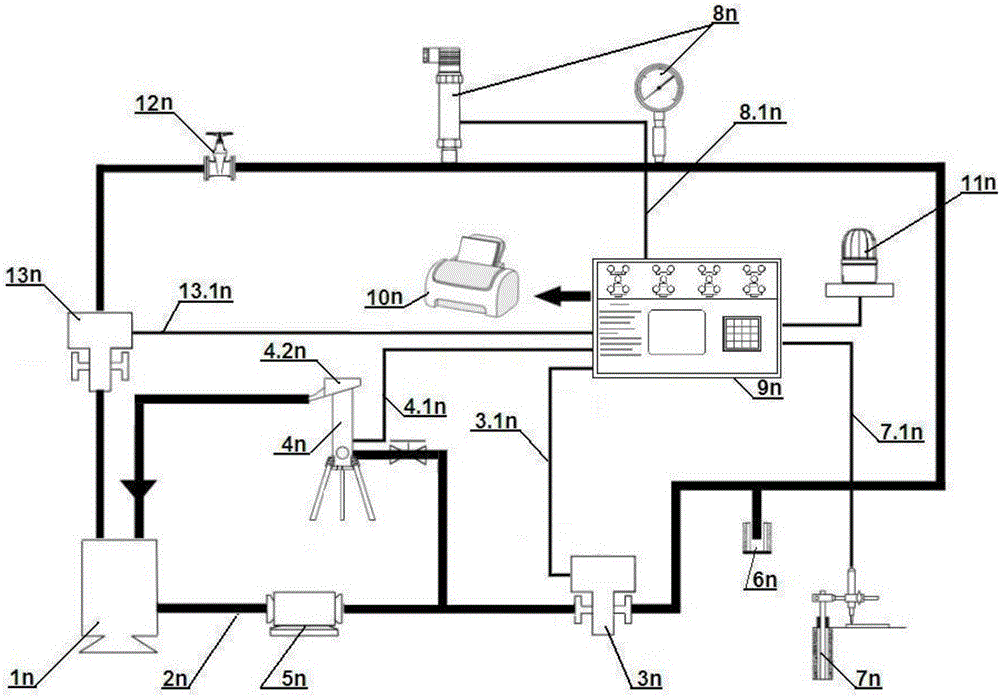

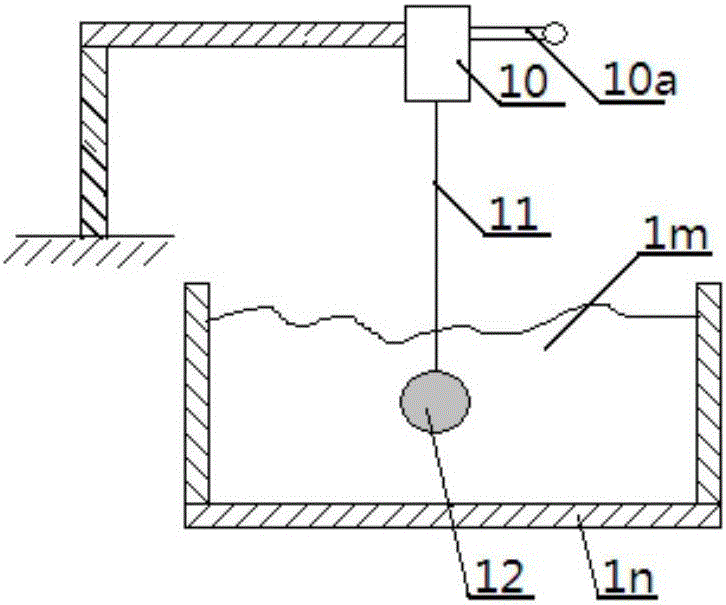

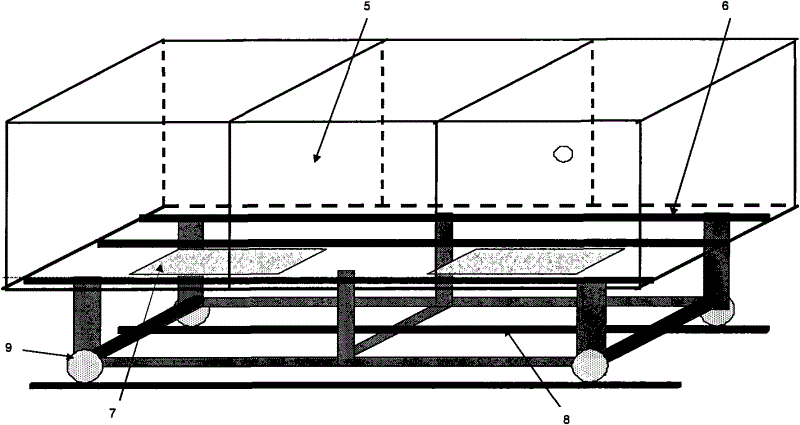

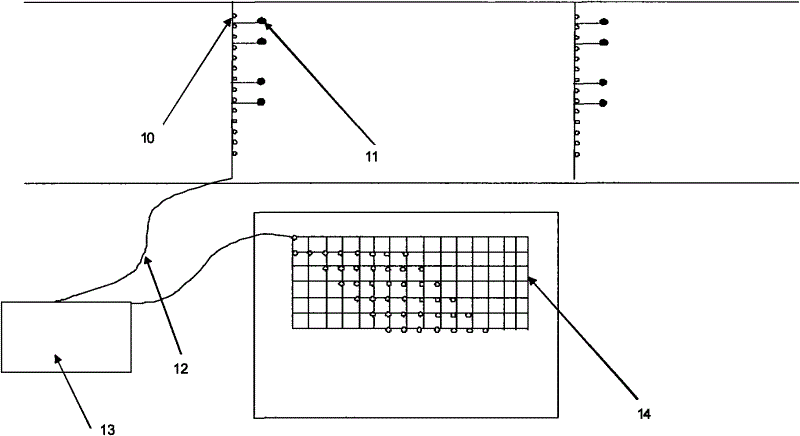

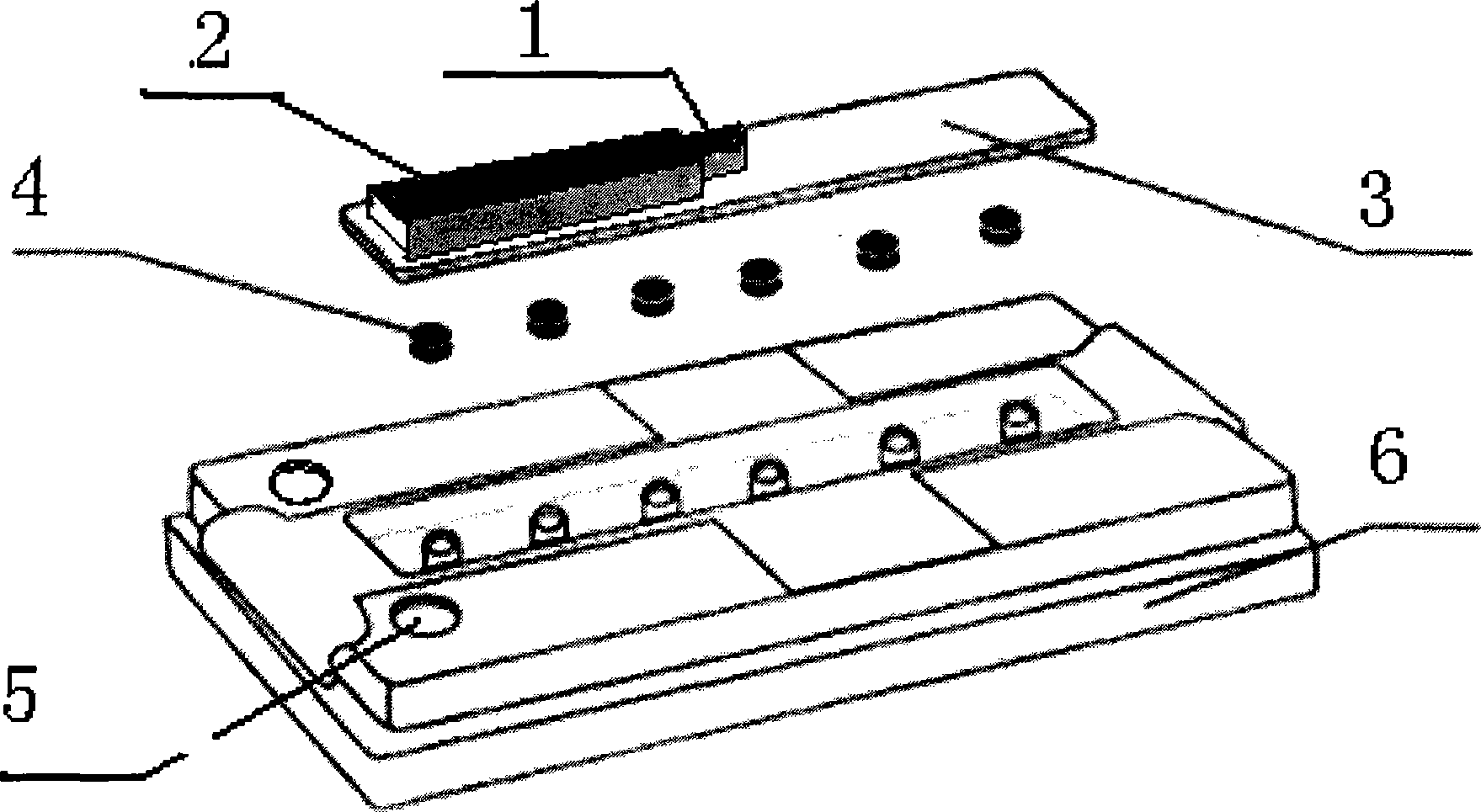

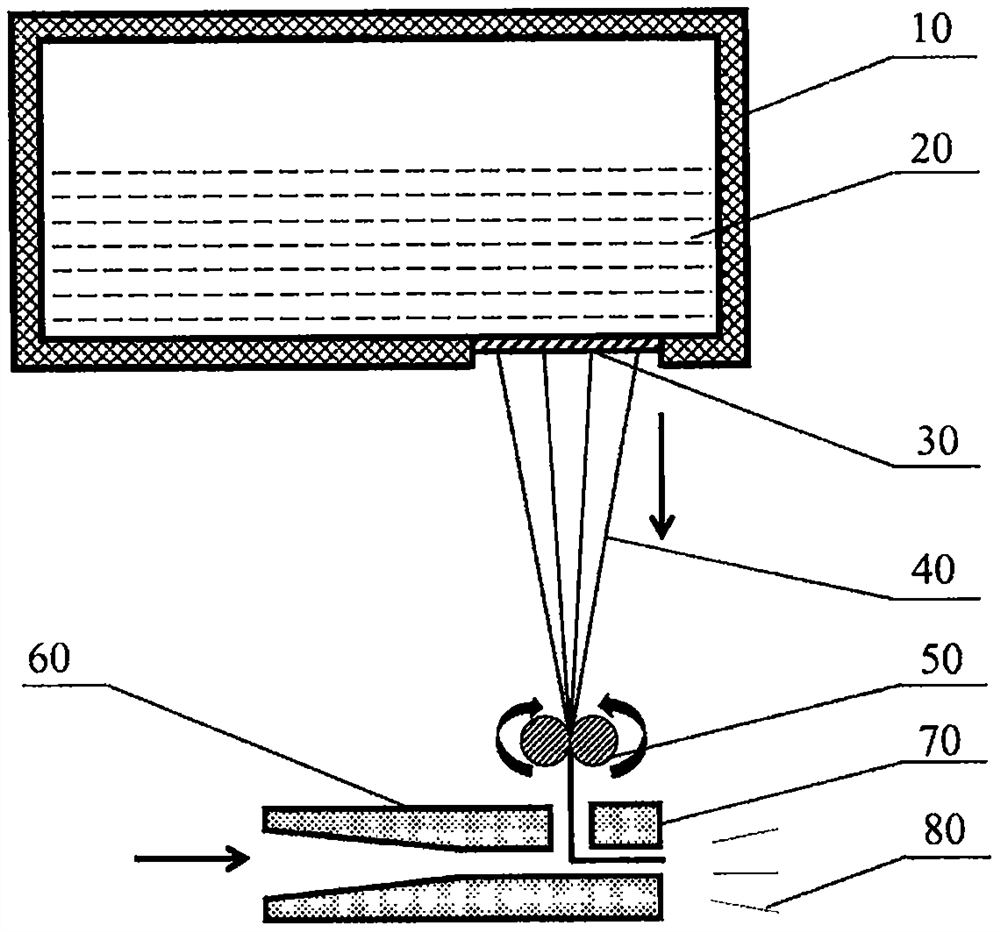

Fire simulation experiment platform for tunnel

InactiveCN101726370AImprove visibilityEasy to observe effectivelySimultaneous control of electric and non-electric variablesAerodynamic testingVisibilityControl system

The invention discloses a fire simulation experiment platform for a tunnel, which comprises a platform main body, a smoke control system, a fire source simulation system and a matched measurement and control system, wherein the platform main body can move horizontally, and at least two of the front surface, the upper surface and the back surface of the platform main body are made of fire-proof transparent materials; the smoke control system can simulate longitudinal wind in the tunnel; the fire source simulation system comprises a porous gas burner capable of controlling fuel flow rate; and the matched measurement and control system comprises a gas component measuring system and a smoke temperature measuring system, wherein the gas component measuring system is used for measuring gas components of burning products, and the smoke temperature measuring system is used for measuring the temperature in the tunnel. In the invention, the fire simulation experiment platform for the tunnel enables the inside of a simulated tunnel to have good visibility, can be used for conveniently and effectively observing the conditions in the tunnel and optically measuring the characteristics of the flow field through laser sheets, and can also realize the purpose of controlling the power of the fire source according to research needs.

Owner:UNIV OF SCI & TECH OF CHINA

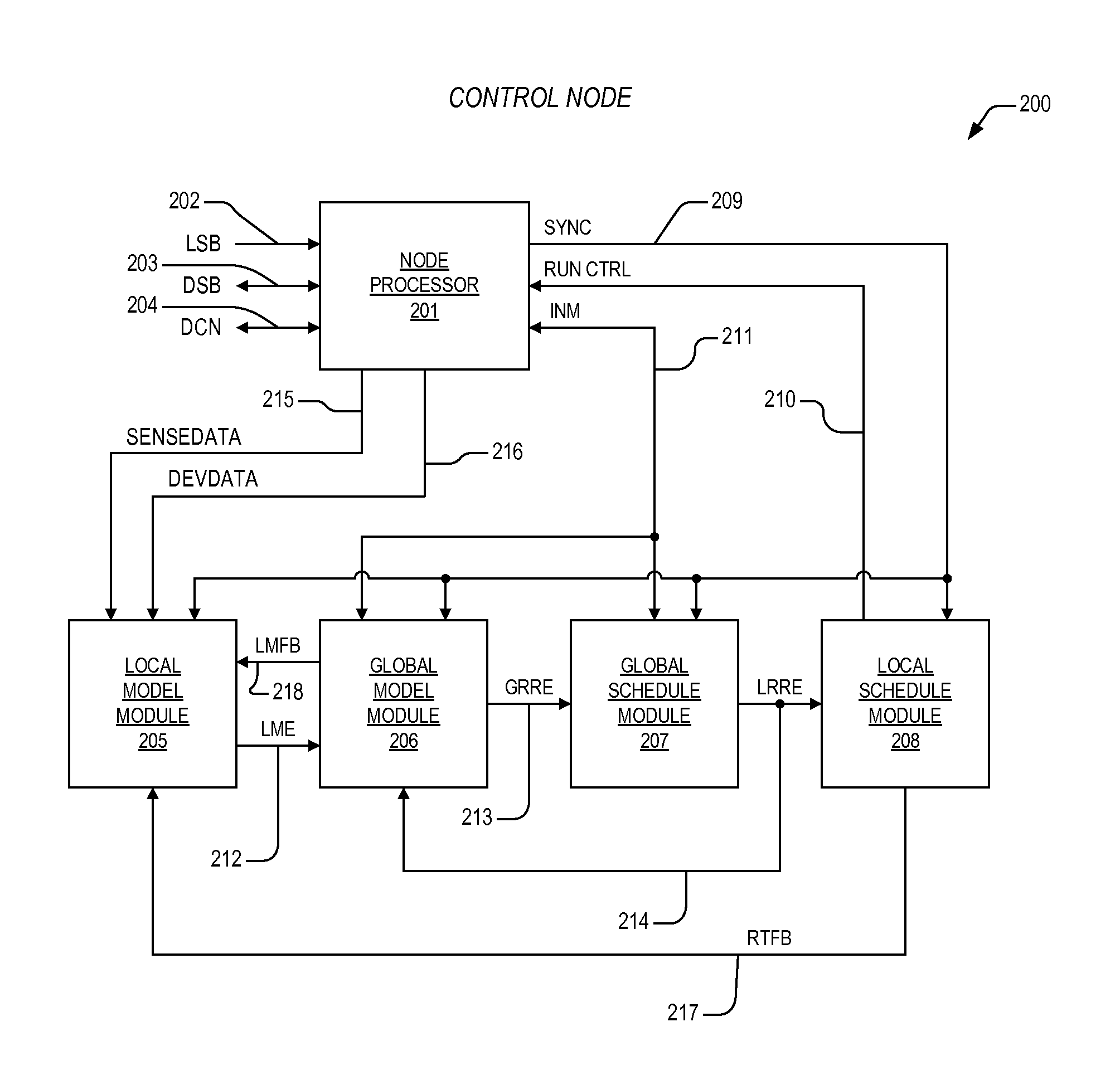

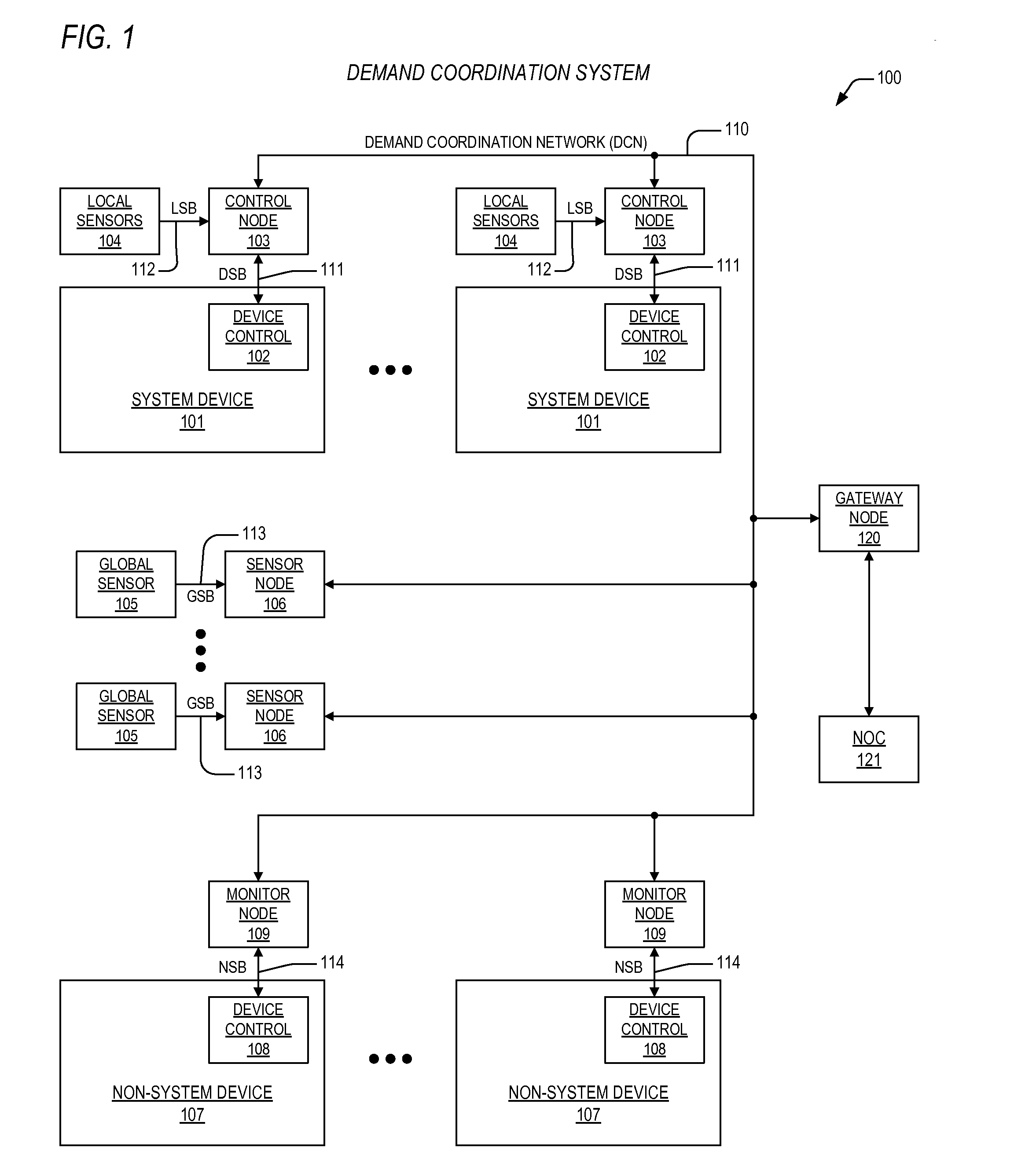

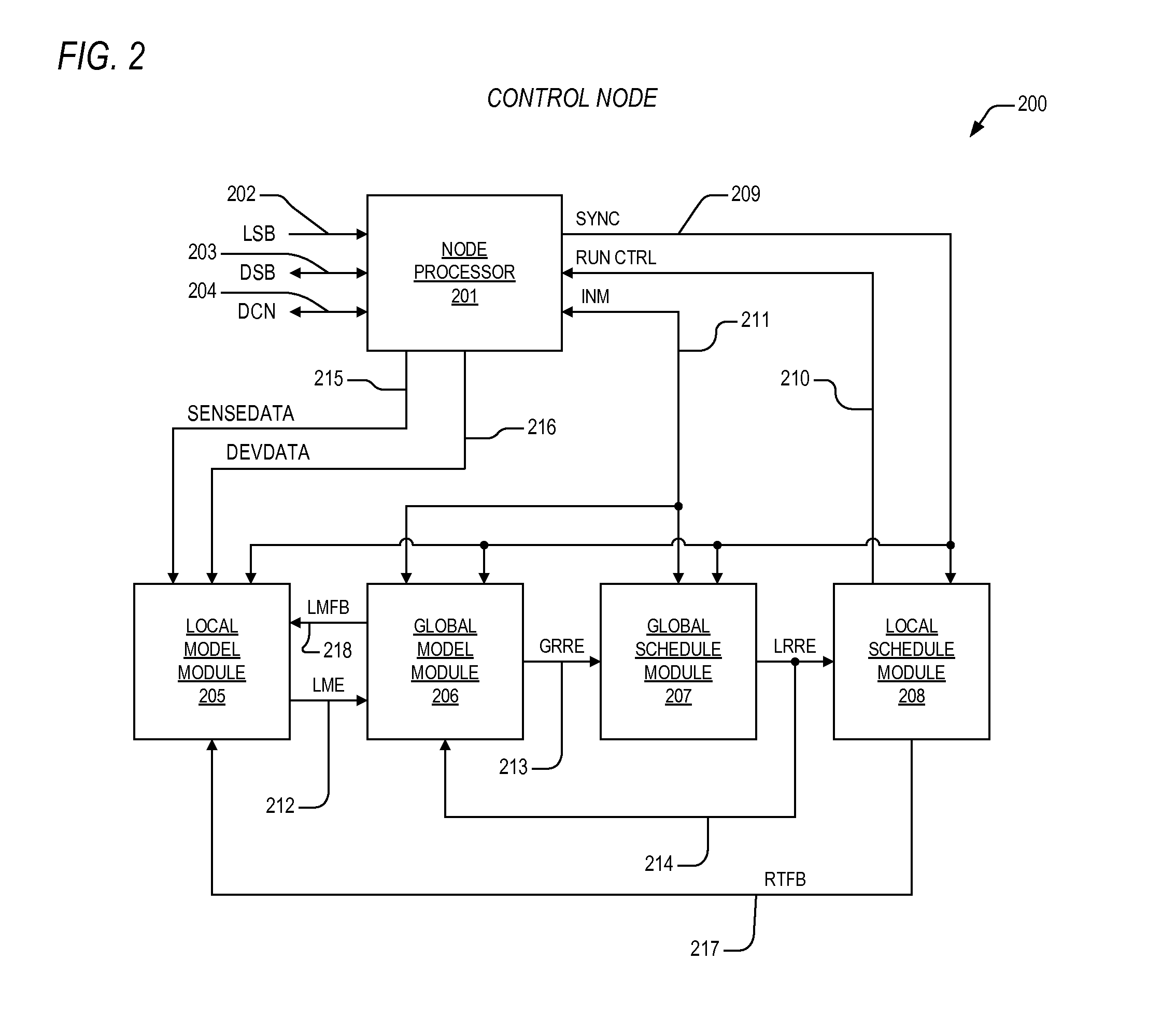

Apparatus and method for demand coordination network

ActiveUS8457803B2Reduce peak demandLevel controlSimultaneous control of electric and non-electric variablesPeak valueEngineering

An apparatus for controlling peak demand of a resource. The apparatus includes a plurality of devices and a plurality of control nodes. Each of the plurality of devices consumes a portion of the resource when turned on, and the each are capable of performing a corresponding function within an acceptable operational margin by cycling on and off. Each of the plurality of control nodes is coupled to a corresponding one of the plurality of devices, where the plurality of control nodes is coupled together via a demand coordination network, and where the plurality of control nodes coordinates run times for the each of the plurality of devices to reduce the peak demand of the resource, and where one or more of the run times start prior to when otherwise required to maintain corresponding local environments, but which still operate within the acceptable operating margin for the corresponding local environments.

Owner:ENEL X NORTH AMERICA INC

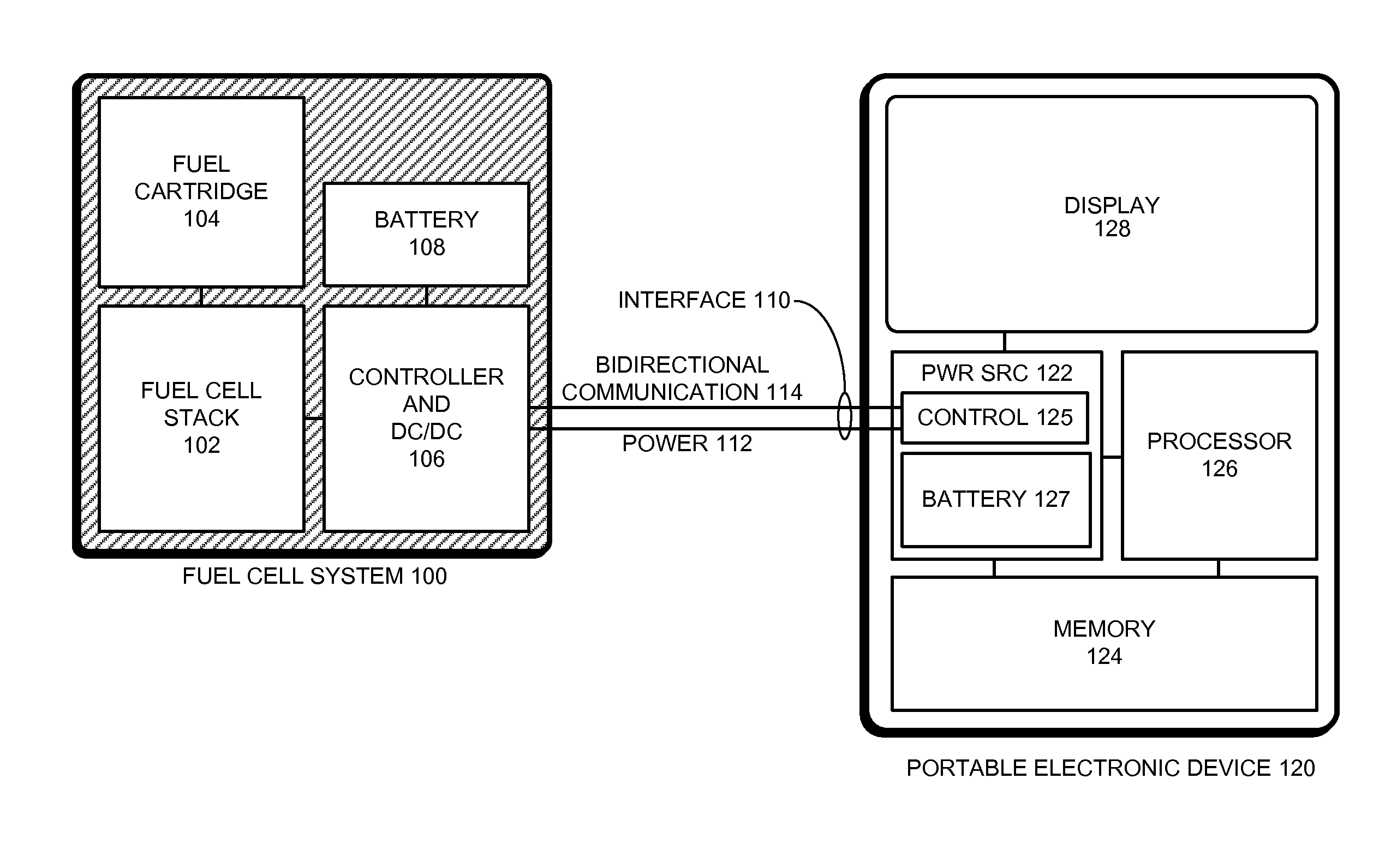

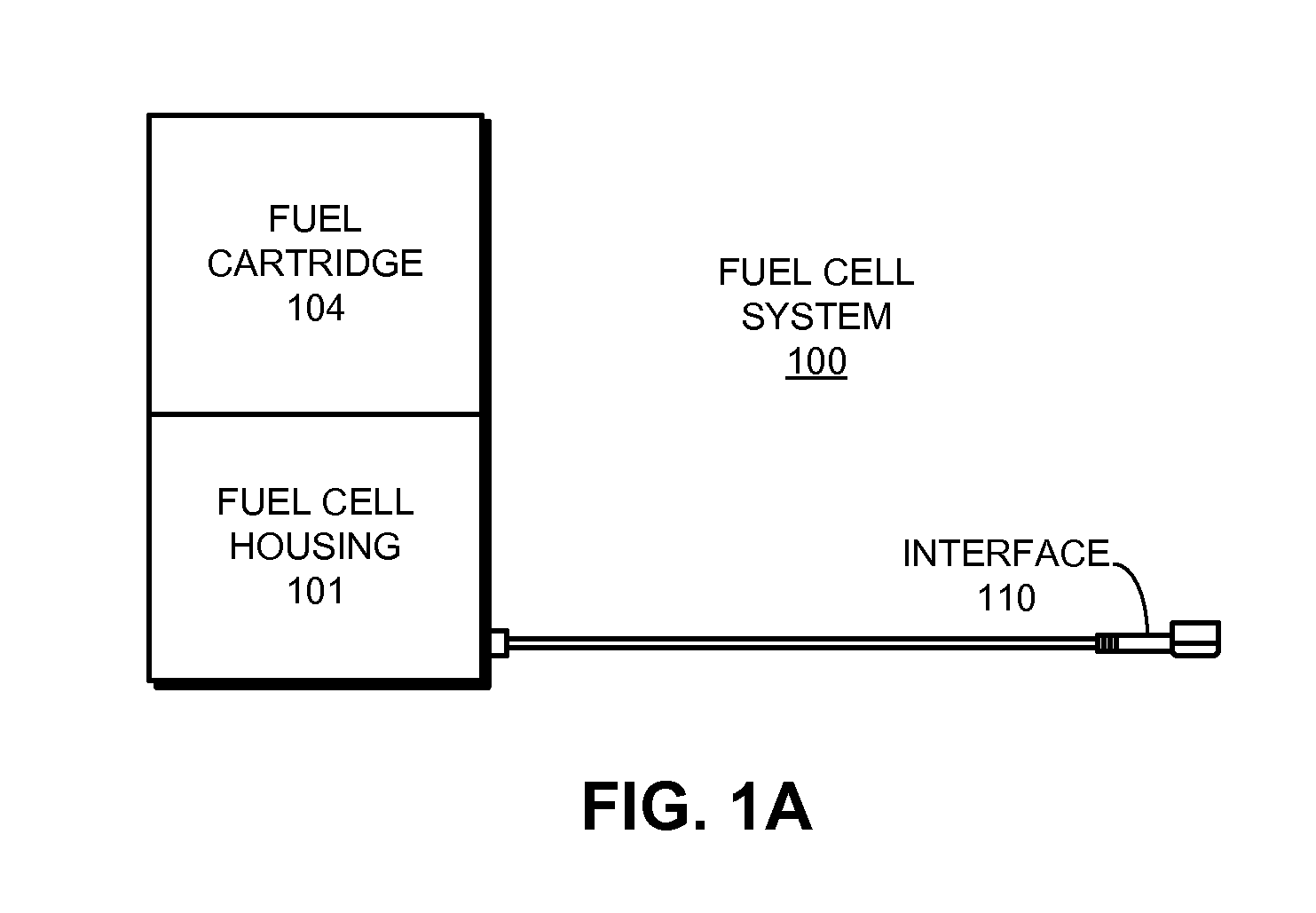

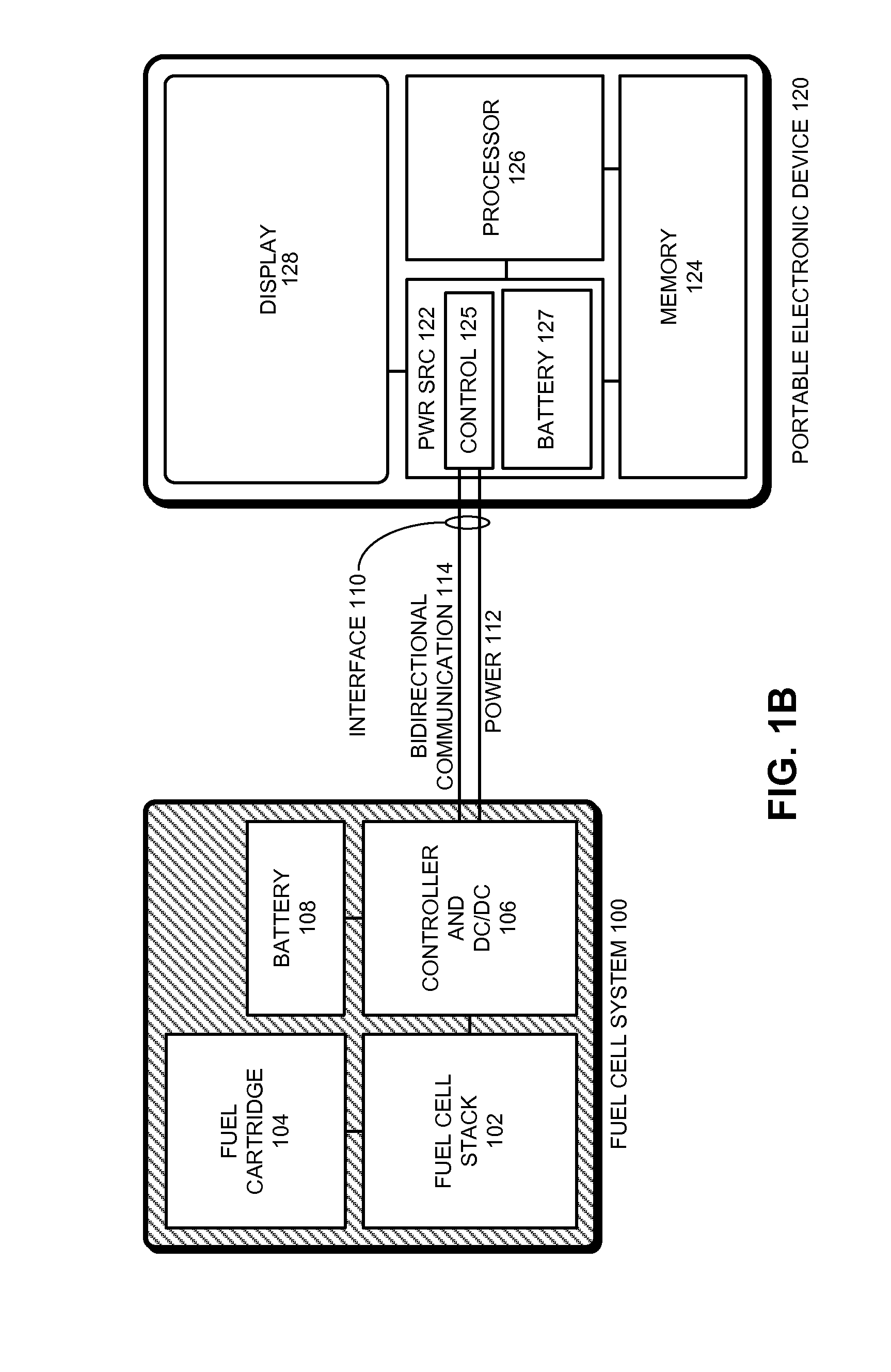

Fuel cell system coupled to a portable computing device

ActiveUS20110313589A1Small sizeReduce weightMechanical power/torque controlLevel controlFuel cellsTelecommunications link

The disclosed embodiments relate to the design of a fuel cell system which is capable of both providing power to and receiving power from a rechargeable battery in a portable computing device. This eliminates the need for a bulky and heavy battery within the fuel cell system, which can significantly reduce the size, weight and cost of the fuel cell system. This fuel cell system includes a fuel cell stack which converts fuel into electrical power. It also includes a controller which controls operation of the fuel cell system. The fuel cell system additionally includes a power link that transfers electrical power between the fuel cell system and the portable computing device, and a communication link that provides communication between the portable computing device and the controller for the fuel cell system. The controller can regulate both the electrical power provided by the fuel cell system to the portable computing device and the electrical power provided by the rechargeable battery to the fuel cell system.

Owner:APPLE INC

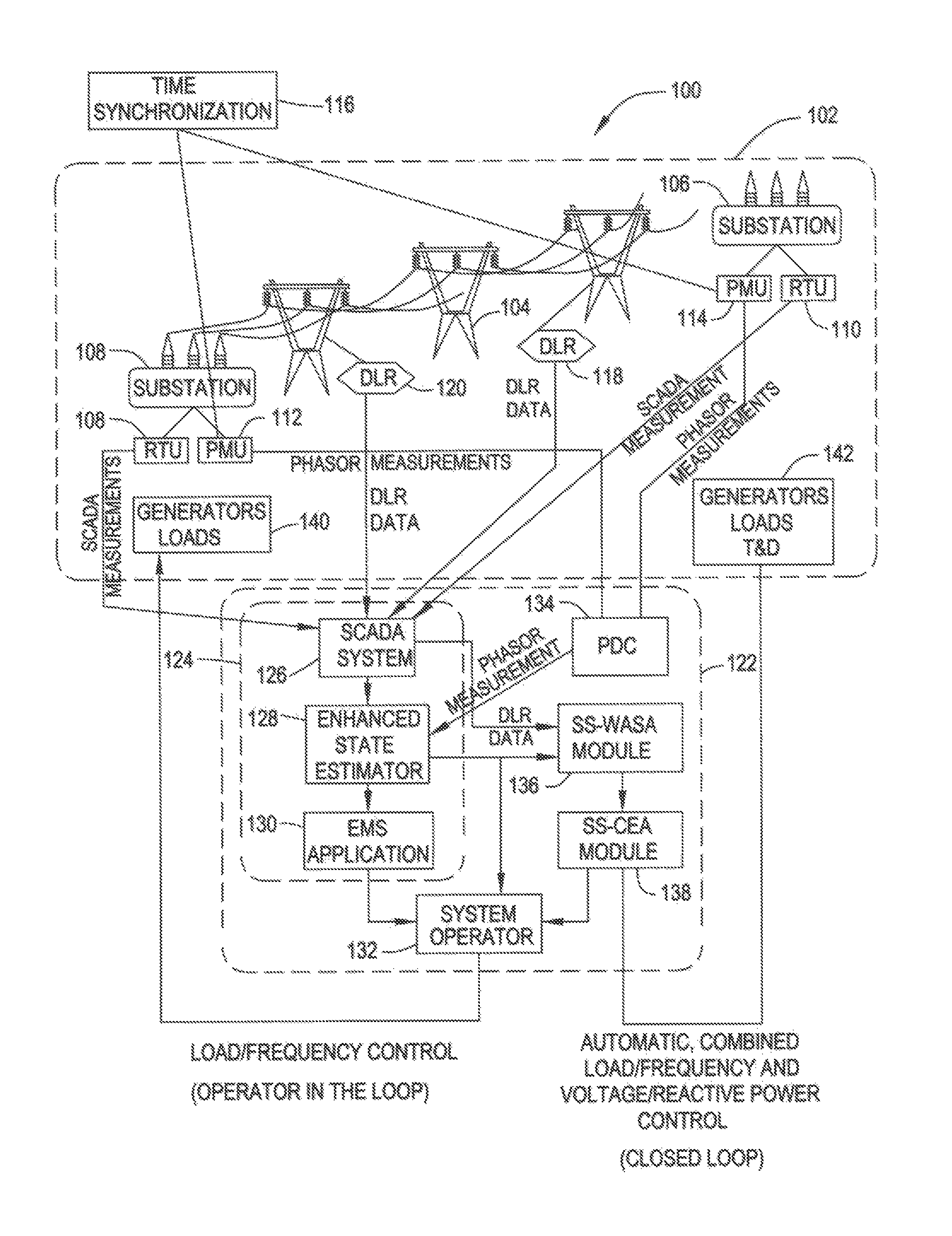

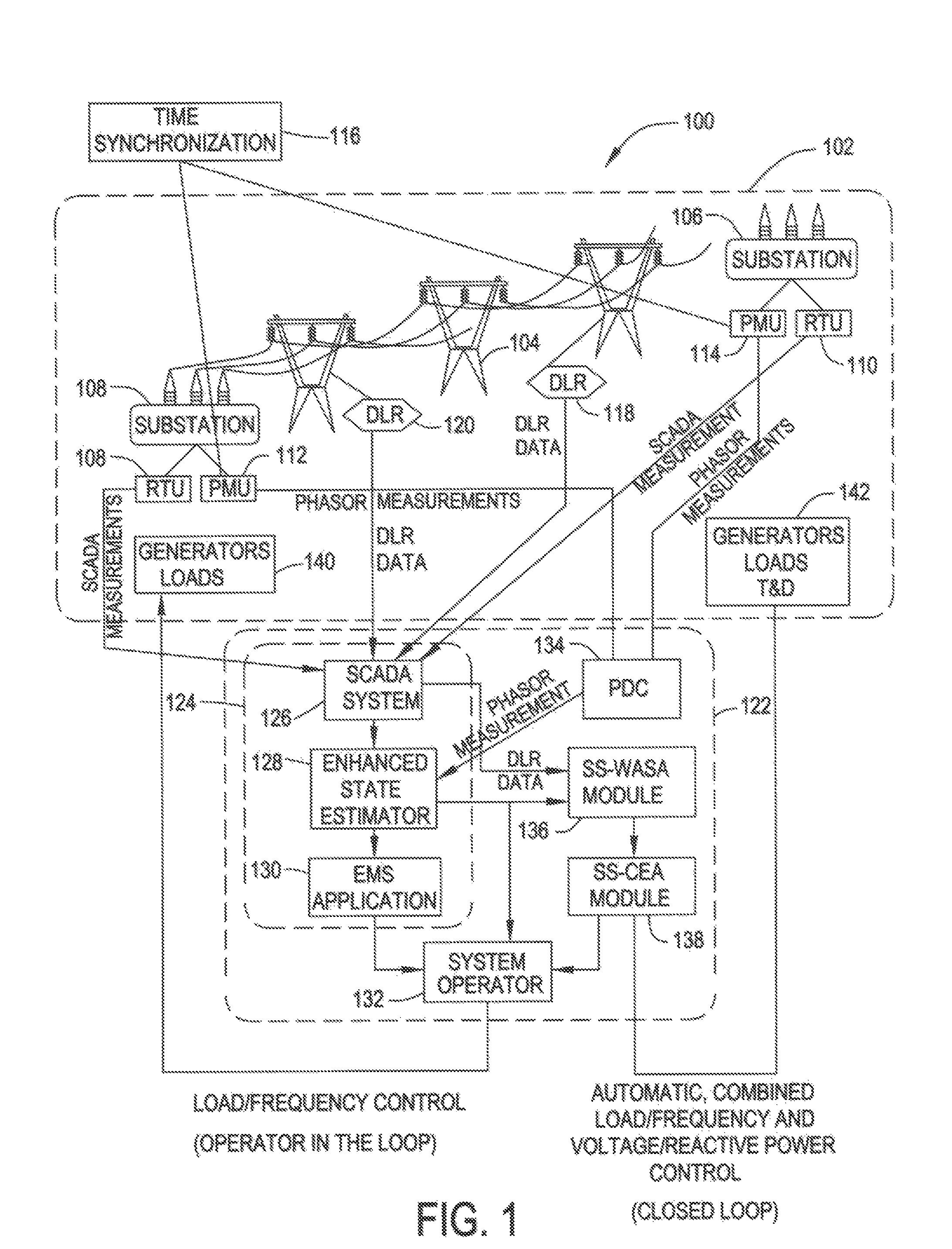

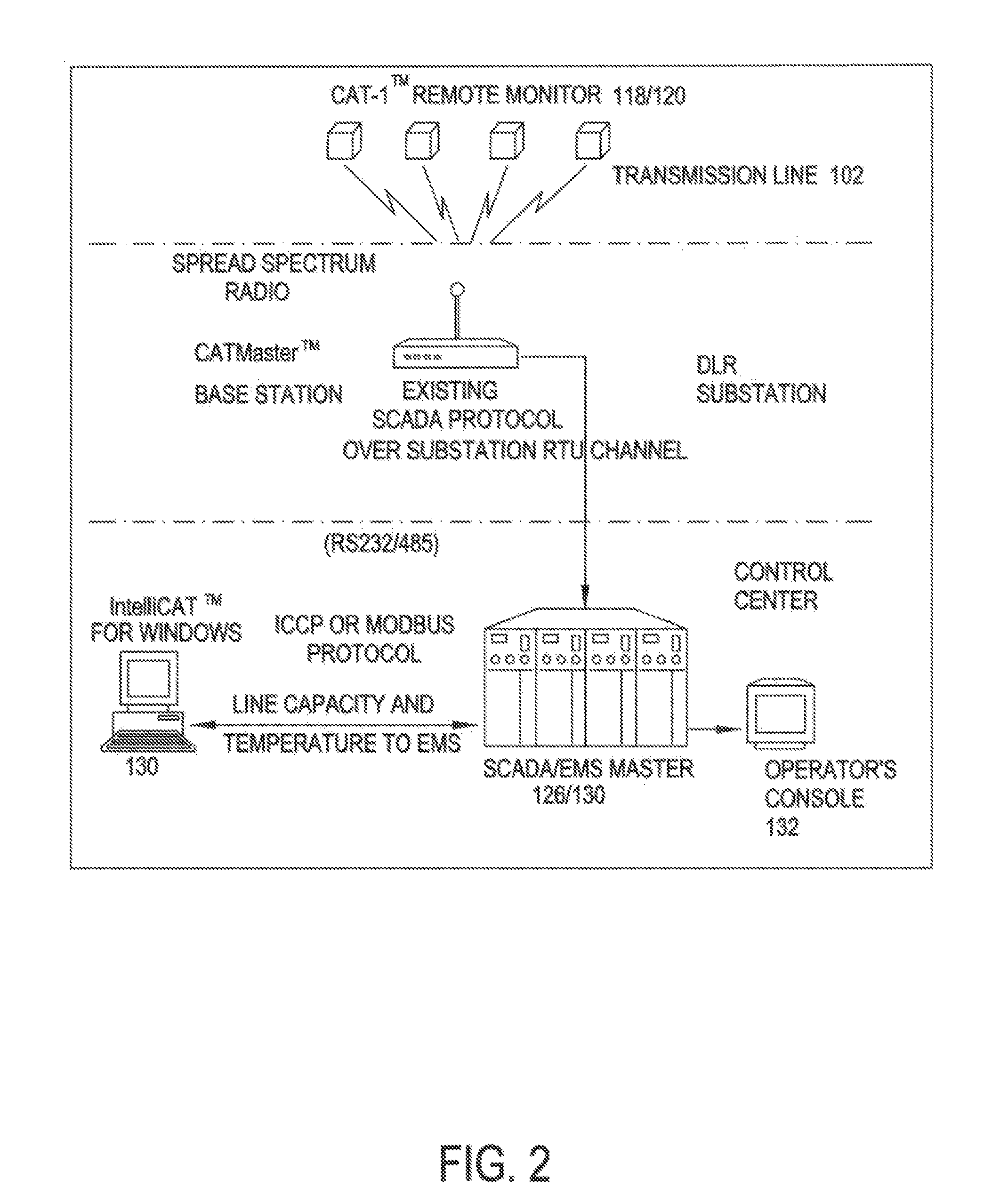

System and method for power grid management

InactiveUS8738191B2Improve overall utilizationEfficient supplyMechanical power/torque controlLevel controlElectric power transmissionPower grid

Owner:AIVALIOTIS SARANTOS K +9

Software modeling systems for metering and translating measurements

ActiveUS20110010158A1Batteries circuit arrangementsSimultaneous control of electric and non-electric variablesOperating pointPower flow

Systems and methods are provided for collecting and aggregating a plurality of power flow measurements from a plurality of devices in a power management system. The error bounds of the aggregated power flow measurement are then determined using at least one error model. Systems and methods are also provided for inferring AC power flows from DC power flows. A device having at least one DC power flow sensor is augmented with at least one AC power flow sensor AC and DC power flows through the device are measured using the sensors over a range of operating points. An inference model of AC power flow in the device as a function of DC power flow is then built, wherein the error of the model is bounded. DC power flow through the device and in similar devices can then be then measured and used to infer AC power flow for the device.

Owner:GRIDPOINT

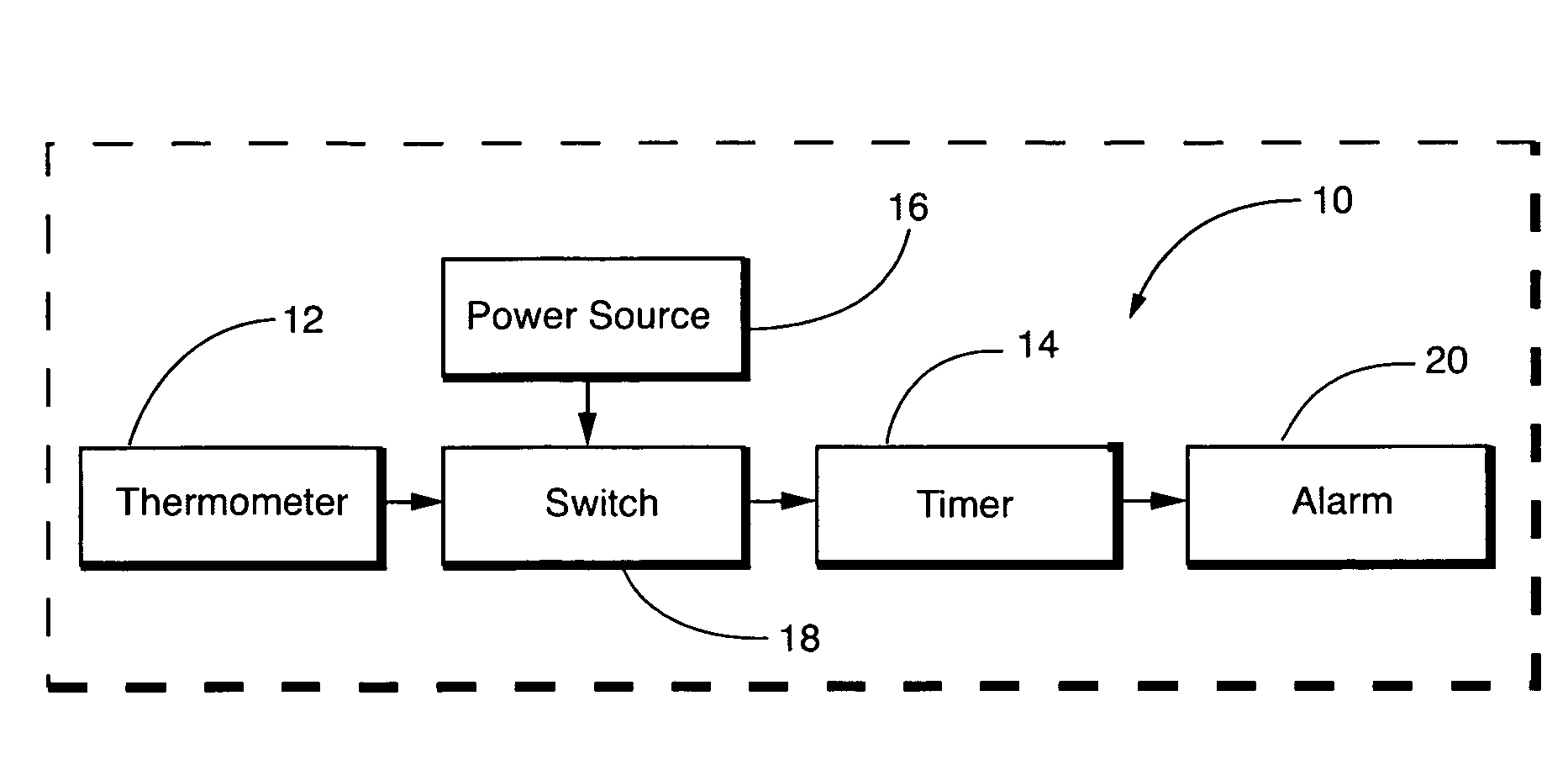

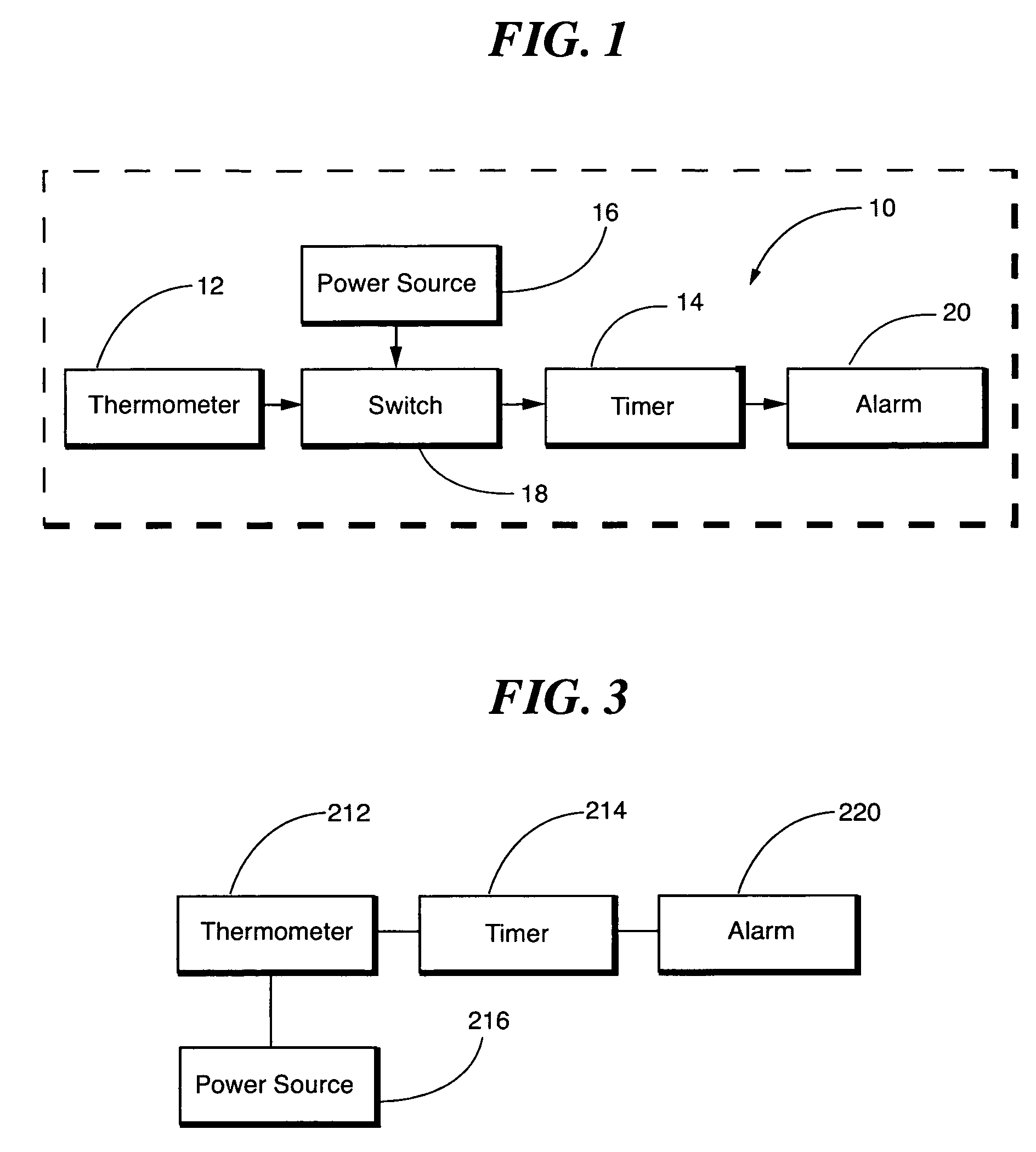

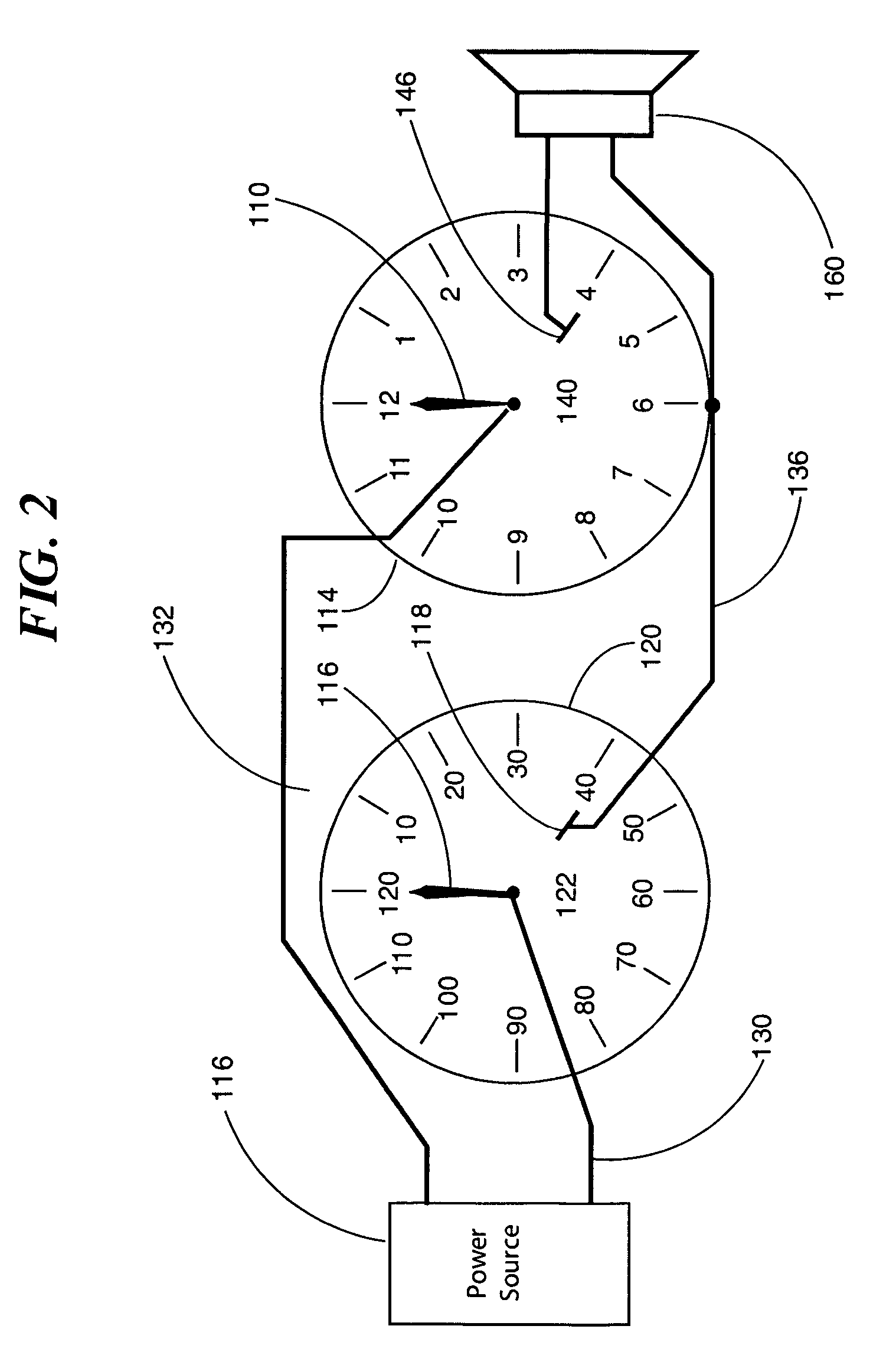

Refrigerated food safety monitor

ActiveUS7360369B2Thermometers using mean/integrated valuesSimultaneous control of electric and non-electric variablesFood safetyEngineering

A food refrigeration monitor includes a thermometer for measuring the temperature. A switch is operatively coupled to the thermometer and switches from a first state to at least a second state when a thermometer measures a temperature above a predetermined temperature. The switch switches from the at least second state to the first state when the temperature is below the predetermined temperature. A timer is coupled to the switch for measuring an amount of time the switch is in the second state. If the measured time is greater than a predetermined time value, an alarm is sounded.

Owner:TAMBORRA DOMINICK

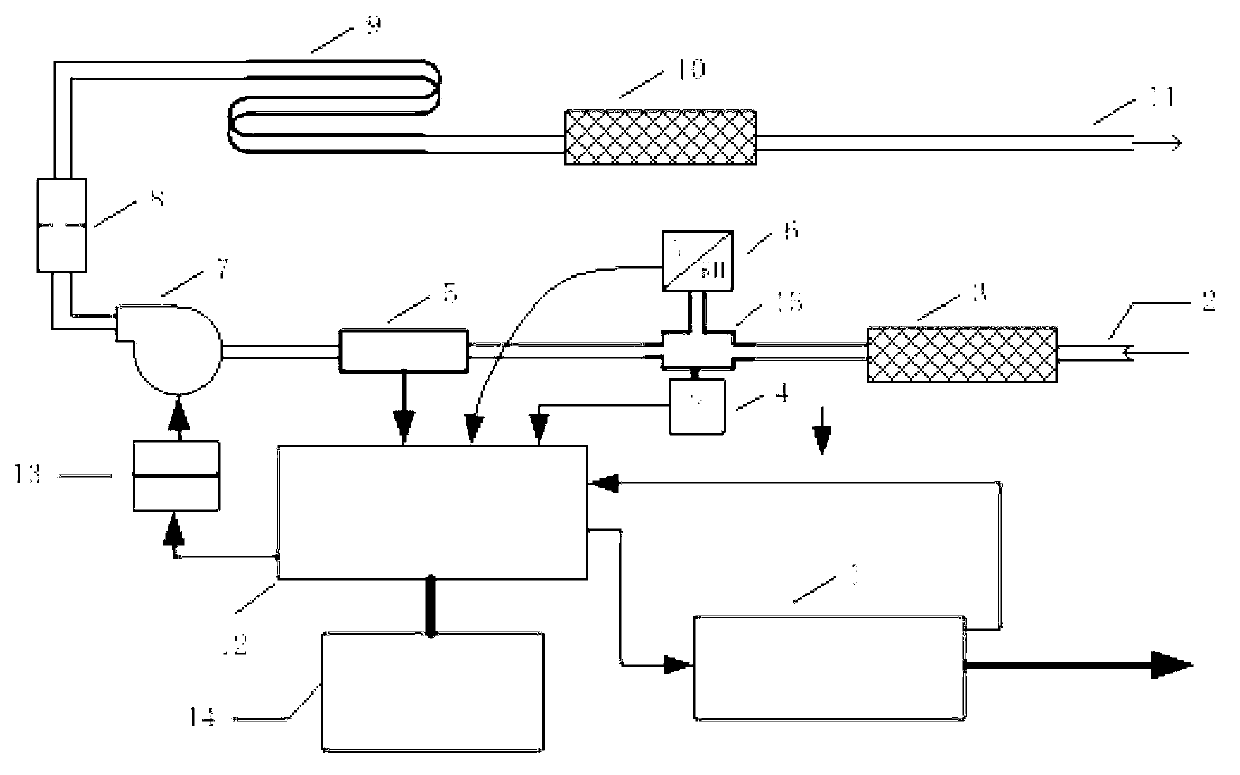

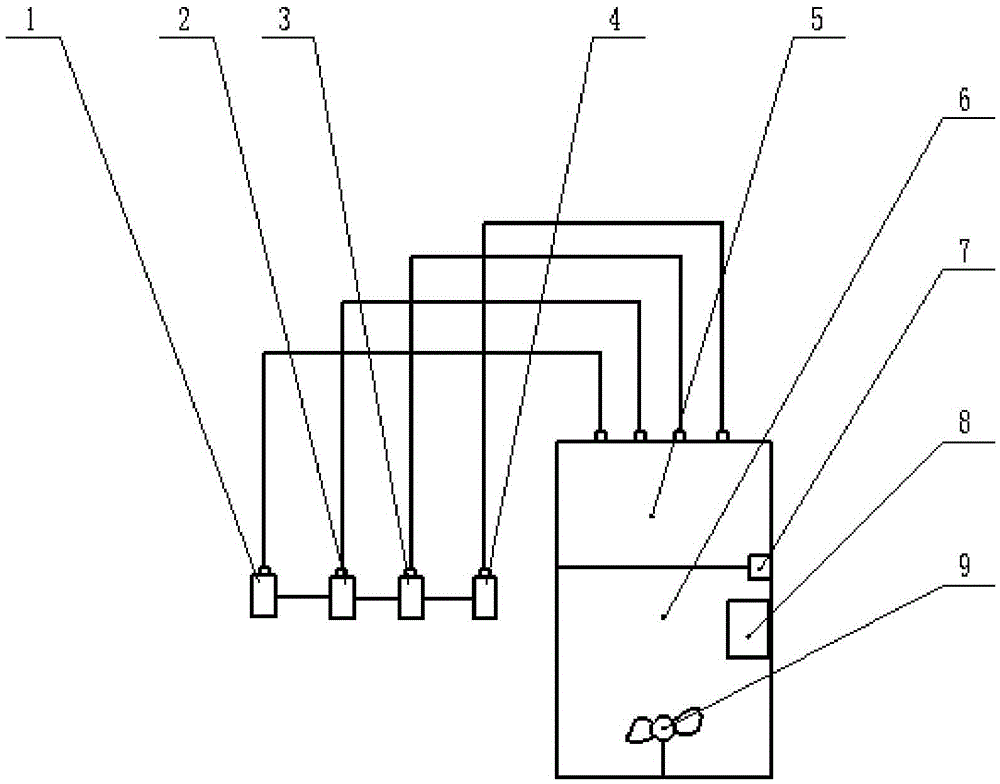

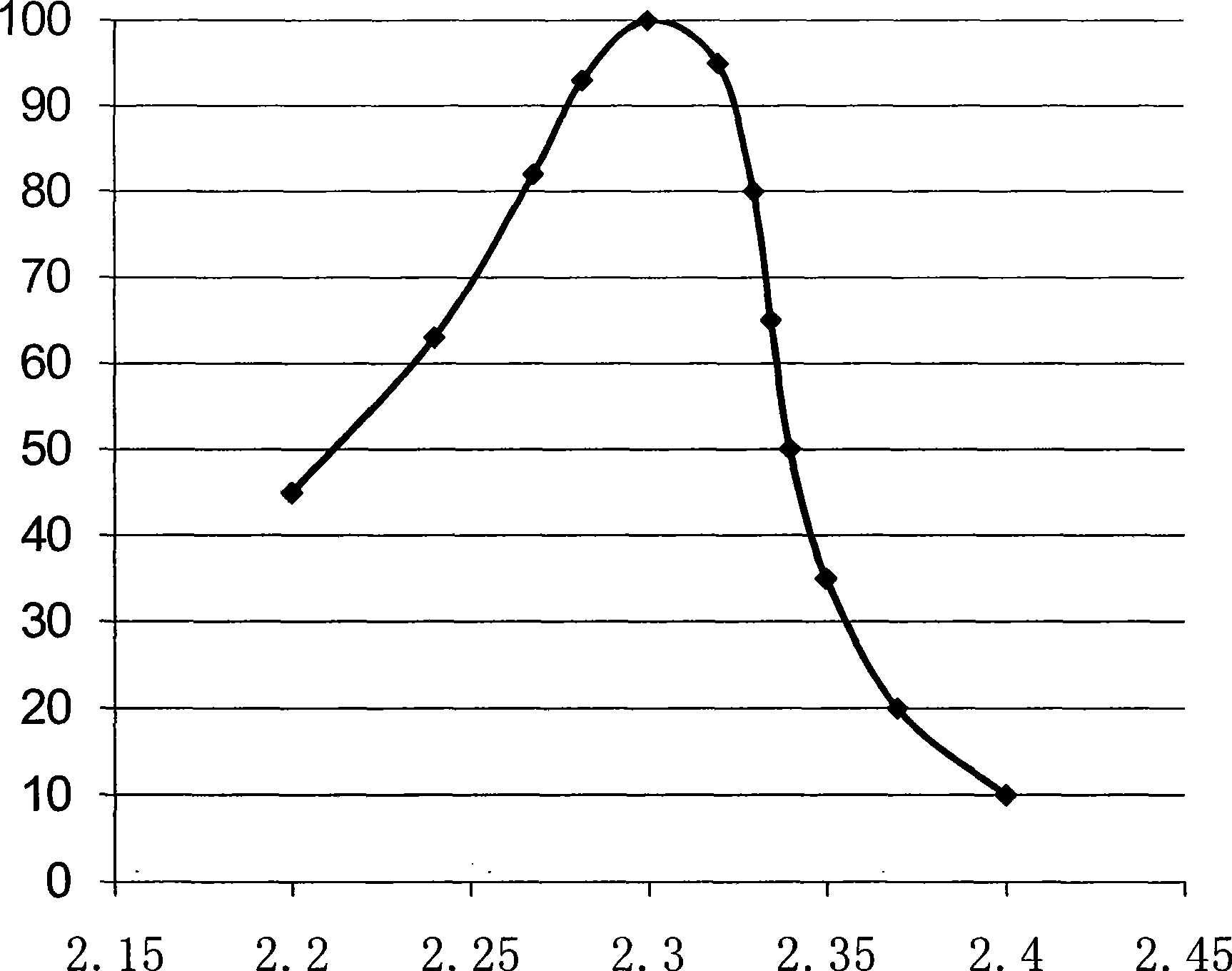

Voltage-and-flow control system used for measurement of aerosol particle size distribution

ActiveCN103135641AGuaranteed uptimeOptimize connection designSimultaneous control of electric and non-electric variablesParticle size analysisMeasuring instrumentData acquisition

The invention discloses a voltage-and-flow control system used for measurement of aerosol particle size distribution and belongs to the technical field of environment aerosol. The voltage-and-flow control system used for the measurement of the aerosol particle size distribution is structurally characterized in that a circuit board is connected with a high-voltage module, a direct-voltage conversion module, a data acquisition card, an absolute pressure sensor, a mass flow meter and a temperature and humidity sensor through guide wires, the direct-voltage conversion module is connected with a draught fan through a guide wire, an air inlet, a pre-filter, a T-shaped tee joint, the mass flow meter, the draught fan, a flow-limiting hole, a radiating tube, a post-filter and an air outlet are connected in sequence through pipelines, the temperature and humidity sensor is connected with a vertical channel of the T-shaped tee joint through a pipeline, and the absolute pressure sensor is connected with the T-shaped tee joint through a pipeline. The voltage-and-flow control system used for the measurement of the aerosol particle size distribution is simple in operation, high in sensitivity, good in sealing performance, high in running stability, capable of being flexibly assembled with an aerosol particle size distribution measuring instrument, and applied to both laboratory measurement and out-field measurement.

Owner:TSINGHUA UNIV

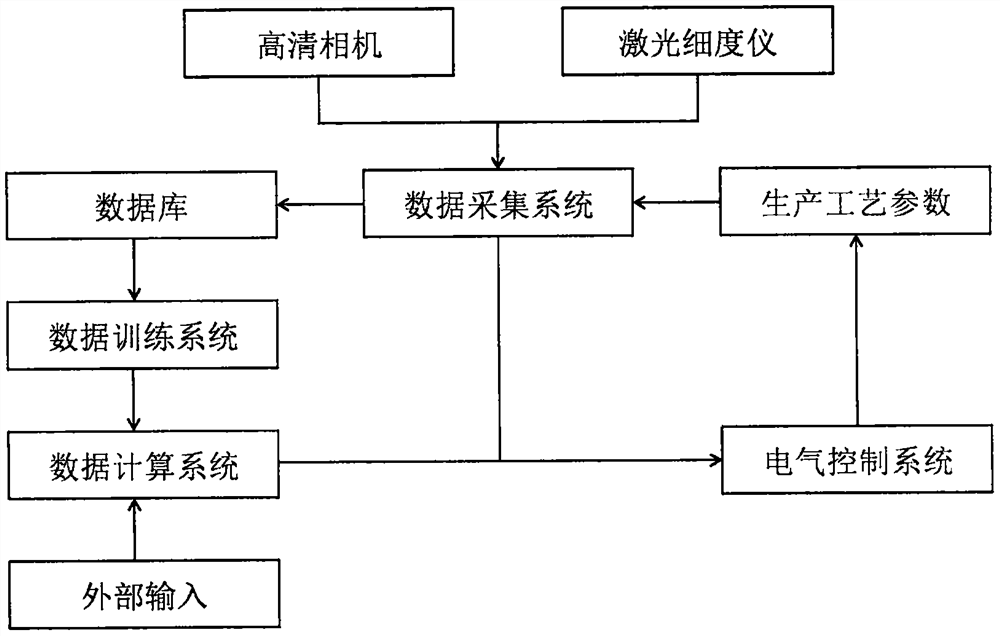

Intelligent grouting system

ActiveCN105045323AAdjust density in real timeReduce cleaning volumeProgramme controlSimultaneous control of electric and non-electric variablesFrequency changerDisplay device

An intelligent grouting system is provided with a single chip microcomputer, a keyboard and a display. Pipelines provided with magnetic valves, sensors or electronic scales are inserted into a grout production barrel, wherein the pipelines are respectively loaded with water, cement powder, sand, a chemical additive, dense grout and so on therein; the proportioning and consumption of grout is controlled through programming, thus a grout proportioning efficiency is high, proportioning is accurate, and labor intensity is low. A frequency converter provided with a communication interface is added to a drive motor of a grouting pump, an input end of the single chip microcomputer is connected with a pressure sensor, an output end of the single chip microcomputer is connected with a high pressure valve and an alarm device; the power of the drive motor and the pressures of the pipelines are controllable, thereby saving electric energy; operating personnel are far away from the high-pressure pipes, thus security is achieved. A tension sensor of which an output end is connected with the single chip microcomputer is fixed over the grout production barrel, a metal weight immersed in cement grout is hanged on a lower end of the tension sensor; the single chip microcomputer continuously measures and displays the proportion, and adjusts the grout concentration in real time to ensure grouting quality, the frequency of cleaning is low. Through adoption of the intelligent grouting system, only grouting parameters need to be manually inputted, the subsequent operations such as grout proportioning and grouting are all automatically performed by the system, thereby saving time and labor. The intelligent grouting system is used for grouting construction of a hydropower station, especially at the places such as side slope and dam foundation.

Owner:成都中大华瑞科技有限公司

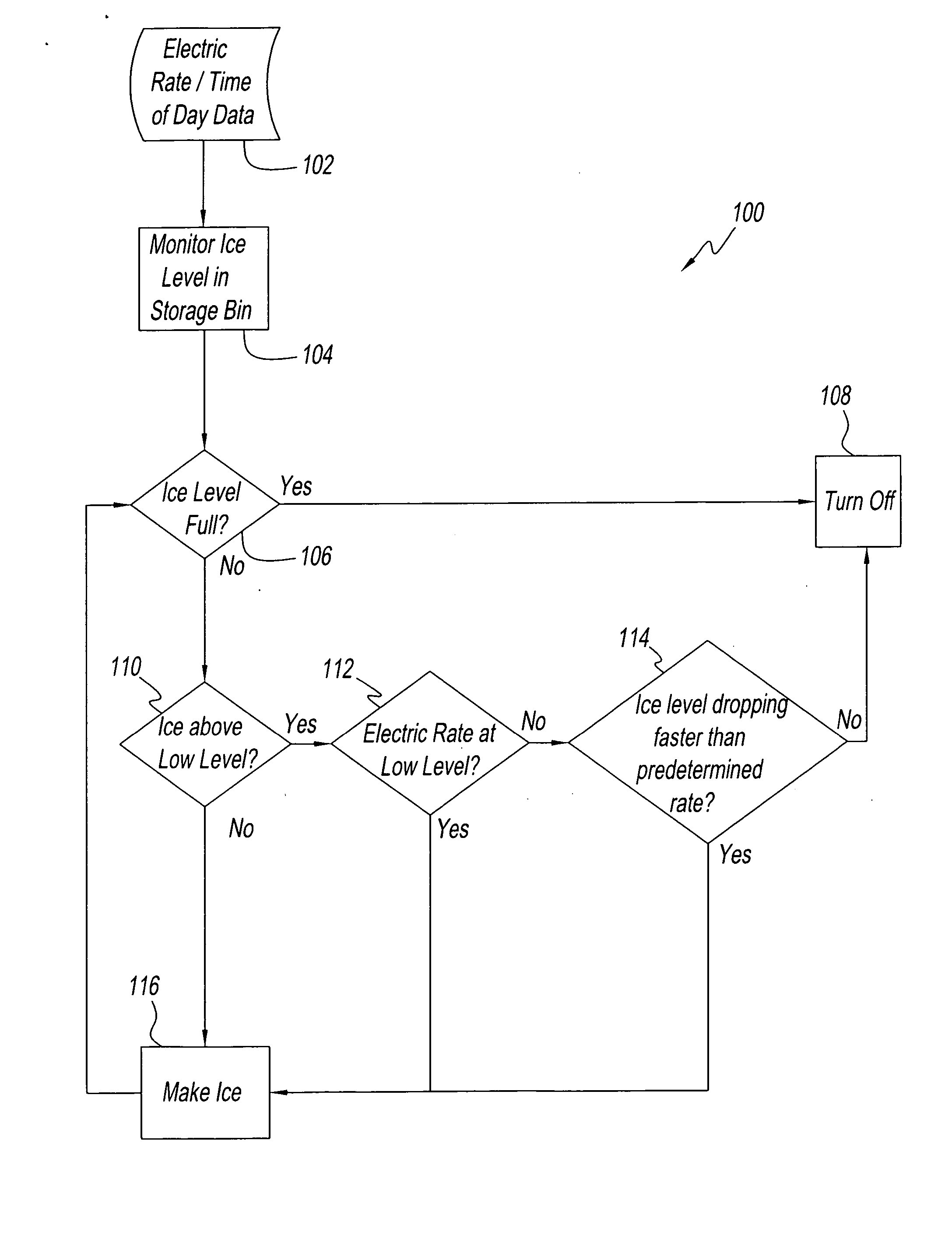

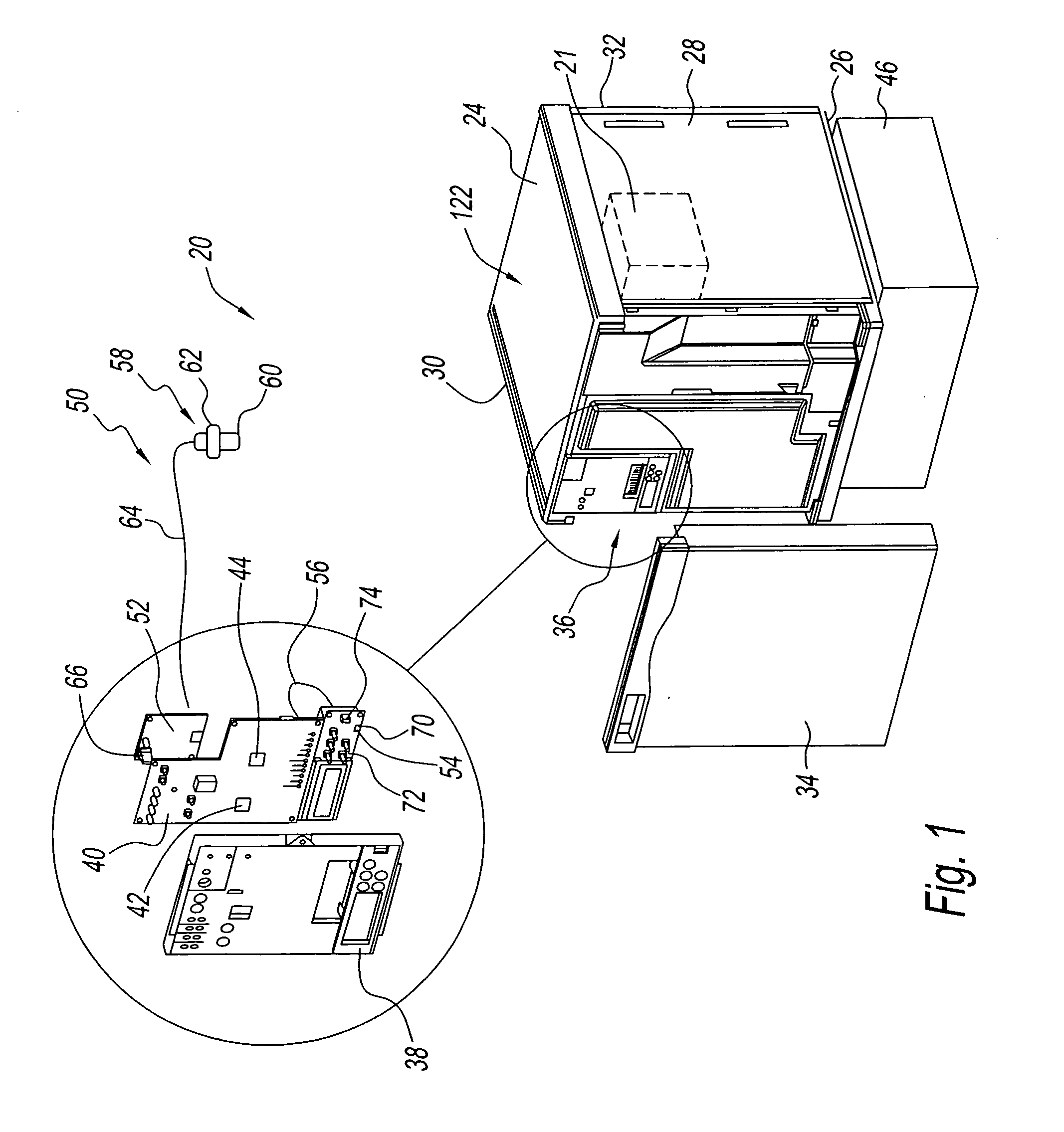

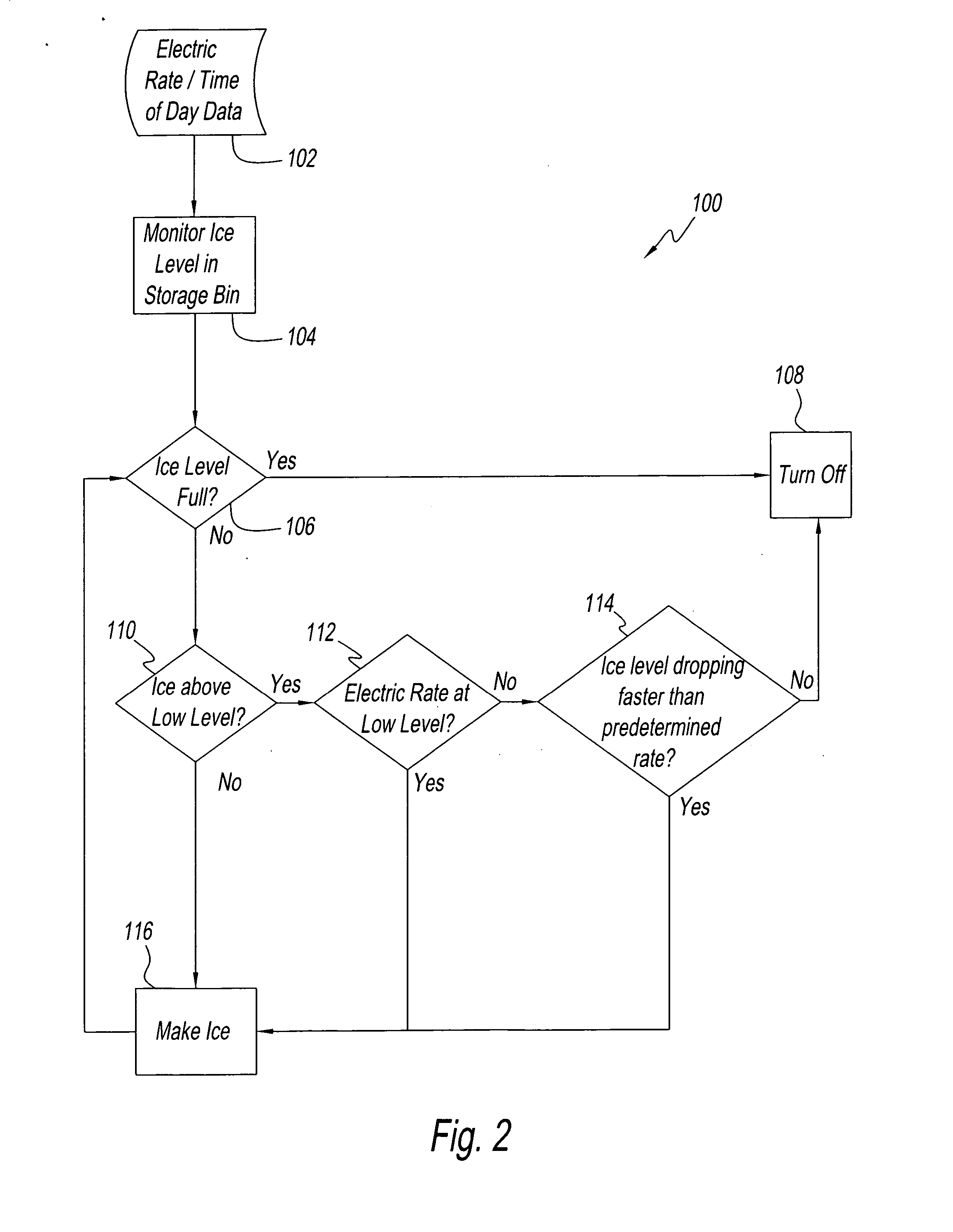

Method and system for regulating the operation of an icemaking machine based to optimize the run time based on variable power rates

InactiveUS20080092571A1Reduce energy costsSimultaneous control of electric and non-electric variablesLighting and heating apparatusEnergy rateEngineering

An ice-making machine having an assembly and a controller that controls said assembly to make ice. A sensing device senses a current level of ice in an ice bin that receives the ice made by the assembly. The controller compares the current level to a high set point and a low set point and, based on a current energy rate, controls the assembly to maintain the current level at or near the high set point when said current energy rate is low and at or near the low set point when the current energy rate is high to provide energy efficiency. The controller and sensing device are part of a retrofit assembly that retrofits an existing ice machine with the energy efficient feature.

Owner:SCOTSMAN GROUP

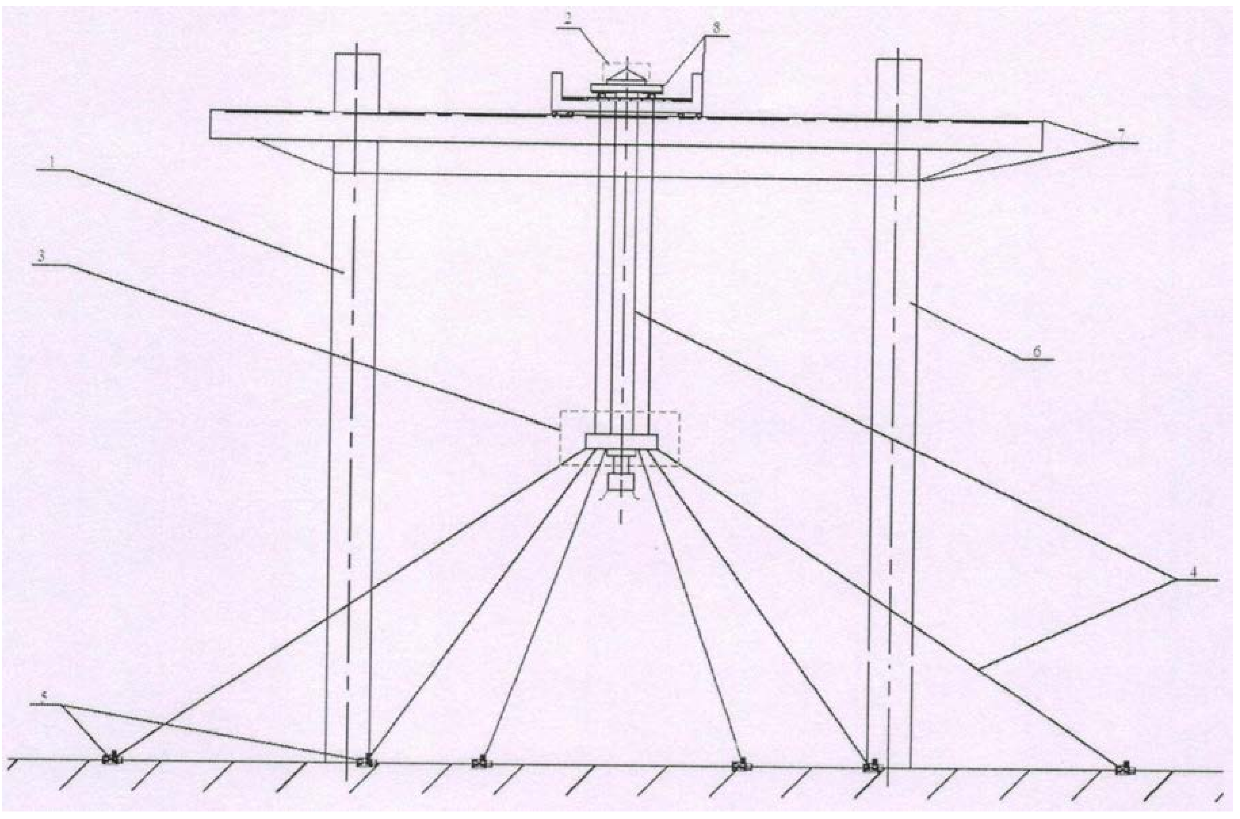

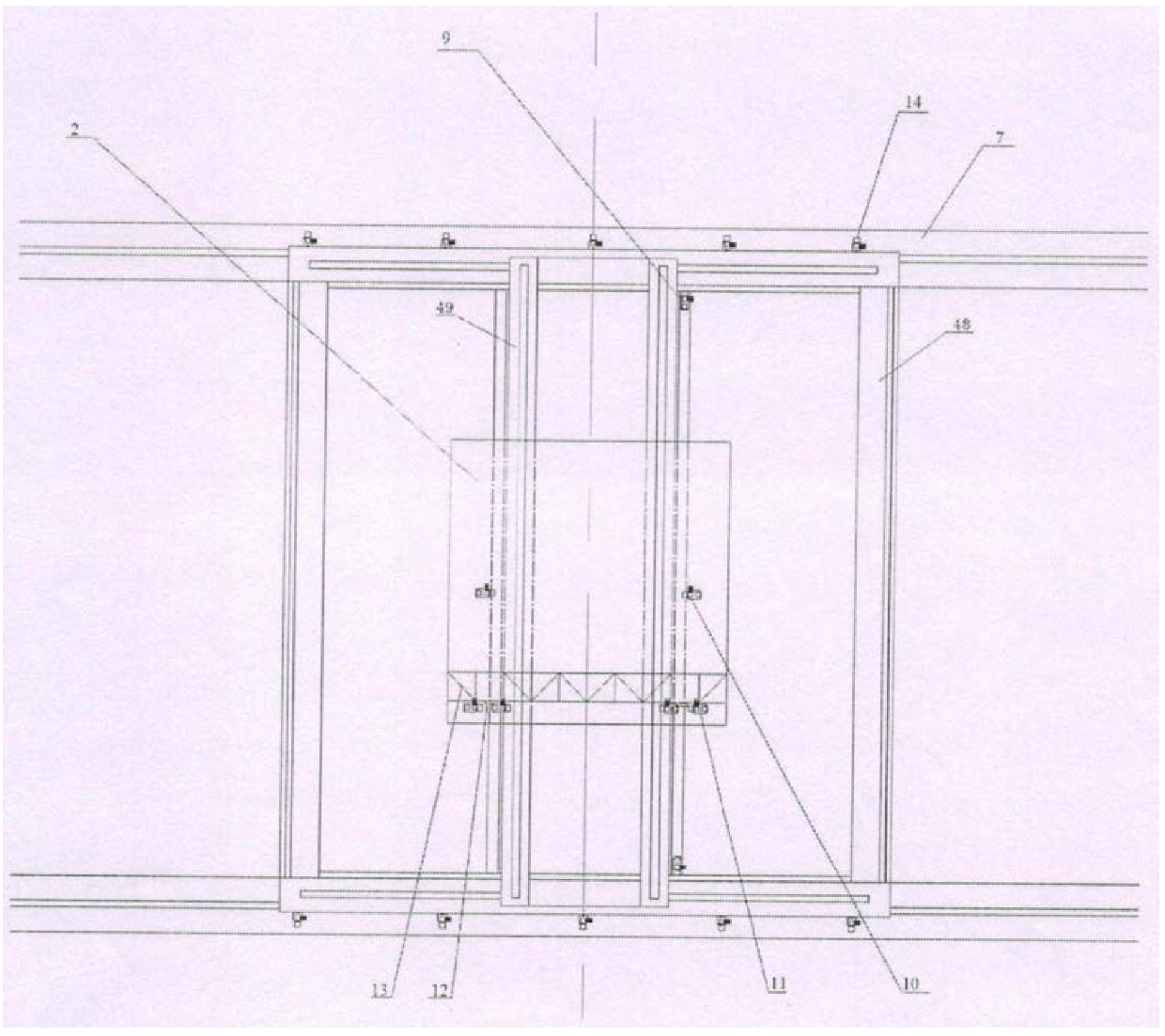

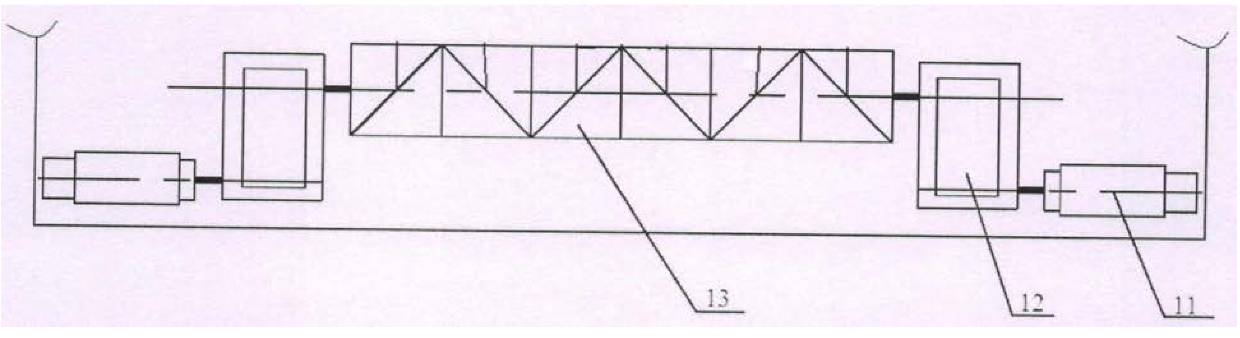

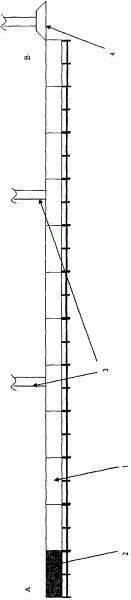

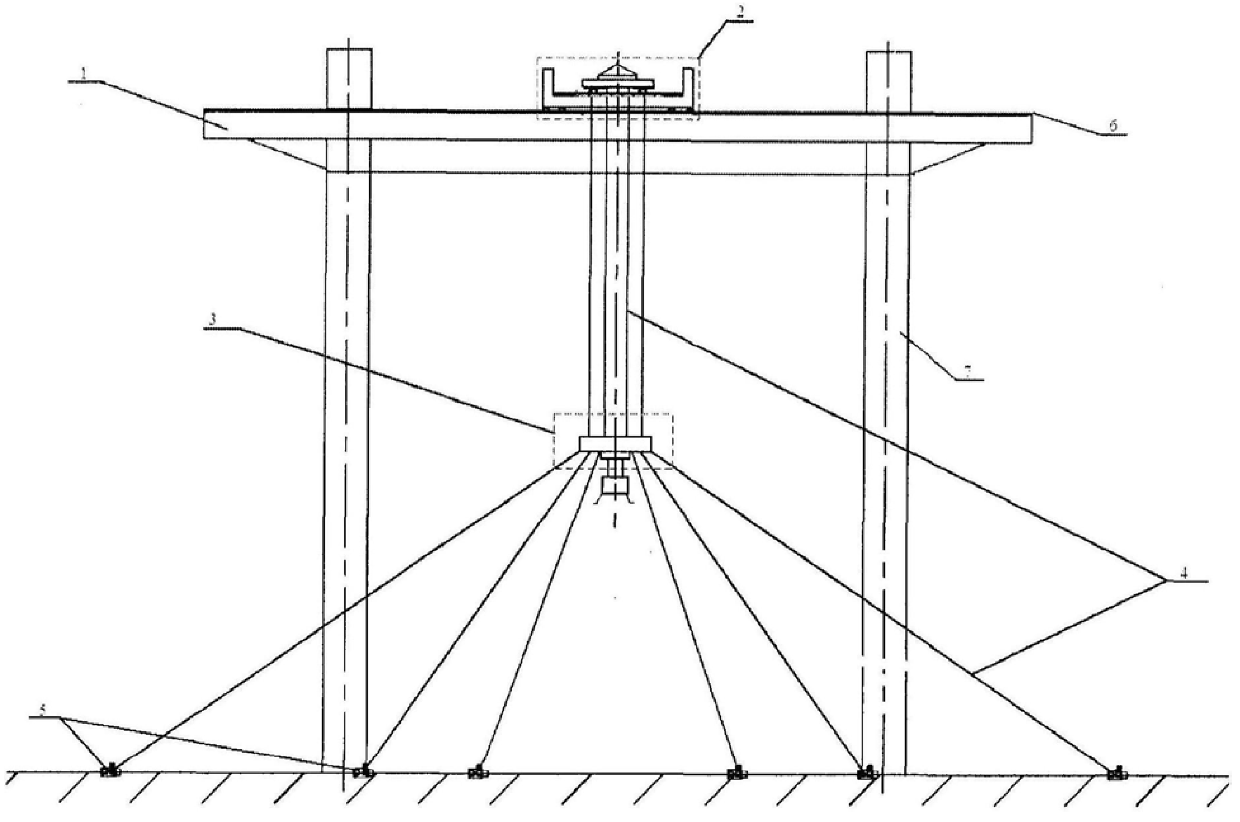

Lunar Landing Test Rig System

InactiveCN107182269BGuaranteed uptimeCosmonautic condition simulationsSimultaneous control of electric and non-electric variablesTowerSystems simulation

The invention discloses a lunar landing test frame system, which can provide a simulated gravity environment on the surface of the moon so as to realize the soft landing of the lunar probe; the test frame system includes a tower, a three-dimensional servo system and a lunar surface simulation area ;The three-dimensional follow-up system includes main lifting device, horizontal follow-up device, fast follow-up device, ground drive device and steel wire rope; the ground drive device is connected to the fast follow-up device through 6 steel wire ropes to provide the fast follow-up device for horizontal follow-up driving force; the fast follow-up device follows the horizontal movement of the detector through the internal cross-shaped moving mechanism; the fast follow-up device is connected to the main lifting device through 6 vertical steel wire ropes, and the main lifting device is installed on the horizontal follow-up device On the upper surface of the upper surface, the horizontal follower follows the horizontal movement of the quick follower through the internal cross-shaped moving mechanism, and the main lifting device is used to adjust the displacement of the quick follower in the vertical direction.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

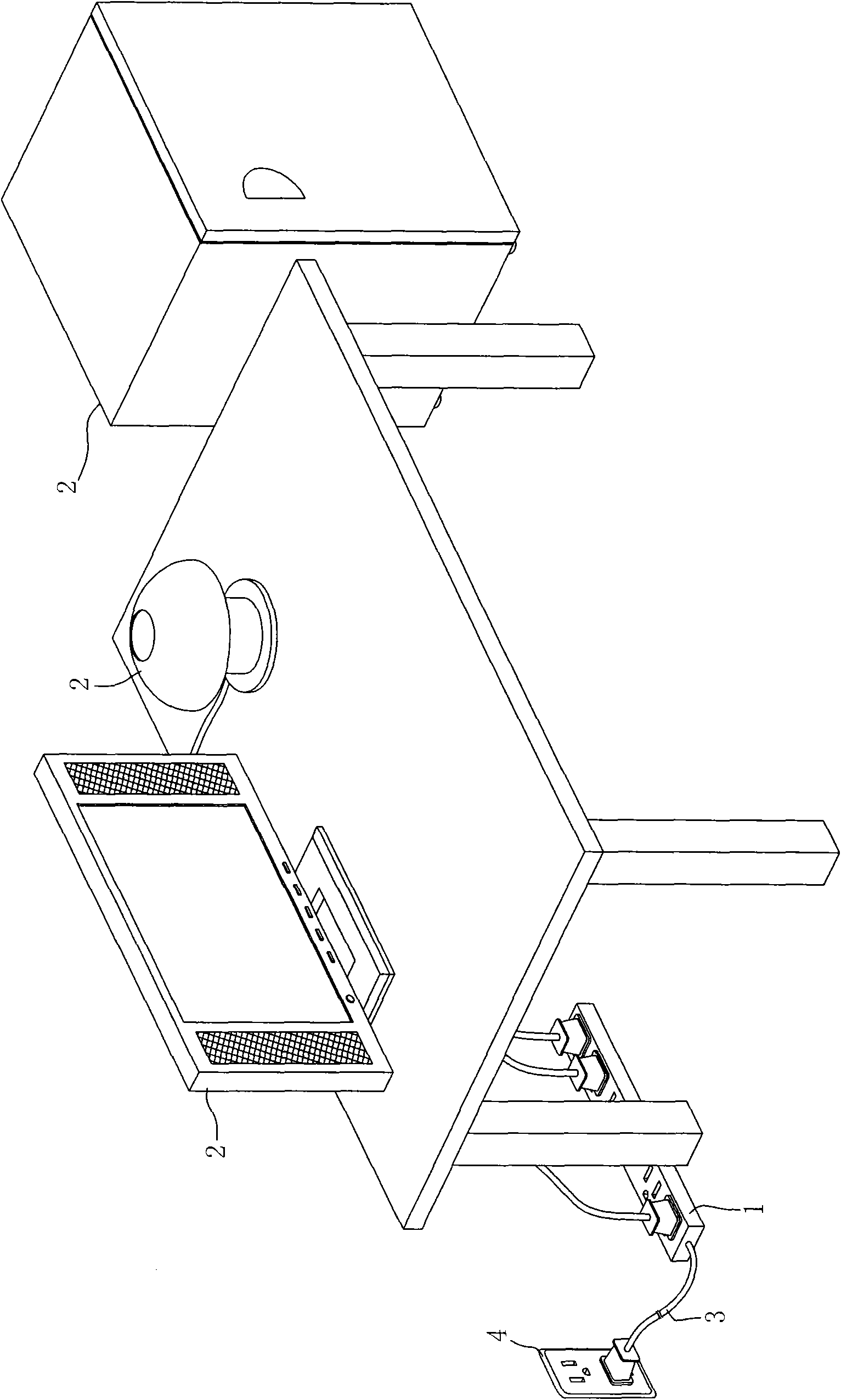

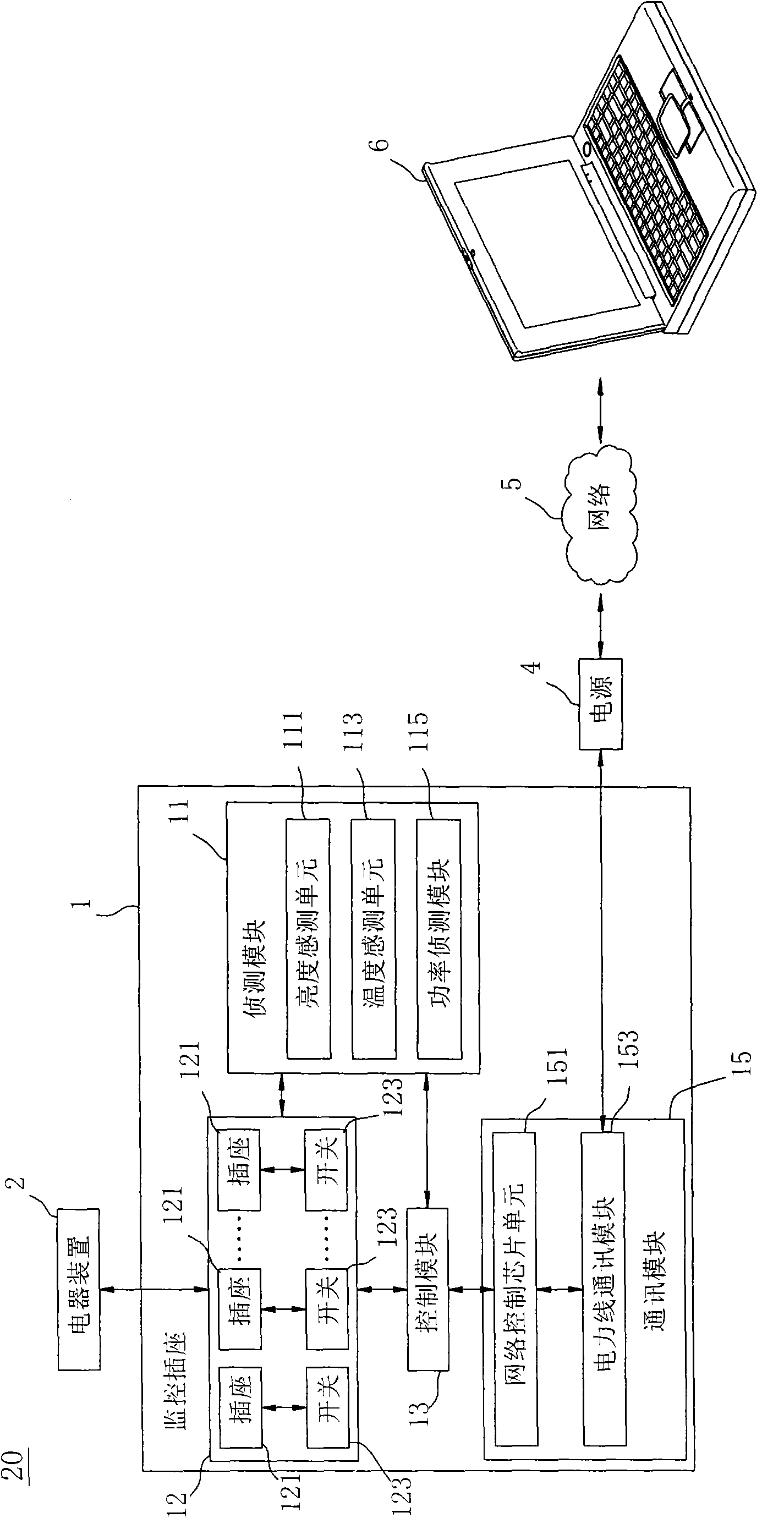

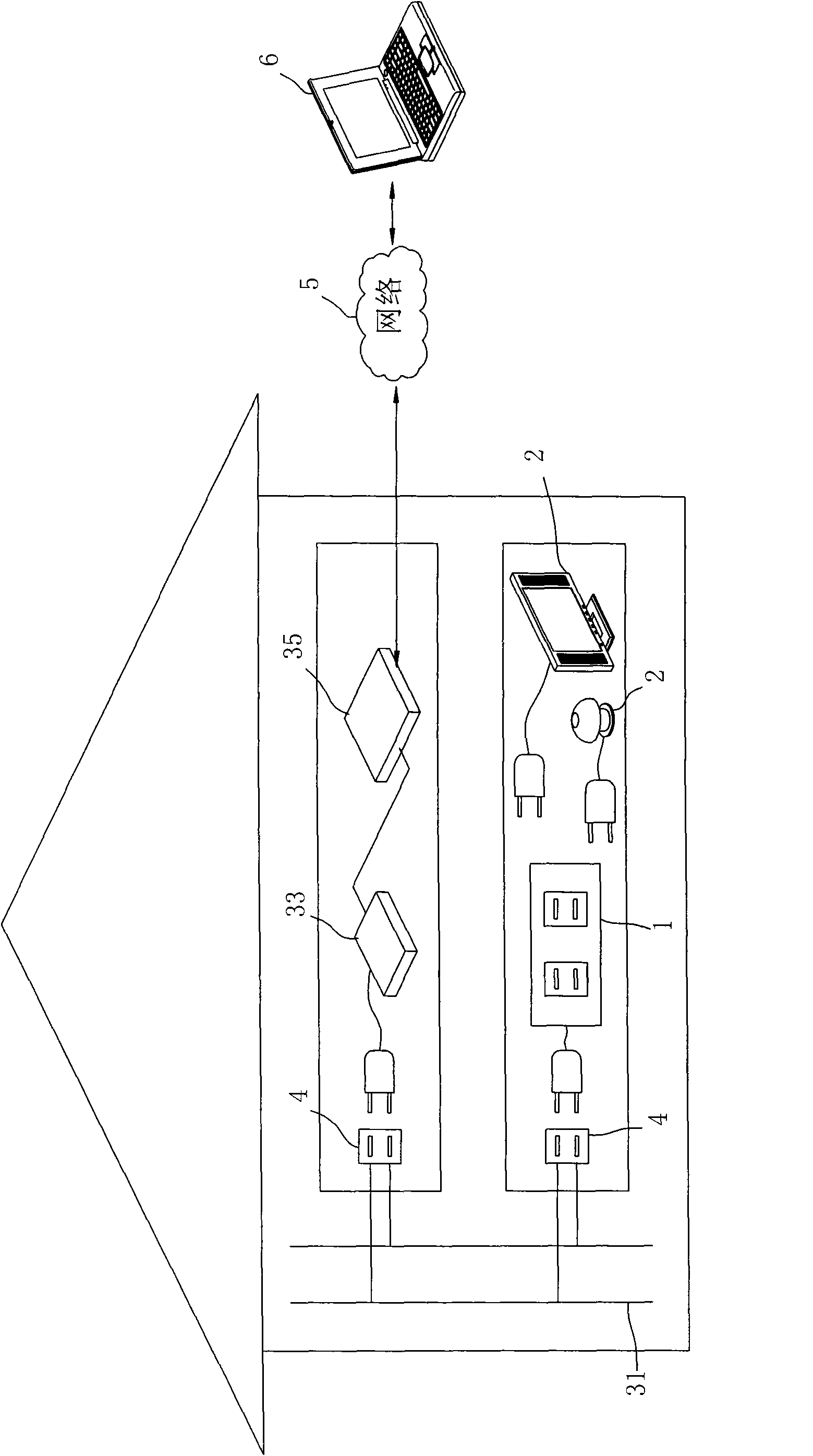

Monitoring socket, monitoring system and control method thereof

InactiveCN101593904AAvoid wastingLow costElectric signal transmission systemsSimultaneous control of electric and non-electric variablesControl systemMonitoring system

The invention relates to a control method of a control system, which is suitable for monitoring a remote electrical device by a host. The control method comprises the following steps: firstly, a monitoring socket is provided, which is in coupling with the electrical device and uses a power line to connect the host through a network; then, the monitoring socket detects the active condition of the electrical device to generate a state information, and sends the state information to the host; sequentially, the host end generates a control information and transmits the control information to the monitoring socket; finally, the monitoring socket controls the active condition of the electrical device according to the control information.

Owner:CAL COMP ELECTRONICS

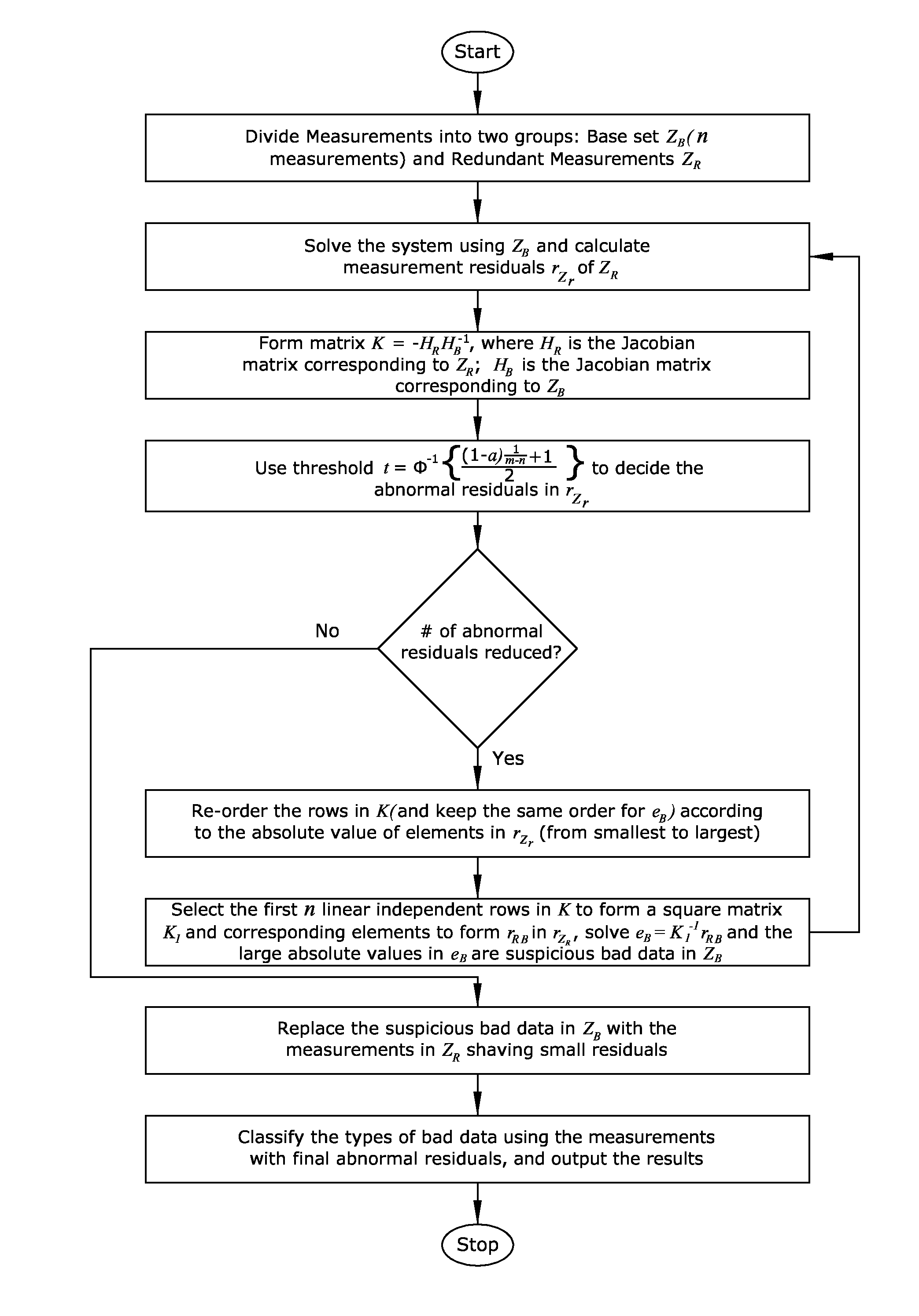

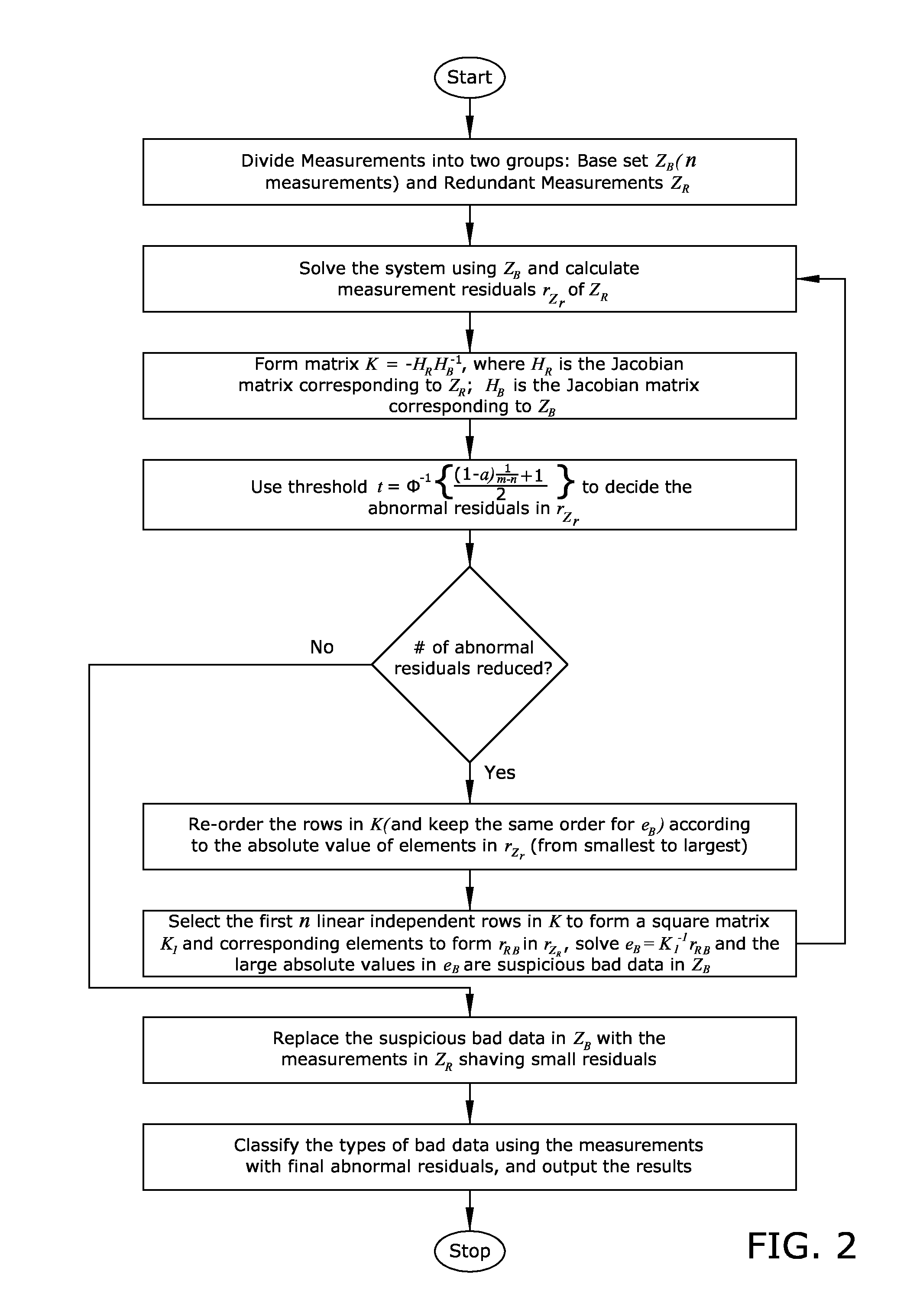

Computer-based method for power system state estimation

A method of power system state estimation for accurately identifying topology errors, parameter errors and measurement value errors for power networks in real-time. The system divides measured data into a base set and a redundant set. The system status is calculated using the base set. A residual vector of the redundant set is computed based on the system status. A matrix is calculated utilizing these sets. A threshold is utilized to decide the abnormal residuals of the redundant set. Colinearity between the residual vector and columns in the matrix are used to decide if base set measurements corresponding to the columns in the matrix are potentially bad data. An iterative process replaces bad data in the base set with measurements in the redundant set having smaller residuals, terminating upon removal of bad data. Topology errors and parameter errors may then be identified using the bad data in the redundant set.

Owner:GOU BEI +1

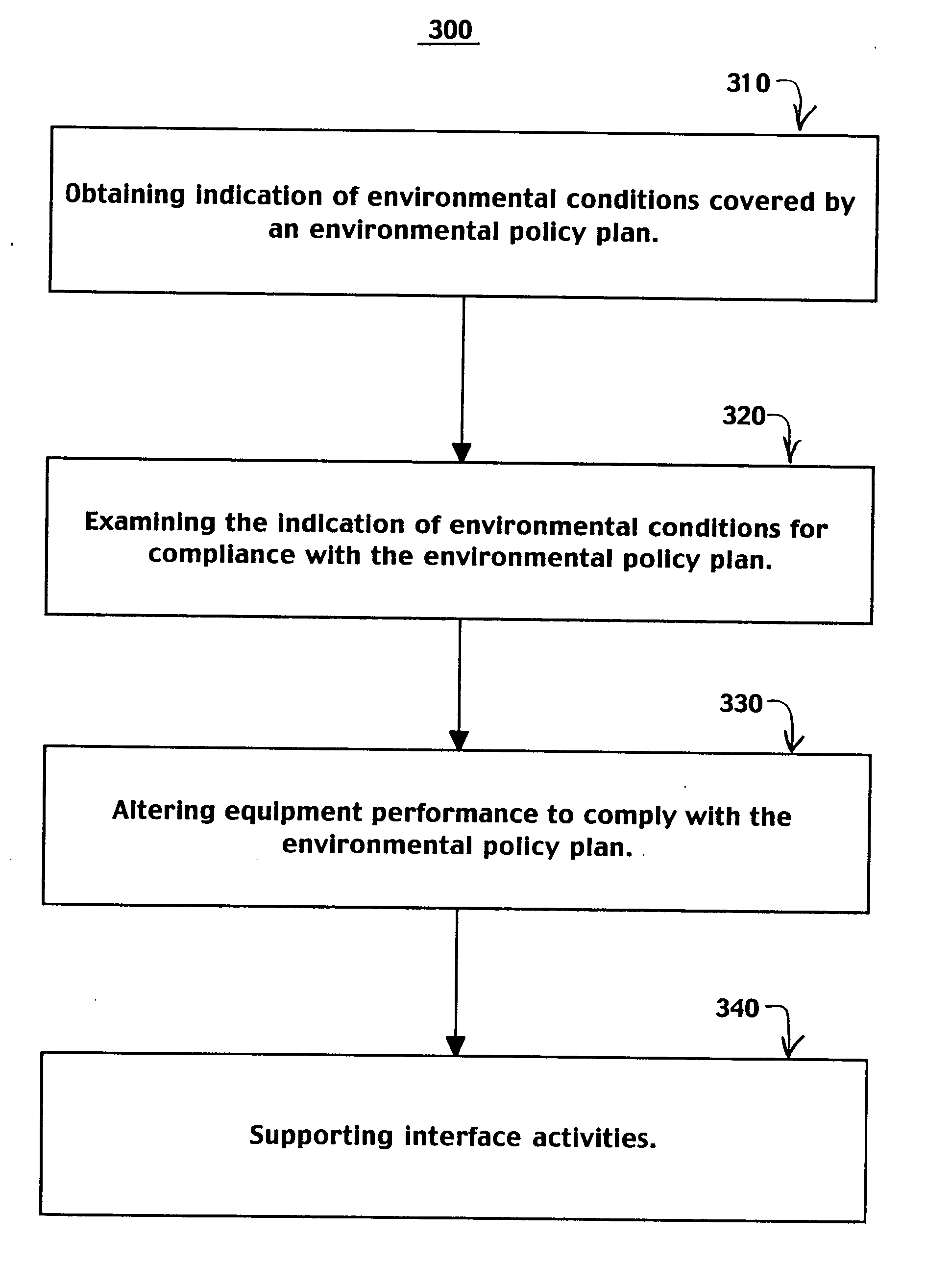

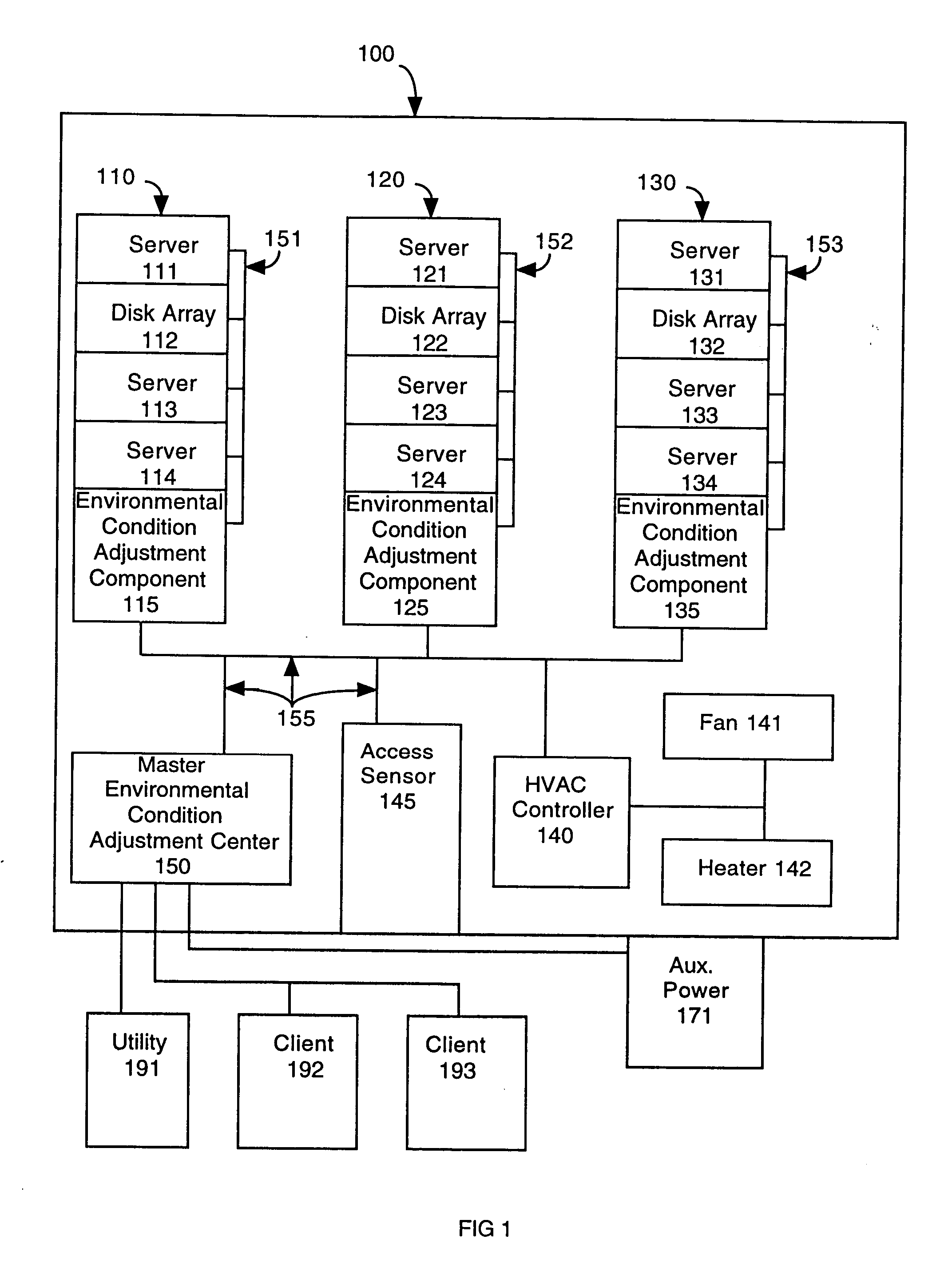

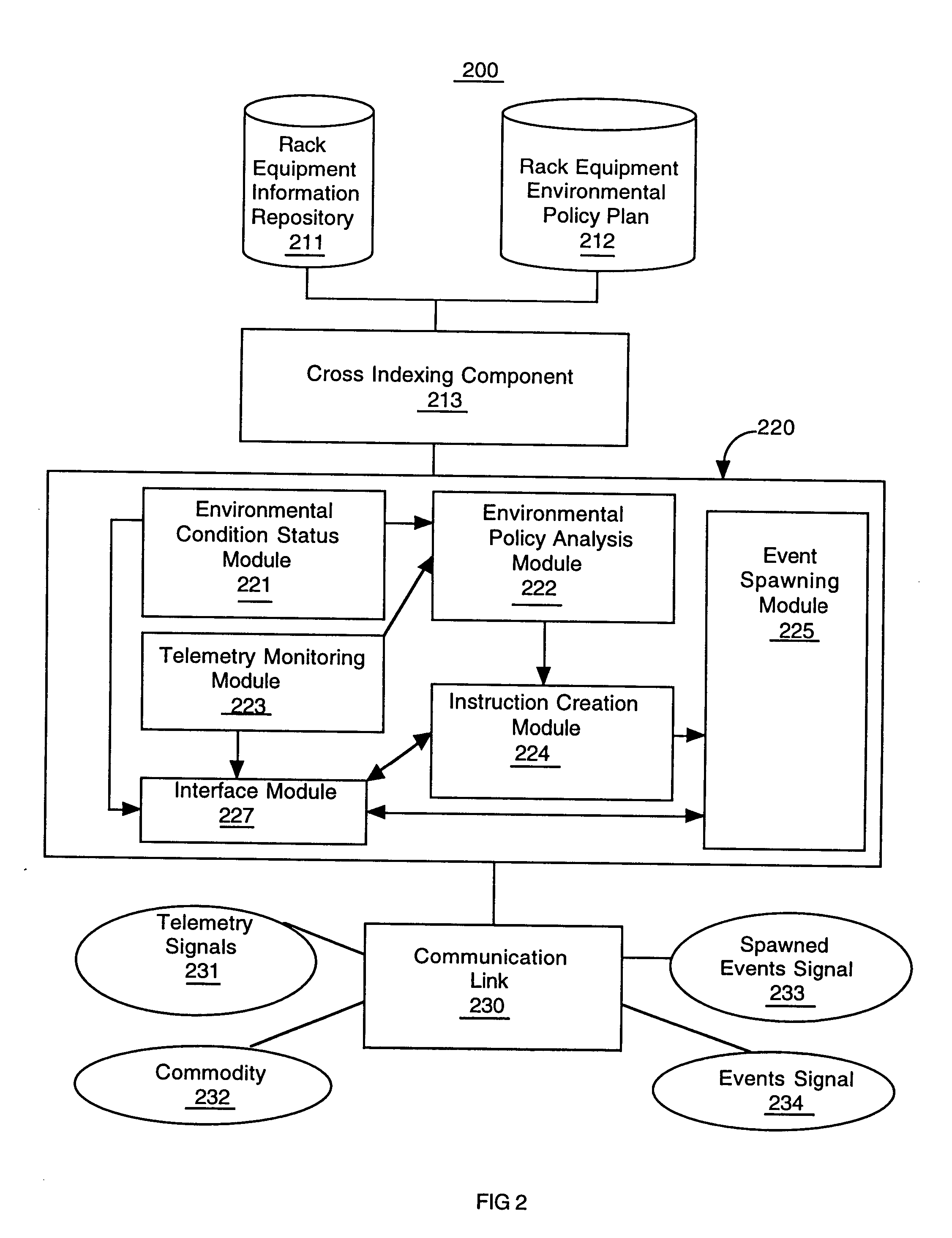

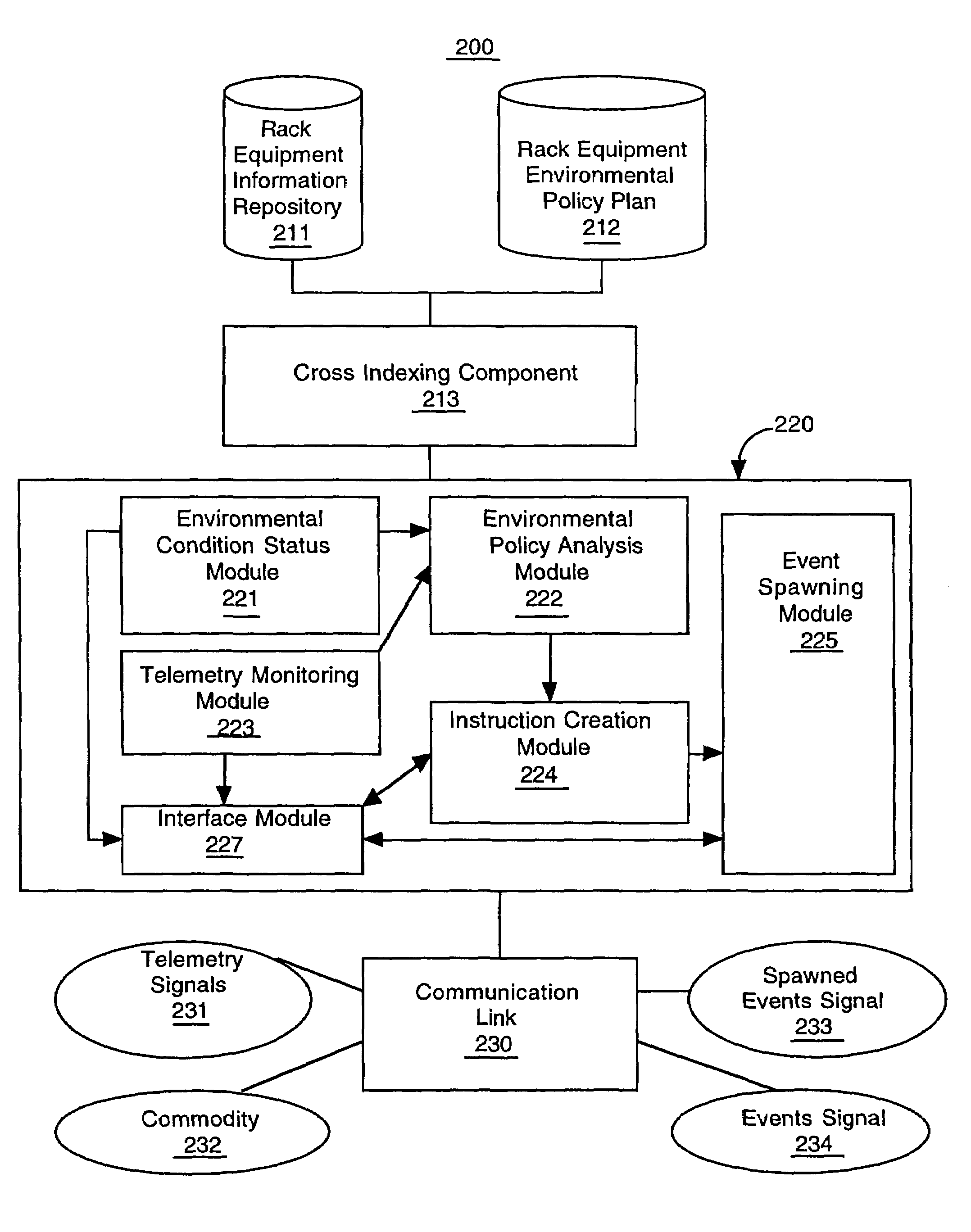

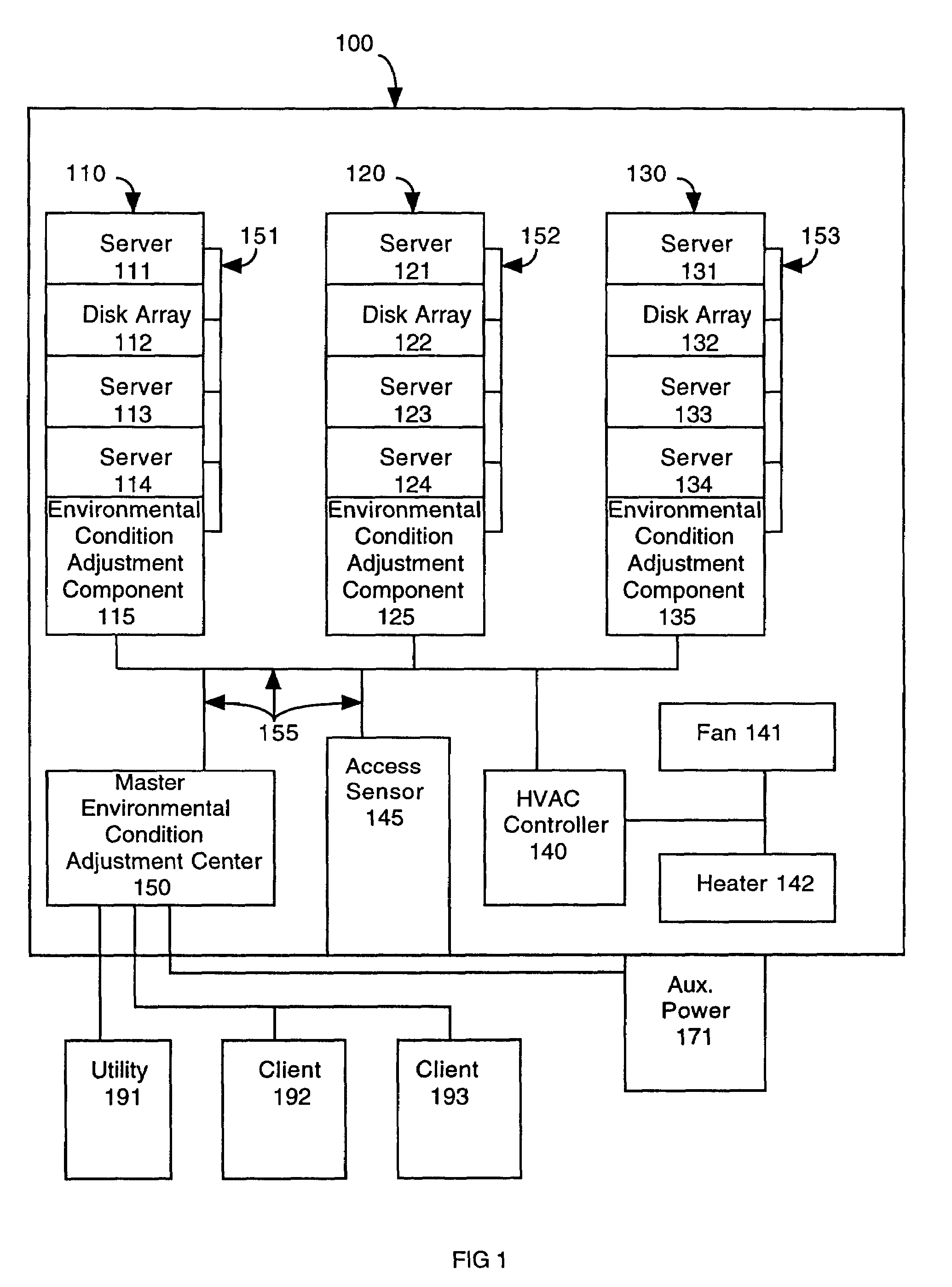

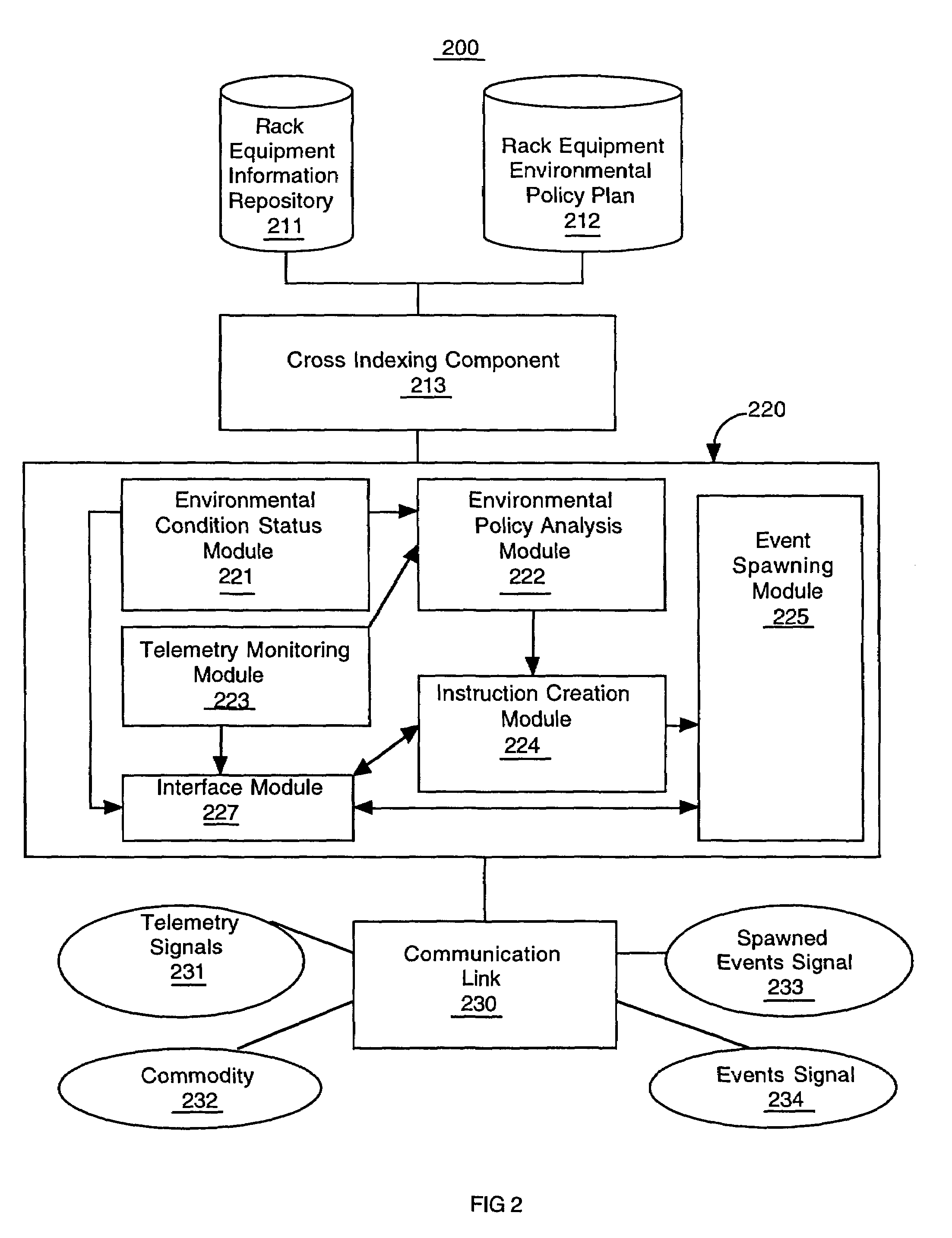

Rack equipment environmental condition adjustment system and method

ActiveUS20050075837A1Simultaneous control of electric and non-electric variablesVolume/mass flow measurementEngineering

A rack equipment environmental condition adjustment system and method is presented. In one embodiment of the present invention, a rack equipment environmental condition adjustment system includes rack equipment for processing information. An environmental condition adjustment component adjusts the rack equipment based upon environmental conditions. A communication bus for communicatively coupling the rack equipment and the environmental condition adjustment component, wherein the communication bus communicates information between the environmental adjustment component and the rack equipment.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Rack equipment environmental condition adjustment system and method

ActiveUS7039539B2Simultaneous control of electric and non-electric variablesVolume/mass flow measurementEngineering

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

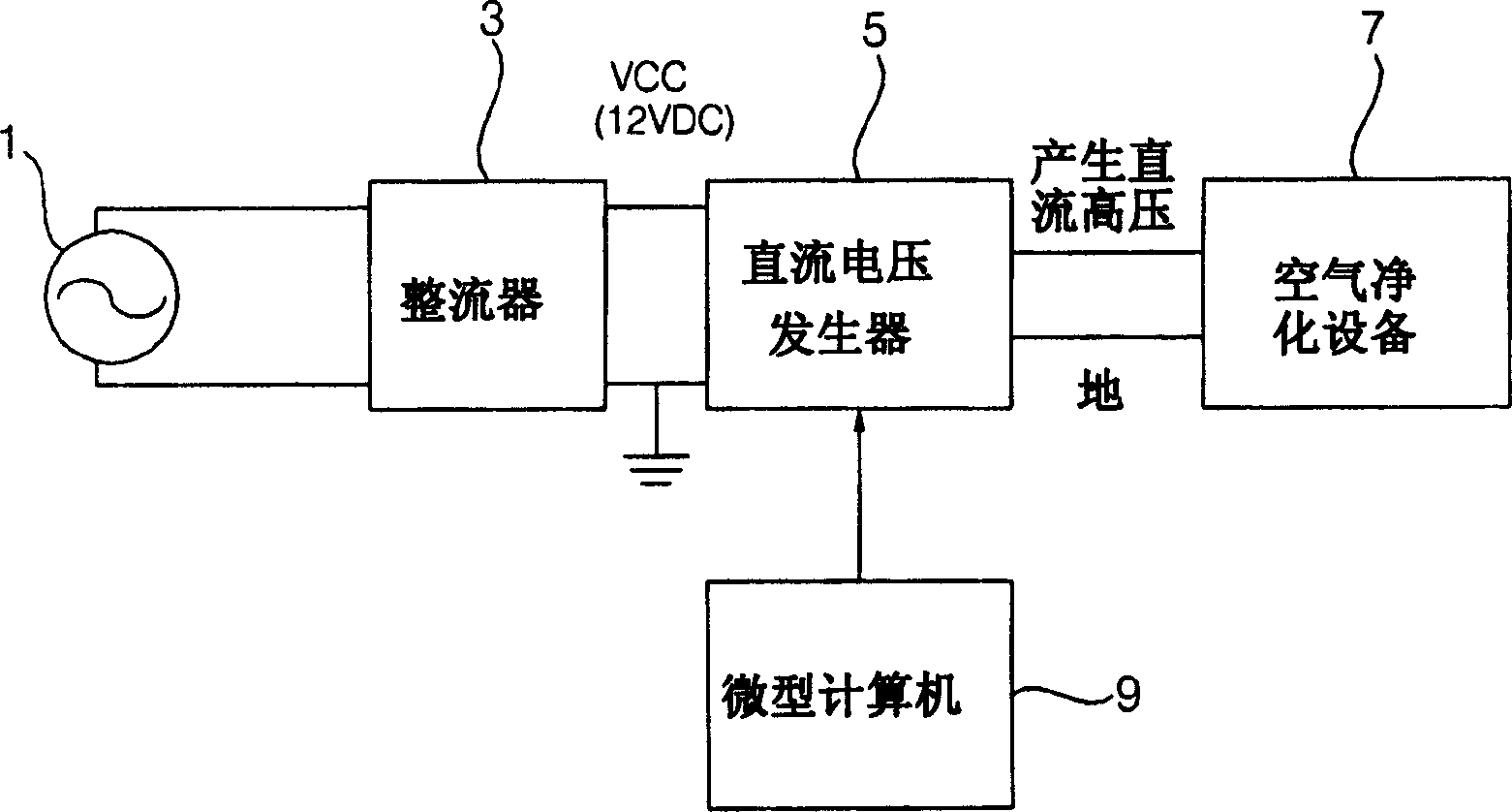

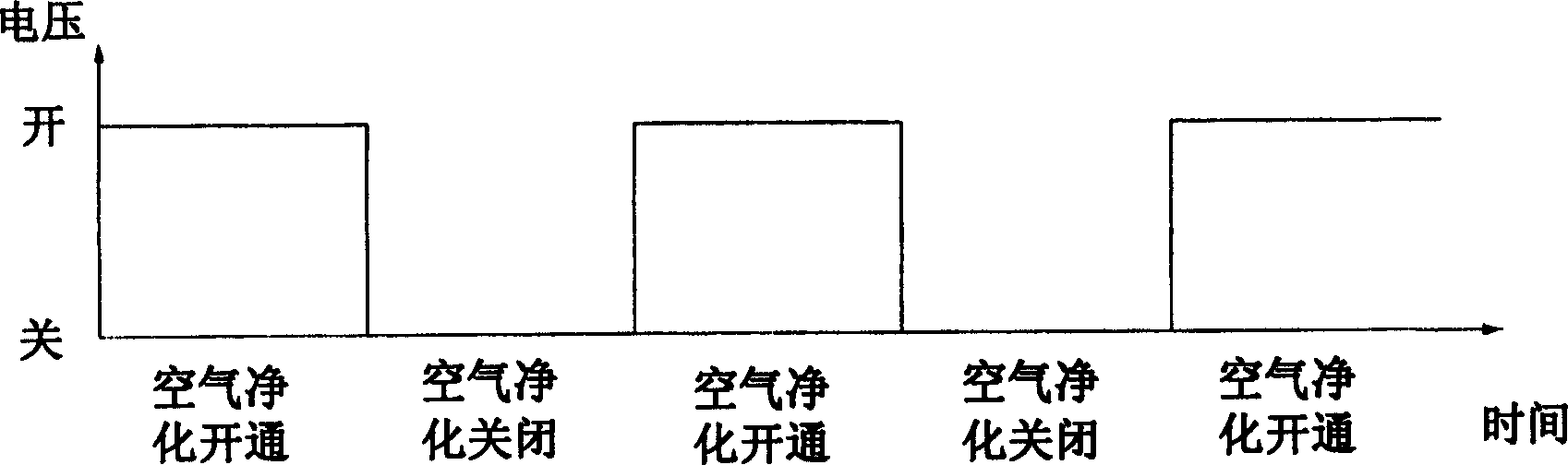

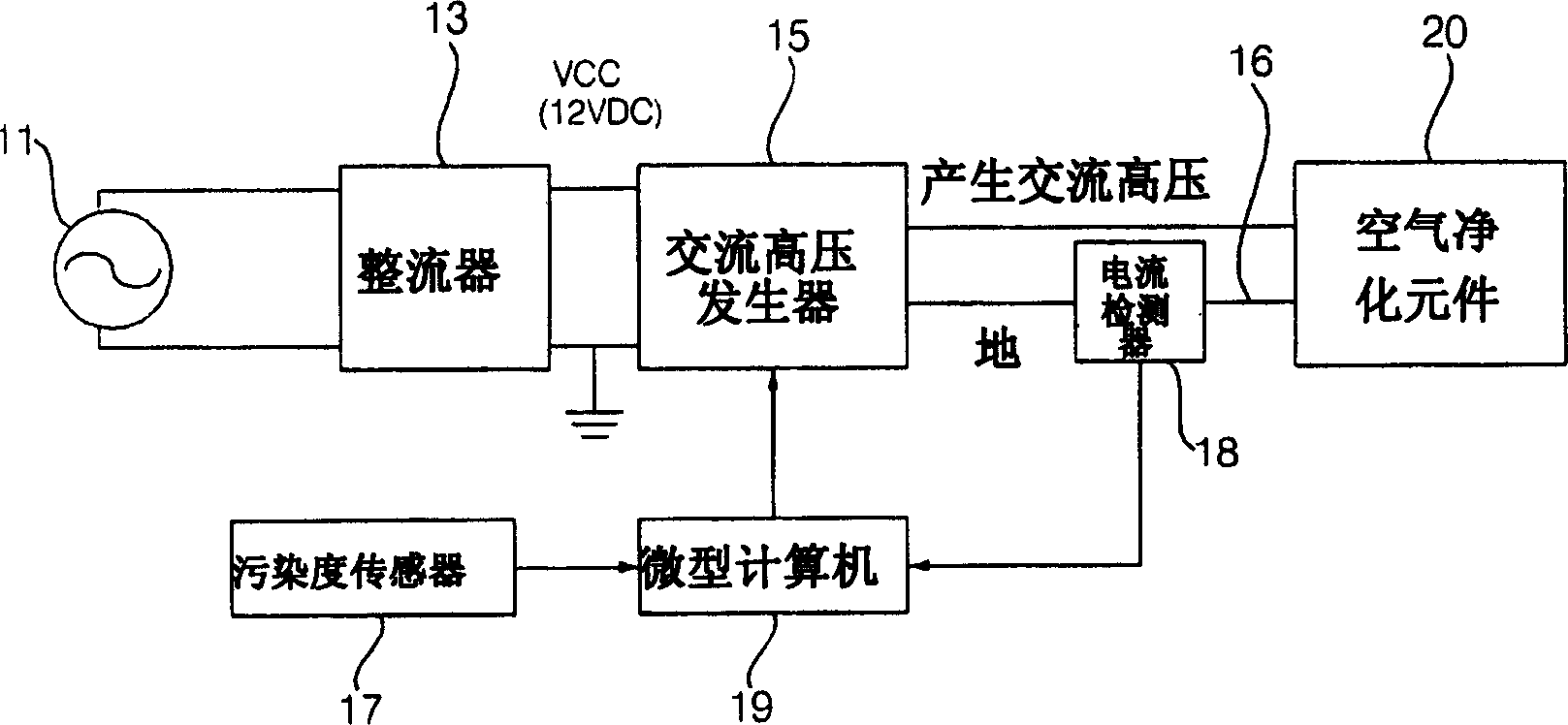

Apparatus and method for controlling air cleaning

InactiveCN1775299AImprove purification effectEffective disinfectionMechanical apparatusSimultaneous control of electric and non-electric variablesAir cleaningHigh pressure

The invention discloses a device and method for controlling air purification. The equipment includes an air cleaning element, a current detector, an AC high voltage generator and a control unit. The air purification element generates negative ions and ozone using plasma discharge and purifies indoor air by the negative ions and ozone. The current detector detects the state of the current flowing through the air cleaning element. The AC high voltage generator generates AC high voltage and applies the AC high voltage to the air cleaning element. The control unit changes the magnitude of the AC voltage applied to the air cleaning element by the AC high voltage generator based on the current detection signal received from the current detector. Therefore, based on the state of the indoor air, ozone below the limit value is sufficiently generated, thereby increasing the air cleaning effect to more effectively sterilize and purify pollutants.

Owner:LG ELECTRONICS INC

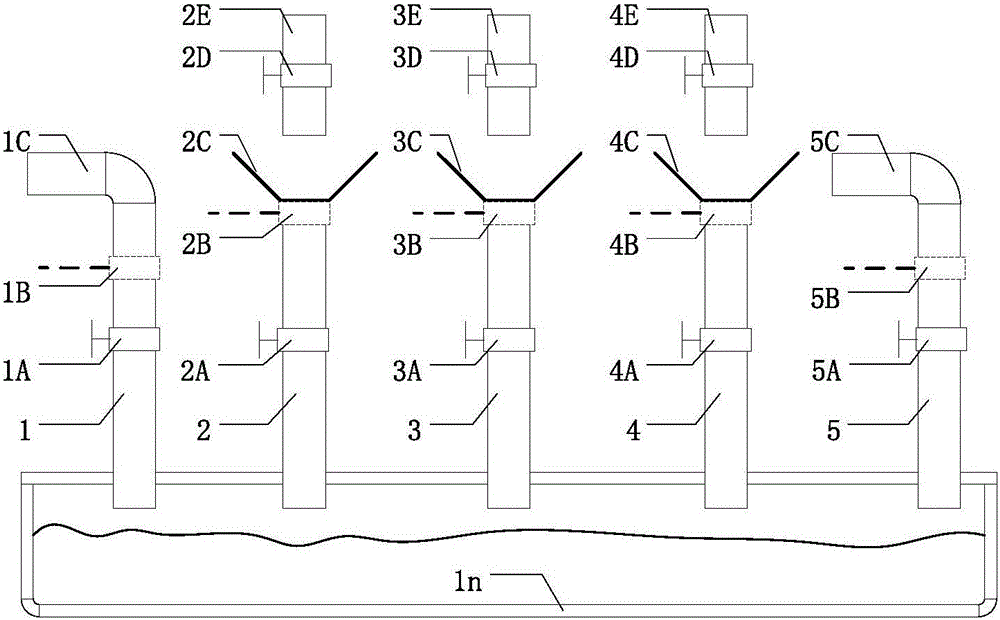

Nutrient solution concentration control method and nutrient solution concentration control system

InactiveCN105573356AControl concentrationReduce wasteControlling ratio of multiple fluid flowsSimultaneous control of electric and non-electric variablesNitrate nitrogenBiology

The invention relates to a nutrient solution concentration control method and a nutrient solution concentration control system, wherein the nutrient solution concentration control method and the nutrient solution concentration control system belong to the field of soilless culture in agricultural production. The nutrient solution concentration control method comprises the following steps of setting the concentration value range of nitrate nitrogen in the nutrient solution, electric conductivity range of the nutrient solution and pH value range of the nutrient solution; firstly adjusting the nitrate nitrogen in the nutrient solution to the preset concentration value range, then adjusting the electric conductivity of the nutrient solution to the preset conductivity range, and finally adjusting the pH value of the nutrient solution into the preset pH value range. Compared with the prior art, the nutrient solution concentration control method is advantageous in that the important function of the nitrate nitrogen in plant growth and relatively high content of the nitrate nitrogen in the nutrient solution are utilized; a nitrate nitrogen index is introduced for managing the nutrient solution; and the concentration of the nitrate nitrogen is individually managed for reducing a defect of incapability of reflecting component change of the nutrient solution and interference of nonnutritive substances according to an EC management method.

Owner:TONGJI UNIV

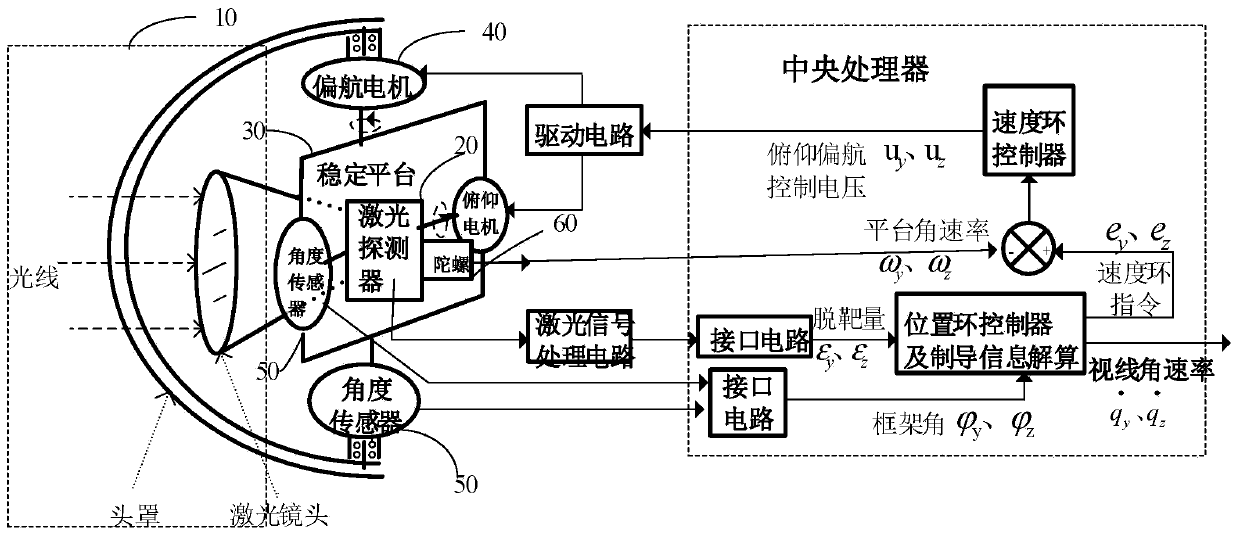

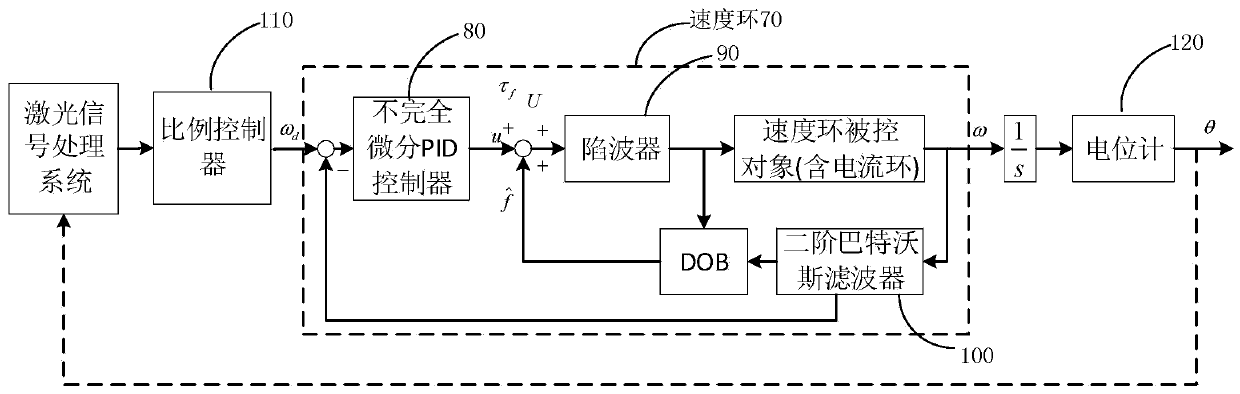

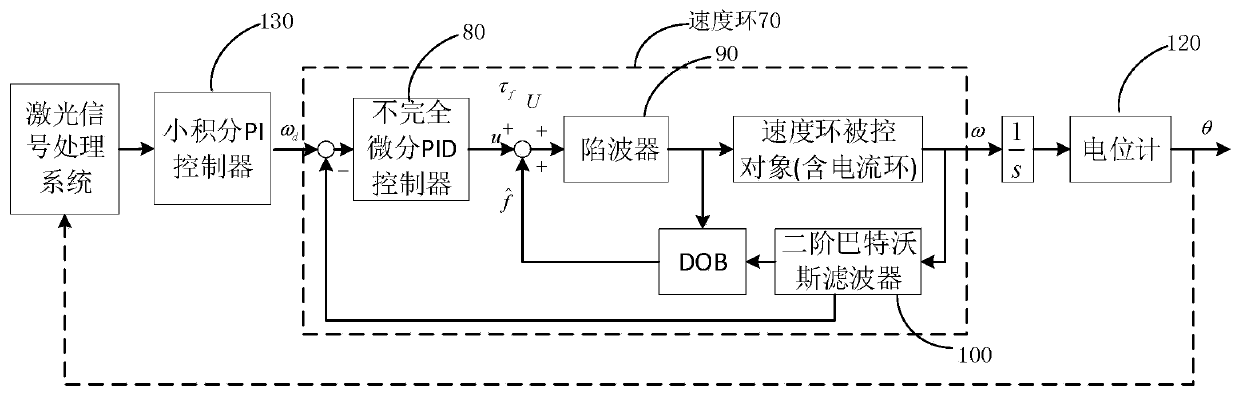

Control method and compound control system for seeker stabilization platform

ActiveCN110231845AEasy to implementSimple structureSimultaneous control of electric and non-electric variablesControllers with particular characteristicsLoop controlProportional control

The invention discloses a control method and compound control system for a seeker stabilization platform. According to the control method, three-loop control over the seeker stabilization platform iscarried out. Three loops comprise a current loop, a speed loop and a position loop. The current loop is realized through adoption of a brush motor PWM power drive chip. The speed loop is realized through utilization of a compound control policy. The compound control policy comprises a butterworth filter, a disturbance observer, a notch filter and incomplete differential PID. The position loop is realized through adoption of a small integral PI or proportion controller. According to the compound control system for the seeker stabilization platform provided by the invention, the seeker stabilization platform is controlled through adoption of the control method for the seeker stabilization platform. According to the control method provided by the invention, system disturbance rejection and speediness can be effectively improved. The control method is easy to realize. The compound control system for the seeker stabilization platform has the advantages of simple structure and easy realization.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Fire simulation experiment platform for tunnel

InactiveCN101726370BVersatileSimultaneous control of electric and non-electric variablesAerodynamic testingVisibilityControl system

The invention discloses a fire simulation experiment platform for a tunnel, which comprises a platform main body, a smoke control system, a fire source simulation system and a matched measurement and control system, wherein the platform main body can move horizontally, and at least two of the front surface, the upper surface and the back surface of the platform main body are made of fire-proof transparent materials; the smoke control system can simulate longitudinal wind in the tunnel; the fire source simulation system comprises a porous gas burner capable of controlling fuel flow rate; and the matched measurement and control system comprises a gas component measuring system and a smoke temperature measuring system, wherein the gas component measuring system is used for measuring gas components of burning products, and the smoke temperature measuring system is used for measuring the temperature in the tunnel. In the invention, the fire simulation experiment platform for the tunnel enables the inside of a simulated tunnel to have good visibility, can be used for conveniently and effectively observing the conditions in the tunnel and optically measuring the characteristics of the flow field through laser sheets, and can also realize the purpose of controlling the power of the fire source according to research needs.

Owner:UNIV OF SCI & TECH OF CHINA

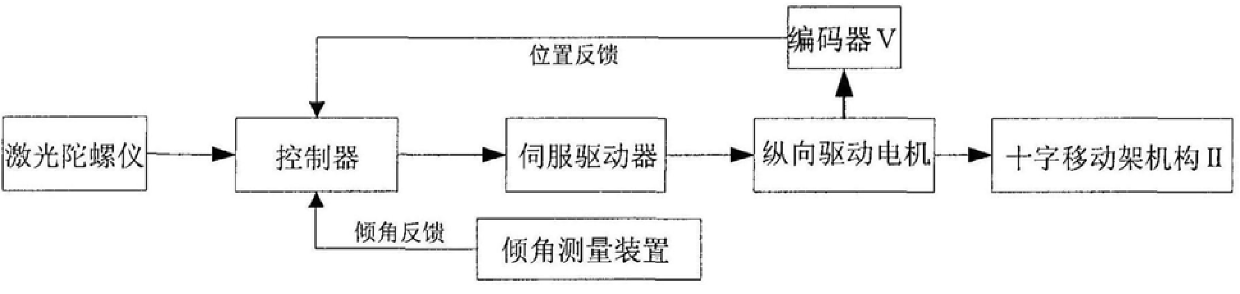

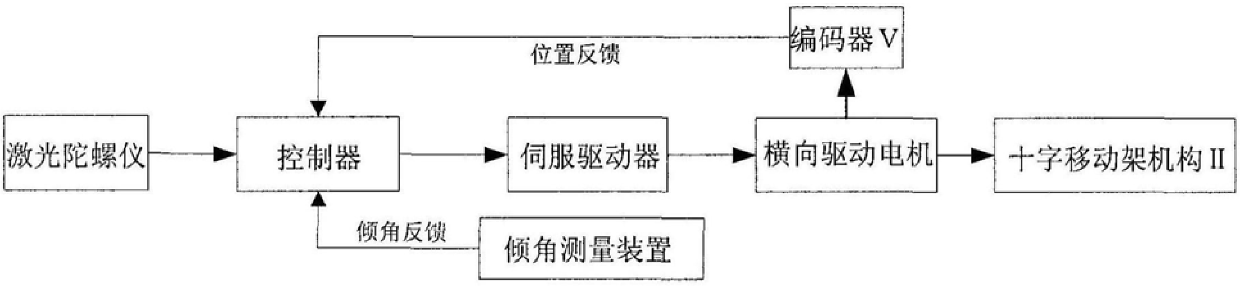

Three-dimensional follow-up system of lunar landing test rig

InactiveCN107182270BCosmonautic condition simulationsSimultaneous control of electric and non-electric variablesRelative displacementObstacle avoidance

The invention discloses a three-dimensional follow-up system of a lunar landing test frame, to achieve the purpose of providing the vertical tension control and horizontal movement follow-up required by the lunar probe in the lunar landing test frame; the three-dimensional follow-up system Including tower follow-up system, fast follow-up system, ground drive system and wire rope; fast follow-up system includes horizontal fast follow-up subsystem and tension adjustment subsystem; tower follow-up system includes first-level horizontal drive subsystem, second-level The horizontal follow-up subsystem and the main lifting subsystem; the ground driving system includes 6 ground driving devices; during the entire operation of the detector, the tension adjustment subsystem provides a vertical upward 5 / 6G pulling force; the detector performs obstacle avoidance In the process of slow and slow descent, the main lifting subsystem controls the relative displacement between the detector and the disc in the vertical direction; the horizontal fast follow-up subsystem follows the detector; the secondary horizontal follow-up subsystem performs two-dimensional horizontal movement Come follow the fast follow-up system.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT

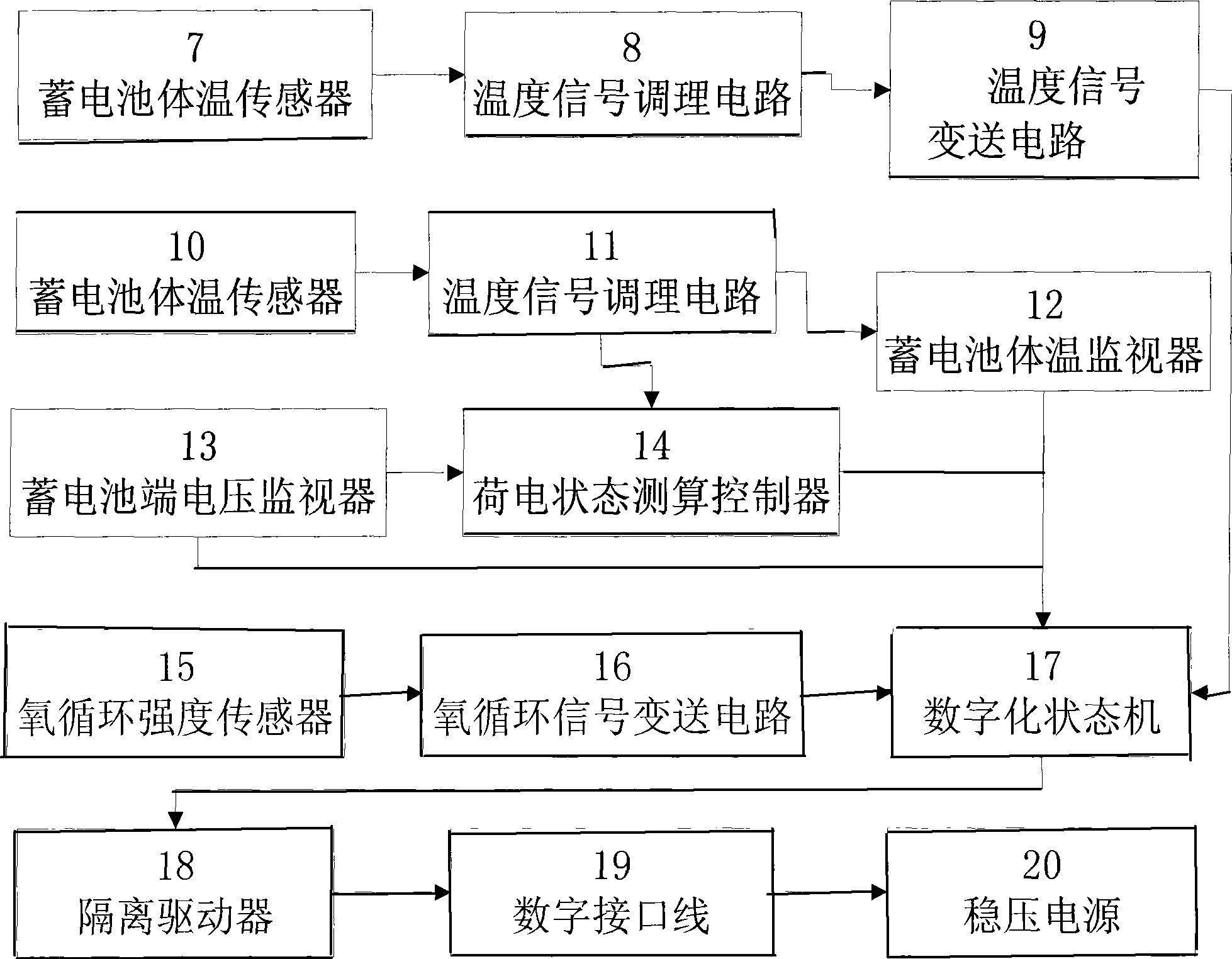

Digital accumulator battery

InactiveCN101546852AReliable transmissionSimultaneous control of electric and non-electric variablesSecondary cellsReliable transmissionDigitization

The invention relates to an accumulator battery, in particular to an accumulator battery digitizing real-time status measuring and control data of the accumulator battery and transmitting the data to an adaptive charger to realize digitalization of measuring and control in the charging process. Parameter setting in the charging process is a deciding factor of the service life of the accumulator battery along a vehicle; in particular, charging voltage adapts to continuous changes of an internal microstructure of the accumulator battery and external environmental temperature; and in order to ensure that a proper charging process is always kept in the complete life cycle of the accumulator battery, the charger is required to have the capacity of automatically adapting to the changes, so that the accumulator battery is required to be capable of outputting the real-time status measuring and control data to provide support for the charging process. Because related physical descriptors are weak, effective perception and reliable transmission are master keys of success. Therefore, the accumulator battery provides a digitization proposal, comprises a measuring and control module, interface specification and a packaging cavity, and is applicable to electric automobiles and electric bicycles with overlong series charging.

Owner:张佳宾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com