Three-dimensional follow-up system of lunar landing test rig

A technology of a follow-up system and a test stand, which is applied in general control systems, control/regulation systems, non-electric variable control, etc., and can solve the problems that cannot be carried out on the moon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with the accompanying drawings and embodiments, the present invention will be described in detail.

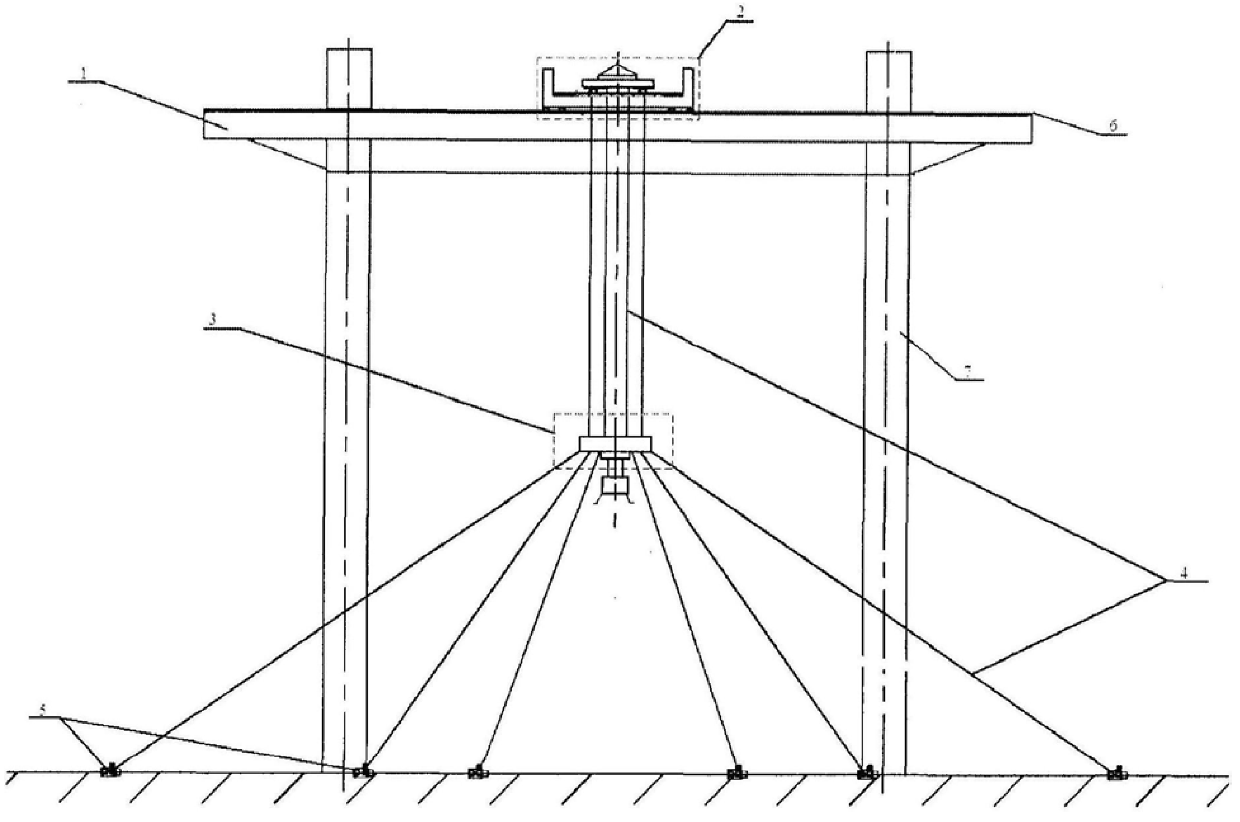

[0043] The tower follower system 2 is arranged on the guide rail 6 of the horizontal tower 1, and can move along the guide rail 6 in the x direction.

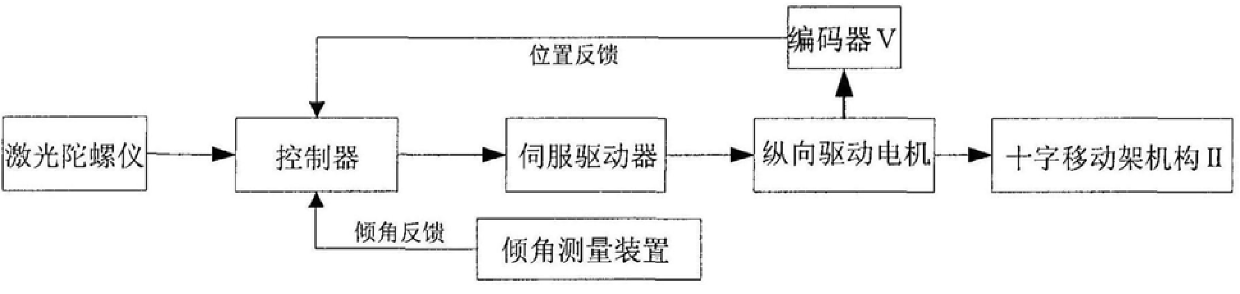

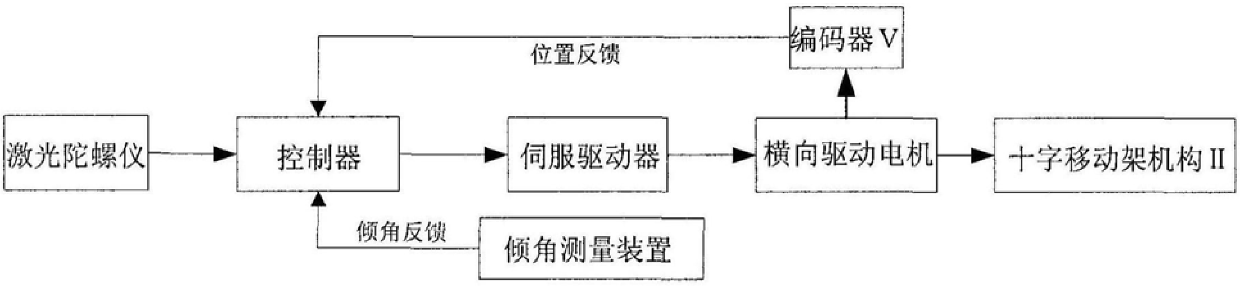

[0044] The fast follow-up system 3 includes a horizontal fast follow-up subsystem and a tension adjustment subsystem. horizontal fast follower

[0048] The operator inputs the tension setting value (5 / 6) G through the controller in the ground control room. The controller calculates

[0061] 1) The controller in the ground control room opens each motor in the three-dimensional servo system through cables.

[0062] 2) The detector is ignited, and the detector starts to operate, and then hovers, avoids obstacles, slows down and lands. same

[0077] In summary, the above are only preferred embodiments of the present invention, and are not intended to limit the scope of protection of the present invention. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com