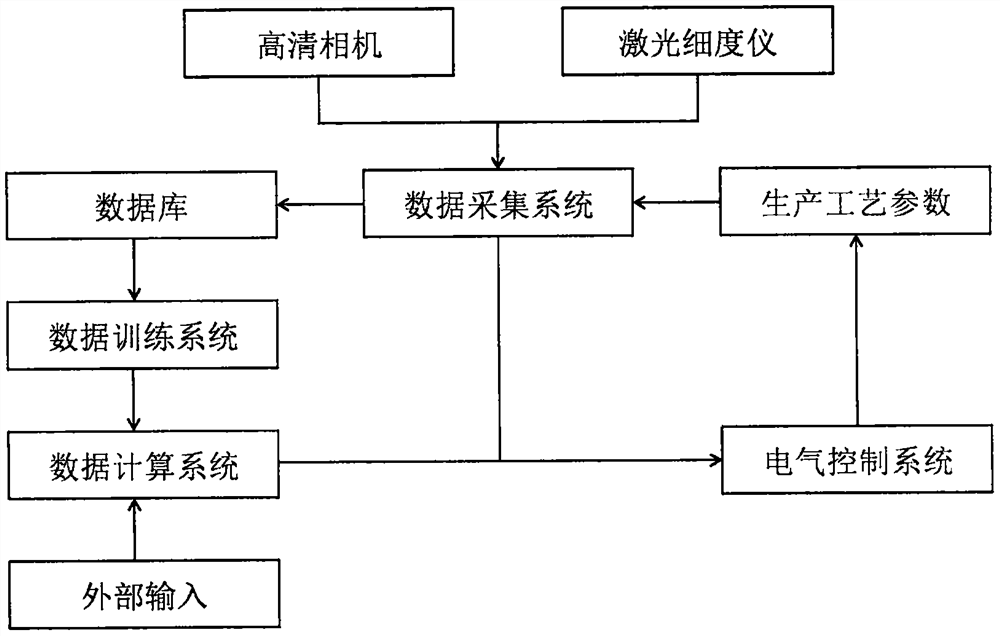

Automatic flame cotton production control system based on a neural network

A technology of neural network and electrical control system, applied in the field of automatic control system of ultra-fine glass wool felt production line, to achieve the effect of improving accuracy, realizing energy saving and emission reduction, and stable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

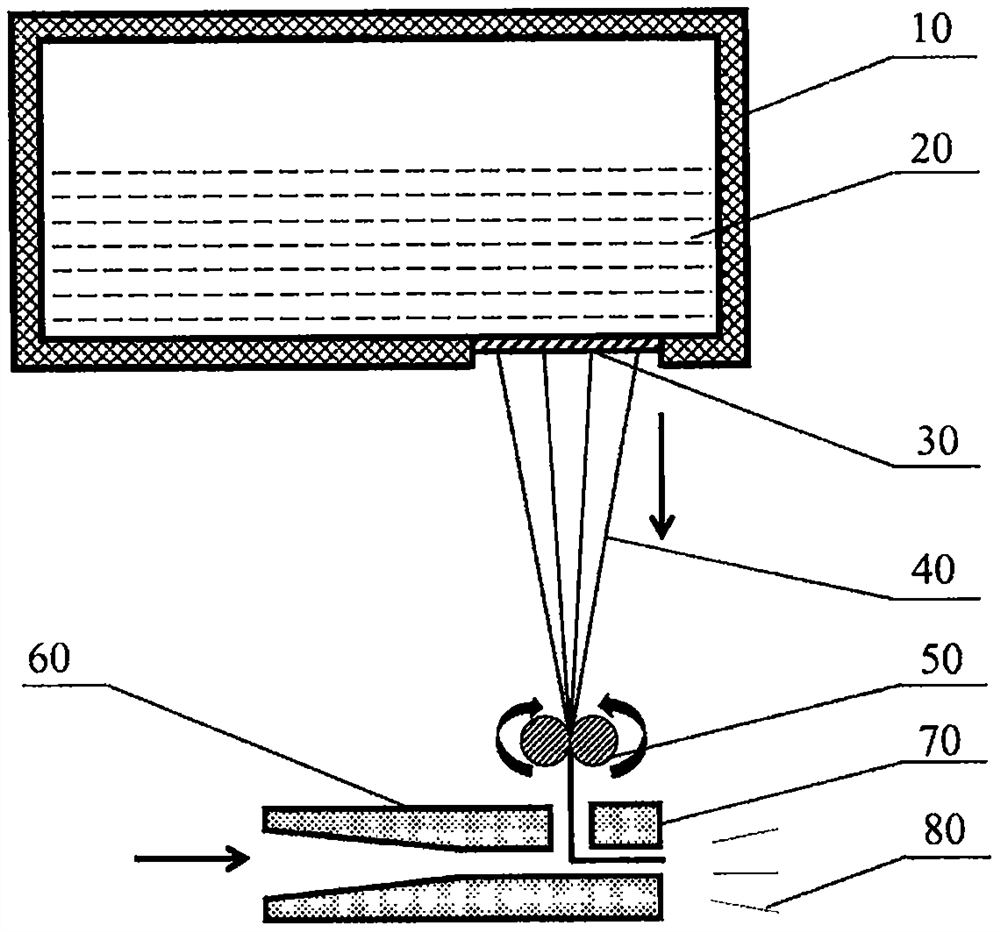

[0016] An automatic control system for flame cotton production based on neural network, which is composed of kiln, drain plate, combustion chamber, flame nozzle, rubber roller, data acquisition system, data calculation system, data training system, electrical control system, database, production process The parameters include kiln natural gas flow rate, kiln liquid level height, drain plate current, rubber roller speed, combustion chamber natural gas flow rate, and combustion chamber air flow rate; the data acquisition system reads various production process parameters in real time and stores them in the database; the data The training system reads the production process parameter records in the database, uses the neural network for training and learning, and constructs the relationship model of the kiln natural gas flow rate, kiln liquid level height, drain plate current, rubber roller speed on the average diameter of the primary fiber and the relationship model of the primary ...

Embodiment 2

[0020] An automatic control system for flame cotton production based on neural network, which is composed of kiln, drain plate, combustion chamber, flame nozzle, rubber roller, data acquisition system, data calculation system, data training system, electrical control system, database, production process The parameters include kiln natural gas flow rate, kiln liquid level height, drain plate current, rubber roller speed, combustion chamber natural gas flow rate, and combustion chamber air flow rate; the data acquisition system reads various production process parameters in real time and stores them in the database; the data The training system reads the production process parameter records in the database, uses the neural network for training and learning, and constructs the relationship model of the kiln natural gas flow rate, kiln liquid level height, drain plate current, rubber roller speed on the average diameter of the primary fiber and the relationship model of the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com