Heat recovery super heat pump system for electric vehicle

A heat pump system, electric vehicle technology, applied in heat pumps, air conditioning systems, heating methods, etc., can solve problems such as waste of resources, and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

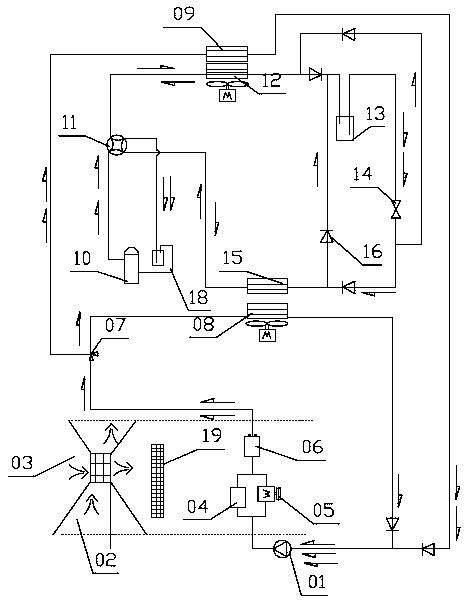

[0019] like figure 1 As shown, the electric vehicle heat recovery super heat pump system of the present invention includes a power pump 01, a motor driver 04, a drive motor 05, a battery 06, a three-way stop valve 07, a first external heat exchanger 15, a second external heat exchanger device 08, compressor 10, four-way valve 11, first in-vehicle heat exchanger 12, second in-vehicle heat exchanger 09, liquid reservoir 13, throttling element 14, control valve 16, gas-liquid separator 18, Electric heater 19. In this embodiment, the throttling element 14 is an expansion valve, and the control valve 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com