Vehicle exhaust heat recovery system and method of managing exhaust heat

a technology for exhaust heat recovery and vehicles, applied in indirect heat exchangers, machines/engines, lighting and heating apparatus, etc., can solve problems such as affecting fuel economy and especially difficult engine warm-up, and achieve the effect of improving transmission durability and fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

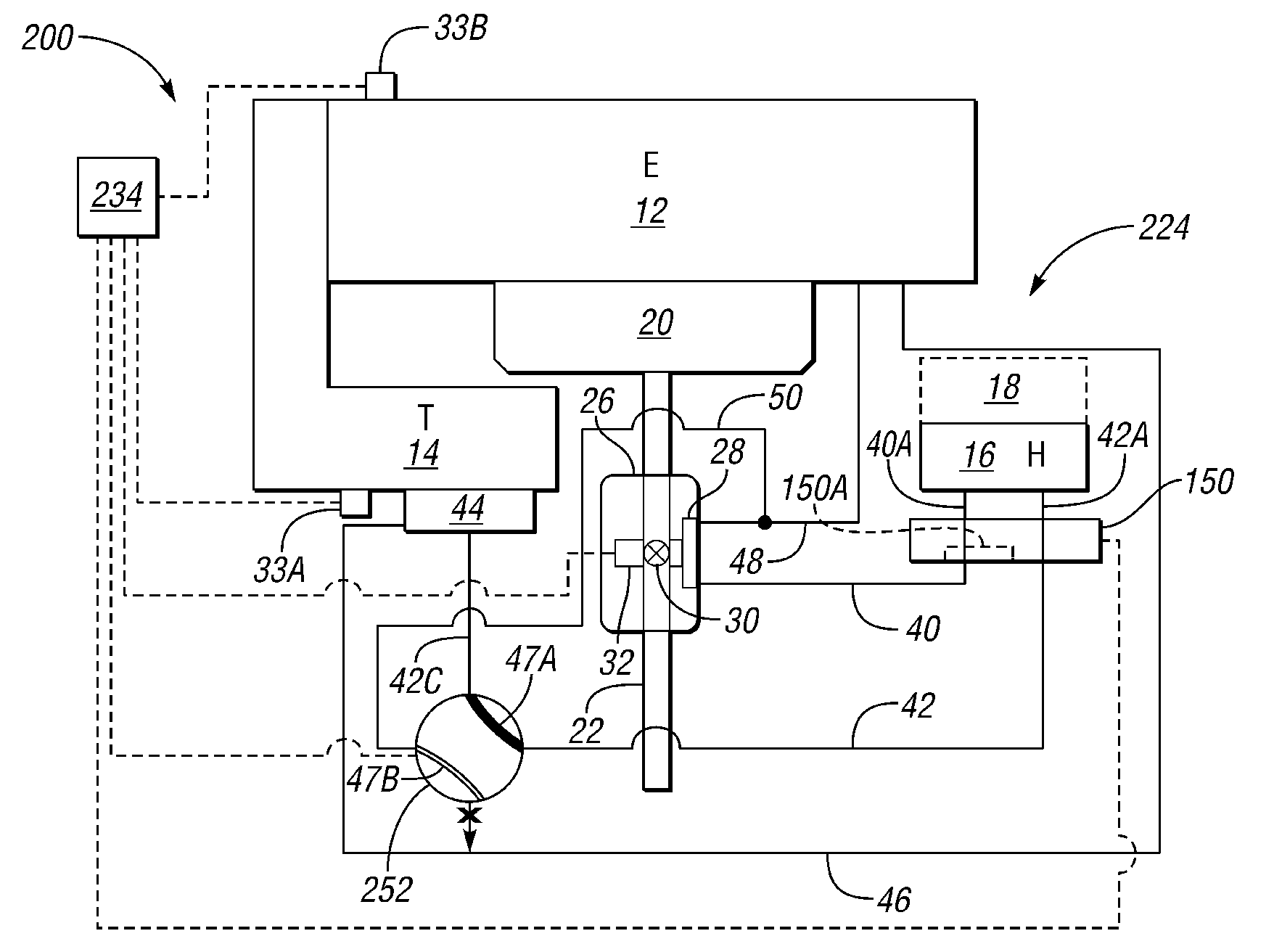

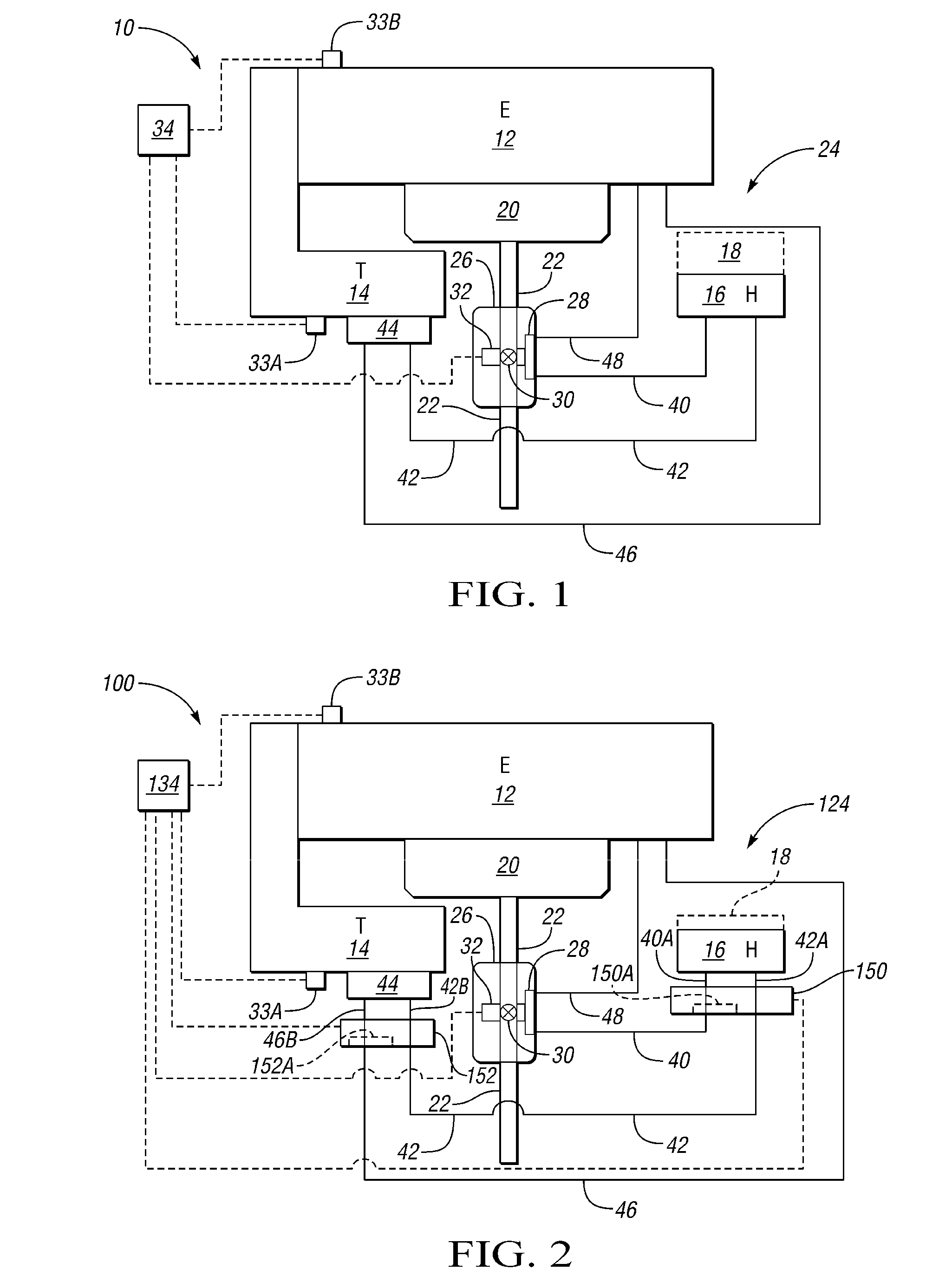

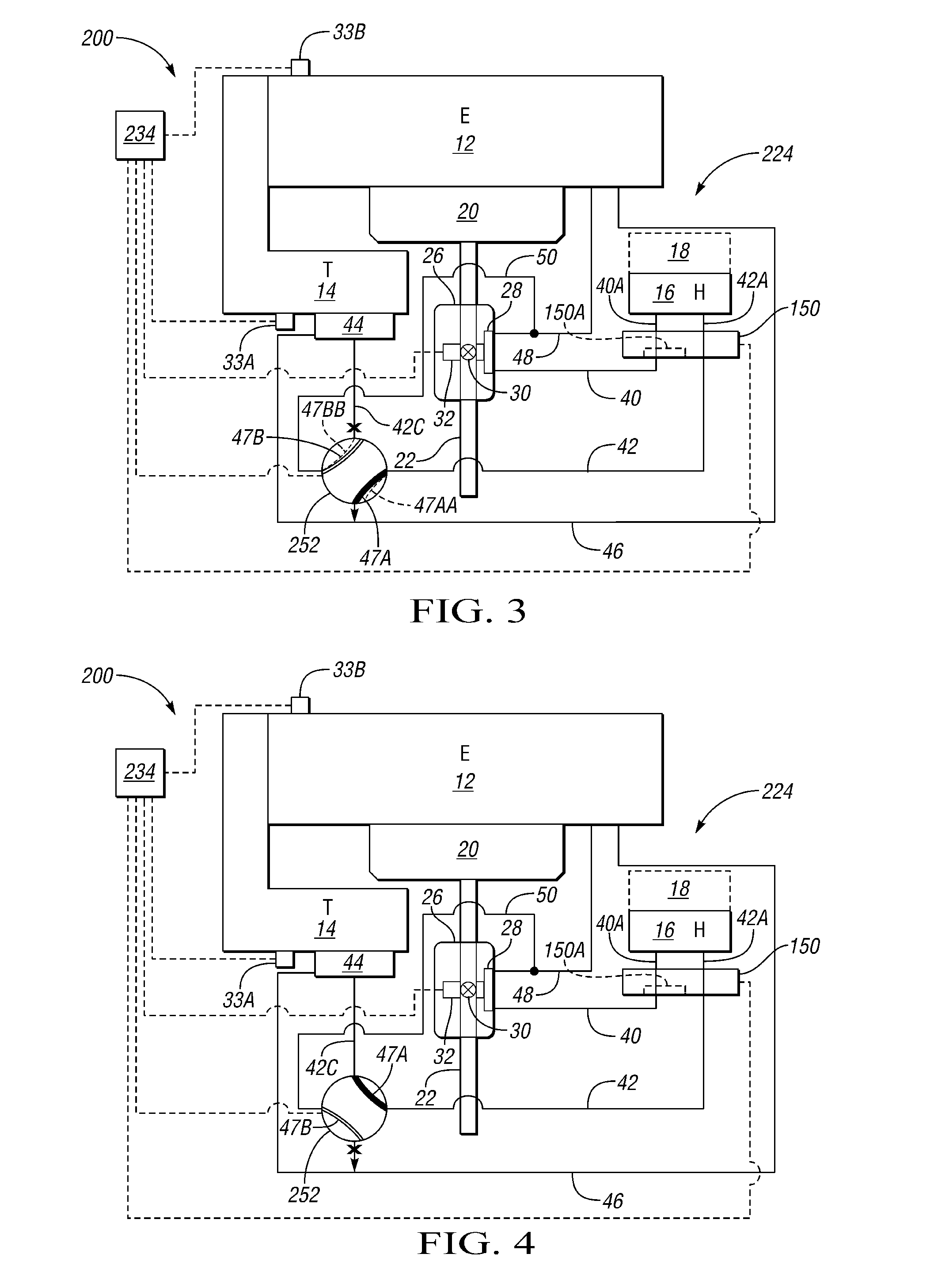

[0016]Referring to the drawings, wherein like reference numbers refer to like components throughout the several views, FIG. 1 shows a vehicle 10 that has an engine 12 (labeled E) for propelling the vehicle 10, a transmission 14 (labeled T) operatively connected to the engine 12, and a passenger compartment heater 16 (labeled H) for heating a passenger compartment, indicated in phantom as 18.

[0017]The engine 10 is an internal combustion engine of the gasoline or diesel type, and generates exhaust gas in an exhaust system that includes an exhaust manifold 20 and an exhaust pipe 22 extending therefrom. The exhaust gas, which is relatively hot, exits the vehicle via the exhaust pipe 22. An exhaust heat recovery system (EHRS) 24 is provided in order to selectively capture some of the exhaust heat for providing heat to the passenger compartment 16, the transmission 14, and the engine 12. The EHRS 24 includes an exhaust heat recovery device (EHRD) 26 positioned in the exhaust system. Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com