Method to control and diagnose an exhaust gas heat exchanger

A heat exchanger and exchanger technology, applied in electrical control, engine control, fuel injection control, etc., can solve the problems of cooling liquid boiling time and lag, and achieve the effect of improving fuel economy and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As required, specific embodiments of the present invention are disclosed herein, however, it is to be understood that the disclosed embodiments are merely exemplary and may be embodied in various and alternative forms. The figures are not necessarily to scale, some features may be exaggerated or minimized to show details of particular components. Therefore, specific structural and functional details disclosed herein are not to be interpreted as limiting, but merely as a representative basis for teaching one skilled in the art to variously employ the present invention.

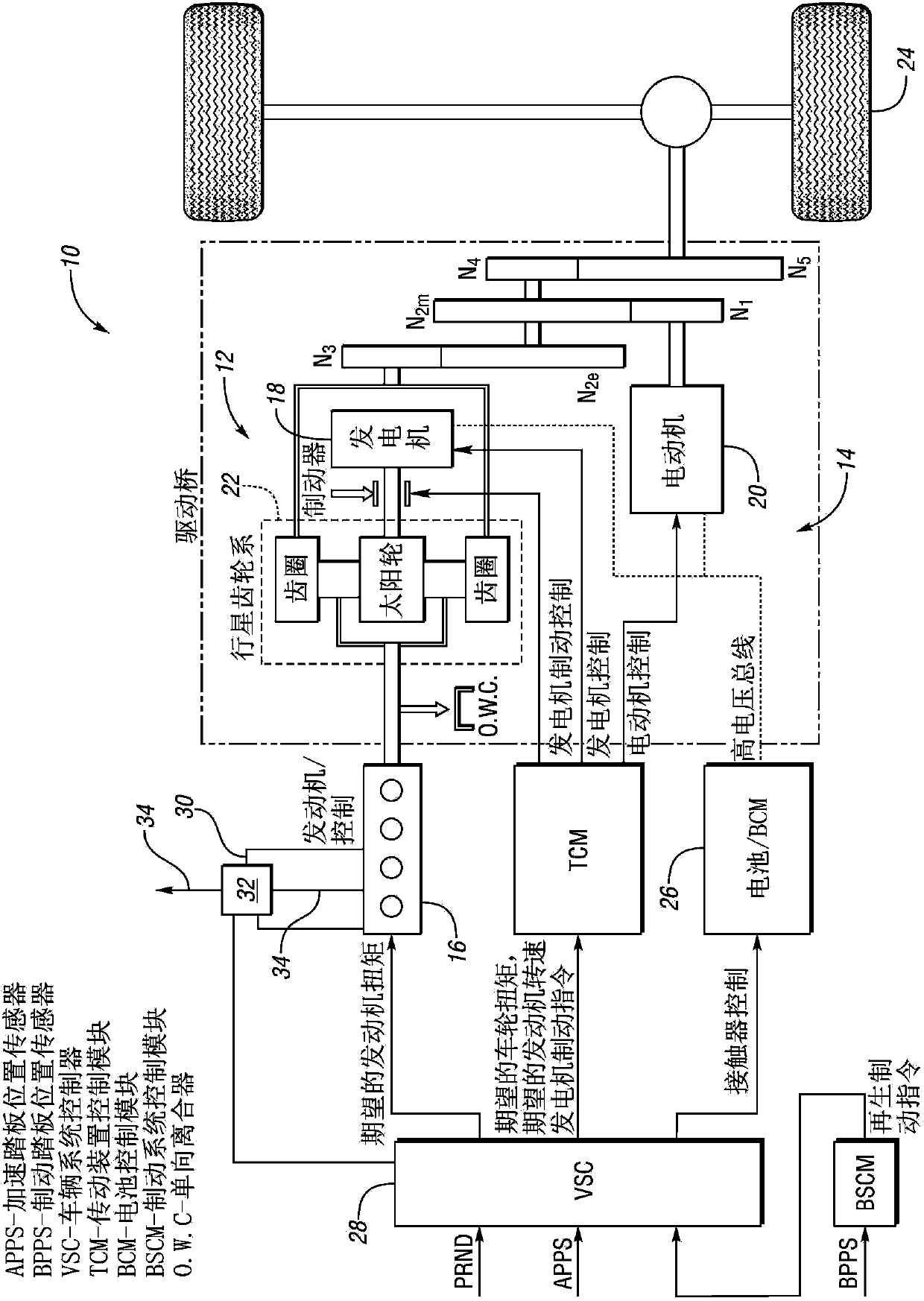

[0039] exist figure 1 In , an embodiment of a hybrid electric vehicle (HEV) 10 is schematically shown. In this drivetrain configuration, there are two power sources 12, 14 connected to the drivetrain: 12 is a combination of engine and generator subsystems connected to each other using planetary gear sets; 14 is the electric drive system (motor, generator machine, battery subsystem). The battery subsys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com