Exhaust heat recovery system

a heat recovery system and exhaust heat technology, applied in the direction of machines/engines, combustion air/fuel air treatment, light and heating equipment, etc., can solve the problems of stock fuel not being efficiently separated, the temperature of other systems of internal combustion engines requiring a rise of temperature, and the heat energy not recovered by the heat pipe, etc., to achieve a certain degree of heat recovery, maintain the warm-up performance of the exhaust purification catalyst, and recover at least a certain amount of exhaust heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

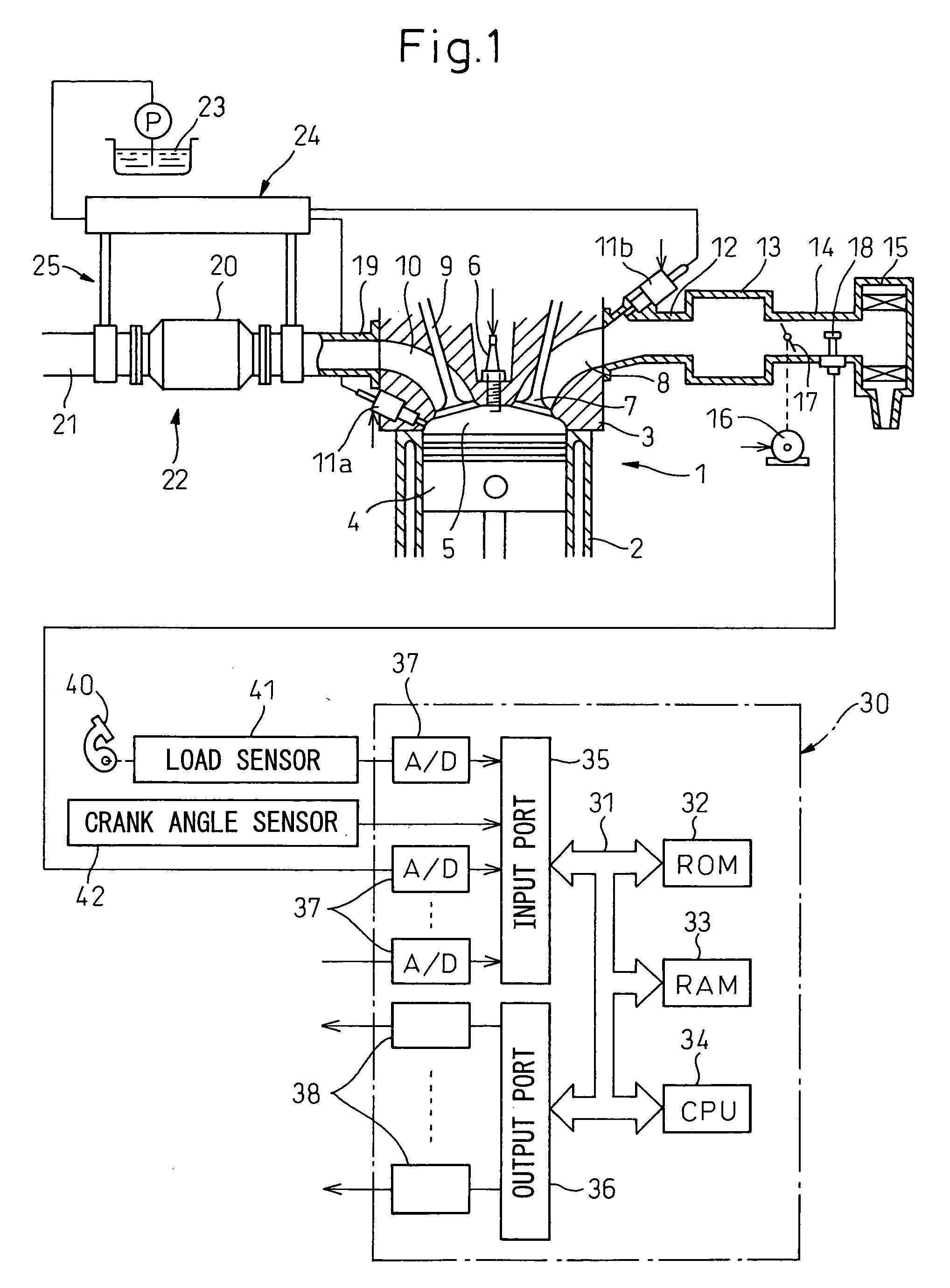

[0028]Below, referring to the drawings, an exhaust heat recovery system of the present invention will be explained in detail. FIG. 1 is a side cross-sectional view of a spark ignition type internal combustion engine at which an exhaust heat recovery system is mounted.

[0029]Referring to FIG. 1, 1 indicates an engine body, 2 a cylinder block, 3 a cylinder head, 4 a piston, 5 a combustion chamber, 6 a spark plug arranged at the center of the top of the combustion chamber 5, 7 an intake valve, 8 an intake port, 9 an exhaust valve, and 10 an exhaust port. On the peripheral region of each cylinder inner wall of the cylinder head 4, a fuel injector 11a for injecting fuel directly into the combustion chamber 5 (below referred to as “in-cylinder fuel injector”) is arranged. Each intake port 8 is connected through an intake branch pipe 12 to a surge tank 13. At each intake branch pipe 12, a fuel injector 11b for injecting fuel toward the inside of the corresponding intake port 8 (below referr...

fourth embodiment

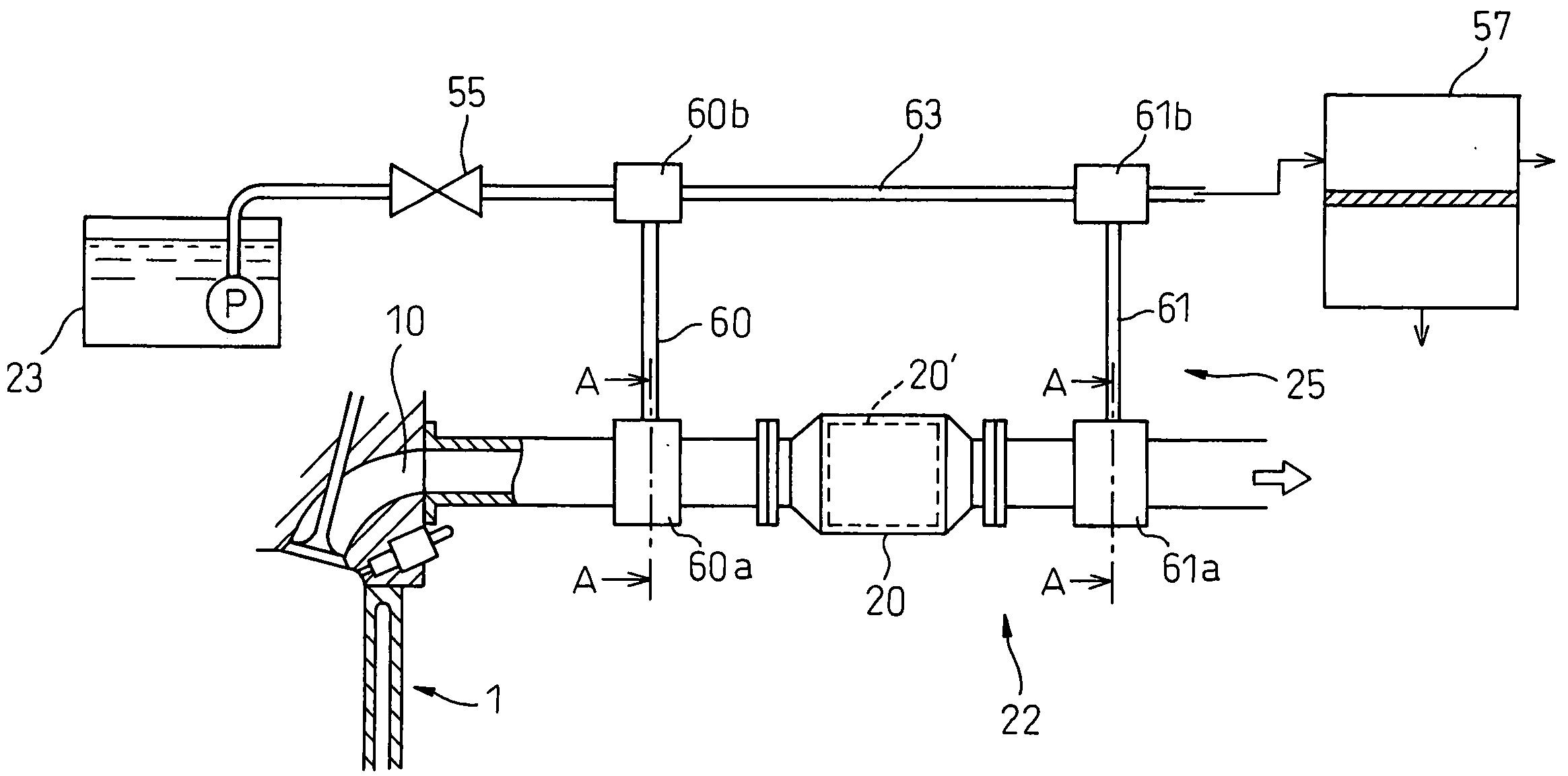

[0086]That is, as shown in FIG. 8, in the fourth embodiment, two fuel feed pipes 63a, 63b are provided between the stock fuel tank 23 and the separation unit 57. The fuel feed pipes 63a, 63b are provided with flow control valves 55a, 55b, respectively. The heat exchange part 60b of the upstream side heat pipe 60 is attached to the first fuel feed pipe 63a, while the heat exchange part 61b of the downstream side heat pipe 61 is attached to the second fuel feed pipe 63b.

third embodiment

[0087]In the present embodiment, when the temperature of the downstream side heat pipe 61 is lower than a certain fixed reference temperature, only the flow control valve 55a provided at the first fuel feed pipe 63a is opened. The flow control valve 55b provided at the second fuel feed pipe 63b is not opened. On the other hand, when the temperature of the downstream side heat pipe 61 is the reference temperature or more, the two flow control valves 55a, 55b are opened. Due to this, in the same way as the third embodiment, it is possible to efficiently supply the heat of the exhaust gas to the stock fuel flowing into the separation unit 57.

[0088]Note that in the present embodiment as well, it is also possible to adjust the opening degree of the second flow control valve 55b in accordance with the temperature of the downstream side heat pipe 61 and the flow rate of the stock fuel to be supplied from the stock fuel tank 23 to the separation unit 57 in the same way as the third embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com