Electrolysis apparatus

a technology for electrolysis apparatus and electrolysis chamber, which is applied in the field of electrolysis apparatus, can solve the problems of limited heat recovery mechanism and limited heat recovery mechanism, and achieve the effect of enhancing the pyroelectric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

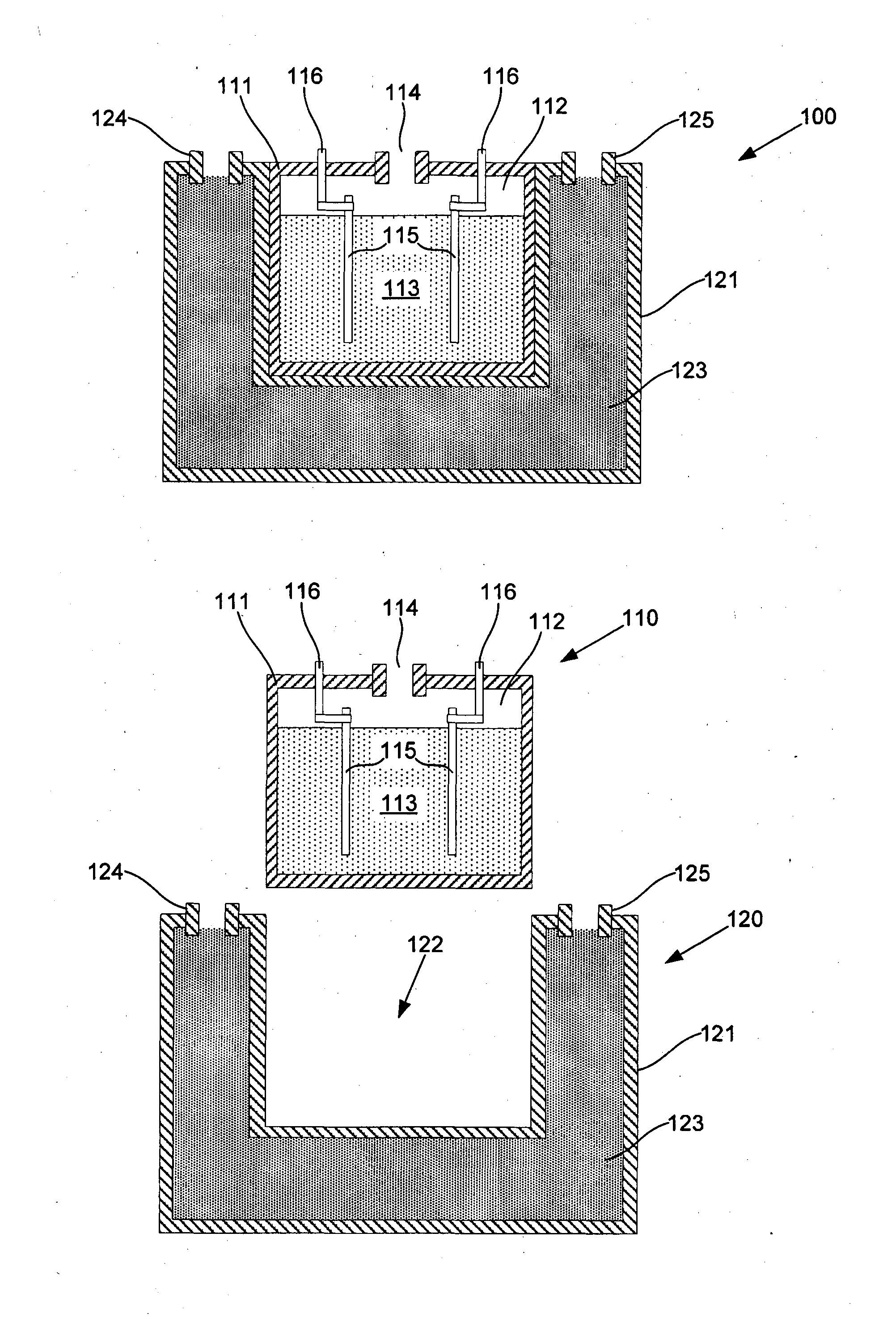

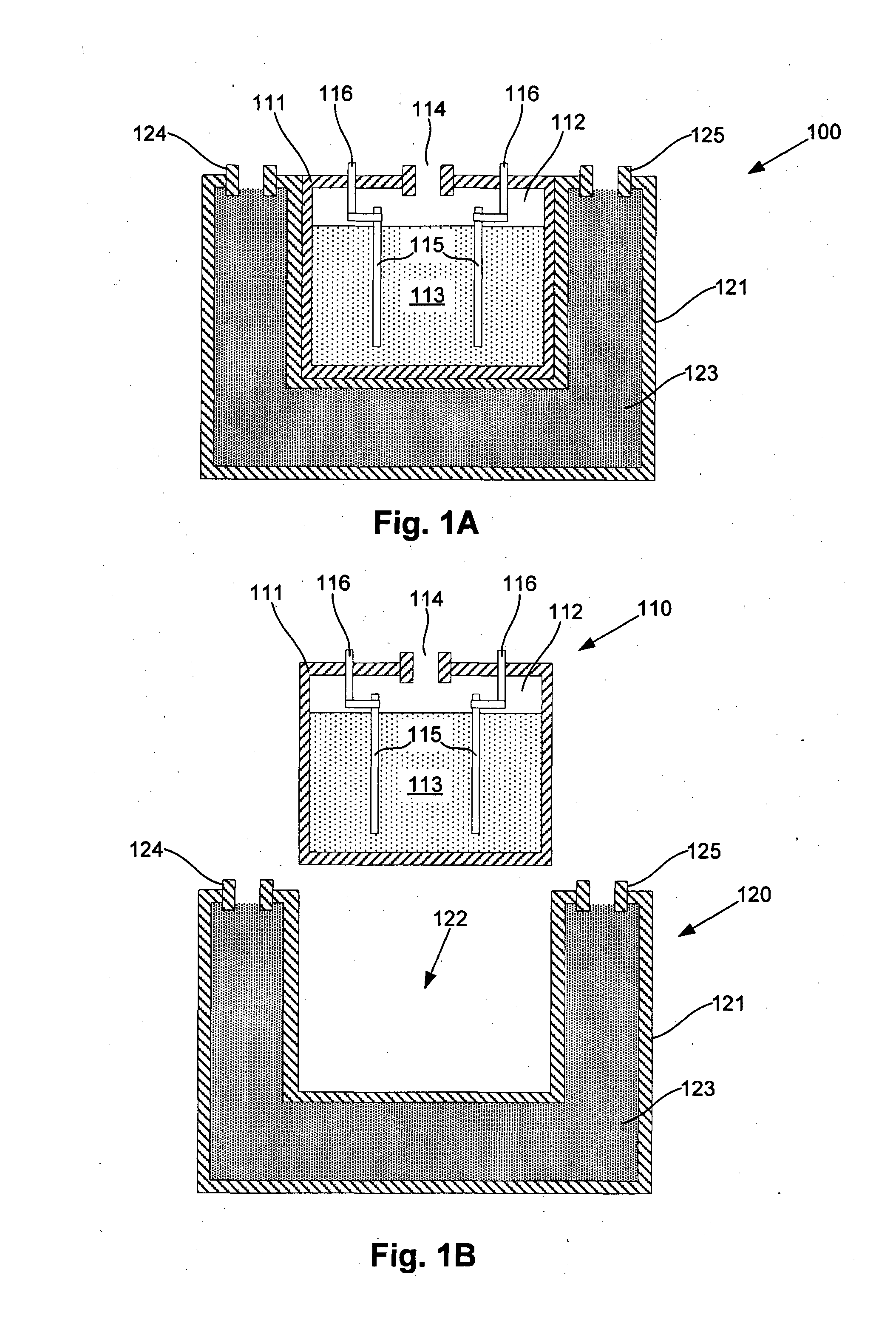

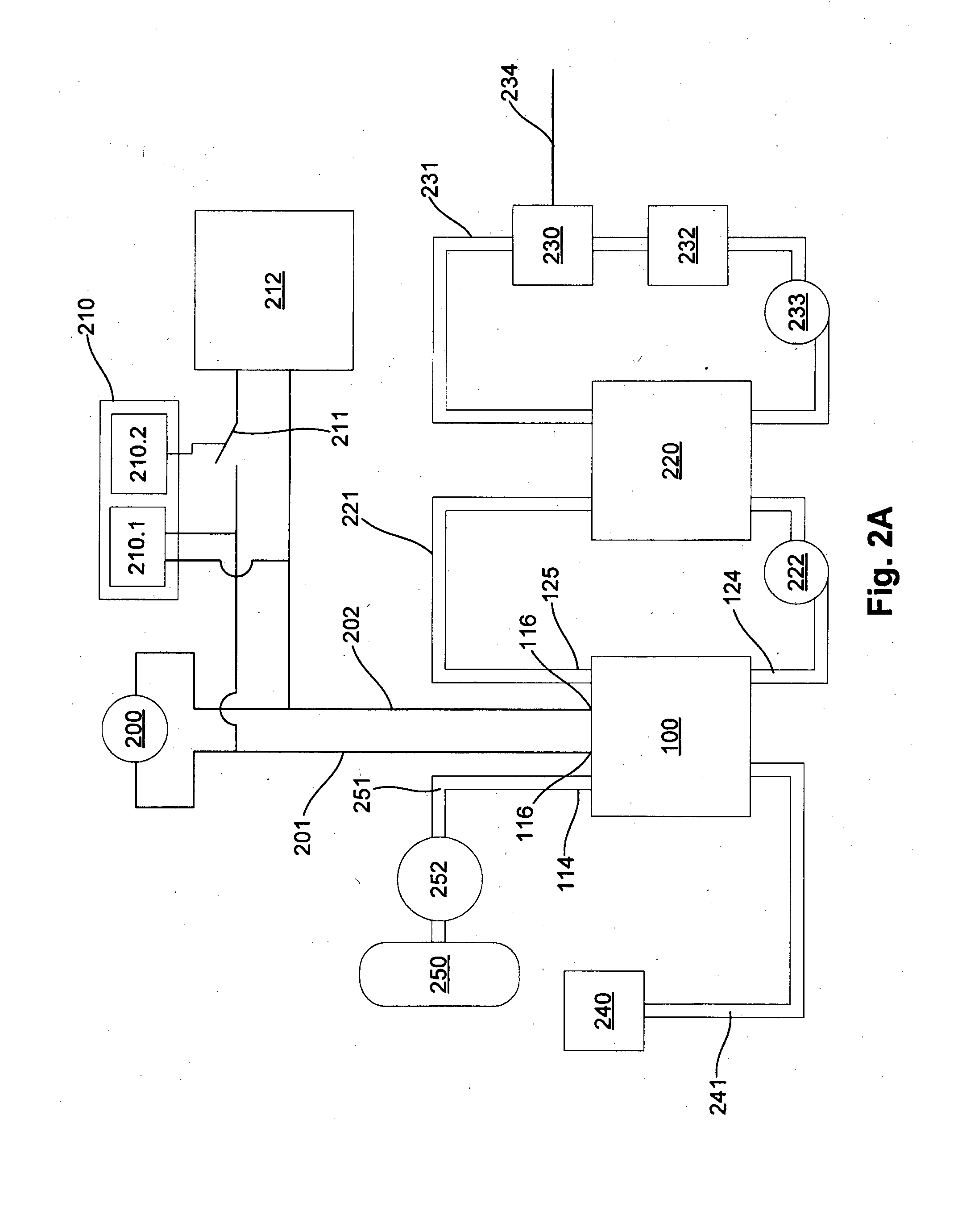

[0255]An example of apparatus for generating hydrogen and heat will now be described with reference to FIGS. 1A and 1B.

[0256]In this example, the apparatus 100 includes an electrolysis cell 110 and a heat recovery module 120. The electrolysis cell 110 includes a cell housing 111 defining an electrolyte cavity 112 containing an electrolyte 113 in use. The electrolyte cavity 112 is typically pressurised in use so that electrolysis is performed at a pressure greater than normal atmospheric pressure.

[0257]The electrolysis cell 110 further includes at least one cell outlet 114 in fluid communication with the electrolyte cavity 112, so that in use electrolysis products generated through electrolysis can be collected therefrom. A plurality of electrodes 115 is provided within the electrolyte cavity 112, the plurality of electrodes 115 defining at least one anode and at least one cathode. The electrodes 115 are connected to respective connectors 116, which are in turn connected to an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com