One piece catalytic converter with integral exhaust manifold

a catalytic converter and exhaust manifold technology, applied in the field of catalytic converters, can solve the problems of multiple parts assembling to arrive at a useful component, inherent gas leak path of multi-piece components,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

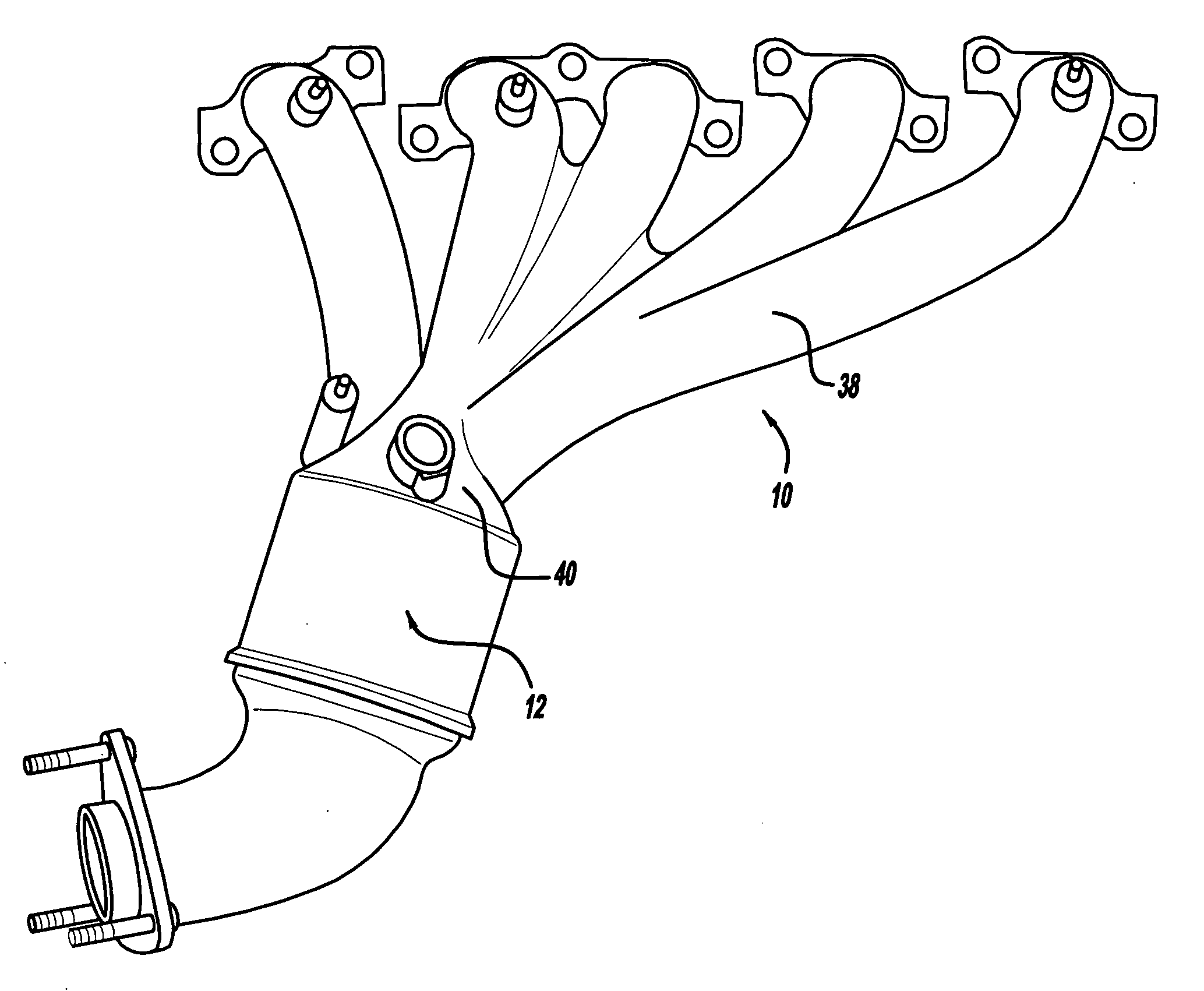

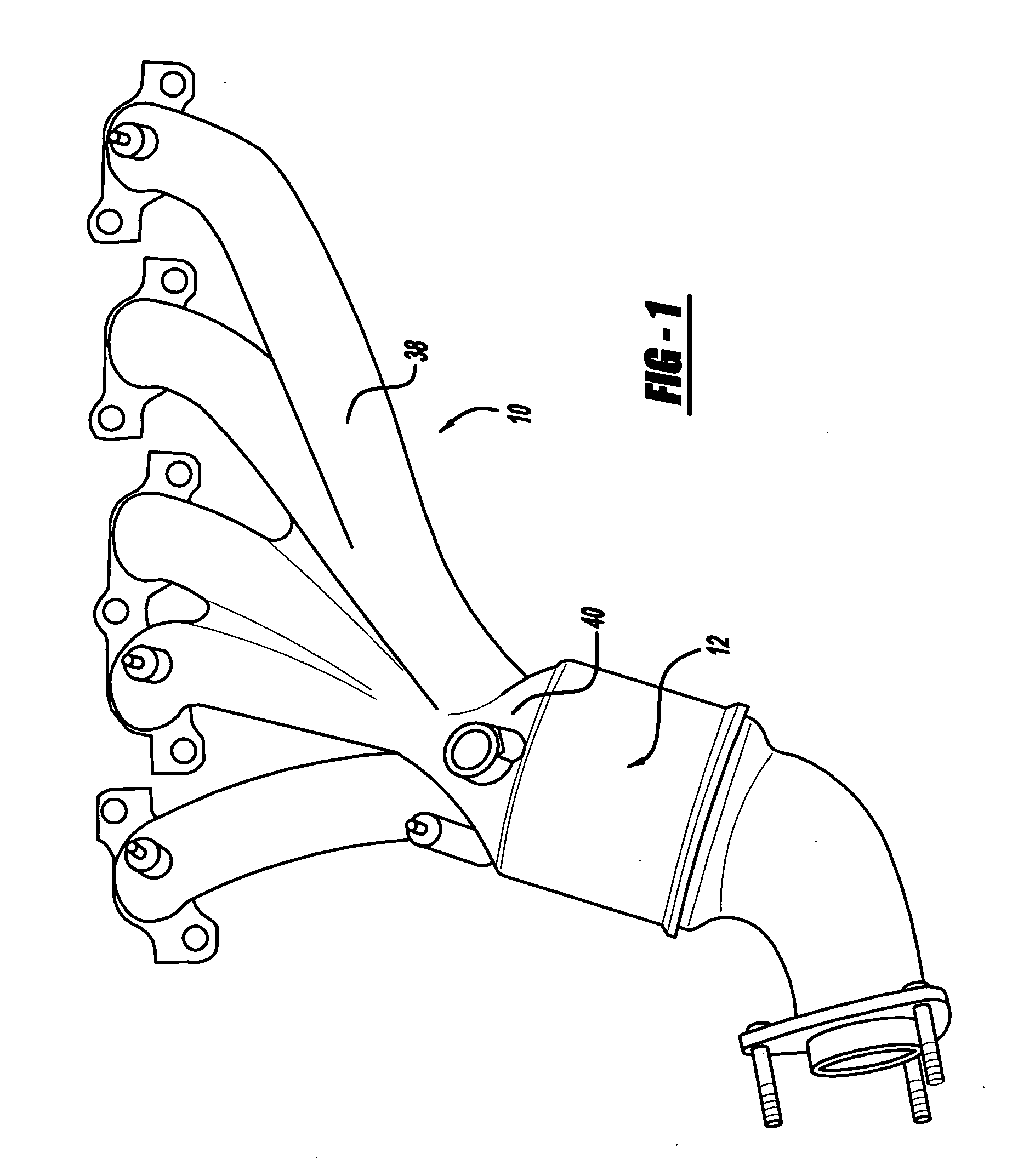

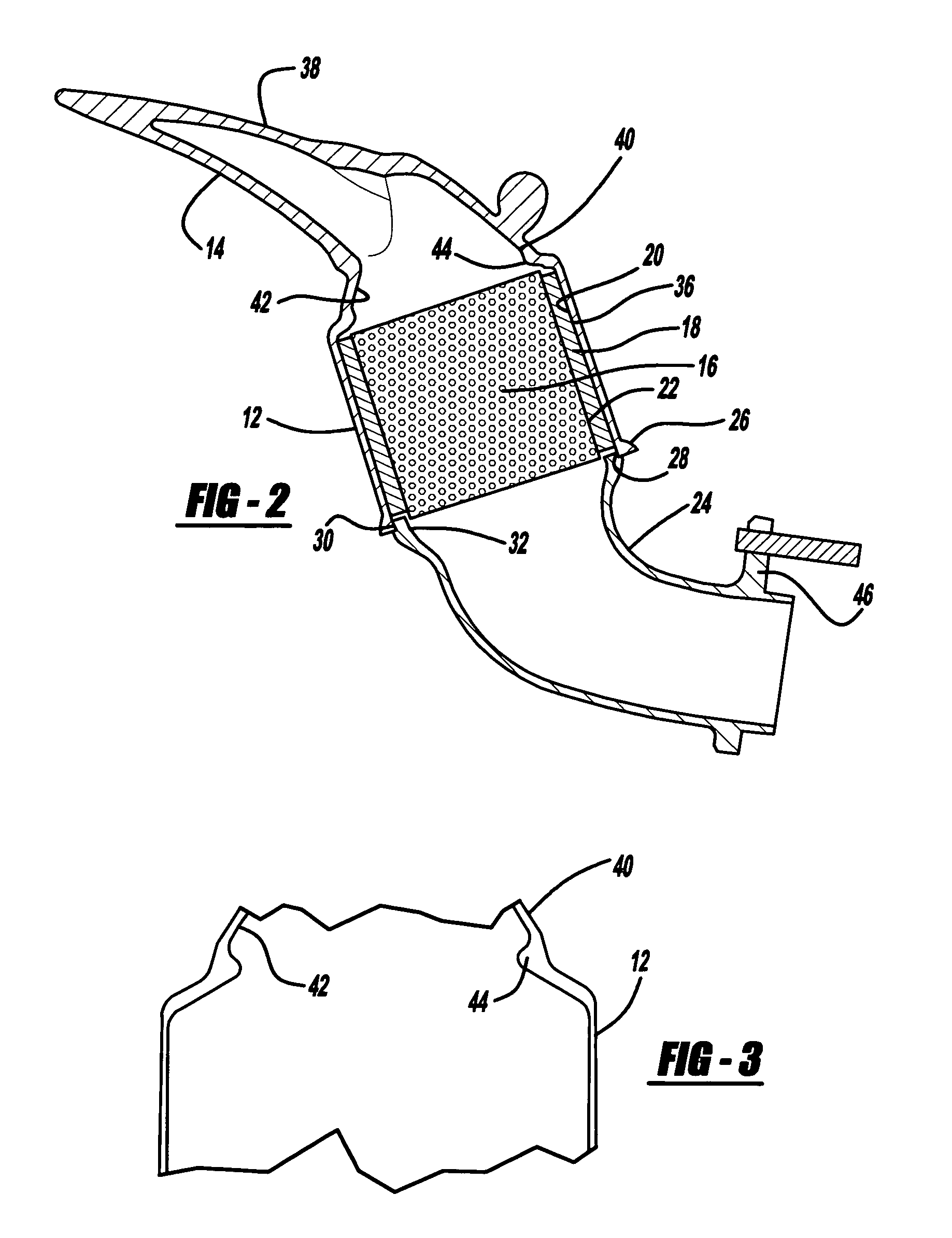

[0012] Referring to FIGS. 1 and 2, shown is a catalytic converter assembly 10 employing a one piece catalytic converter can and integral manifold assembly. The converter can portion is defined by reference numeral 12 and the manifold is defined by reference numeral 14. Generally, the catalytic converter can portion 12 houses the components necessary for converting the exhaust gases prior to discharge from the vehicle to the atmosphere. While not specifically shown, the converter can and / or the manifold portion of the assembly can be provided with various sensors to monitor gas flow through the system.

[0013] As illustrated, the catalytic conversion components inserted within the converter can portion 12 include a substrate 16 which is held in place by a mounting mat 18. Z-seals (not shown) which are known in the art, may be used in association with the mat to assist in securing the substrate within the converter can. The mounting mat is disposed adjacent the inner wall 34 of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com