Exhaust mixer element and method for mixing

a technology of mixer element and mixer, which is applied in the direction of machines/engines, transportation and packaging, separation processes, etc., can solve the problems of packaging problems of today's increasingly complex vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]The following description is merely exemplary in nature and is not intended to limit the present disclosure, its application or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

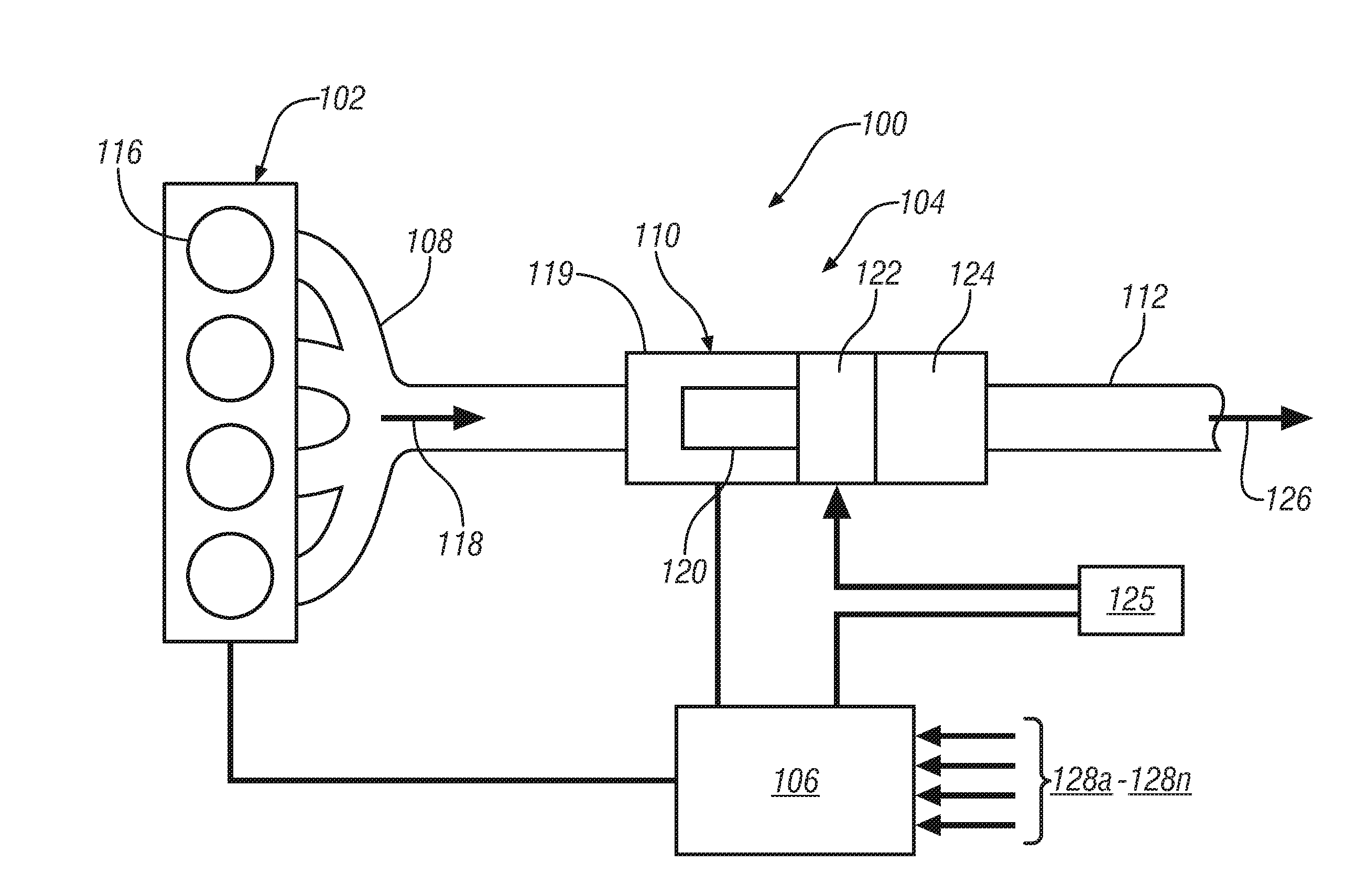

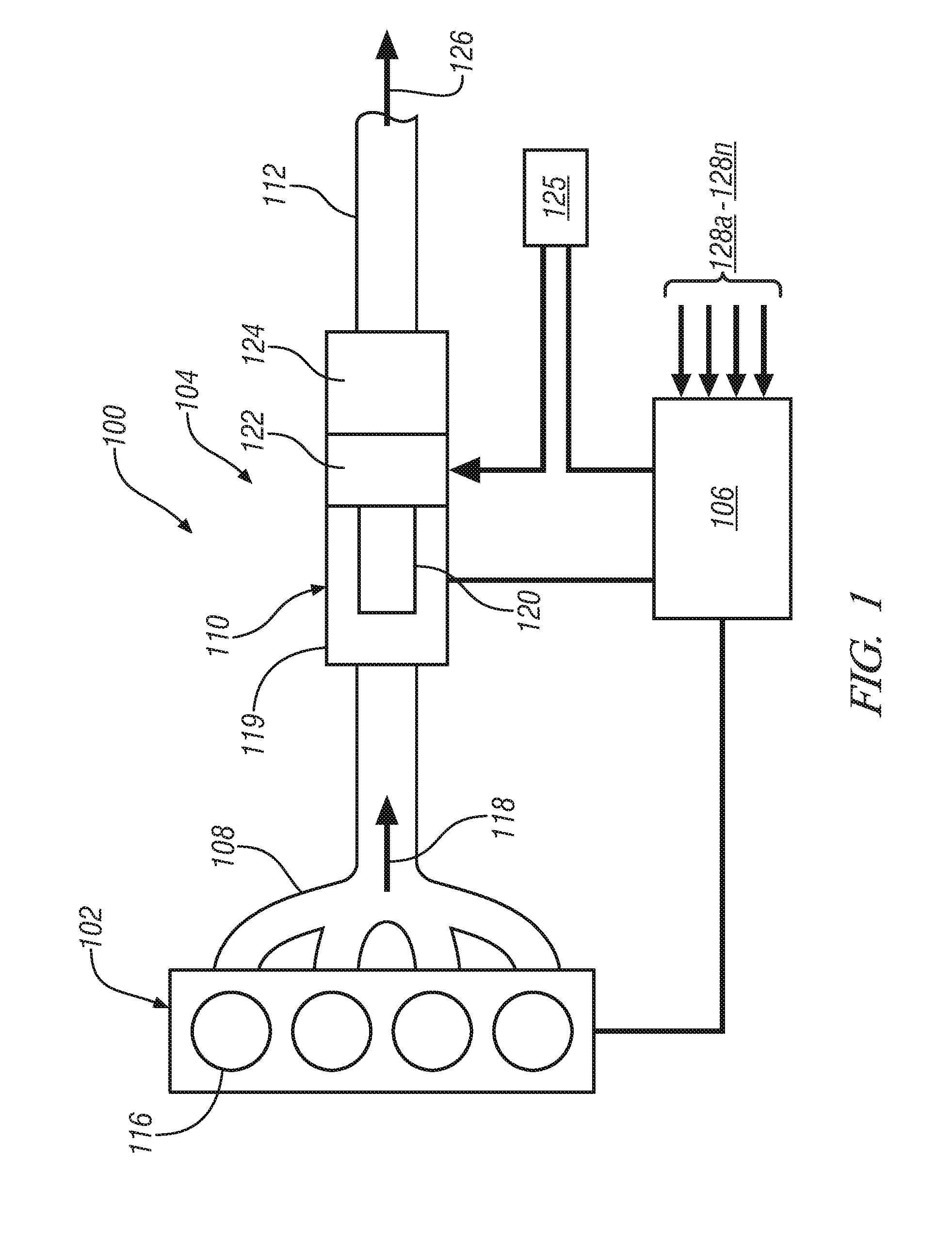

[0016]FIG. 1 is a schematic diagram of an embodiment of an engine system 100. The engine system 100 includes an internal combustion engine 102, an exhaust system 104 and an engine controller 106. The exhaust system 104 includes an exhaust manifold 108, an exhaust after treatment apparatus 110 and an exhaust conduit 112. Cylinders 116 are located in internal combustion engine 102, wherein the cylinders receive a combination of combustion air and fuel. The combustion air / fuel mixture is combusted resulting in reciprocation of pistons (not shown) located in the cylinders 116. The reciprocation of the pistons rotates a crankshaft (not shown) to deliver motive power to a vehicle powertrain (not shown) or to a genera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| motive power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com