High-strength metal filtering tube and preparation method thereof

A filter tube, high-strength technology, applied in the direction of filtration separation, separation method, gravity filter, etc., can solve the problems of broken filter element failure, filter failure, and the preparation method of high-strength metal filter tube has not yet been found, to achieve good permeability, Improve strength, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

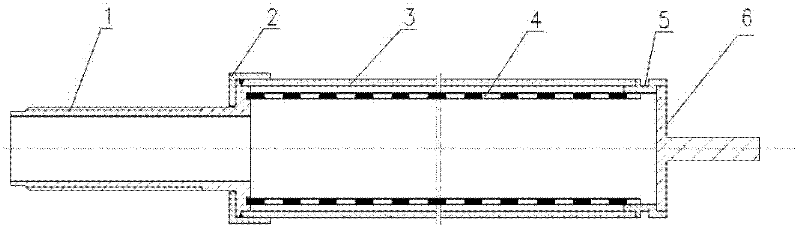

[0027] The high-strength metal filter tube provided by the present invention and preparation method thereof, its processing steps are as follows:

[0028] Step 1: Put the uniformly mixed powder into the mold of the cold isostatic pressure tube for molding. The molding pressure is 150-250MPa. The material of the metal powder can be stainless steel series (SS316L, SS304, etc.), high-temperature alloy series according to the working conditions. (Hastelloy (Hastelloy), Inconel (Inconel alloy), etc.) or other metal materials, the particle size of the powder used can be determined according to the permeability, pore target, filtration flow capacity, etc. of the filter tube to be manufactured.

[0029] The second step: put the powder tube green body prepared in the second step into the vacuum sintering furnace, and sinter at 800-1300°C, with a vacuum degree of 10 -1 ~10 -3 Pa, the holding time is 1 to 3 hours, and the powder tube obtained by sintering has a filter structure that mee...

Embodiment

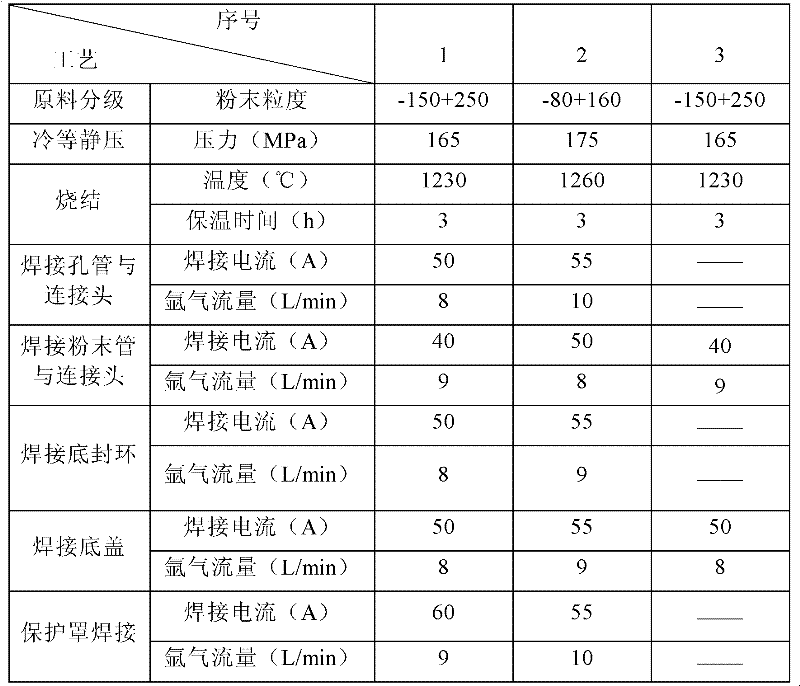

[0037] The method of the invention is used to prepare a high-strength structural metal filter tube. The comparison of the embodiments of the present invention is shown in the table below. Table 1 is the stainless steel 316L raw material composition that the embodiment of the present invention adopts; Table 2 is the technological system and parameter of the metal filter tube of high-strength structure prepared by the present invention; Table 3 is the performance comparison of the metal filter tube of high-strength structure prepared by the present invention surface. In the above list, serial numbers 1-2 are embodiments of the present invention, and serial number 3 is a comparative example of the prior art.

[0038] As can be seen from Table 3, the tensile strength and flexural strength of the metal filter tube based on the present invention have been significantly improved, and the metal filter tube prepared by the present invention can greatly improve the resistance of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com