Method for testing subarea strain in low-cycle fatigue process of non-uniform structure welding joint

A low-cycle fatigue, tissue welding technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve problems such as reducing the amount of experiments, and achieve the effect of avoiding fracture failure and effectively evaluating the low-cycle fatigue life of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The 120mm thick CrMoV steel was used as the research material, and the multi-layer multi-pass submerged arc welding method was used to complete the welding, and the weld width was about 20mm.

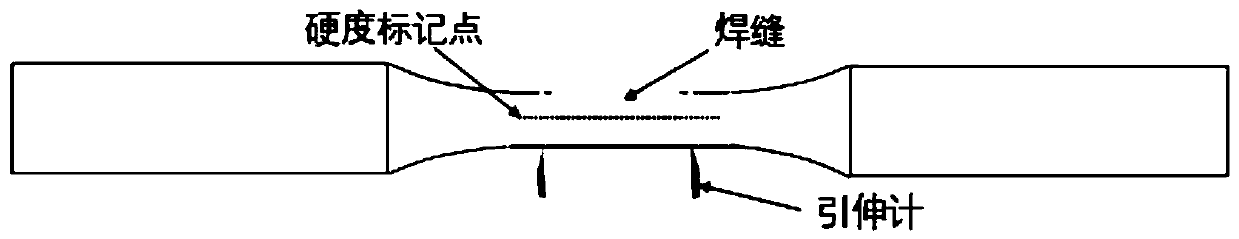

[0058] The first step is to process 21 standard low-cycle fatigue samples with the weld as the center, the gauge length of the parallel section is 30mm, and the low-cycle fatigue extensometer is used to measure 25mm.

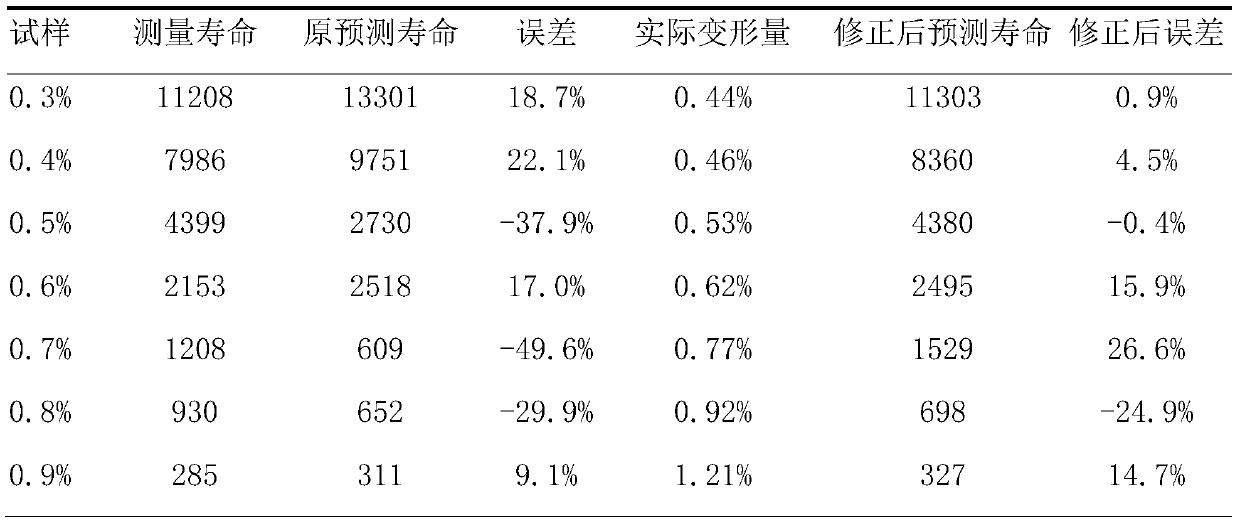

[0059] In the second step, 16 samples were selected and subjected to low-cycle fatigue at strain amplitudes of 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, and 0.9%, respectively, and each strain amplitude was repeated twice, for a total of 14 samples are required.

[0060] The third step is to judge that the fracture position of the low-cycle fatigue samples is in the center of the weld, and mark the hardness points of the remaining 7 samples on the automatic hardness machine. The distance between each hardness point is 100um, and the length of the total hardness point is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com