Porous metal rod

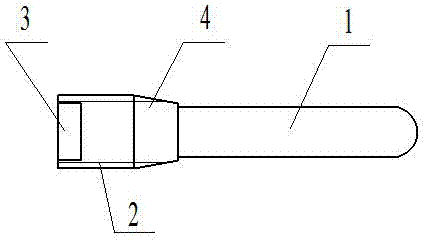

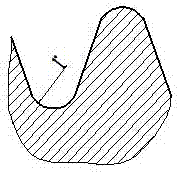

A porous metal and round rod technology, which is applied in the field of porous metal rods for medical implants, can solve the problems of poor bone tissue growth at the front end of the porous tantalum rod, affecting the treatment effect, and fracture, so as to improve the success rate of treatment and facilitate installation , to avoid the effect of fracture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

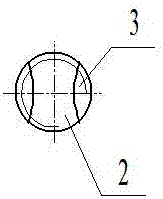

Embodiment 1

[0032] Mix polyvinyl alcohol, distilled water, and tantalum powder with an average particle size of less than 5 microns and an oxygen content of less than 0.1% according to the weight ratio of 7:125:150 to make a slurry. The average pore size is 0.6mm and the density is 0.022g / cm 3 The porous polyurethane foam is put into the slurry, so that the pores of the polyurethane foam are filled with the tantalum powder slurry, and the polyurethane foam is dried in a vacuum oven at a drying temperature of 60°C, for a drying time of 10 hours, and a vacuum of 1Pa. Then pass the vacuum below 10 -4 Pa, temperature 600°C, heat preservation time 120 minutes for degreasing treatment, and then vacuum sintering, sintering temperature 2100°C, heat preservation 2 hours, vacuum degree 10 -4 Pa, the sintering process is filled with hydrogen protection. The porosity of the prepared porous tantalum is 50%, and the pore size is 100µm-310µm. This material is machined to produce the desired porous t...

Embodiment 2

[0035] This embodiment is similar to Embodiment 1, except that the porosity of porous tantalum is 85%, the pore size is 300µm-500µm, the length of the reduced part of the thread is 50% of the length of the thread part, and the radius of the fillet at the root of the thread is 0.65mm .

Embodiment 3

[0037]This example is similar to example 1, with reference to the preparation method of example 1, the difference is that metal niobium is used to prepare, the root diameter of the threaded part is 1.2 times the diameter of the round bar-shaped part, and the root diameter of the threaded part is close to the round bar-shaped part It gradually decreases towards the round rod-shaped part, until the junction of the threaded part and the round rod-shaped part decreases to 1.05 times the diameter of the round rod-shaped part, and the length of the root diameter of the threaded part close to the round rod-shaped part gradually decreases towards the round rod-shaped part. 20% of the length.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com