Patents

Literature

42results about How to "Meet bending needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

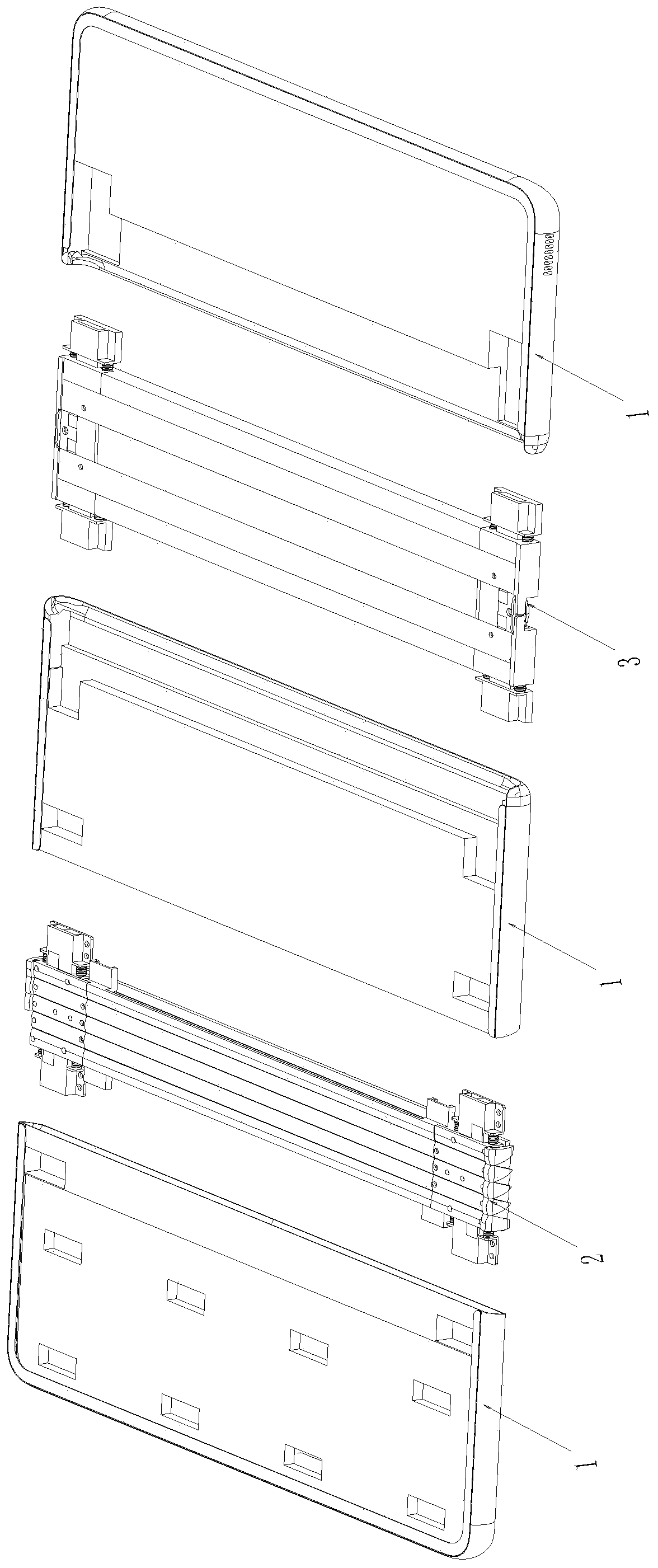

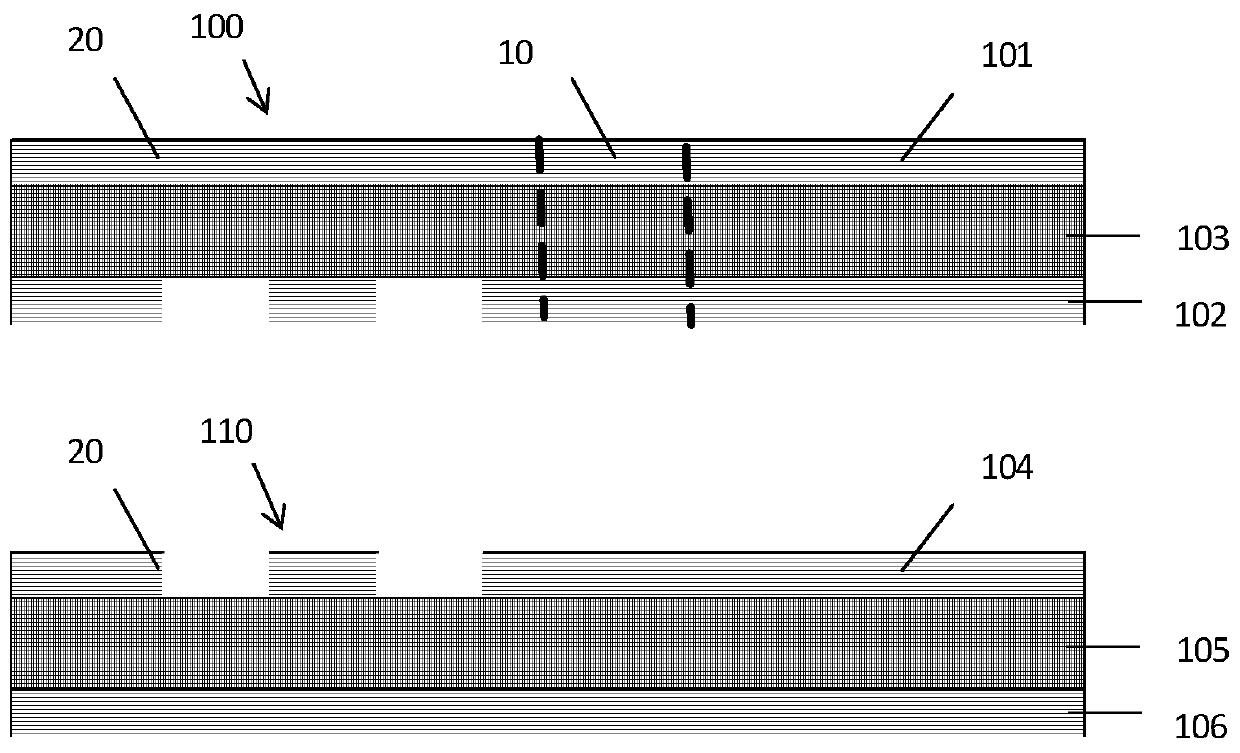

Flexible display module and preparation method thereof

InactiveCN107871453AMeet bending needsAvoid bending requirementsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayComputer science

The embodiment of the invention provides a flexible display module and a preparation method thereof. The problem that an existing flexible display module is likely to lose efficacy after being bent issolved. The flexible display module comprises a flexible glass layer and a display panel arranged in the flexible glass layer.

Owner:YUNGU GUAN TECH CO LTD

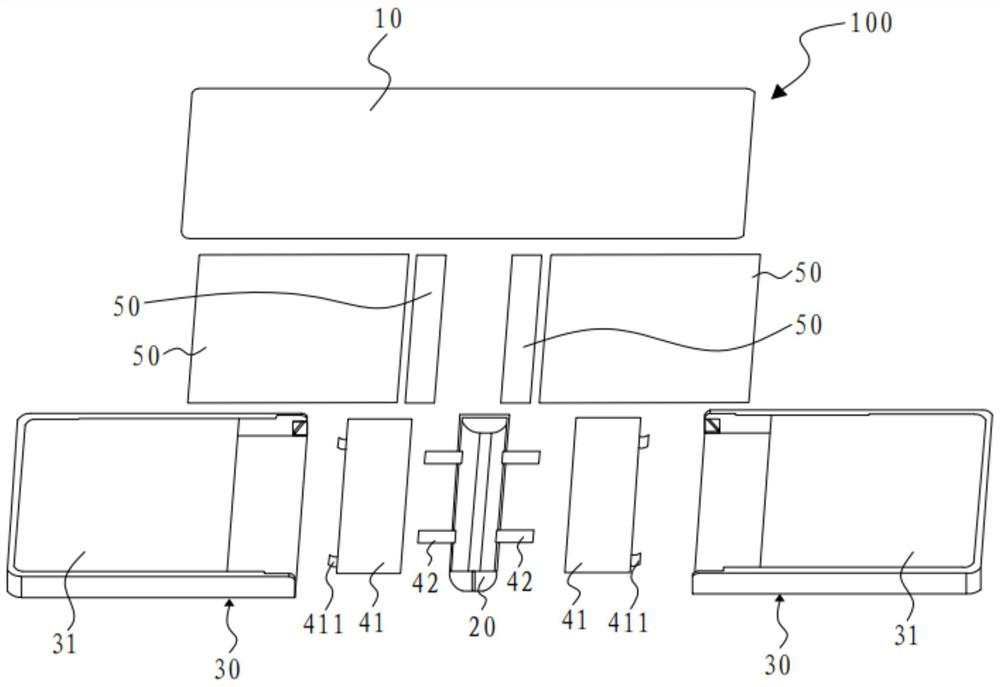

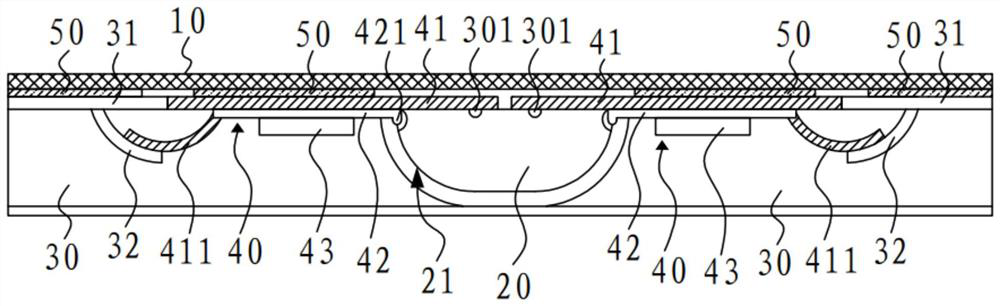

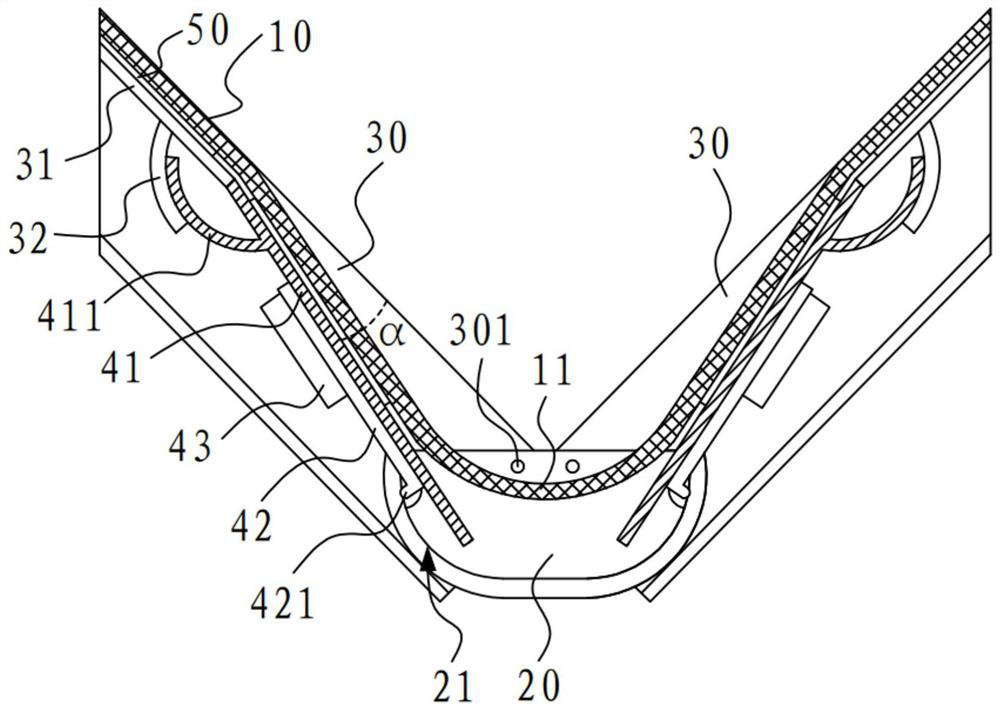

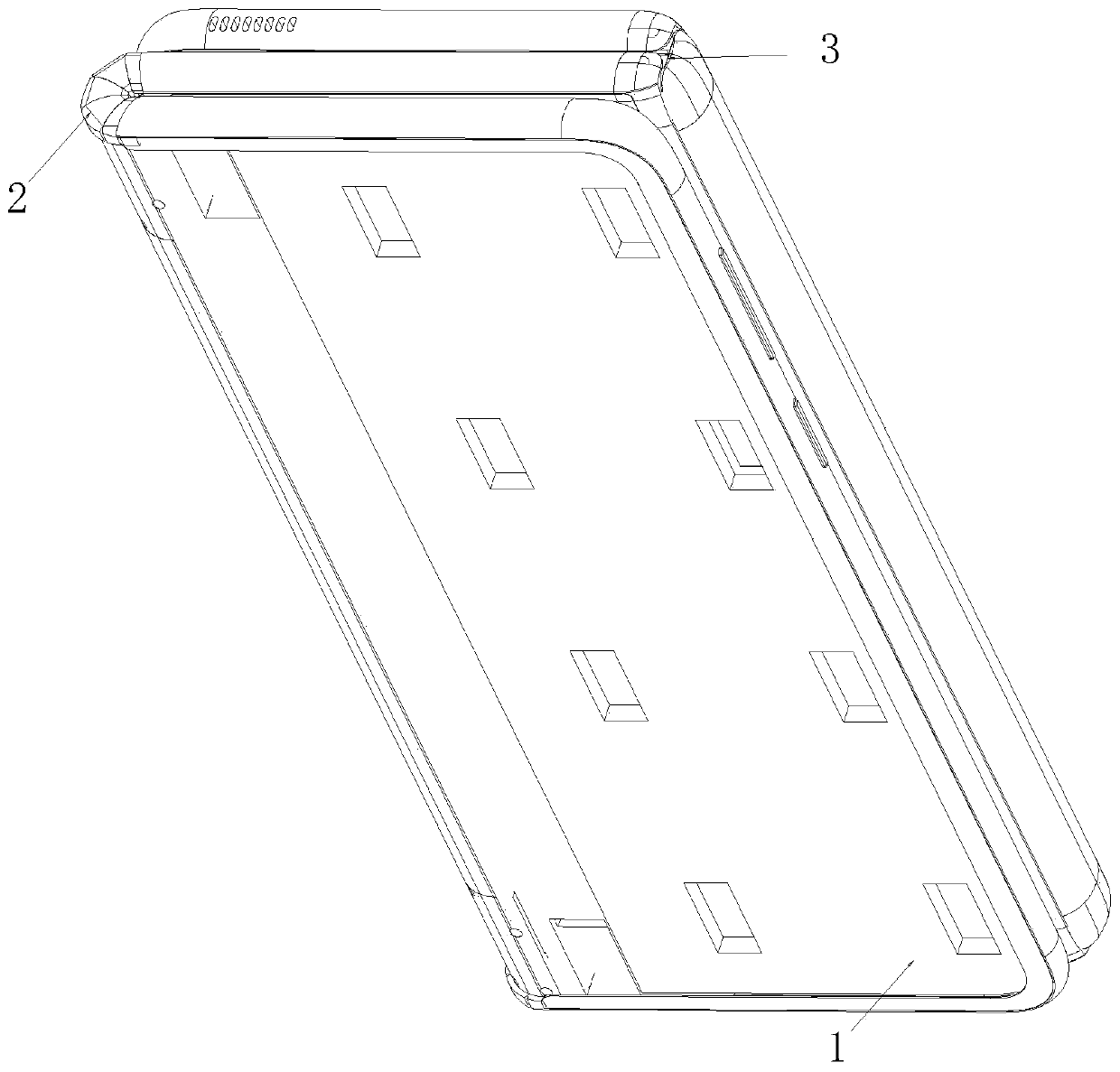

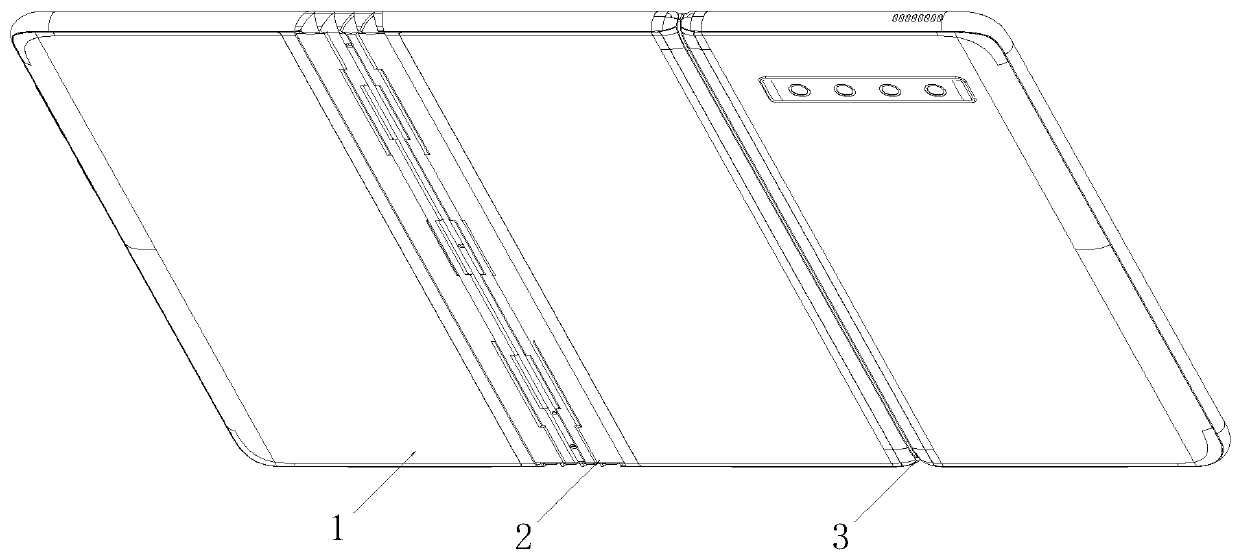

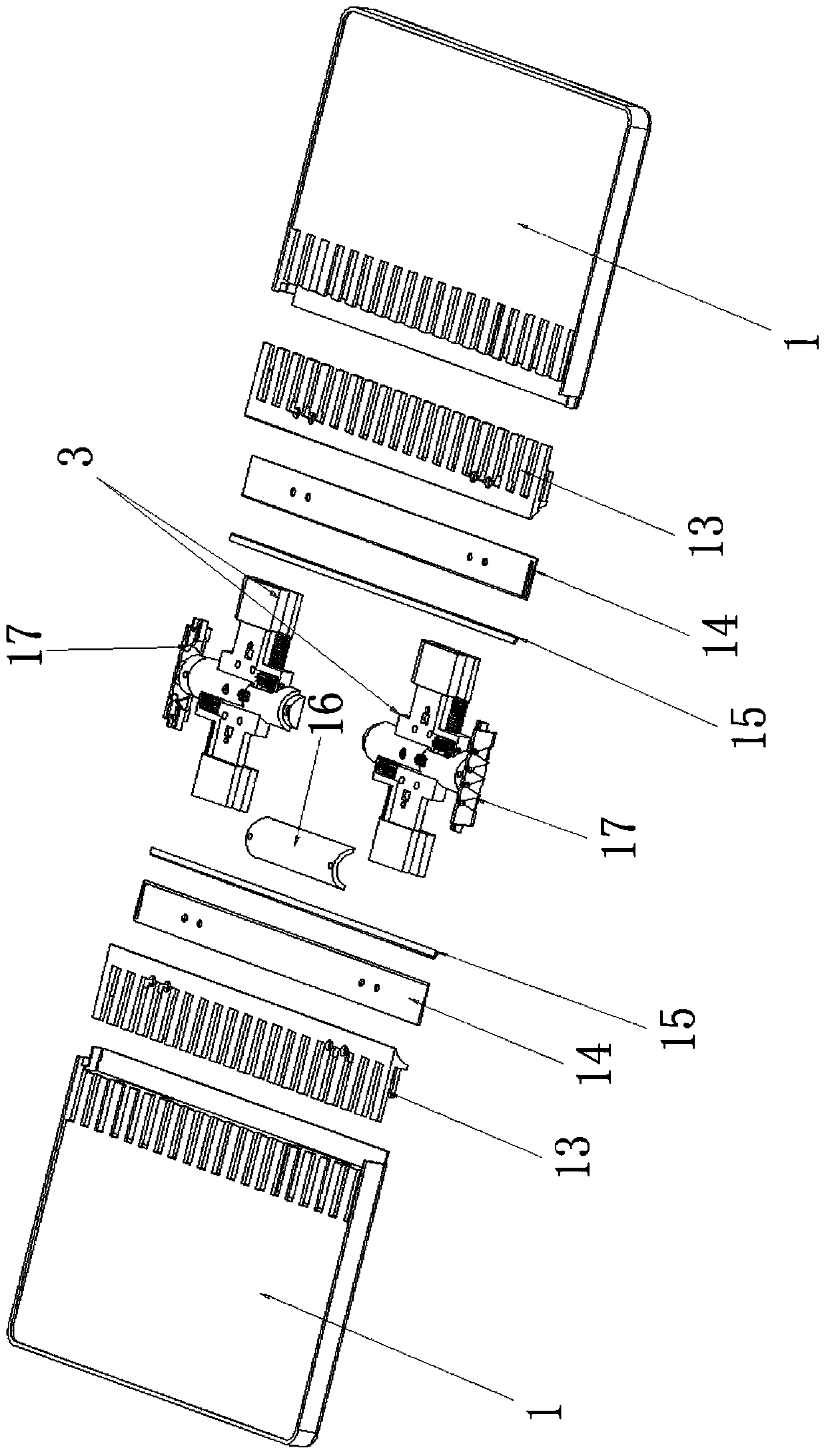

Folding display device

ActiveCN112150921AReduce crush damagePlay a supporting roleCasings with display/control unitsCasings/cabinets/drawers detailsDisplay deviceEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

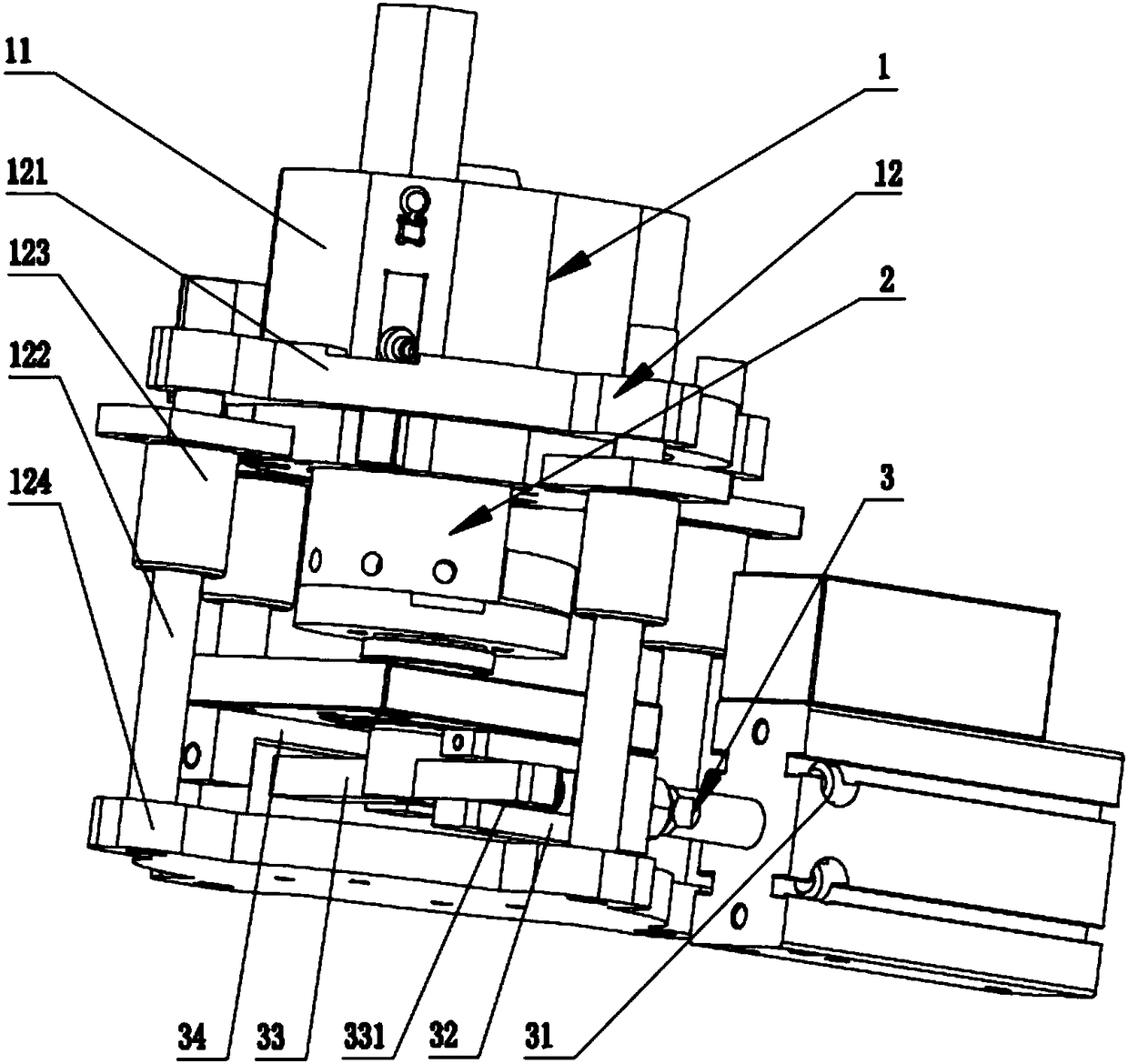

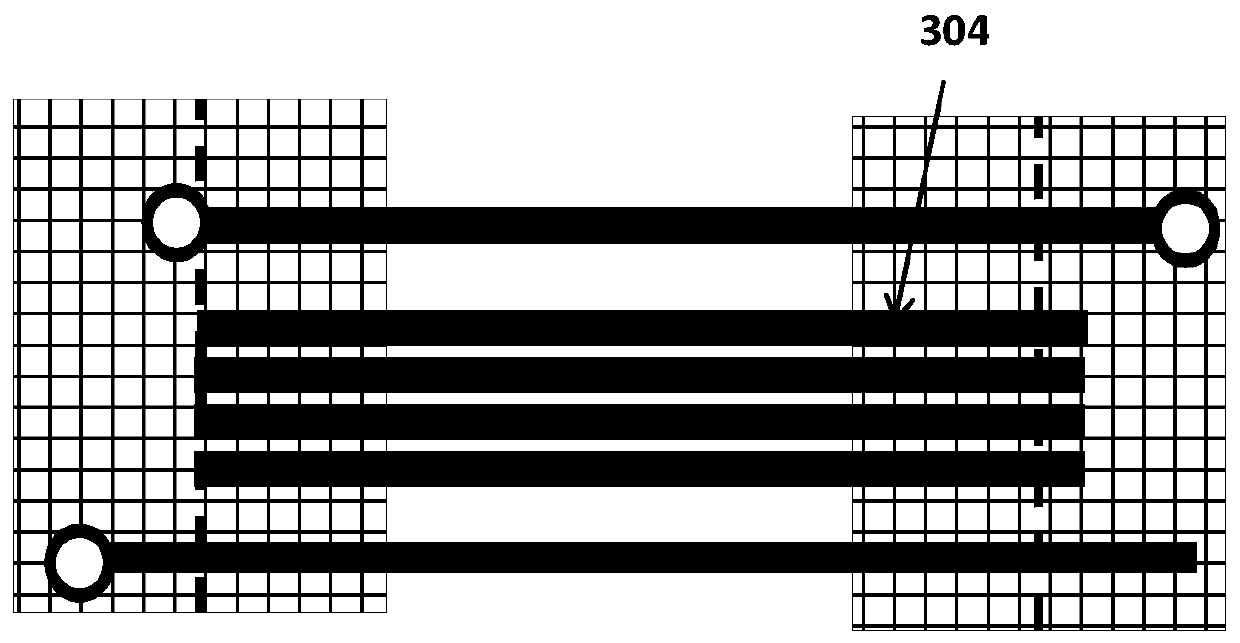

Synchronous rotating mechanism for inward and outward folding of flexible screen

PendingCN110131299AMeet the double-fold functionPrevent top screenPivotal connectionsIdentification meansSelf lockingEngineering

The invention discloses a synchronous rotating mechanism for inward and outward folding of a flexible screen. The mechanism comprises three rotationally connected cases and rotary mechanisms for connecting the cases, wherein the rotary mechanisms include an outward-folding rotary mechanism and an inward-folding rotary mechanism; the inward-folding rotary mechanism comprises an inward-folding package body and an inward-folding rotary shaft; the inward-folding rotary shaft comprises an inward-folding moving frame, a sliding moving frame and a compensation moving frame, and the sliding moving frame and the compensation moving frame are bilaterally symmetrically arranged, combined and connected; the sliding moving frame comprises a first sliding moving frame body and a second sliding moving frame body; two slots are formed in the inward-folding moving frame; a sliding groove, a sliding block and a sliding post are arranged on each of the first sliding moving frame body and the second sliding moving frame body; each sliding post can slide in the corresponding slot, the corresponding sliding groove and the corresponding sliding block; the sliding posts can rotate in the corresponding slots to be flattened, upward and downward movement is realized, and accordingly, the condition that the mechanism jacks the screen is avoided; clamping point grooves are combined with corresponding positioning pins, so that a clamping point self-locking function is available in both 0-degree and 180-degree states; each sliding groove and the corresponding sliding post are in sliding connection and achieve semi-arc locking synchronization, and a compensation function is achieved in a screen unfolding state.

Owner:DONGGUAN JINFENG ELECTRONICS

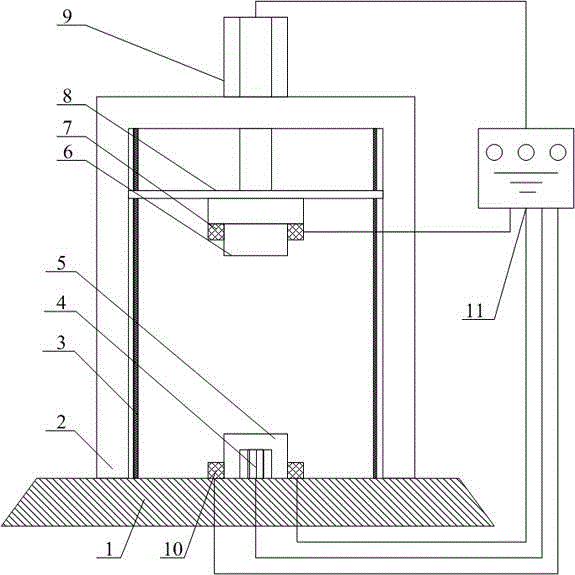

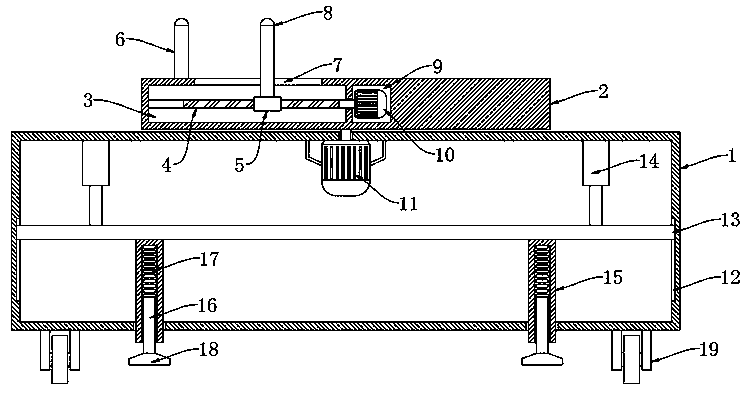

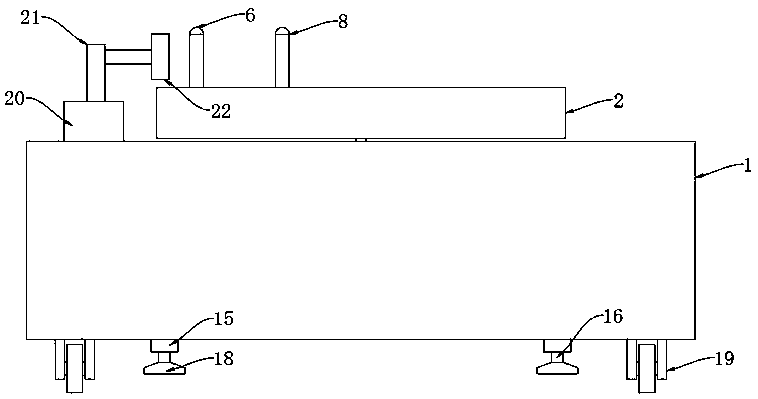

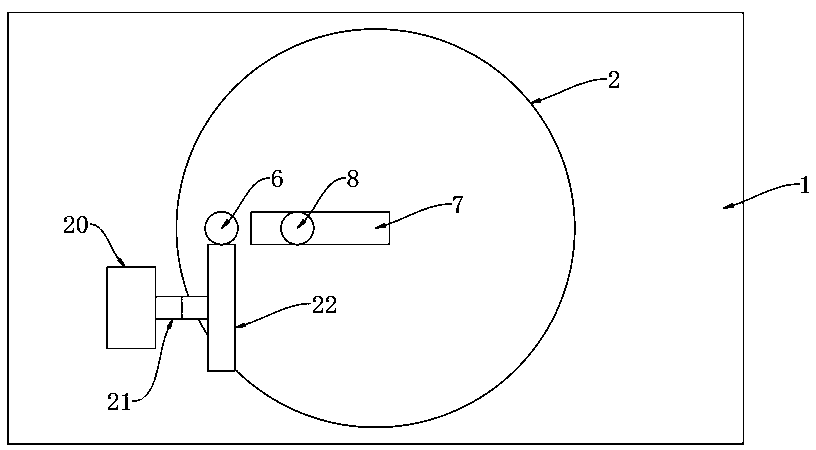

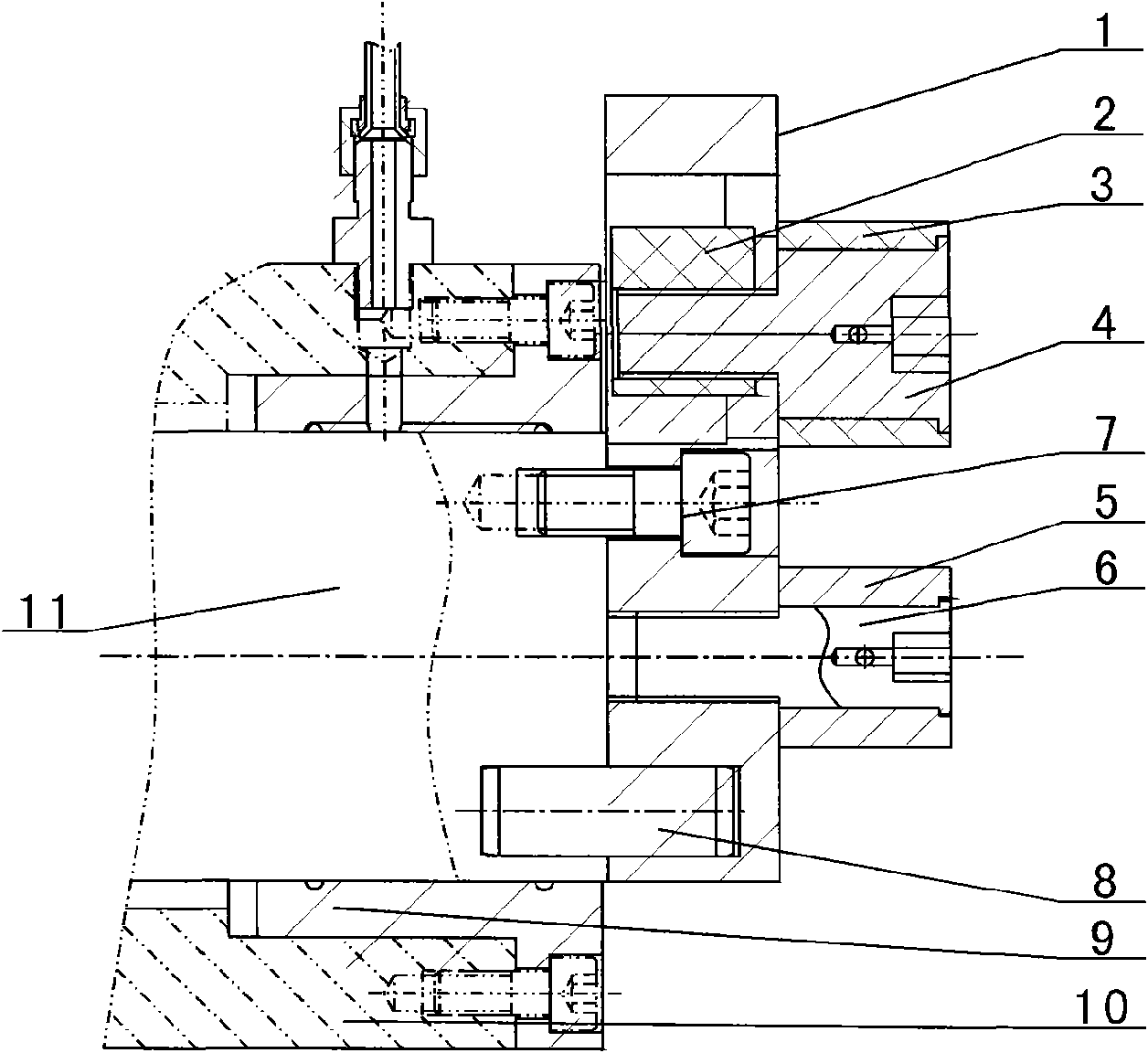

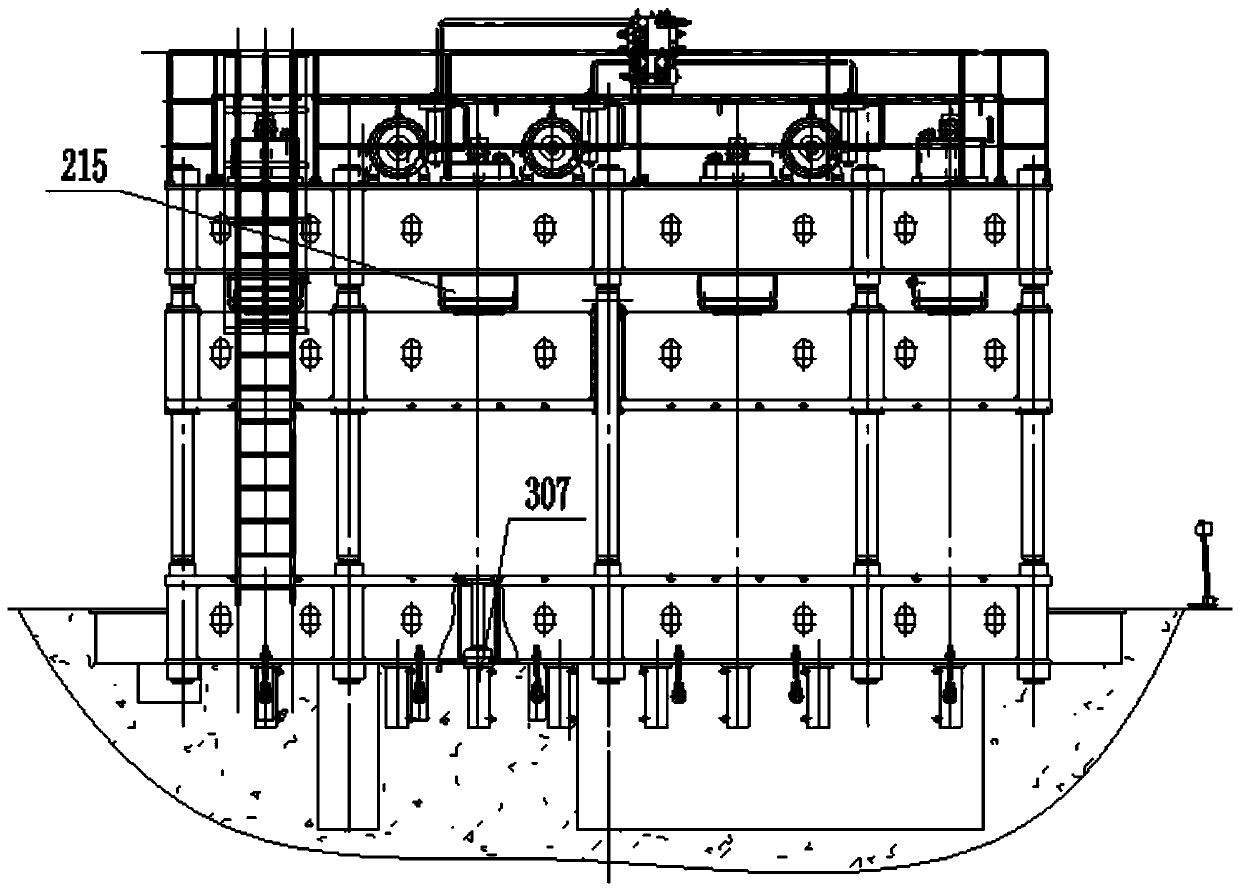

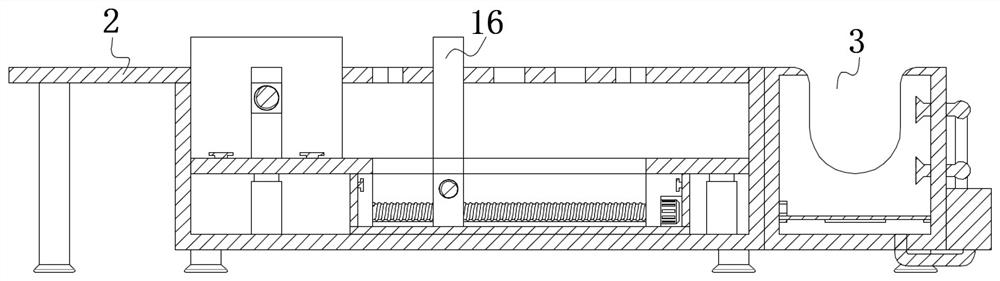

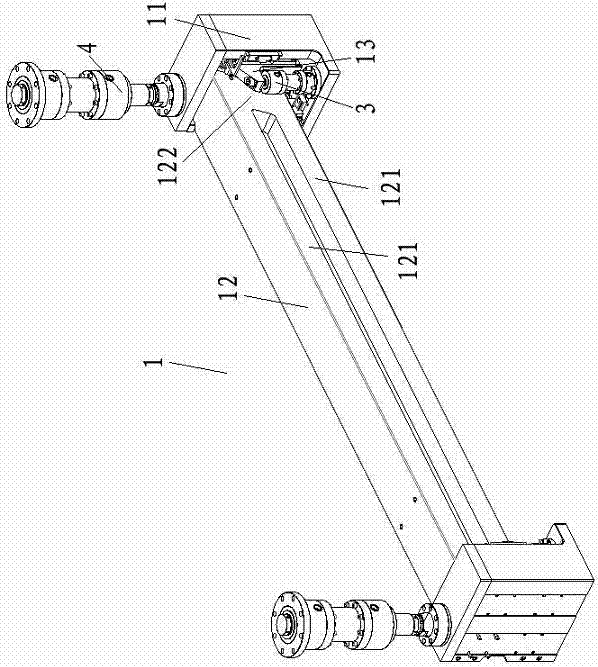

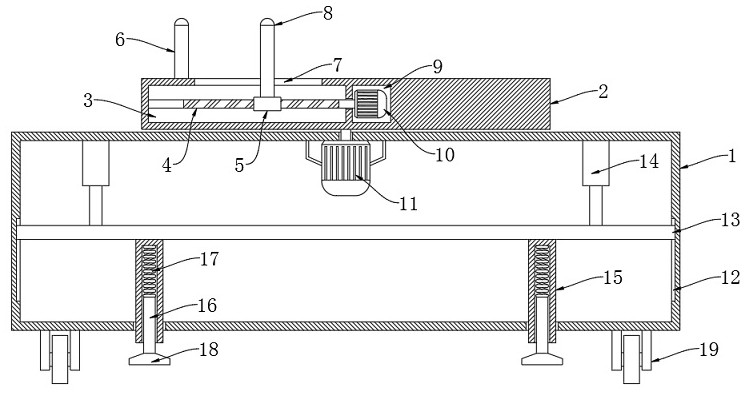

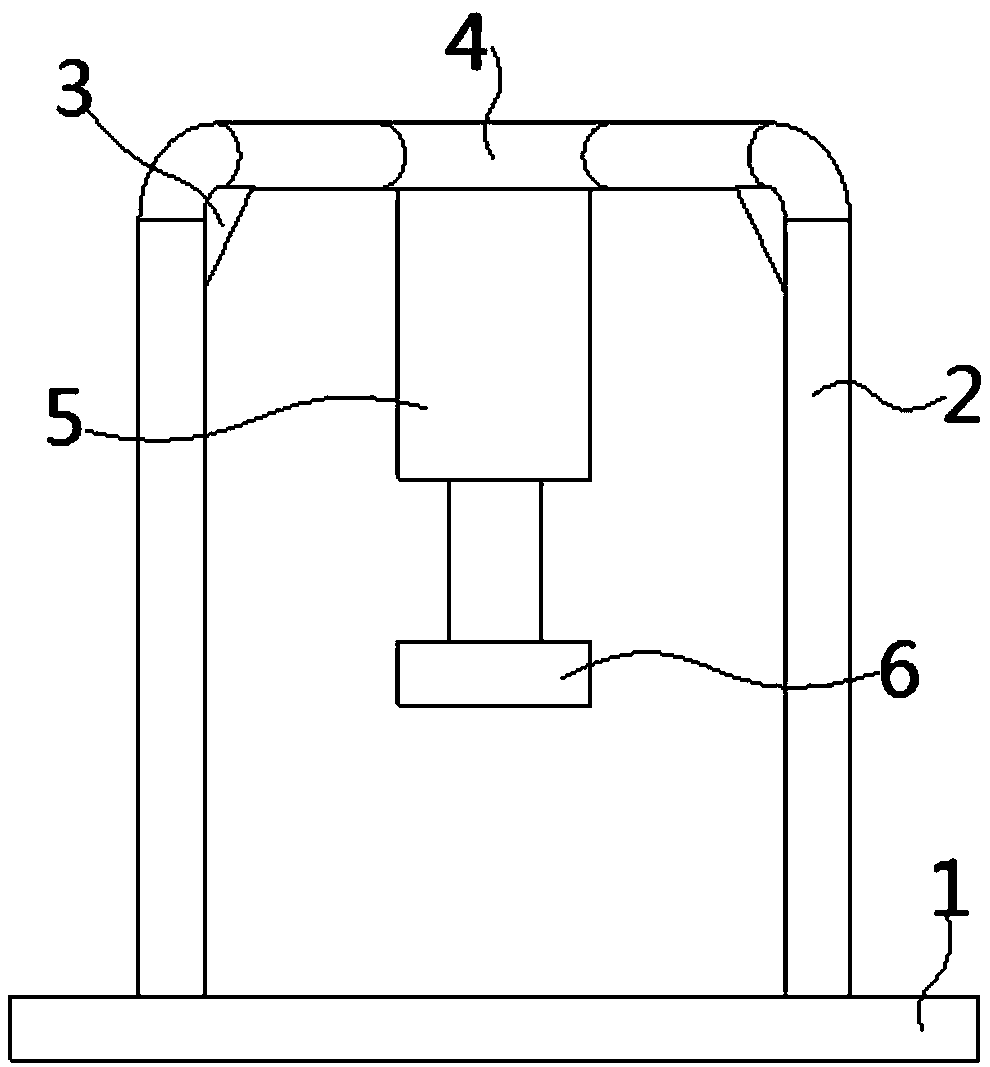

Hydraulic dynamic bending machine

InactiveCN104588505AEasy to controlUniform and precise forceShaping toolsMetal working apparatusEngineeringInverted u

The invention discloses a hydraulic dynamic bending machine, and belongs to the field of machining. The hydraulic dynamic bending machine comprises an inverted U-shaped rack, a hydraulic driving device, a connecting block, an upper die, a lower die, a control unit and two guide posts, wherein the hydraulic driving device is erected at the top part of the rack and is connected with the control unit, the two guide posts are respectively arranged at two side edges in the rack, the connecting block is arranged at the inner side of the rack and is connected with the lower end of the hydraulic driving device, the two guide posts can be respectively inserted into two ends of the connecting block, the connecting block can move up and down along the guide posts, the upper die is connected below the connecting block, the lower die is arranged right under the upper die, a distance sensing device is arranged between the upper die and the lower die, and the distance sensing device is connected with the control unit. Through the matching of an infrared transmitter and an infrared sensor between the upper die and the lower die, the distance between the upper die and the lower die can be accurately controlled, thus the stress on a plate during a bending process is more uniform and accurate, and the quality of finished plates is ensured.

Owner:江苏久日数控机床有限公司

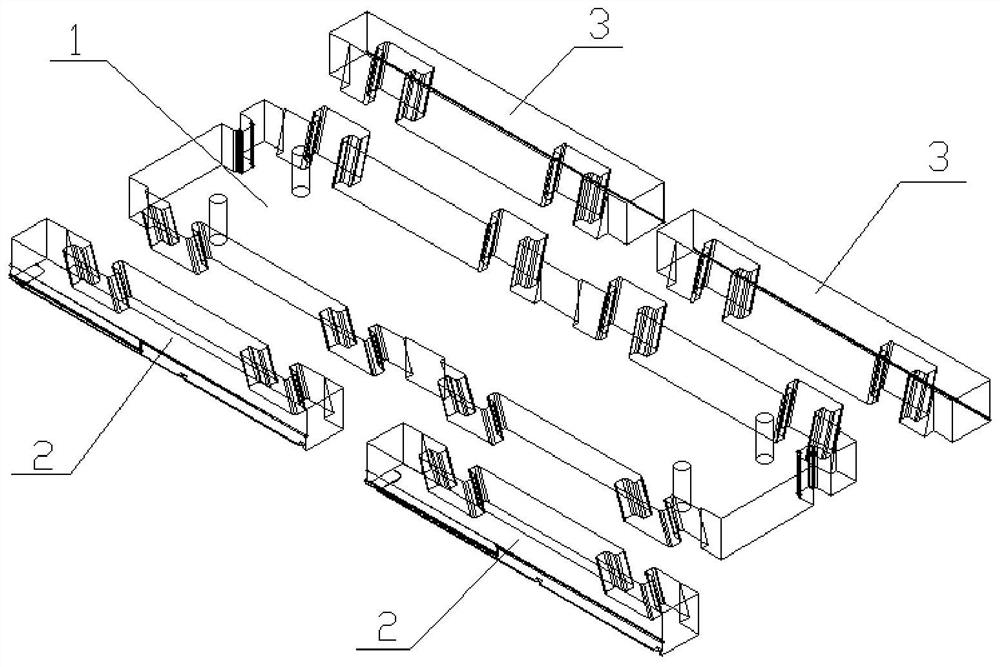

Universal bending machine

The invention discloses a universal bending machine which comprises a slanting wedge knife holder which can vertically and horizontally move and a supporting frame which is positioned at the two ends of the slanting wedge knife holder and has the supporting effect, wherein bending knives are installed on one side surface of the slanting wedge knife holder; an angle pressing block which is parallel to the a slanting wedge knife holder is arranged on the bending knife facing the slanting wedge knife holder and is installed on a drive frame which can vertically move; the blade part of the angle pressing block is opposite to a blade of the corresponding bending knife; a bending platform for bearing a plate to be bended is arranged below the angle pressing block; the two ends of the bending platform are supported by the supporting frame; the angle pressing block is composed of a plurality of pressure blocks which can be clamped with the drive frame; at least one clamping table is arranged on the top surface of each pressure block and is matched with a clamping groove formed in the side surface or the lower surface of the drive frame; and when the clamping table on each pressure block is inserted into the corresponding clamping groove formed in the drive frame, each pressure block is hung below the drive frame. By the universal bending machine, materials can be bent in various shapes and at various angles, and can be bent towards different directions so as to meet various bending needs.

Owner:JIANGSU BVM INTELLIGENT TECH

A synchronous rotating mechanism based on concentric shaft outward folding

PendingCN109743431AMeet bending needsMeet dampingTelephone set constructionsEngineeringMechanical engineering

Owner:DONGGUAN JINFENG ELECTRONICS

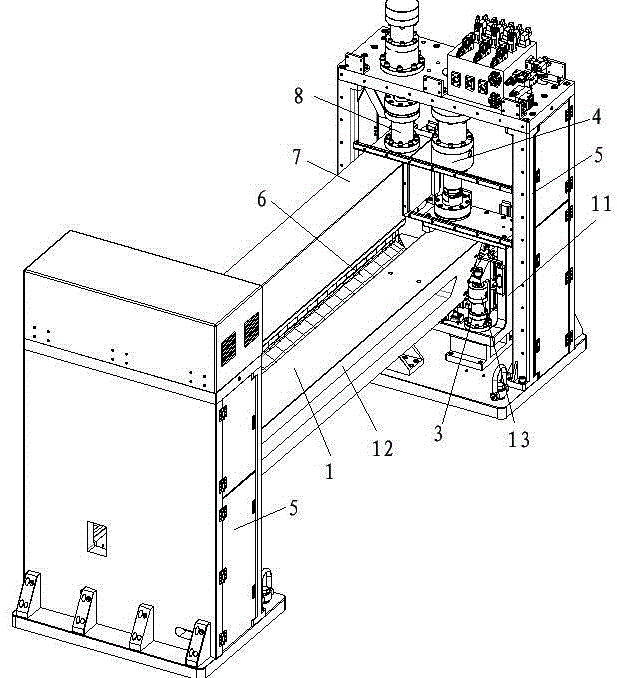

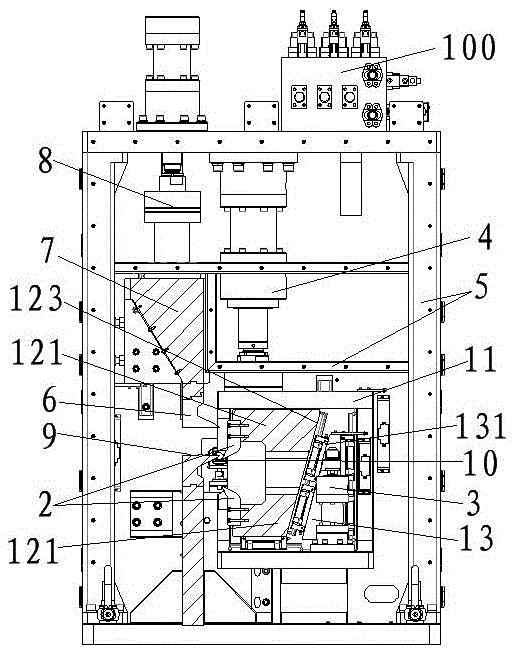

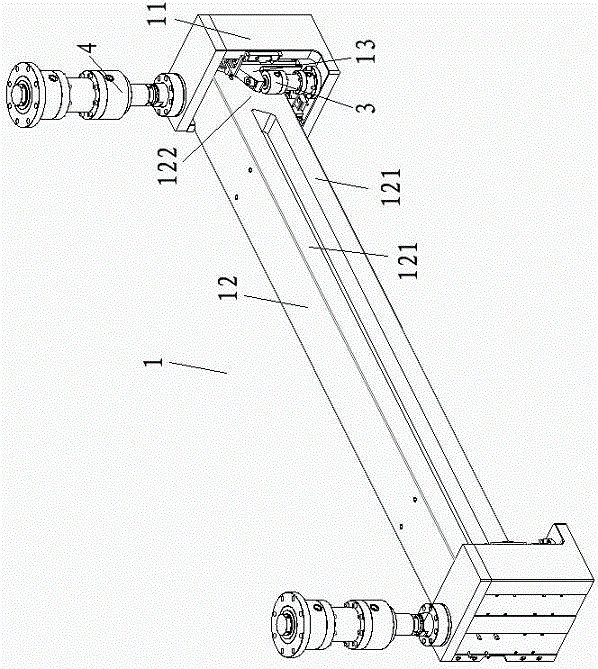

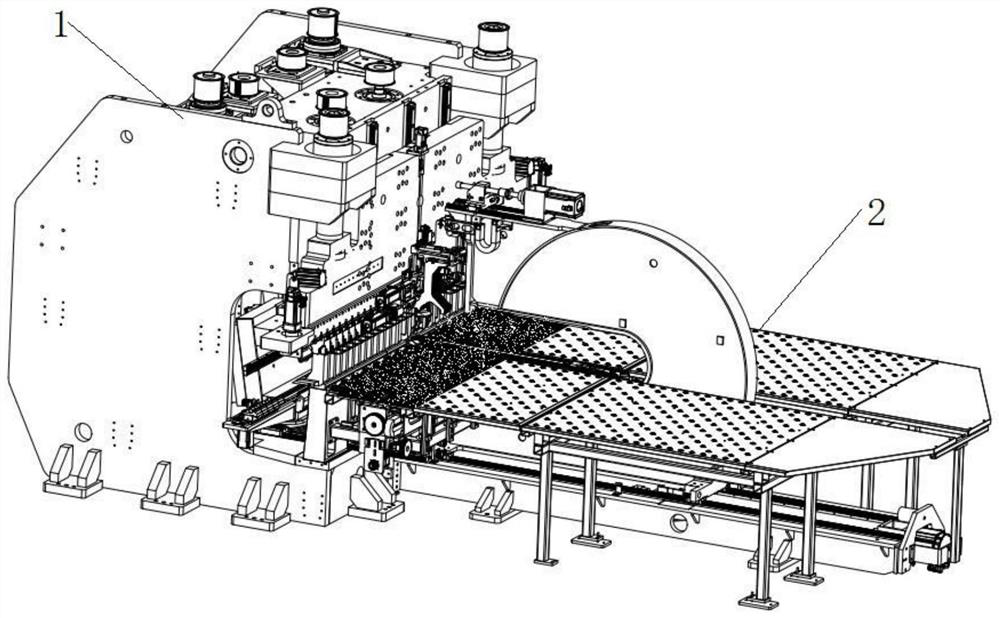

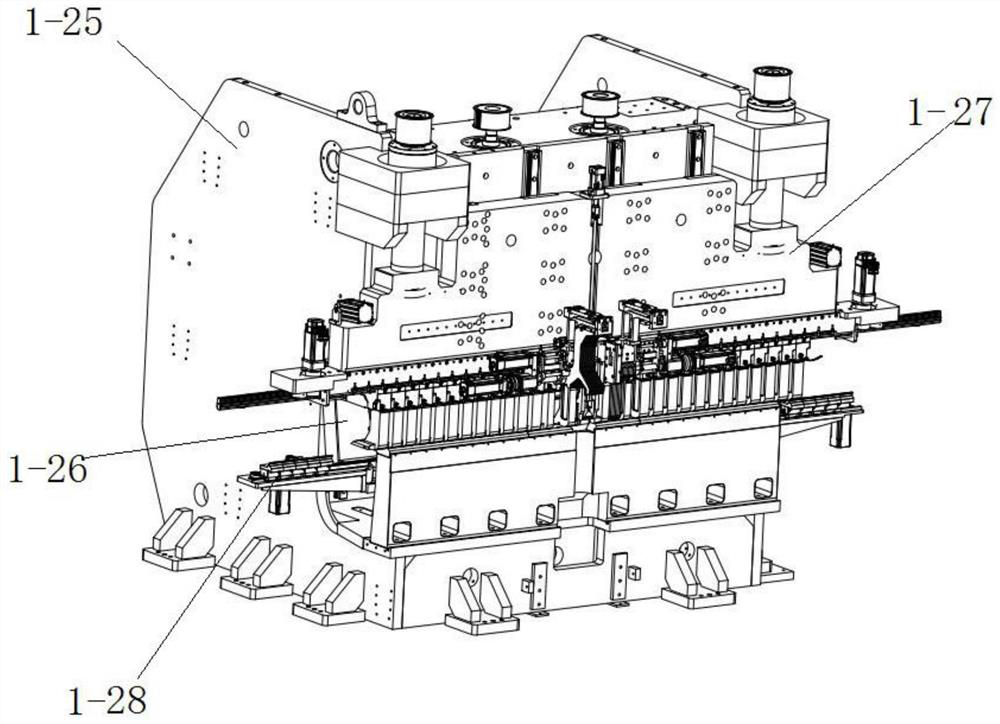

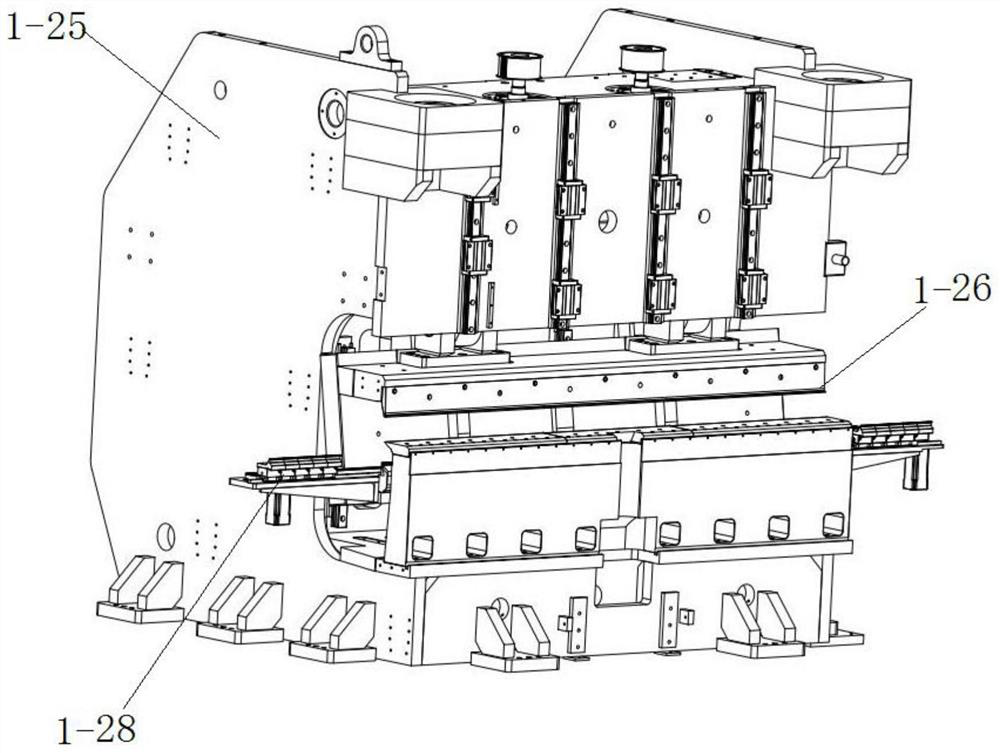

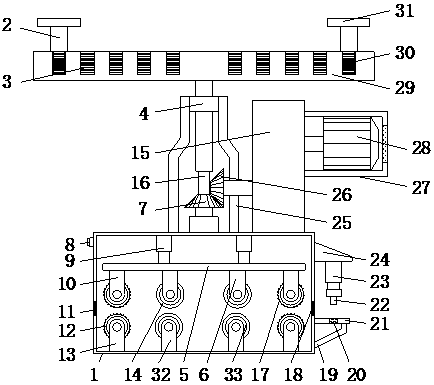

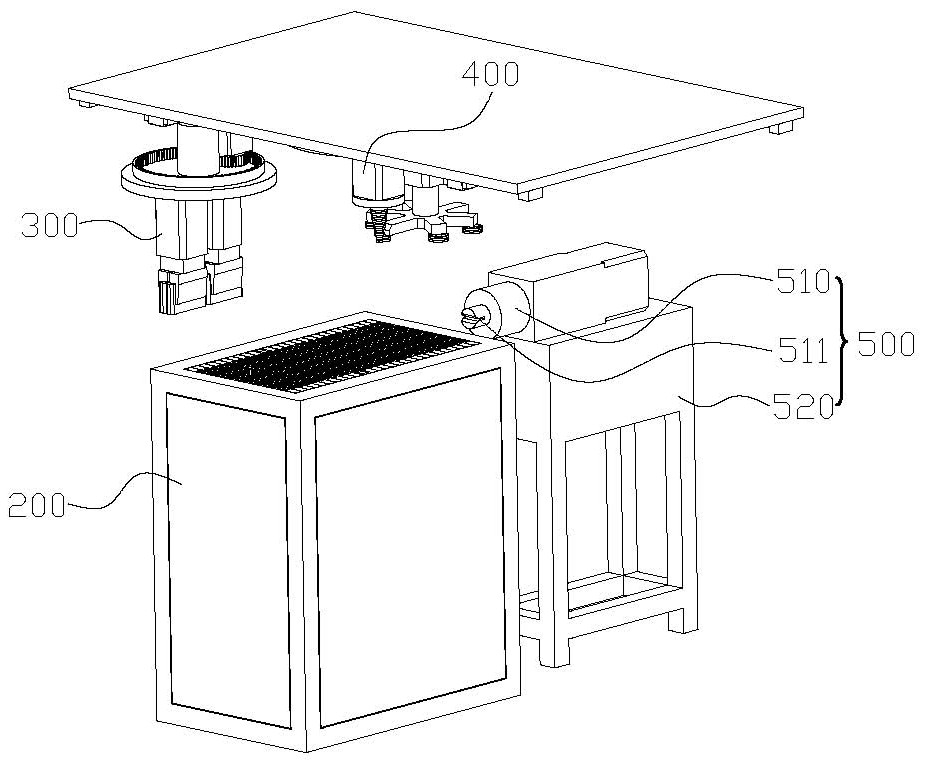

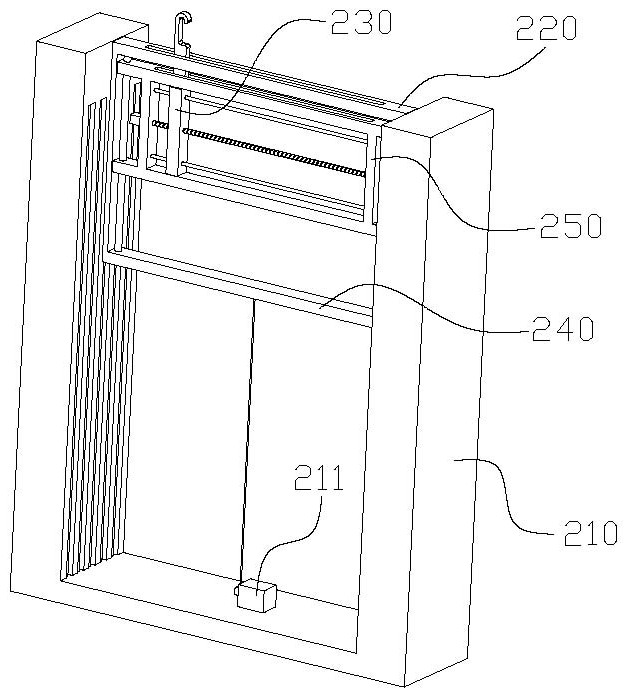

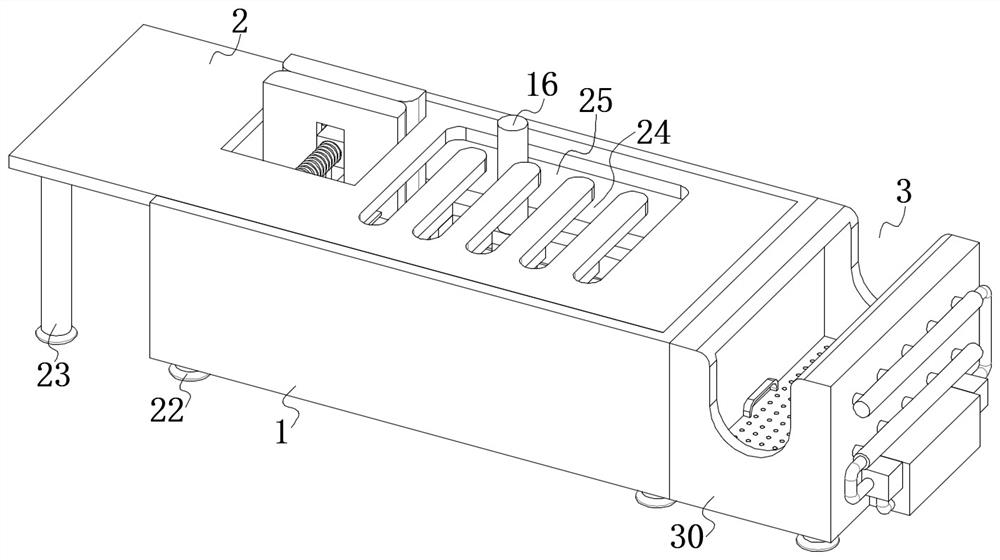

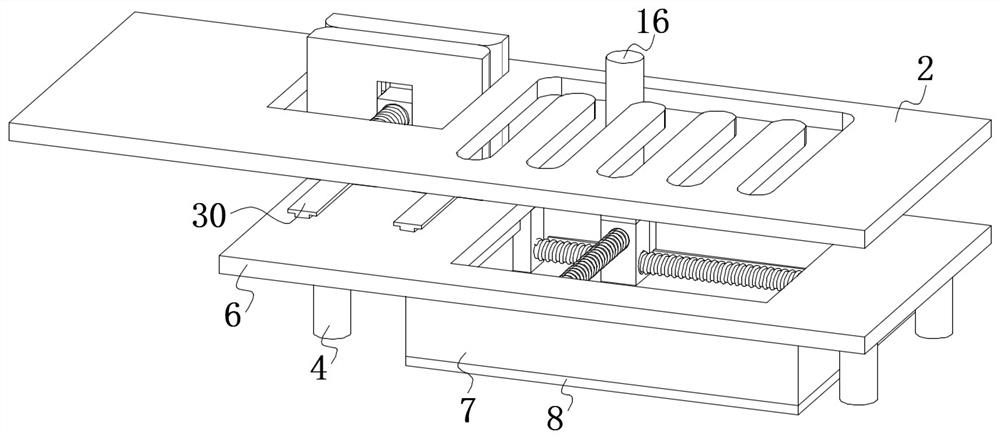

Full-automatic bending machine

PendingCN113649438ACompact structureSmall footprintShaping toolsMetal-working feeding devicesRobot handStructural engineering

The invention discloses a full-automatic bending machine. The full-automatic bending machine comprises a bending machine main machine and a positioning and clamping workbench; the bending machine main machine comprises a main machine shell; an electric servo bending center tool driving mechanism is arranged in the main machine shell; an automatic tool changing device matched with the electric servo bending center tool driving mechanism is mounted on a bending operation opening of the main machine shell; a local bending mechanism is mounted on a lower tool of the electric servo bending center tool driving mechanism and comprises a local bending sliding rail, a left local bending assembly and a right local bending assembly; the left local bending assembly and the right local bending assembly are mounted on the local bending sliding rail in a sliding manner and symmetrically arranged at the two ends of the lower tool; the positioning and clamping workbench comprises a feeding rotary manipulator and a bearing table; and the bearing table comprises positioning equipment and a supporting rack. The positioning equipment and the supporting rack are connected into a whole. By means of the full-automatic bending machine, the bending efficiency can be remarkably improved, labor input is reduced, and the automation degree is improved.

Owner:HEBEI HANZHI CNC MASCH CO LTD

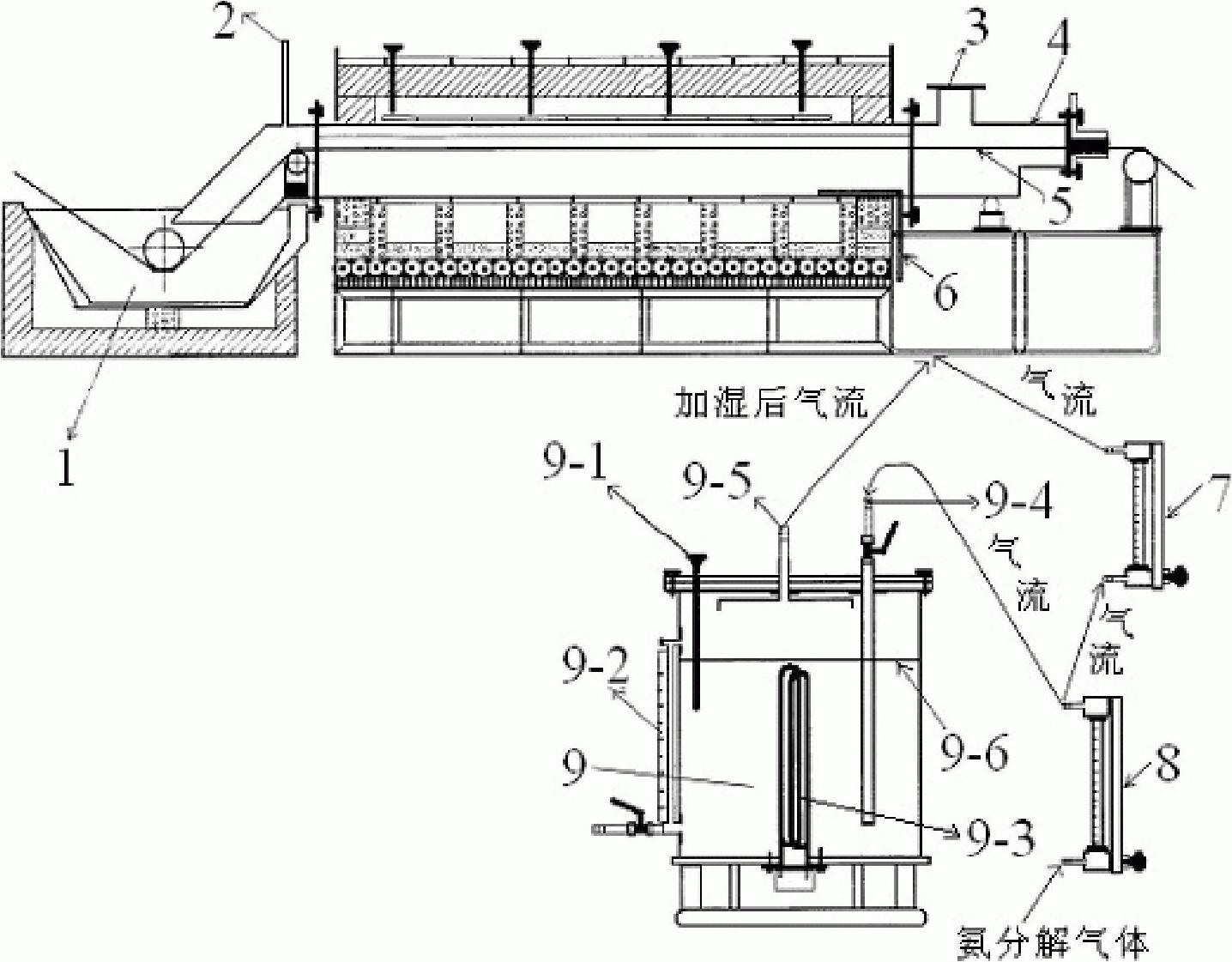

Process for quenching die-cutting rule band steel for printing

InactiveCN101818233ASolve the shortcomings of poor bending performanceMeet bending needsFurnace typesHeat treatment bathsStrip steelAmmonia

The invention belongs to printing industry, and in particular relates to a process for quenching die-cutting rule band steel for printing. The quenching process comprises the following step: preserving the heat of band steel for a certain period of time at a quenching heating temperature in a lead bath band steel quenching furnace by taking water as a main decarburizing medium and an taking ammonia-decomposed gas as a heating medium, wherein the total flow rate of the ammonia-decomposed gas is 3 to 5 times (m<3> / h) that of the interval volume of a muffle pipe and is introduced into the muffle pipe of the lead bath band steel quenching furnace after being divided into paths through a main flow meter, wherein one path directly enters the muffle pipe through a mixing pipe by means of a branch flow meter and the other one enters the muffle pipe through the mixing pipe after being mixed with water steam in a humidifier; and the temperature preserving time is 3 to 4 times that of t, wherein t=a*k*D=1*1.8*D (a is a heating coefficient with a unit of minute / millimeter; k is a band steel charging coefficient and D is an effective band steel thickness with a unit of millimeter). The defect of poor bending performance in heat treatment band steel used by a die-cutting rule product for printing is overcome and the bending requirement of the die-cutting rule product for printing can be met.

Owner:余姚市宝马印刷器材有限公司

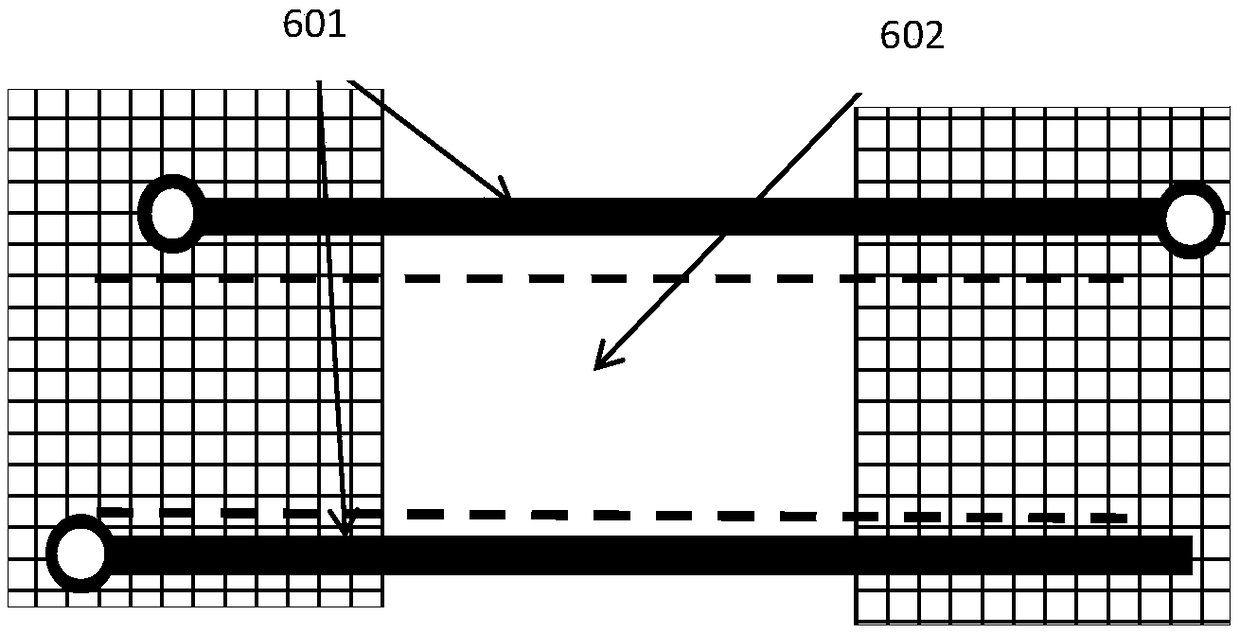

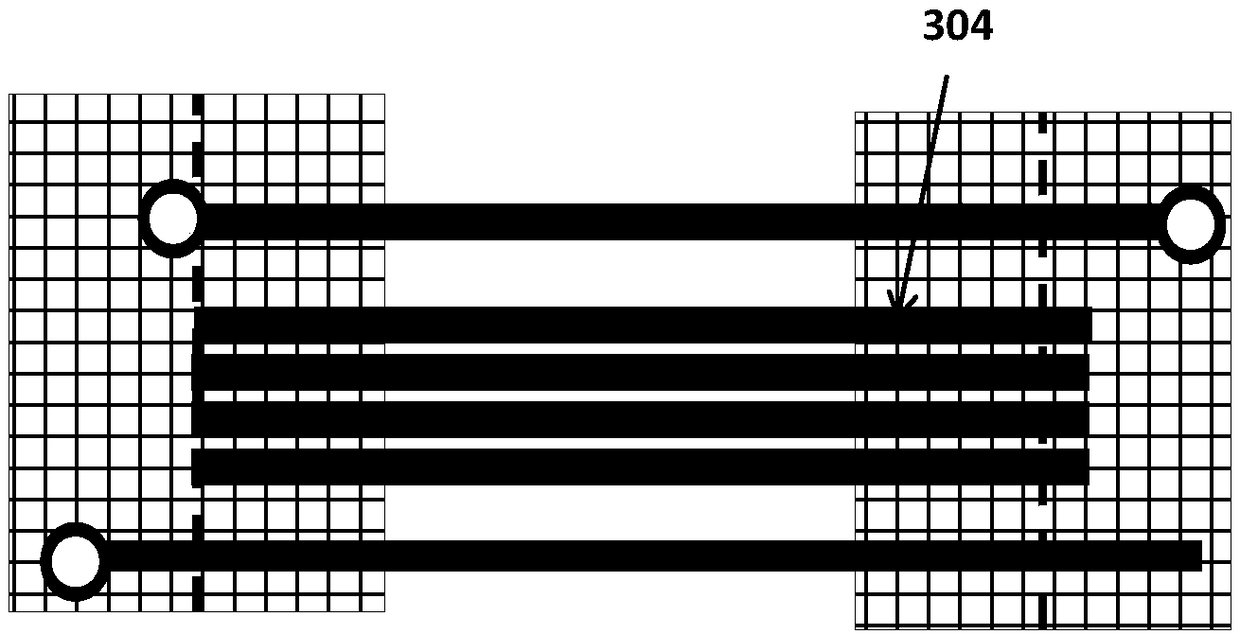

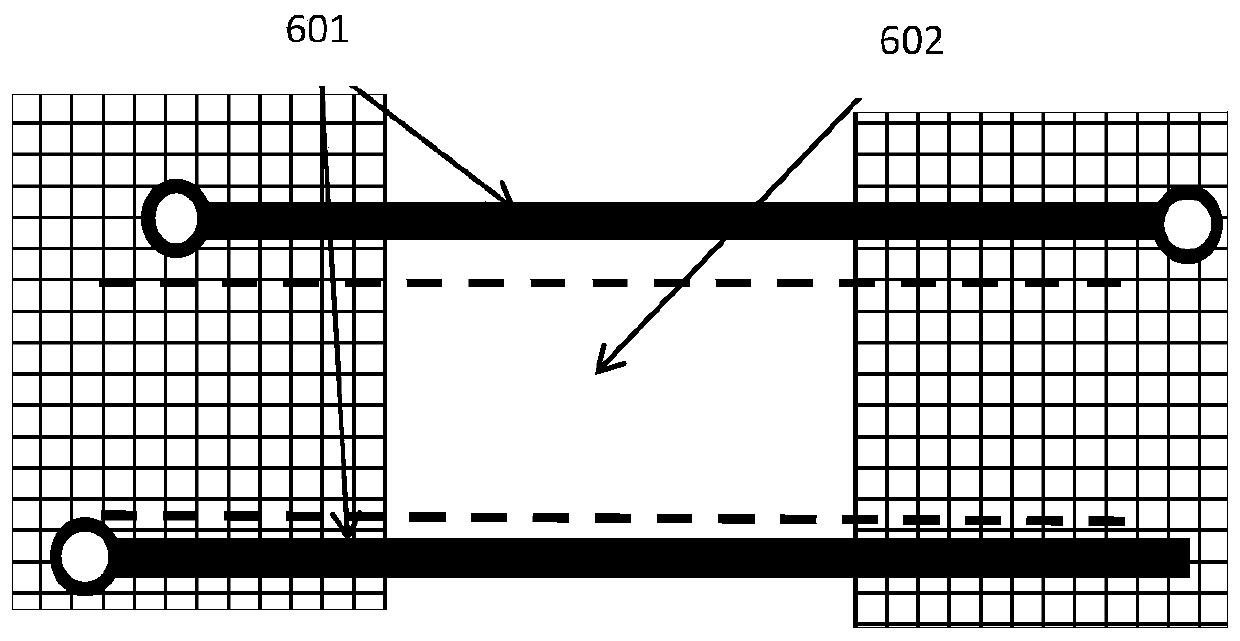

Half-bent printed circuit board and making method thereof

ActiveCN108419384ASolve crackingImprove reliabilityPrinted circuits structural associationsMultilayer circuit manufactureEngineeringCopper

The invention provides a half-bent printed circuit board and a making method thereof. The making method includes: pre-arranging a bent area on an inner-layer circuit board; arranging non-conducting wires in a copper-free area of an inner-layer circuit layer of the bent area; especially arranging non-conducting wires in a copper-free area of an outer-layer circuit layer in a matched manner; especially arranging the non-conducting wires according a specific layout mode to form a specific half-bent circuit board making process. The half-bent circuit board made by the making process can reduce stress directly acting on the circuit board in the process of bending, the problem that the inner-layer circuit board in the bent area cracks during board bending is solved, certain bending needs are metwithout adopting expensive PI films, and cost reduction and meeting of bending needs are well balanced; the half-bent circuit board has high reliability and excellent thermostability.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

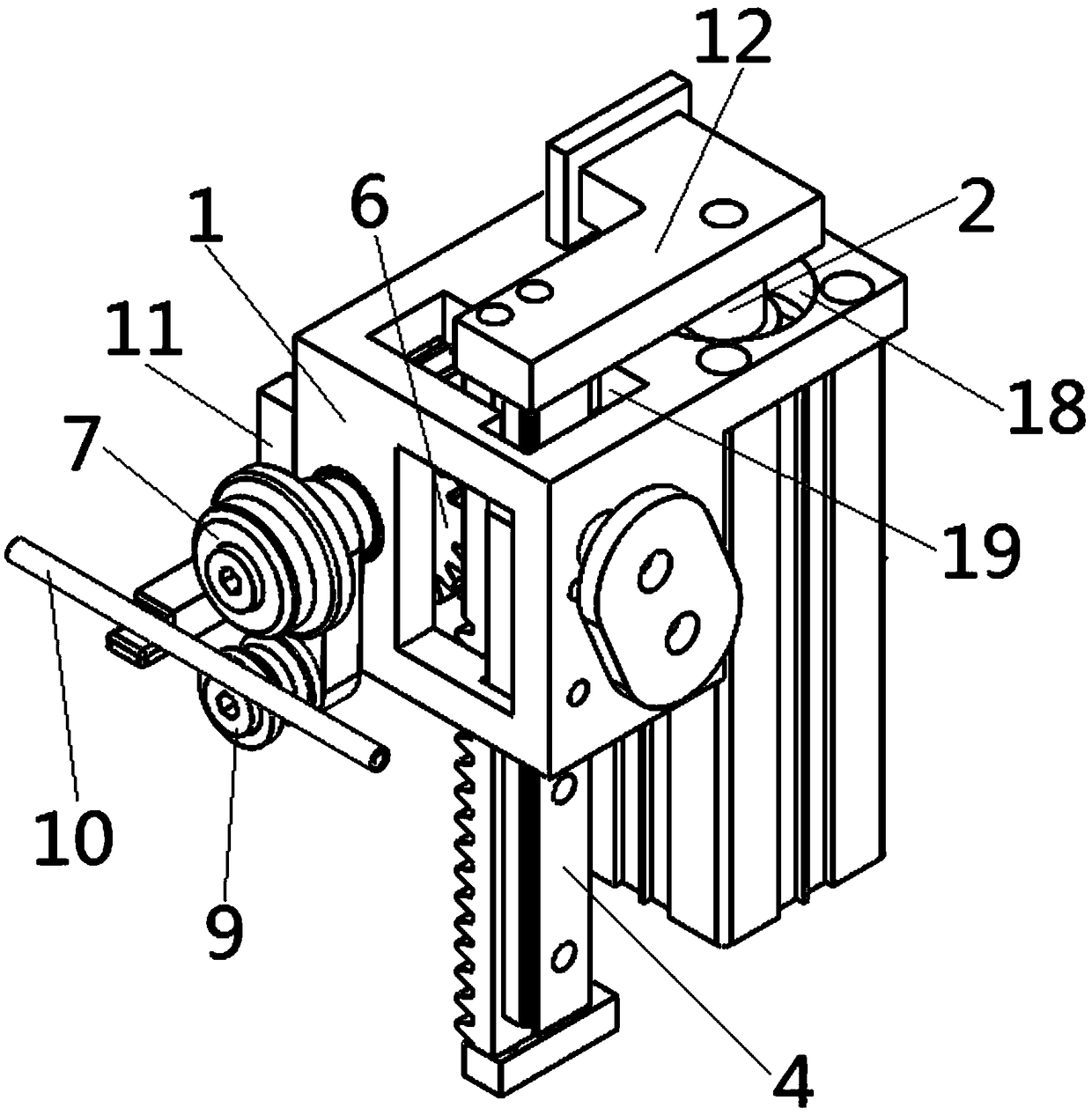

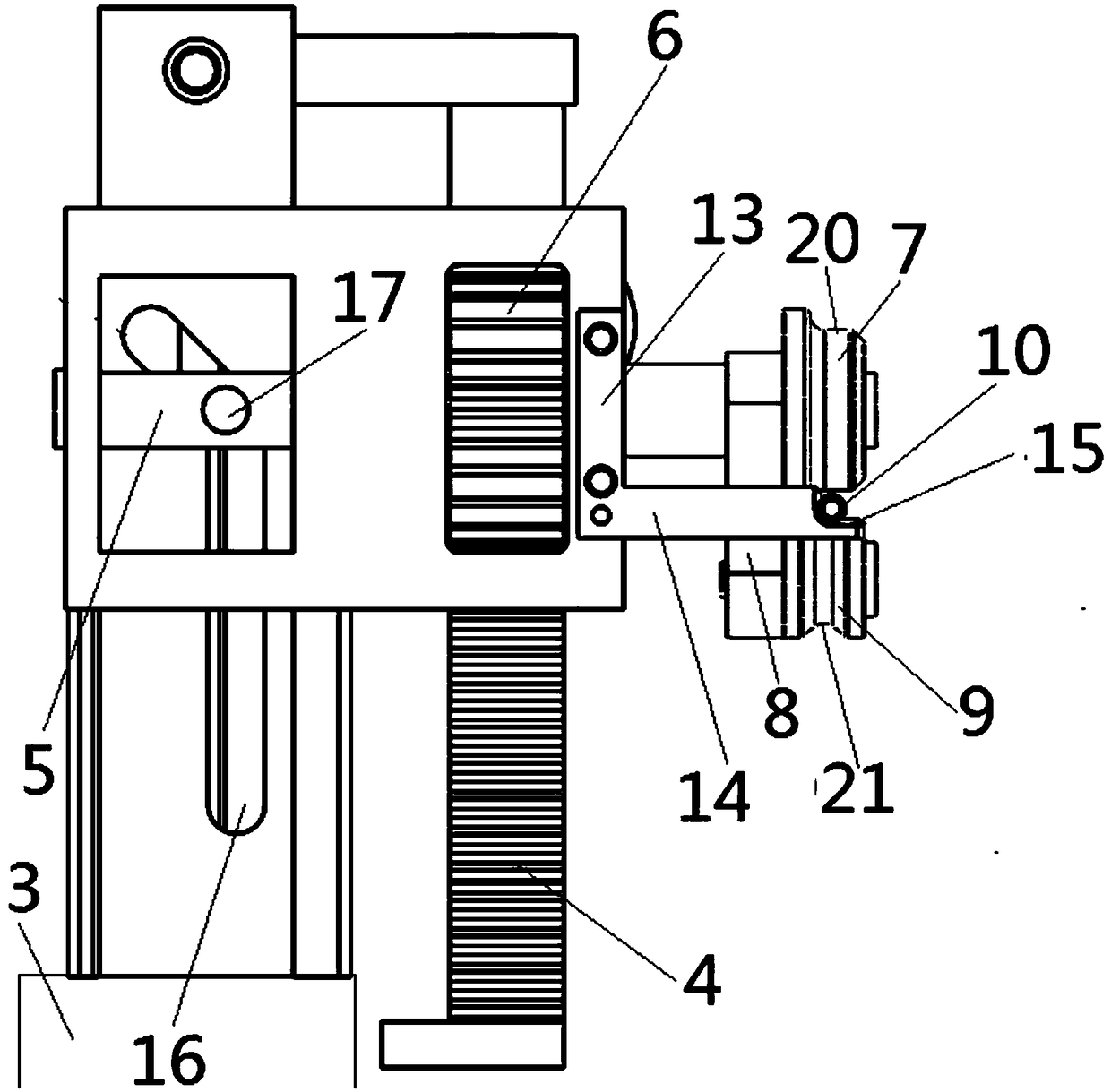

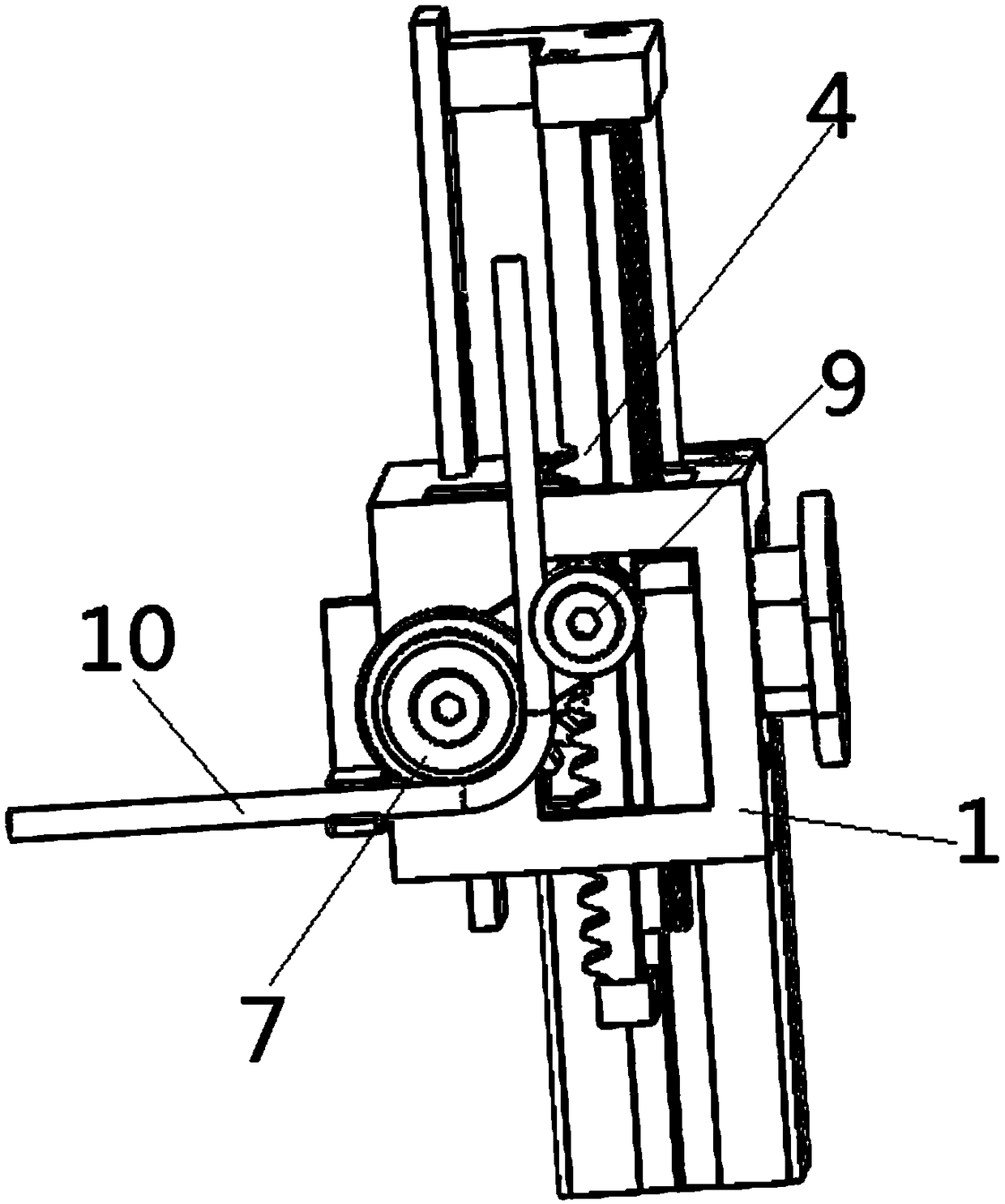

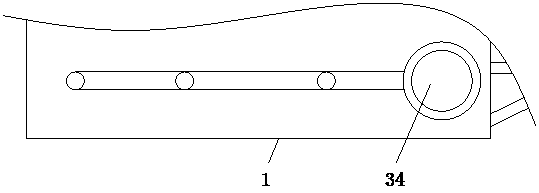

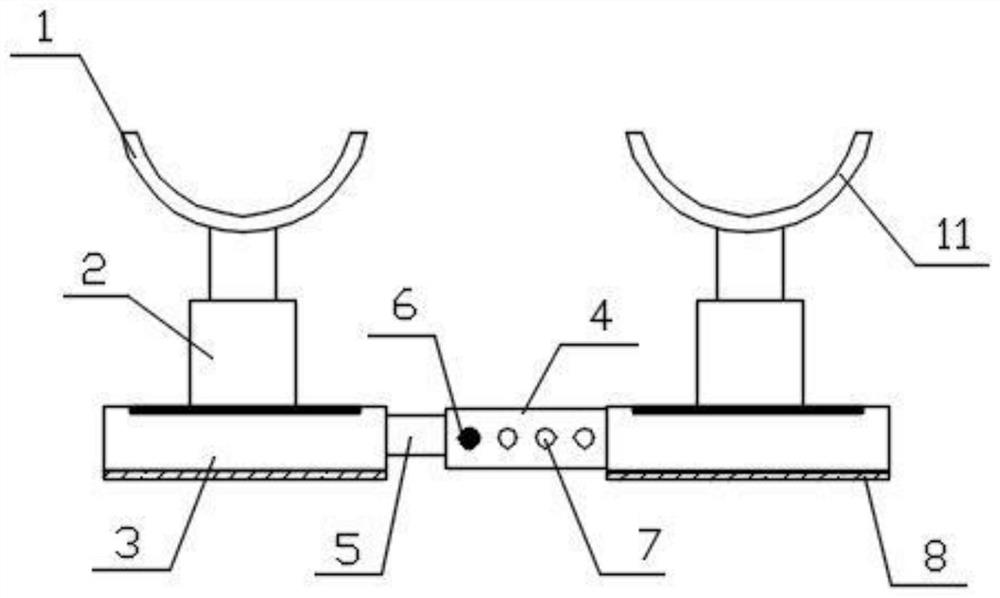

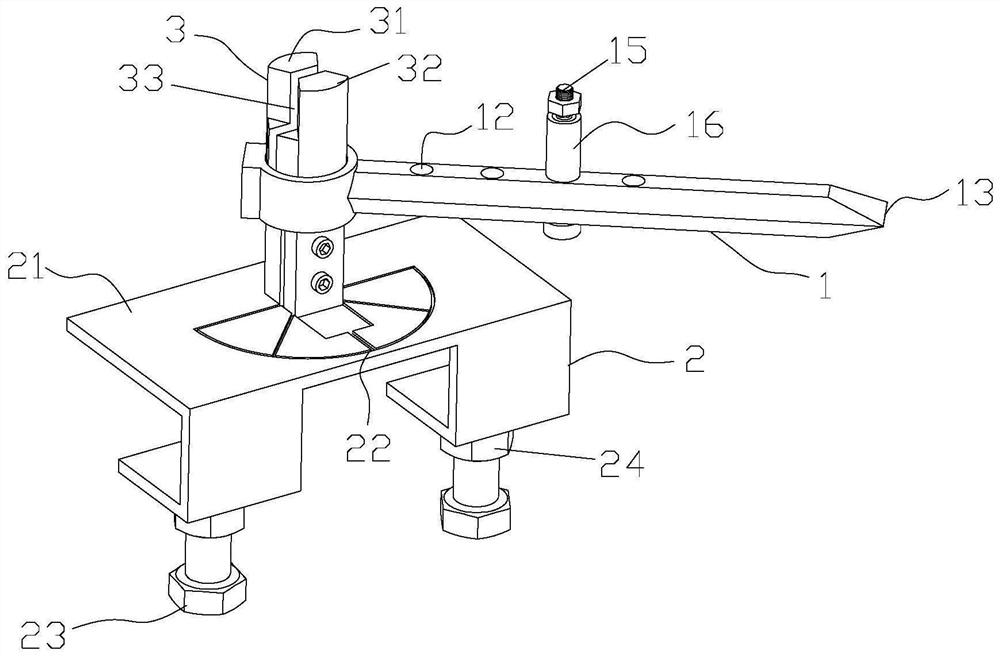

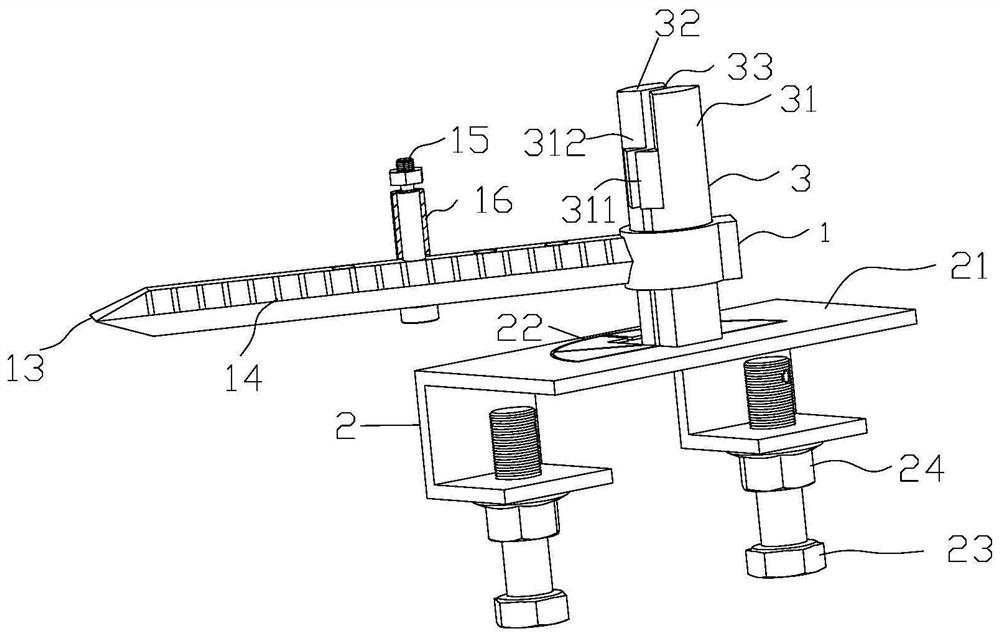

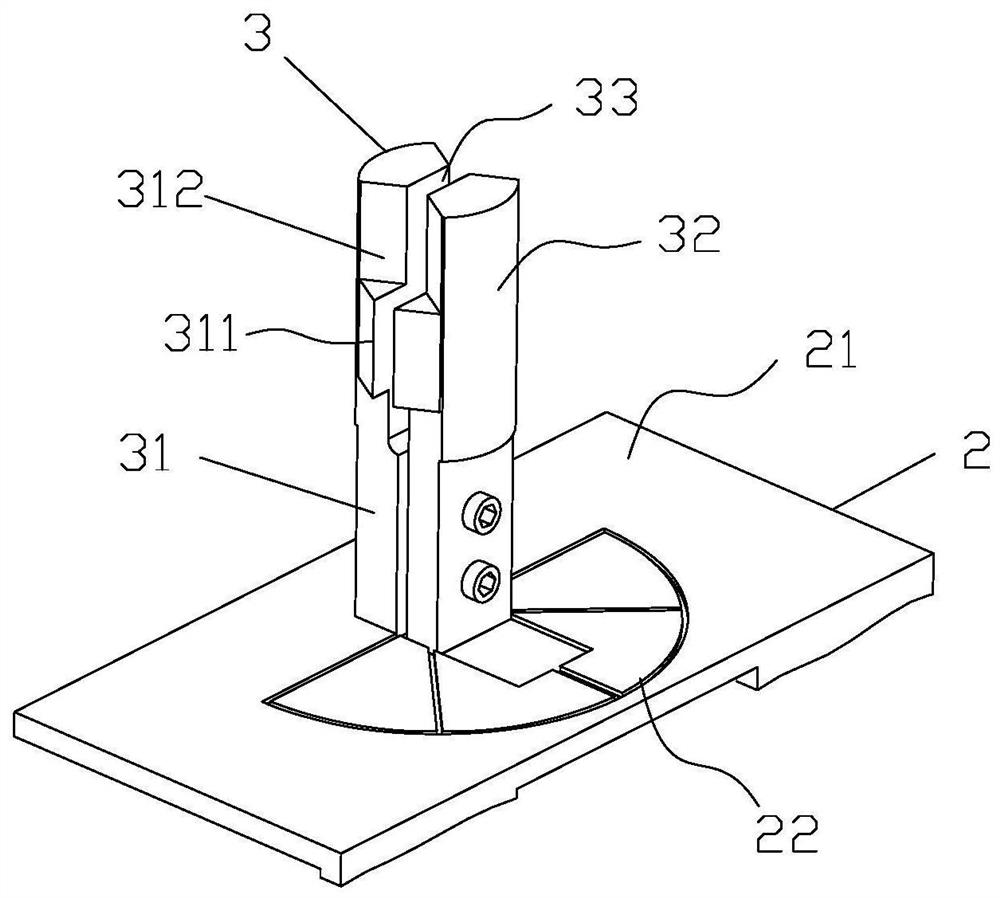

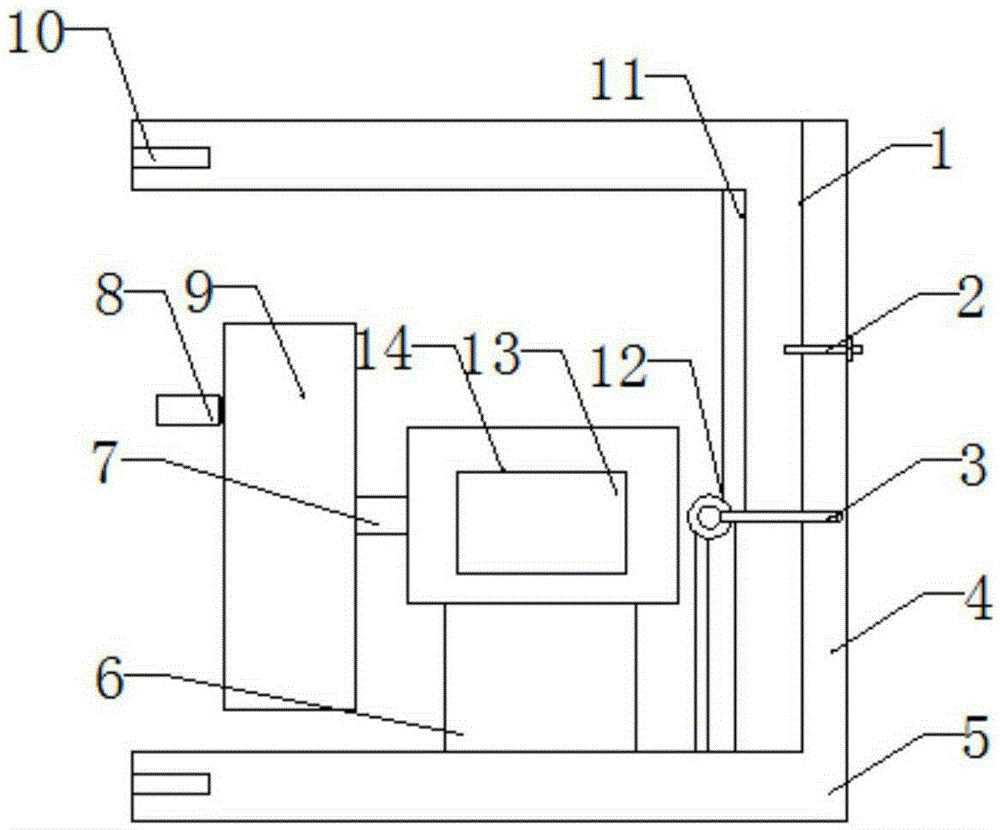

A kind of bending tool for automobile brake hard tube

ActiveCN107891077BSimple structureConvenient and fast bending operationVehicle componentsEngineeringTube bending

The invention provides an automotive braking hard tube bending tool applied to the technical field of automotive braking rod hard tube production and processing equipment. A tool frame (1) of the automotive braking hard tube bending tool is connected with a fixing component, a lifting stand column (2) in the tool frame (1) is connected with a retractable cylinder (3) and is connected with a meshing rack (4); a meshing gear (6) is mounted on a rotating shaft (5) on the tool frame (1); the meshing gear (6) is meshed with the meshing rack (4); an extruding wheel (7) is mounted at one end of the rotating shaft (5); a connecting rod (8) is further mounted on the rotating shaft (5); and a bending wheel (9) is mounted at an end of the connecting rod (8). By the automotive braking hard tube bending tool, tube bending operation can be finished conveniently and rapidly; while tube bending efficiency is improved, the labor intensity of operators can be reduced greatly; tubes with different diameters can be bent; the universality of use of the tool is improved; and the processing cost is reduced.

Owner:WUHU TONHE AUTOMOBILE FLUID SYST

Machining device for construction steel bar and application method thereof

The invention discloses a machining device for a construction steel bar and an application method thereof. The machining device comprises a straightening box. A first electric telescopic rod is fixedly connected to the top of an inner cavity of the straightening box. A supporting plate is fixedly connected to the bottom of the first electric telescopic rod. Upper conveying roller brackets are fixedly connected to the left and right ends of the bottom of the supporting bracket. Through action of the first electric telescopic rod, the supporting plate, the upper conveying roller brackets, upperconveying rollers, the upper conveying roller brackets, upper guide roller brackets, lower conveying roller brackets, lower conveying rollers, lower guide roller brackets, lower guide rollers, a second supporting seat, a second electric telescopic rod, a cutting rod, a first supporting seat, a reserved opening, a bearing, a rotating shaft, a second bevel gear, a rotating disc, threaded holes, threaded rods, anchor stocks, limiting plates, a ratchet wheel non-return mechanism, a first bevel gear, and a first motor, steel bar machining efficiency is effectively improved, great convenience is brought for application of users.

Owner:河南永益同丰智能科技有限公司

Steel bar bending device used for building construction based on PLC control

InactiveCN110883266AStable jobPlay a supporting roleMetal working apparatusCircular discElectric machine

The invention discloses a steel bar bending device for building construction based on PLC control. The device comprises a hollow workbench and a disc rotatably connected to an upper end of the workbench. The steel bar bending device adopts a PLC steel bar bending system, a first motor is fixedly installed at a top in the workbench, and an output shaft of the first motor penetrates through the upper end of the workbench and is fixedly connected to an axis of a lower end of the disc. In the invention, a stabilizing mechanism and a clamping mechanism are arranged, an electric push rod can be controlled to work during usage so that a connecting plate pushes a sleeve to move downwards, and a supporting rod presses downwards. A supporting seat replaces a roller to support the workbench so that the steel bar bending device is more stable. A situation that a steel bar bending angle deviates is avoided, the second motor can be controlled to work, a distance between a movable clamping roller anda fixed clamping roller is adjusted, the steel bars of different specifications are clamped and fixed, and bending requirements of the steel bars of different thicknesses are satisfied.

Owner:ZHONGHENG CONSTR GRP

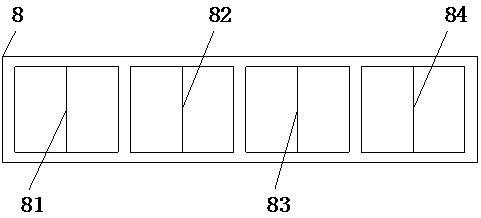

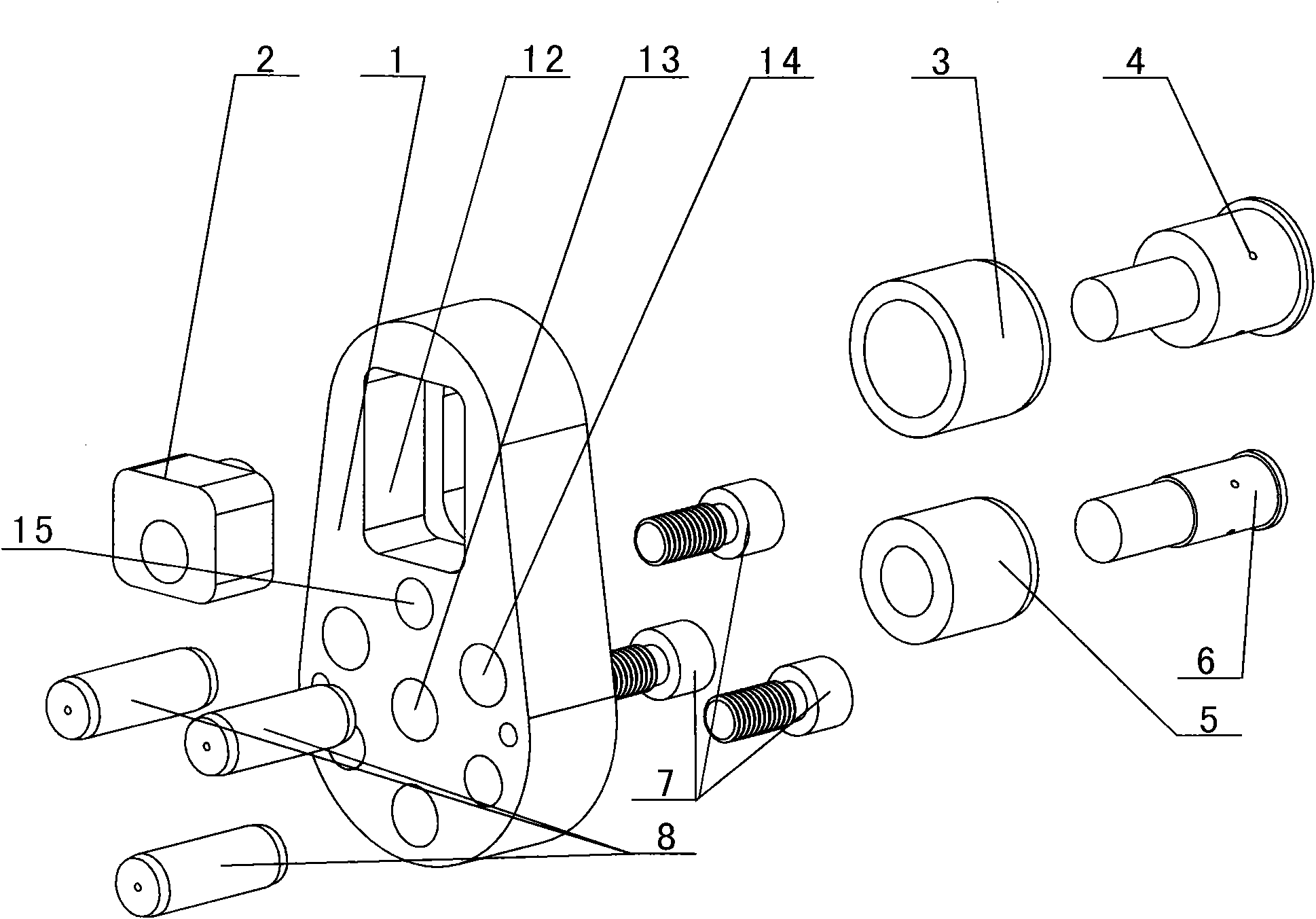

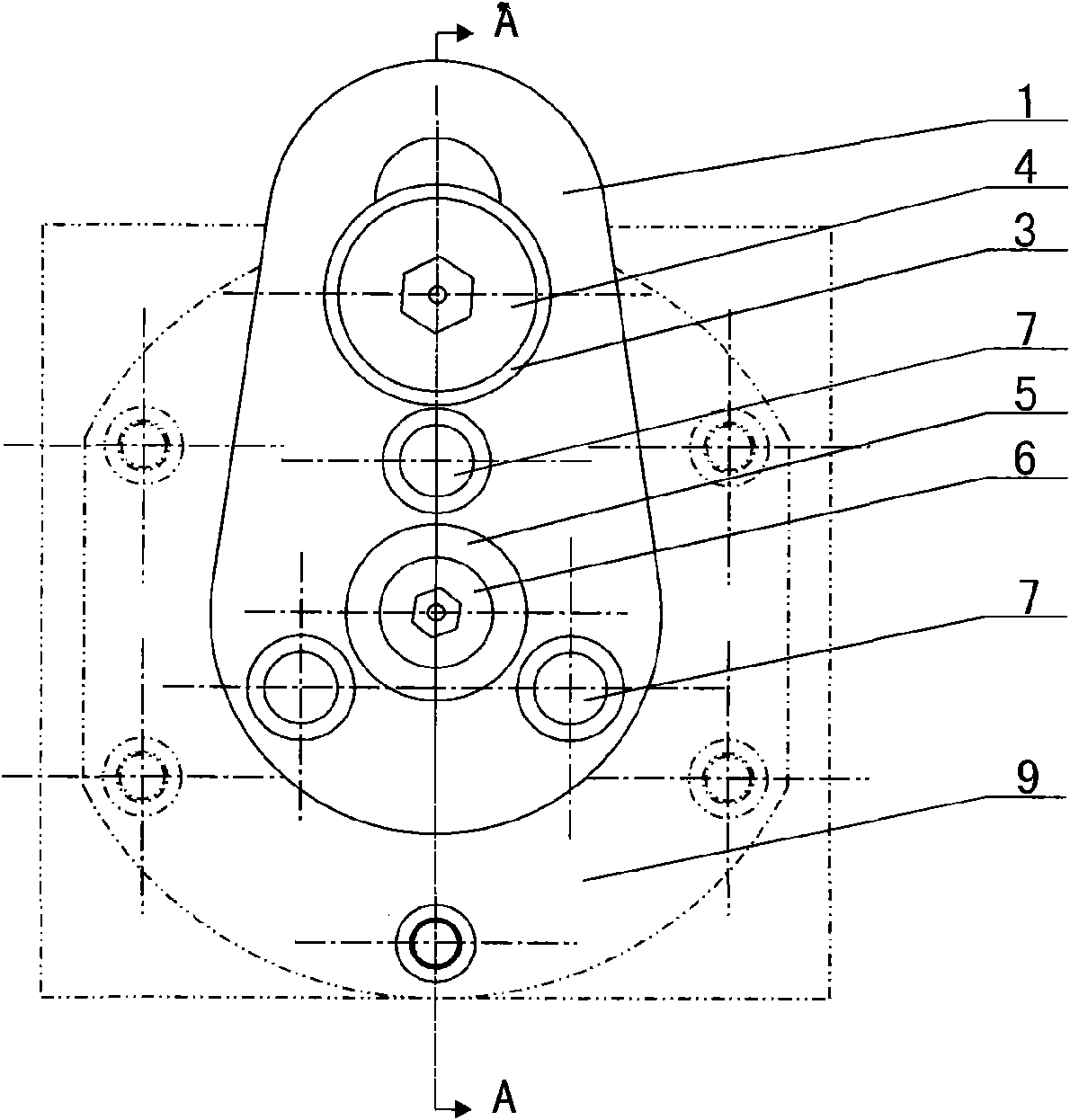

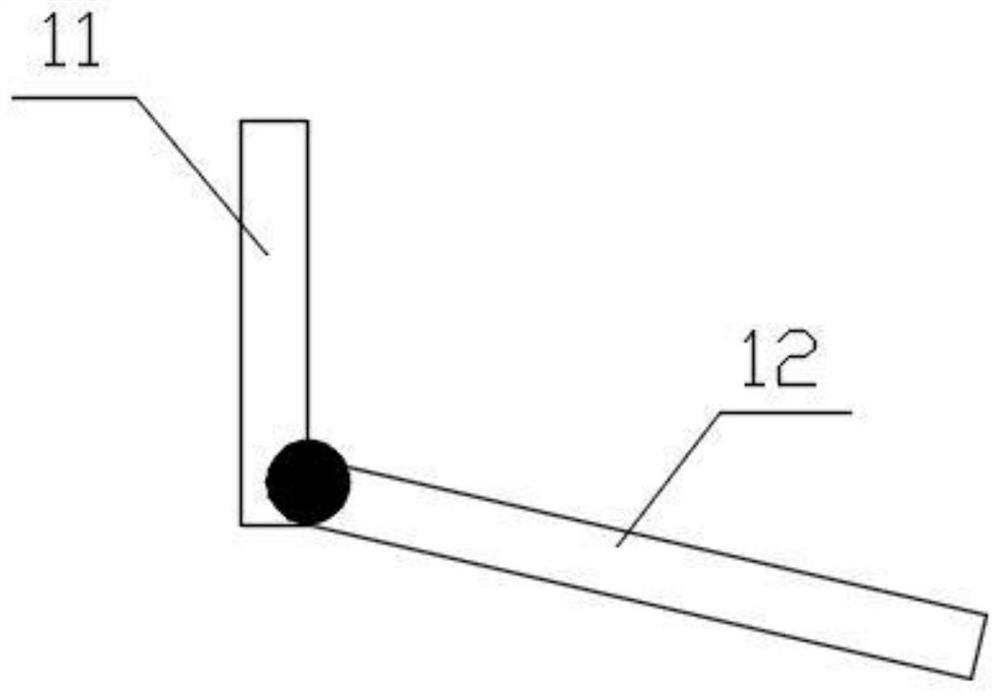

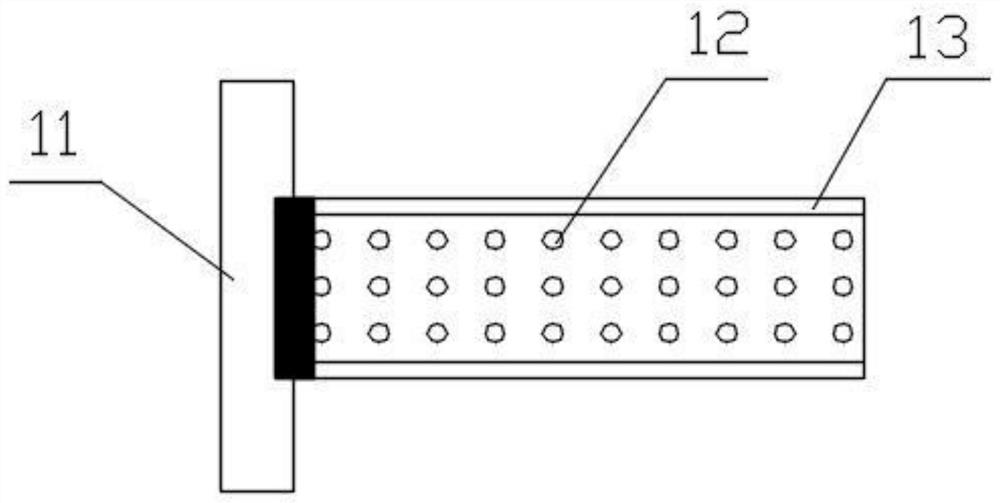

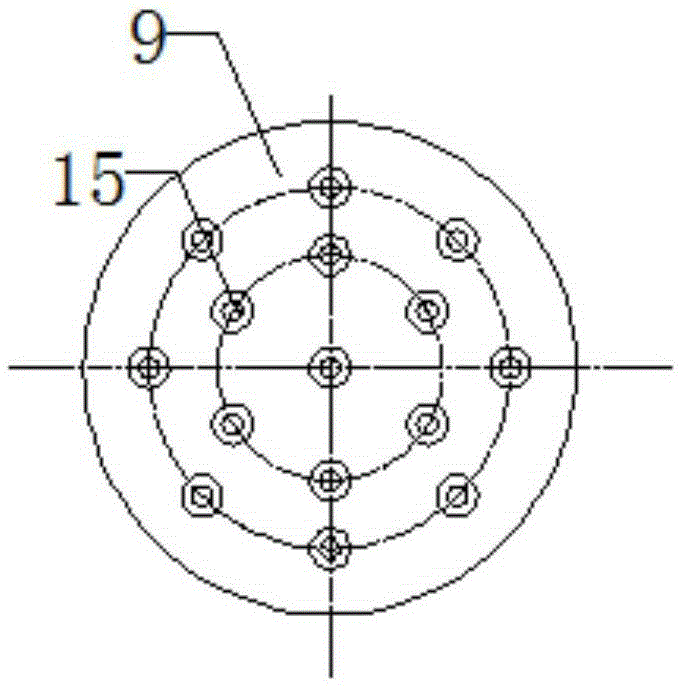

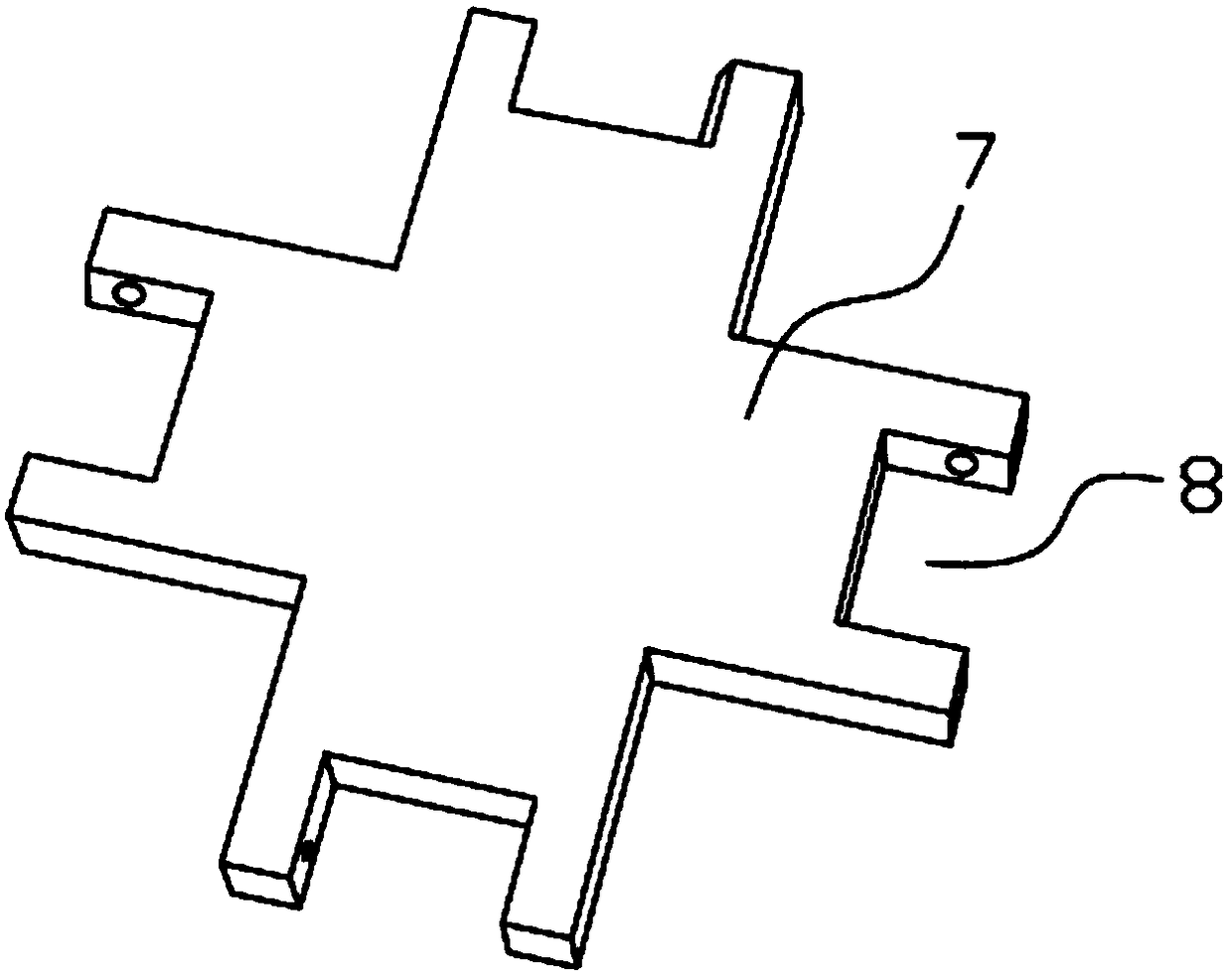

Bending head device of reinforced hoop bending machine

The invention discloses a bending head device of a reinforced hoop bending machine, which relates to a bending head of the reinforced hoop bending machine. The lower part of a bending plate (1) is connected with a bending main shaft (11) by bolts (7) and connecting pins (8), an adjusting block guide slot (12) is arranged at one side of a setting board at the upper part of the bending plate, and an adjusting block (2) is arranged in the adjusting block guide slot by a bending shaft (4); a spindle through hole (13) is arranged in the center of the lower part of the bending plate, a bending spindle (6) is penetrated in the spindle through hole, a plurality of pin holes (14) and screw holes (15) that are equidistant with the axle center of the spindle through hole are respectively arranged around the spindle through hole; and the bolts and the connecting pins are respectively penetrated in the screw holes and the pin holes. The bending head as an independent component brings great convenience for processing and maintaining and realizes the advantages of less occupying space, low cost, manpower and material resource saving, and the like.

Owner:LUOYANG TIHOT RAILWAY MACHINERY MFG

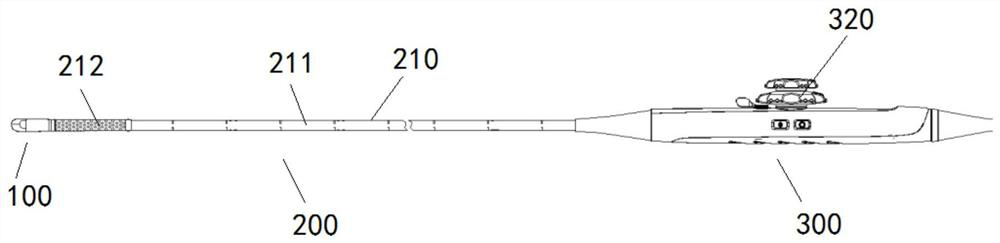

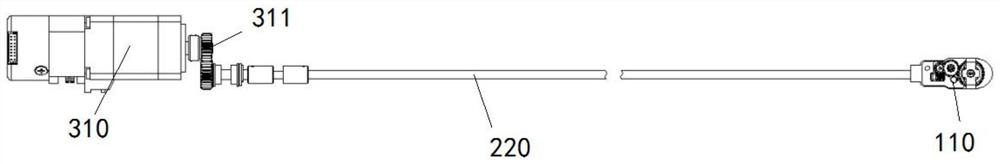

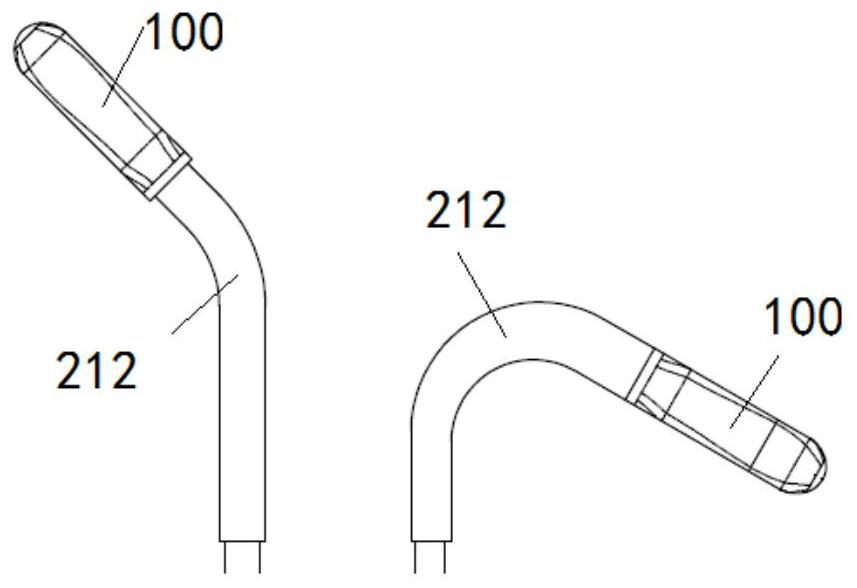

Ultrasonic probe

PendingCN112274175AMeet bending needsHigh transmission precisionUltrasonic/sonic/infrasonic diagnosticsSurgeryEngineeringBend radius

The invention provides an ultrasonic probe. According to the ultrasonic probe, an elastic shaft of the ultrasonic probe comprises a main shaft section and an inclination angle shaft section, and the main shaft section and the inclination angle shaft section are connected into a whole; the main shaft section and the inclination angle shaft section have different minimum bending radiuses, and particularly, the minimum bending radius of the inclination angle shaft section is smaller than the minimum bending radius of the main shaft section, which can be realized by setting the main shaft sectionand the inclination angle shaft section to be of different structures, to be made of different materials or to be manufactured by using different processes, etc; the minimum bending radius of the mainshaft section is large, so high transmission precision can be guaranteed during long-distance rotary transmission, and the bending requirement of the main shaft section can be met; due to the fact that the rotation transmission of the whole elastic shaft is mainly based on the main shaft section, although the minimum bending radius of the inclination angle shaft section is small, the transmissionprecision of the whole elastic shaft cannot be greatly affected; and on the contrary, due to the fact that the minimum bending radius of the inclination angle shaft section is small, the requirementfor a small bending radius can be met, and the bending requirement of the inclination angle pipe can be better met.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

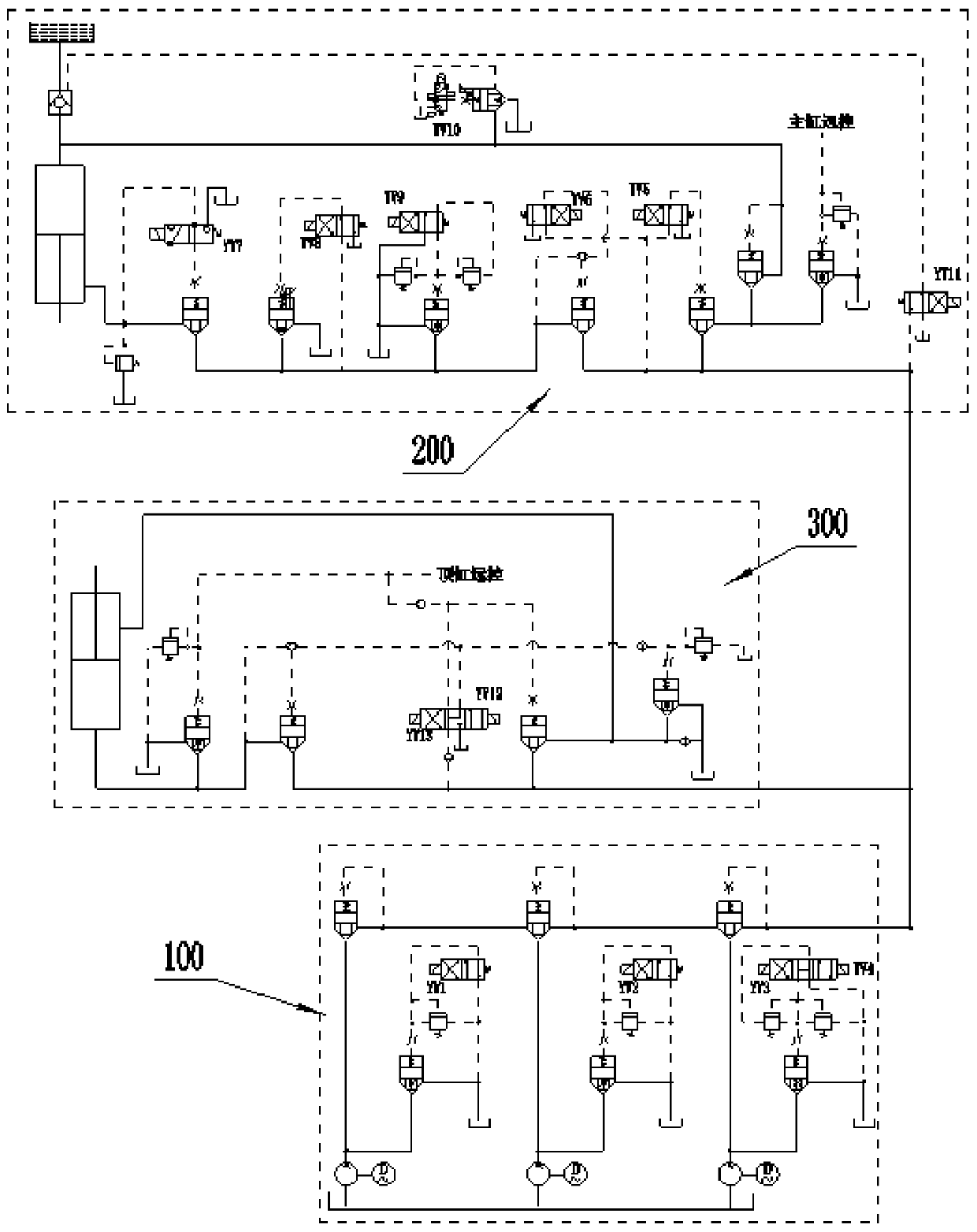

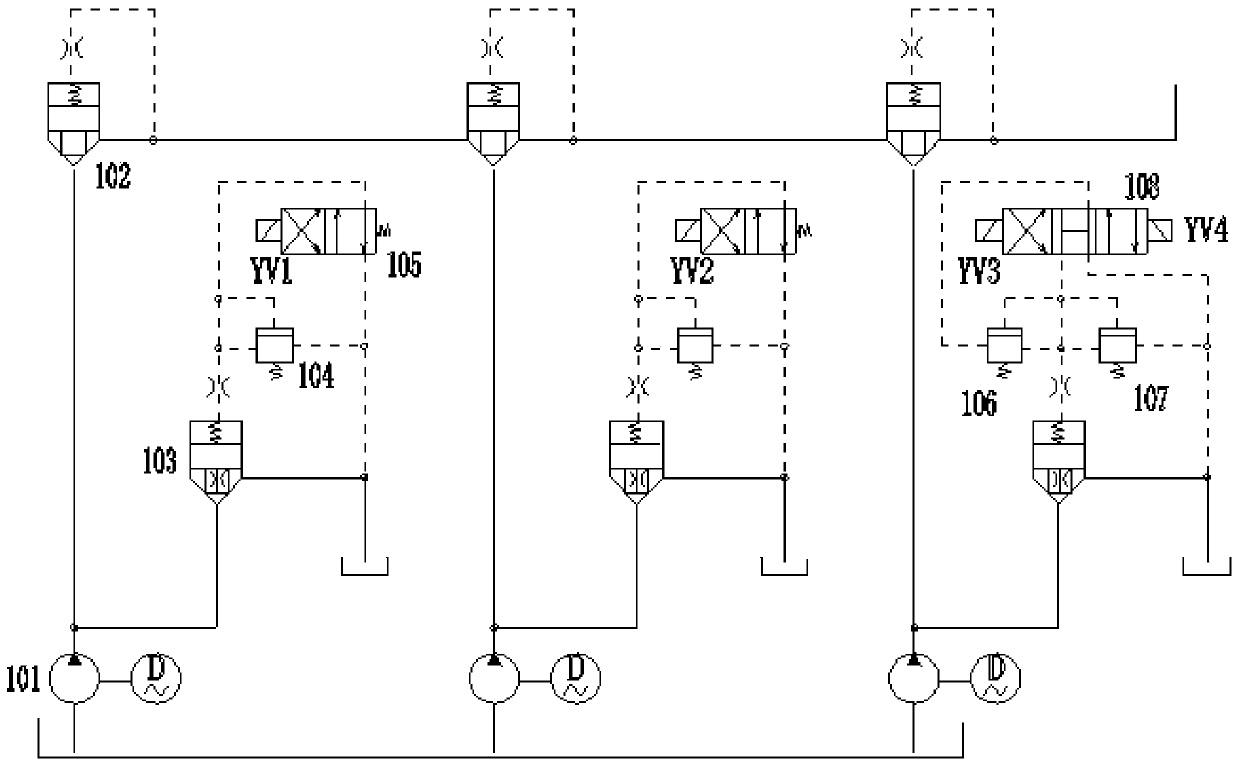

A method of using the hydraulic system of a multi-cylinder linkage hydraulic press

ActiveCN108035926BReduce shock loadExtended service lifeServomotor componentsServometer circuitsPetroleum engineeringPressure release

The invention discloses a multiple-cylinder linkage hydraulic machine hydraulic system use method, and belongs to the technical field of hydraulic machines. The method comprises the control steps of main oil cylinder rapid down, main oil cylinder slow down, main oil cylinder pressure maintaining, main oil cylinder pressure release, main oil cylinder return and the like; when main oil cylinder rapid down is performed, a cartridge valve III, a cartridge valve VII and a cartridge valve VI are switched on, a cartridge valve IV is switched off, an upper cavity of a main oil cylinder is subjected tooil taking, and a lower cavity of the main oil cylinder is subjected to oil return; when main oil cylinder slow down is performed, a cartridge valve VII and a cartridge valve V are switched on, the cartridge valve VI is switched off, the upper cavity of the main oil cylinder is subjected to oil taking, the lower cavity of the main oil cylinder is subjected to oil return, and a workpiece is pressed; when main oil cylinder pressure maintaining is performed, the cartridge valve VII and the cartridge valve VIII are switched off, oil lines of the upper cavity and the lower cavity of the main oil cylinder are disconnected, and the main oil cylinder is locked; when main oil cylinder return is performed, the cartridge valve III is switched off, the cartridge valve IV and the cartridge valve VII are switched on, the lower cavity of the main oil cylinder is subjected to oil taking, and the upper cavity of the main oil cylinder is subjected to oil return. Accordingly, control over actions such as large hydraulic machine rapid down, slow down, pressure maintenance, pressure release and return can be achieved stably and reliably.

Owner:TIANSHUI METALFORMING MACHINE TOOL GRP ANHUI PRESS

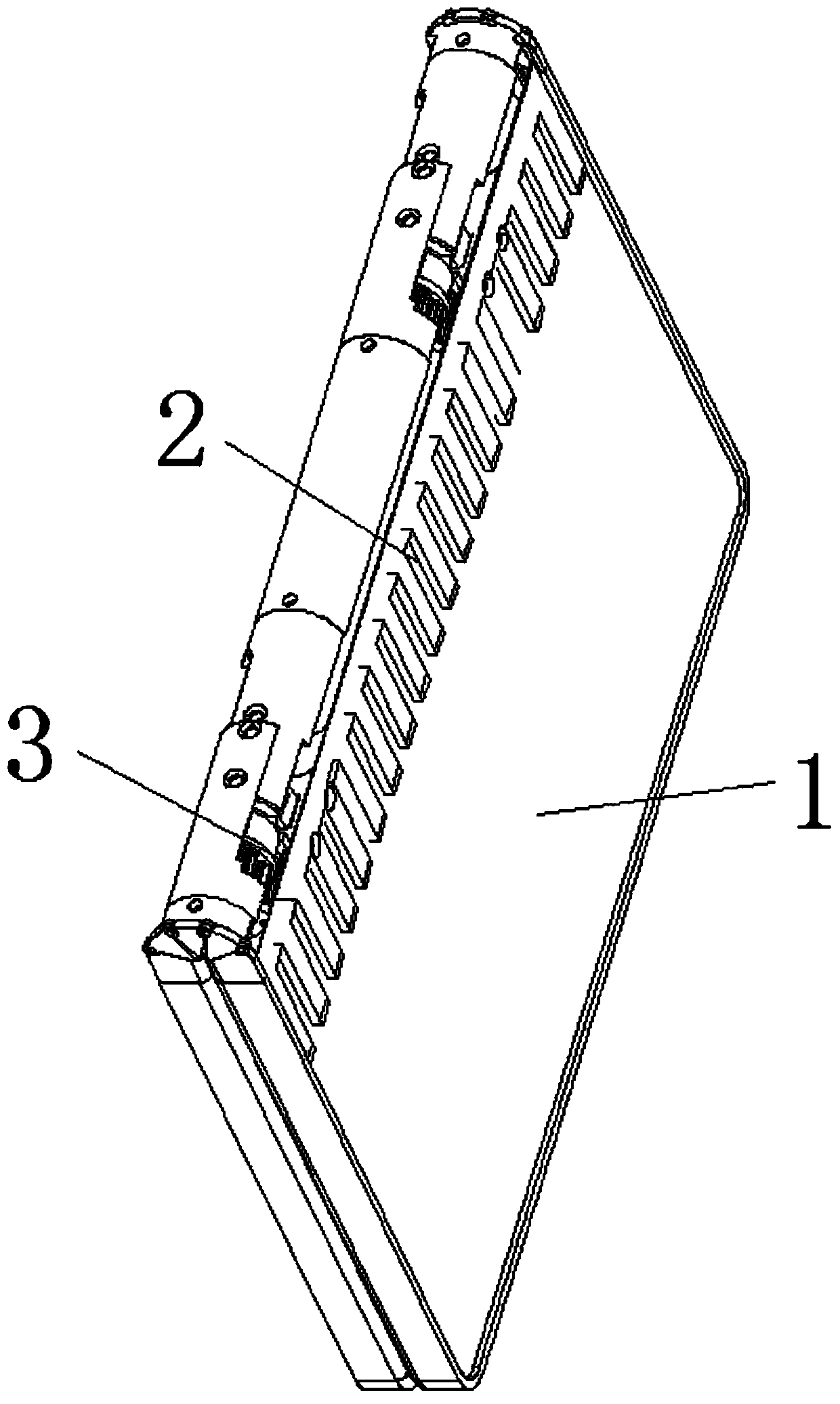

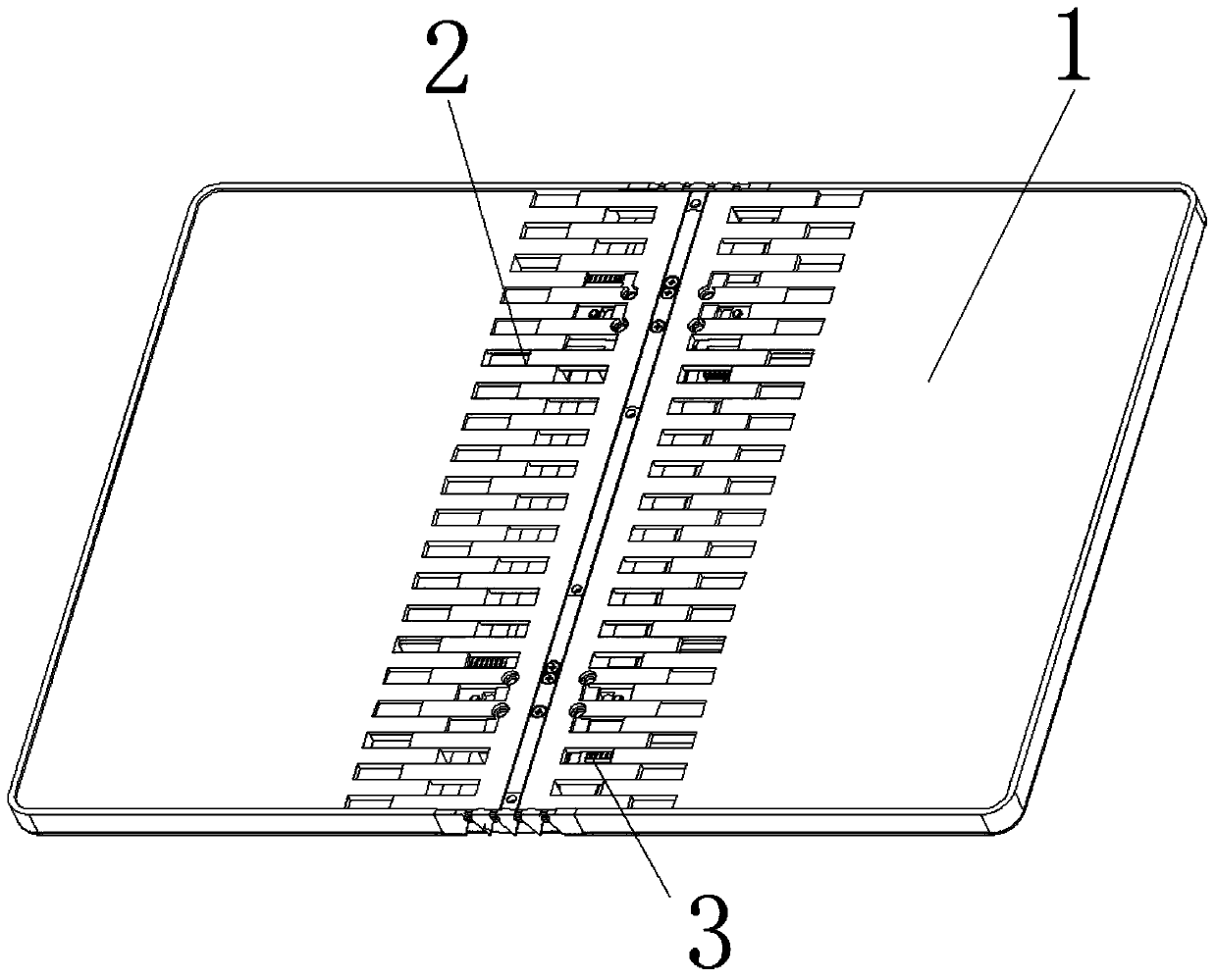

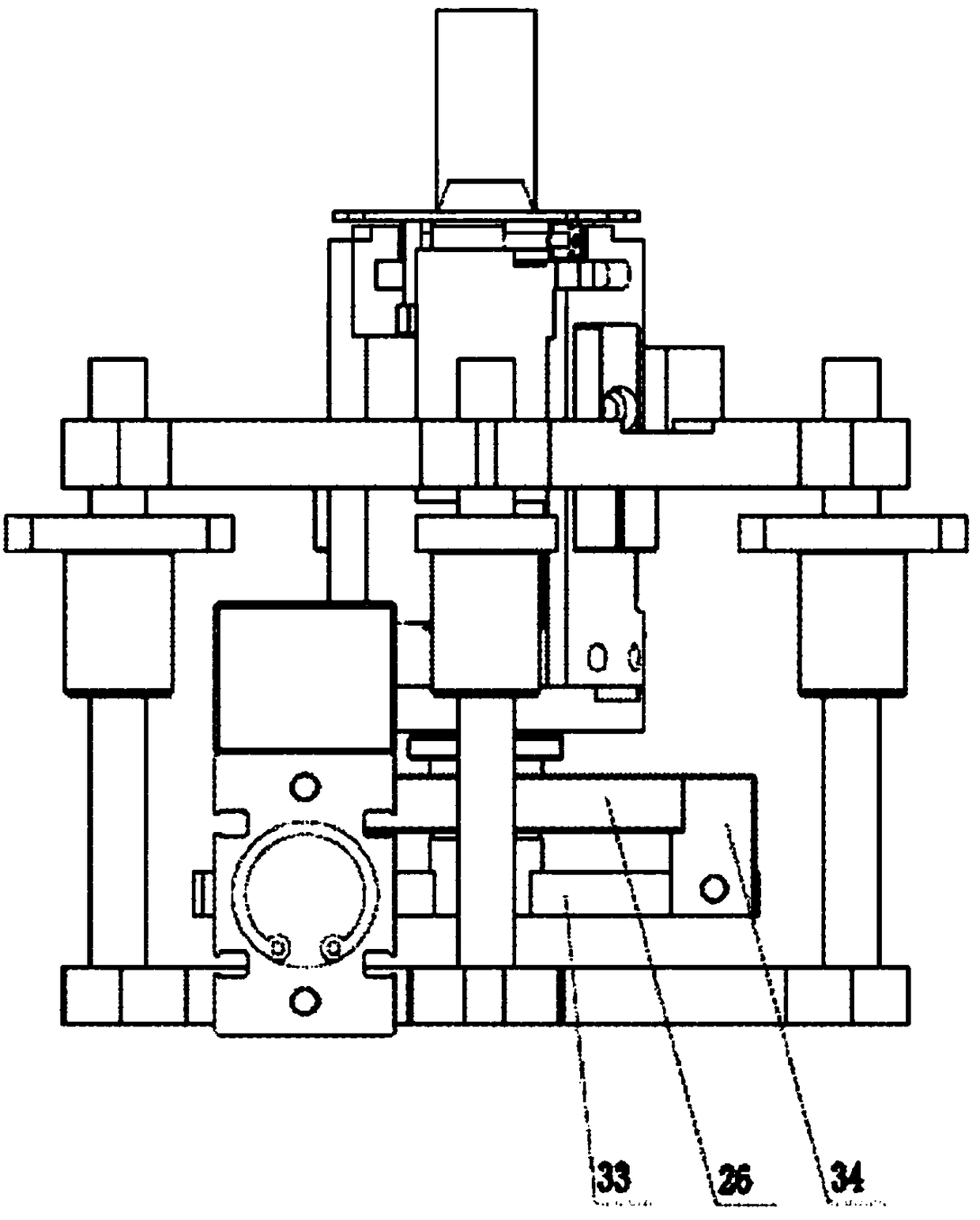

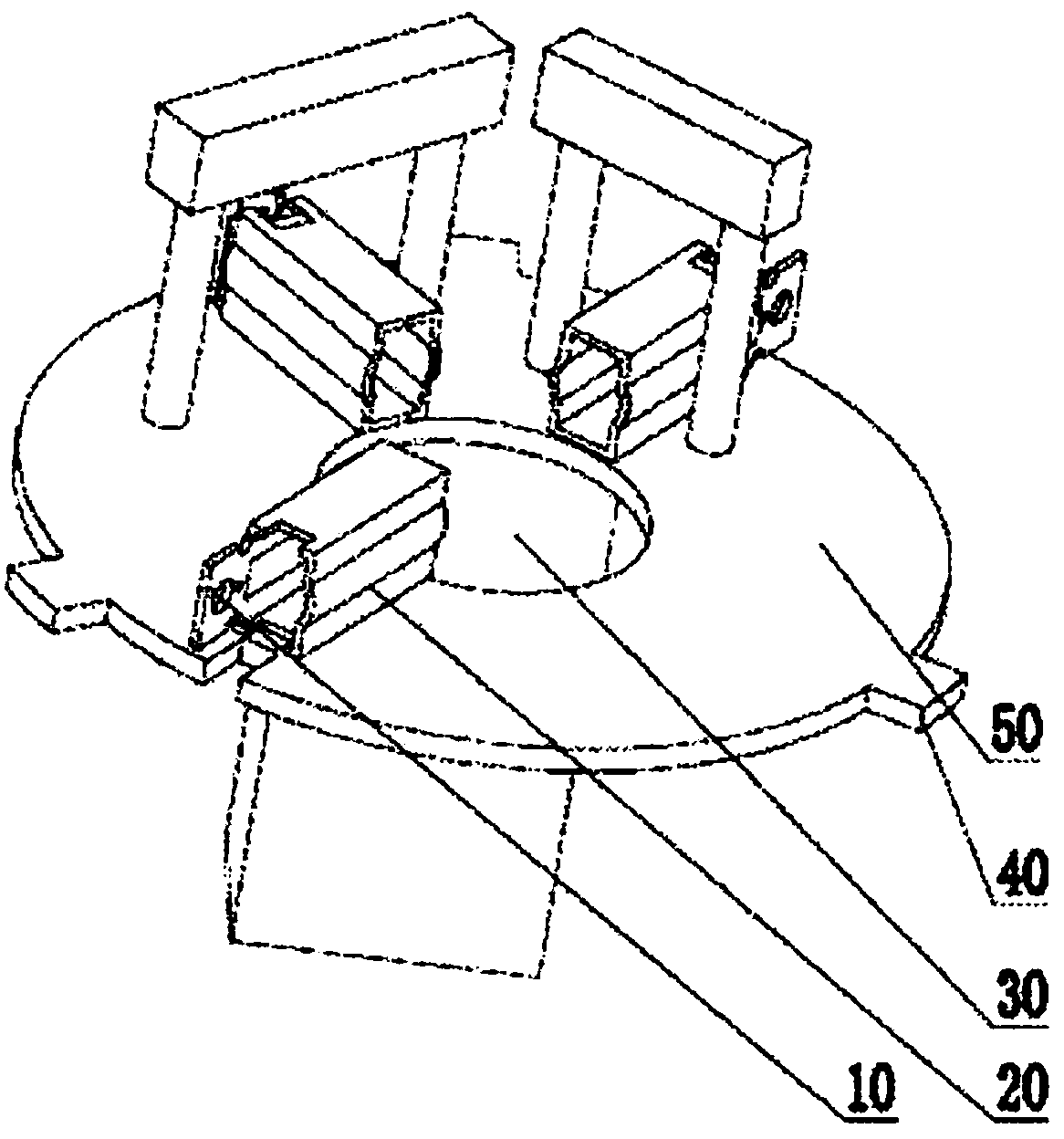

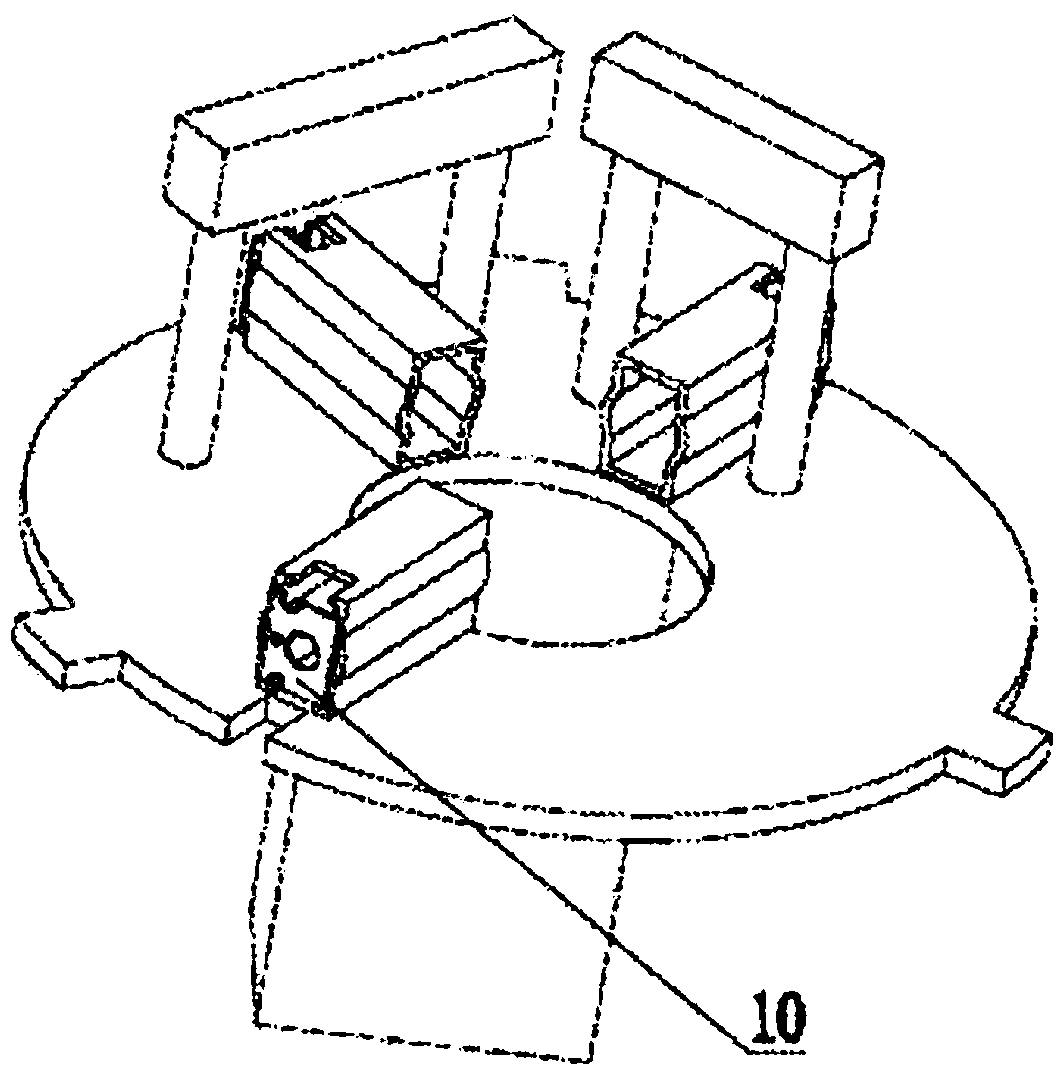

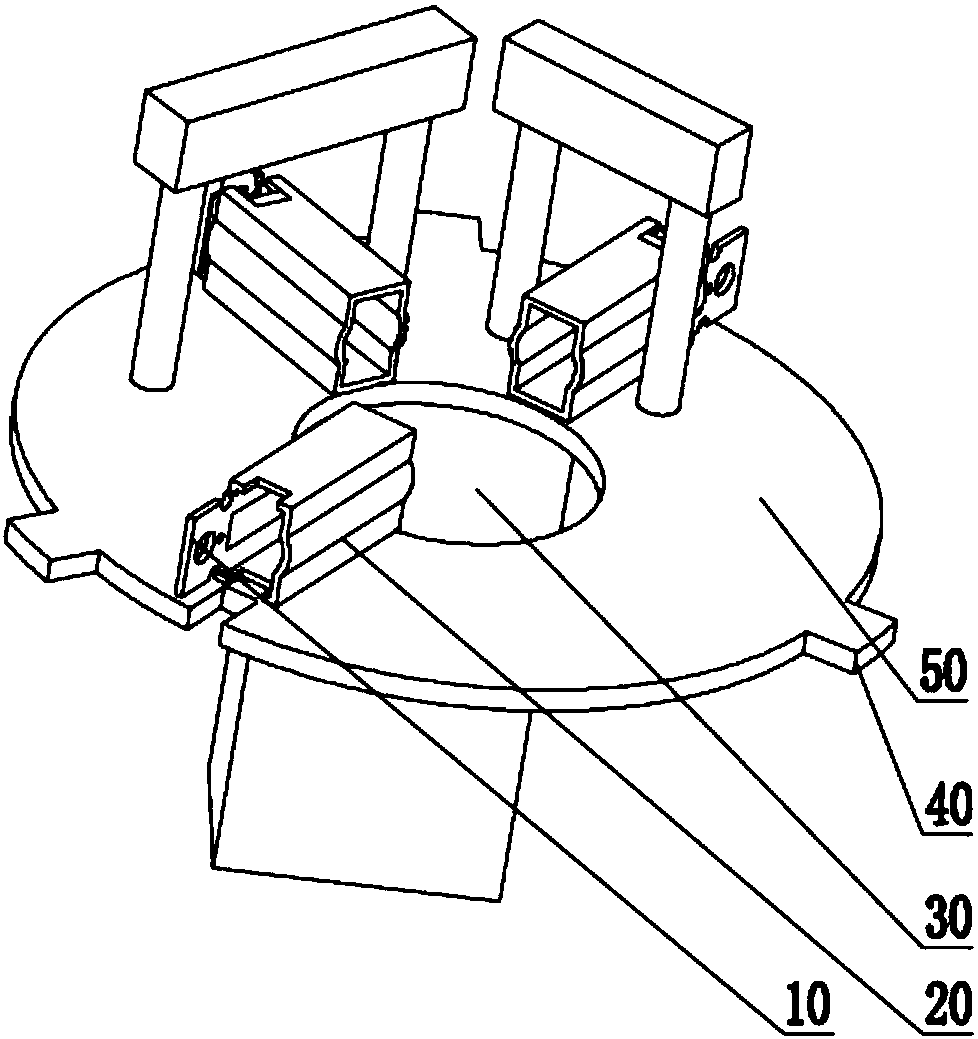

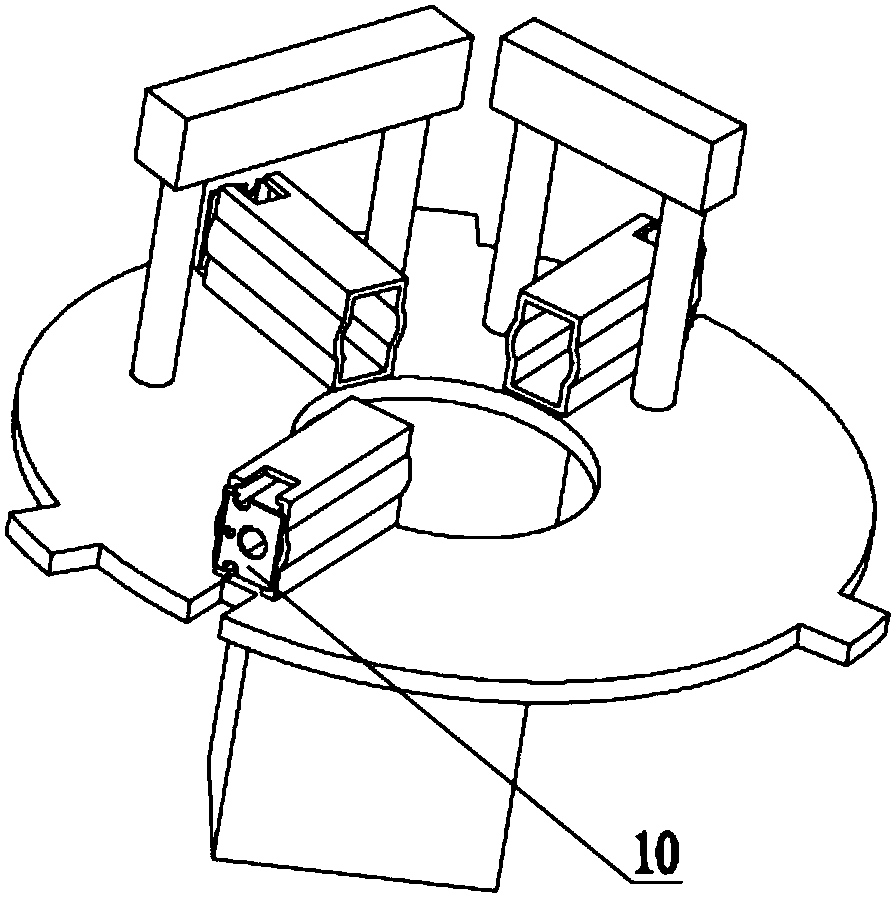

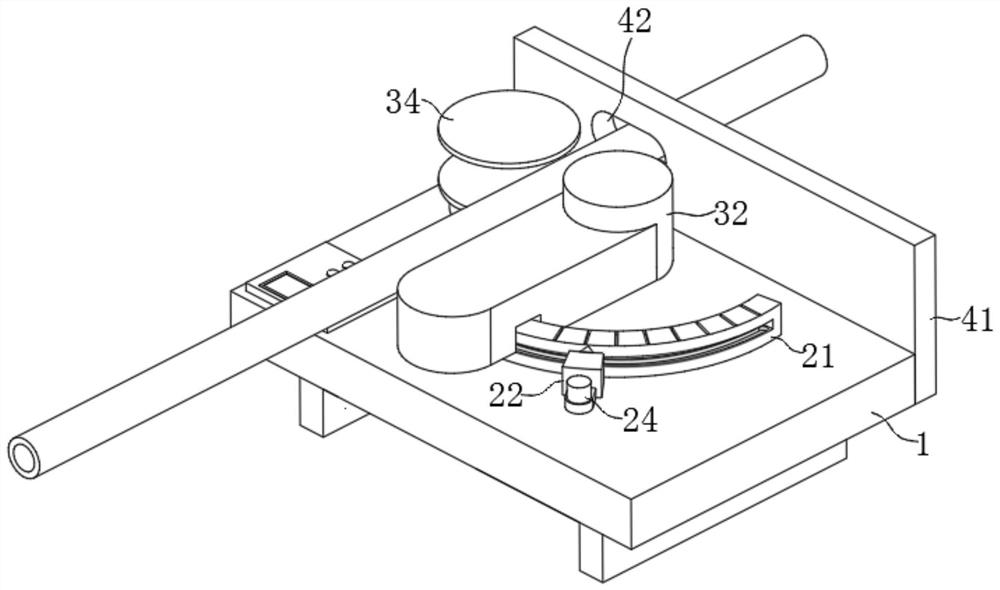

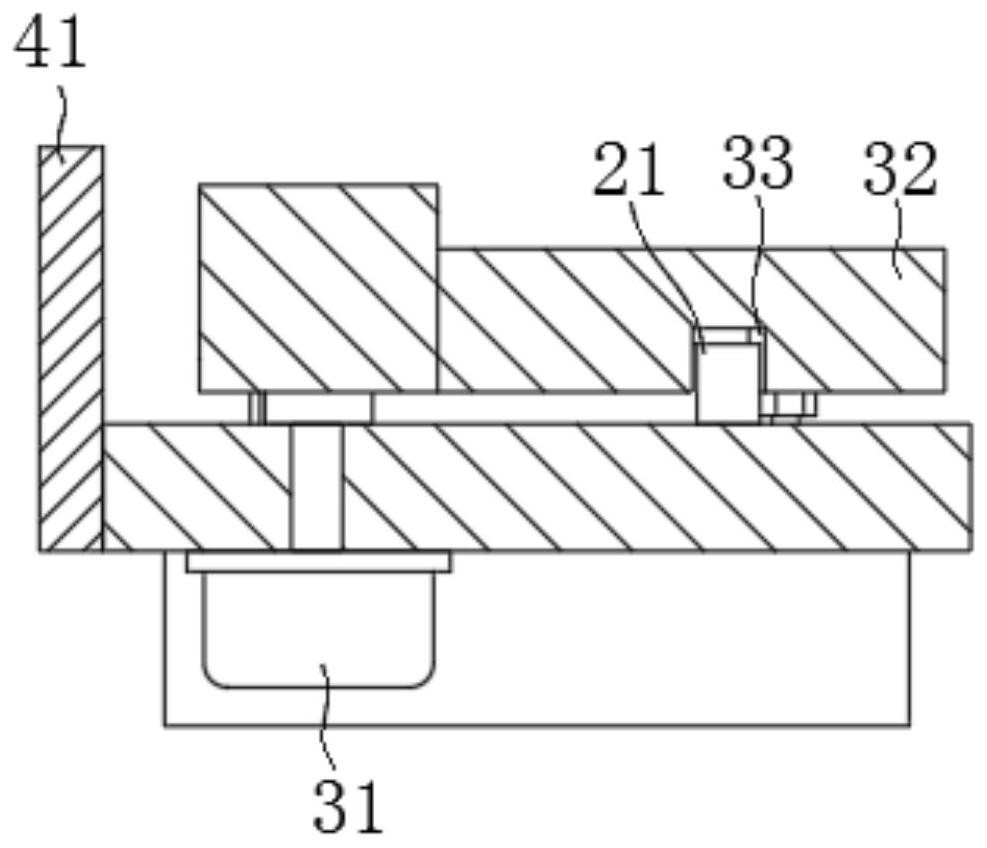

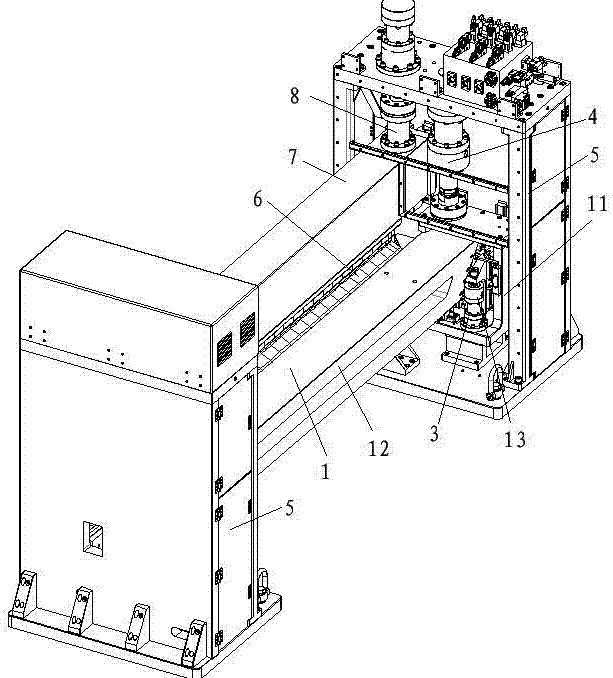

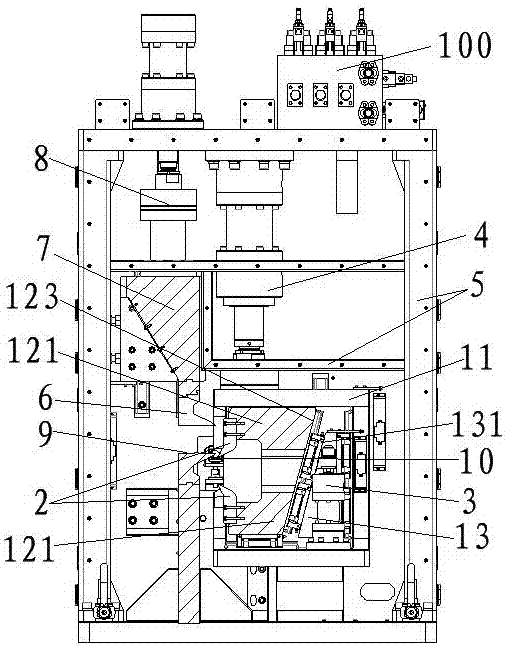

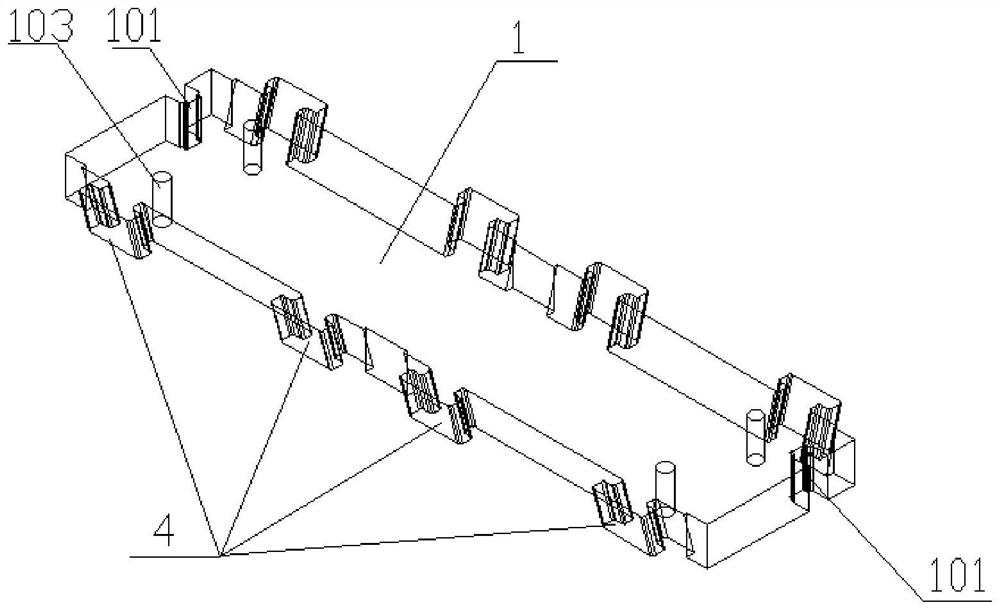

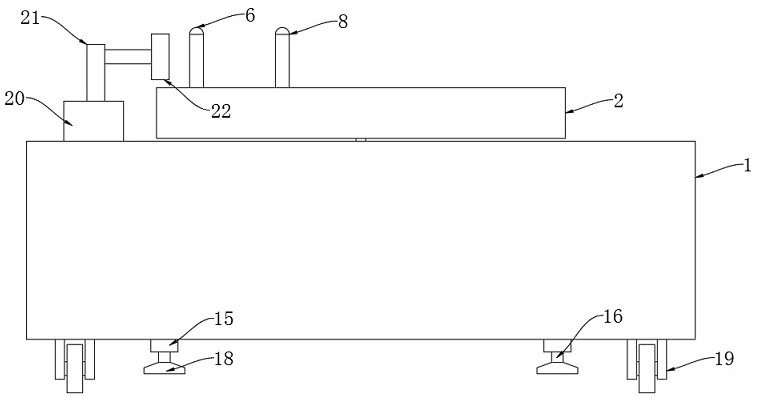

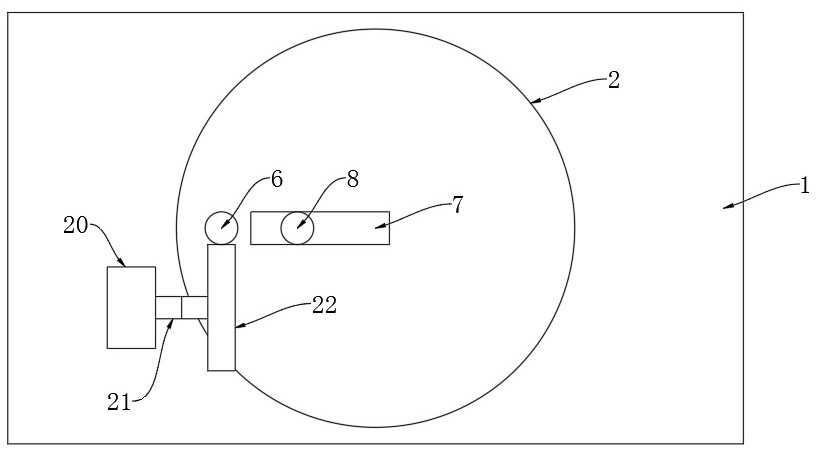

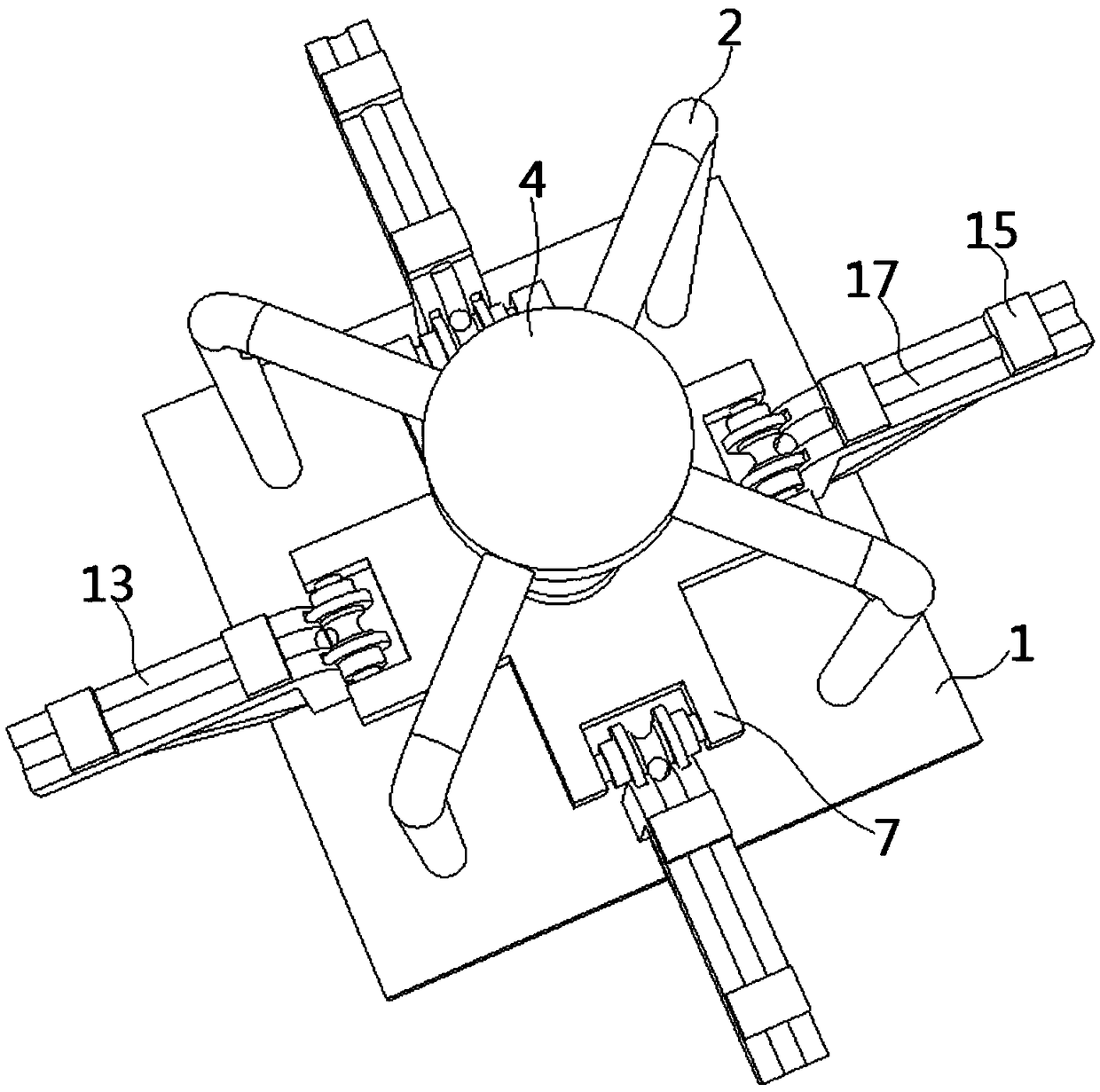

A kind of rotary bending equipment and its processing method

ActiveCN106270041BExquisite designSimple structureMetal-working feeding devicesPositioning devicesMechanical engineeringEngineering

The invention discloses rotary bending equipment and a machining method thereof. The rotary bending equipment comprises a to-be-machined product fixing carrier, a rotary bending mechanism and a driving mechanism, wherein the to-be-machined product fixing carrier is used for fixing a to-be-machined product; the rotary bending mechanism is used for bending turned edges of the to-be-machined product, and the rotary bending mechanism and the to-be-machined product fixing carrier are coaxially arranged; the driving mechanism is used for driving the rotary bending mechanism to reciprocate in the horizontal direction. According to the rotary bending equipment and the machining method thereof, the design is ingenious, the structure is simple, the product is positioned by the to-be-machined product fixing carrier, three arc-shaped bending push heads on the rotary bending mechanism apply force to the turned edges respectively by the aid of rotary movement, synchronous and accurate bending of the three turned edges on the product is realized, the whole bending process is performed automatically, the efficiency is high, influences of manual operation are free, the problems that the bending angles are not uniform, the turned edges are deformed and damaged and the like due to manual operation are solved, and the machining quality of a final product is guaranteed.

Owner:汪静

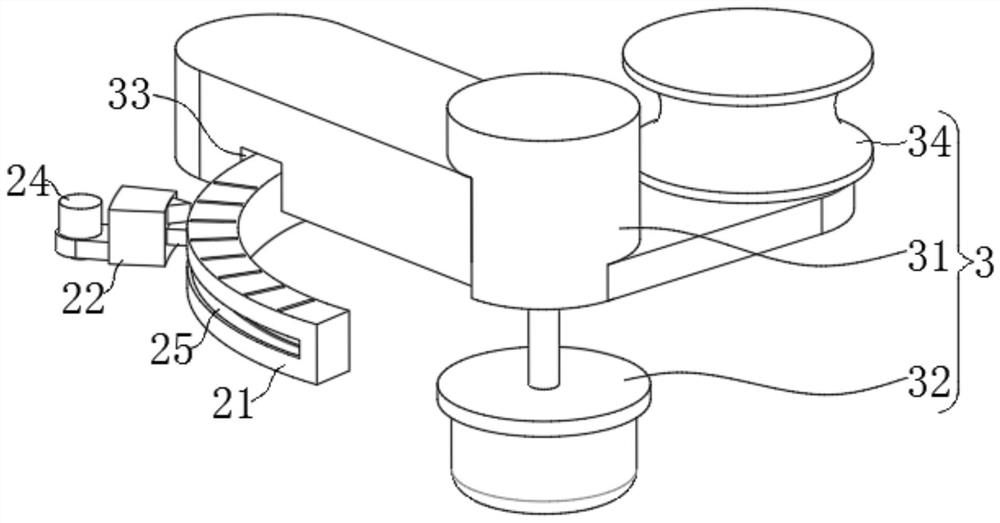

Brush box angle automatic bending mechanism and method

The invention discloses an automatic bending mechanism and method for the angle of a brush box. The automatic bending mechanism comprises a fixing carrier for a product to be machined, a rotating bending mechanism and a driving mechanism, wherein the fixing carrier for a product to be machined is used for fixing a product to be machined, the rotating bending mechanism is used for bending flanges of the product to be machined on the fixing carrier for a product to be machined, the rotating bending mechanism and the fixing carrier for a product to be machined are coaxially arranged, and the driving mechanism is used for driving the rotating bending mechanism to rotate in the horizontal direction in a reciprocating mode. The automatic bending mechanism is elaborate in design and simple in structure, the product is positioned through the fixing carrier for a product to be machined, then three arc bending push heads on the rotating bending mechanism are made to apply push force to the flanges respectively through the rotating movement, the three flanges on the product to be machined are synchronously and precisely bent, the whole bending process is automatically carried out, efficiency is high, and the influence of manual operation is avoided; thus, the problems of nonuniformity of bending angles in manual operation, deformation and breakage of the flanges and the like are solved, and the machining quality of the end product is ensured.

Owner:新井田智能装备(江苏)有限公司

Adjustable leg support

InactiveCN113730135AAchieve supportMeet bending needsOperating tablesDiagnosticsPhysical medicine and rehabilitationMedicine

The invention relates to the technical field of medical instruments, in particular to an adjustable leg support which comprises a leg supporting plate making contact with legs, a lifting rod allowing the leg supporting plate to be longitudinally adjusted up and down and a base used for installing the lifting rod, the leg supporting plate, the lifting rod and the base form two sets of supporting units, the supporting units are symmetrically arranged, a telescopic assembly used for adjusting the distance is arranged between the two sets of supporting units, the telescopic assembly comprises a sleeve arranged on the side face of the base at one end and an adjusting rod arranged on the side face of the base at the other end, the adjusting rod is connected with the sleeve through a positioning bolt inserted into the sleeve, the legs of a patient are supported through the two sets of leg supporting blocks with the distance adjustable, and medicine application or medicine changing operation is facilitated; and the height of the supporting block can be adjusted through the lifting rod, so that the bending requirements of different degrees of patients are met.

Owner:南京市高淳人民医院

Bending device

PendingCN112536343AAchieve bendingImprove bending efficiencyMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention discloses a bending device. The bending device comprises a fixing mechanism, a clamping mechanism and a bending mechanism, wherein the clamping mechanism comprises a fixed rod fixed on the fixing mechanism and a movable rod movably arranged on the fixing mechanism; a clamping chamber is formed between the fixed rod and the movable rod, so that the movable rod can be close to or far away from the fixed rod; the bending mechanism comprises a rod body and a lantern ring fixed to the end of the rod body; the clamping mechanism is sleeved with the lantern ring so that the rod body canrotate in the horizontal plane with the clamping mechanism as an axis; and a threaded rod is detachably arranged on the rod body and rotatably sleeved with a sliding sleeve column. A cylindrical or plate-shaped workpiece can be bent, a bending angle and a bending point can be conveniently controlled, and the bending efficiency and effect of the workpiece are improved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

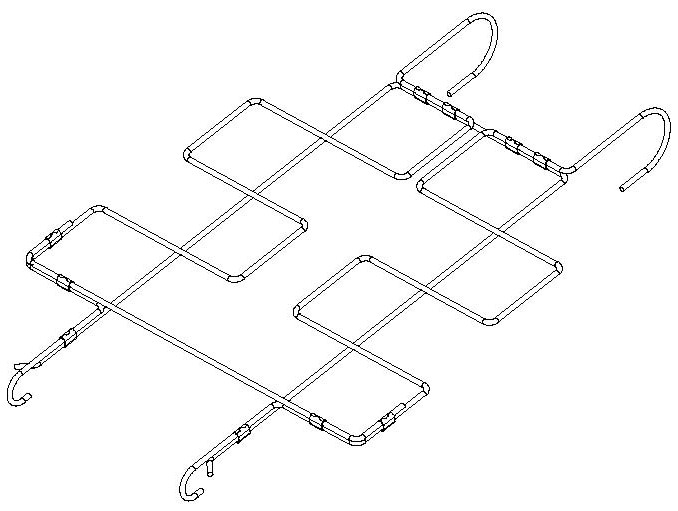

Curving unit and bending device comprising curving unit

The invention particularly relates to a curving unit and a bending device comprising the curving unit. The bending device further comprises a supporting unit and a bending unit. The supporting unit isused for supporting a steel wire to be bent and fixing the steel wire. The bending unit and the curving unit are arranged above the supporting unit. The bending unit is used for bending the steel wire on the upper surface of the supporting unit according to a certain angle. The curving unit is used for curving the steel wire on the upper surface of the supporting unit according to a certain curvature radius. By arrangement of the supporting unit, the steel wire can be conveniently supported and fixed; meanwhile, by arrangement of the curving unit and the bending unit, the steel wire can be curved through the curving unit, the bending unit is used for bending the steel wire into a designated angle, and therefore, various bending requirements of the steel wire are met; and the device can automatically bend the steel wire and is quite convenient to use.

Owner:安庆中巨机电科技有限公司

Small reinforcing steel bar bending device

The invention provides a small steel bar bending equipment, which includes an upper moving part, a set bolt, a handle, a body, a base, a fixed frame, a rotating shaft, a fixed pin, a turntable, a card slot, a rack, a gear, an operation panel, a motor and tapered hole; the rack is fixed on the upper moving part, the operation panel is fixed on the motor, the motor is connected to the turntable through the rotating shaft, and the motor is fixed on the fixed On the frame, the fixed frame is welded to the base, and the handle is fixedly connected to the gear. The structure of the invention is simple, and the bending radian of the steel bar can be set through the operation panel, and the length range of the bent steel bar is large. The weight is small and the transportation is convenient, so it is suitable for popularization.

Owner:杜丽娜

Auxiliary equipment for laying water and electricity pipelines for house building and construction

PendingCN114210787APlay a positioning roleMeet bending needsApparatus for laying cablesLine tubingArchitectural engineering

The invention provides auxiliary equipment for laying water and electricity pipelines in housing construction. The auxiliary equipment for laying the house building water and electricity pipelines comprises a main body plate; the angle adjusting structure is arranged at the top of the main body plate, and the angle adjusting structure comprises an arc-shaped scale plate with angle scales and a positioning block. According to the auxiliary equipment for laying the house building water and electricity pipelines, the angle adjusting structure is arranged on the main body plate and is mainly used for adjusting the rotating angle of the rotating part, so that the rotating part can accurately bend a wire pipe to the needed angle according to the machining requirement, and the machining efficiency is improved. The arc-shaped scale plate with the angle scales is matched with the positioning block for use, the positioning block serves as a rotating end point of the rotating piece, the positioning block is used for positioning the rotating piece, and after the arc-shaped scale plate and the positioning block make contact, the rotating piece cannot continue to rotate, the traditional mode that people judge the angle by themselves is changed, and use is more convenient.

Owner:大庆珑达建工集团有限公司

Multi-angle metal bending device and method for automobile part machining

InactiveCN112570515AImprove bending effectImprove bending efficiencyShaping toolsMetal-working feeding devicesMotor vehicle partMachining process

The invention discloses a multi-angle metal bending device for automobile part machining, and belongs to the technical field of metal machining. The device comprises an outer box body, and the inner wall of the outer box body is fixedly connected with a working table; one surface of the outer box body is fixedly connected with a cooling mechanism; the inner wall of the outer box body is fixedly connected with one ends of a group of electric telescopic rods which are distributed in a rectangular array; the other ends of the group of electric telescopic rods are fixedly connected with an adjusting mechanism; the adjusting mechanism comprises a lifting plate; the lower surface of the lifting plate is fixedly connected with an outer frame body; the lower surface of the outer frame body is fixedly connected with a bottom plate; the inner wall of the outer frame body is slidably connected with a bending assembly; the bending assembly comprises two sliding plates a; and one surface of one ofthe sliding plates a is rotationally connected with a threaded screw rod a. According to the multi-angle metal bending device, through the design of a fixed clamping plate, a sliding clamping plate, athreaded lead screw c and a threaded seat, the device can conduct full-automatic bending on strip-shaped metal of various different sizes, the cooling function is achieved, and therefore the machining efficiency of metal parts and the safety in the machining process are improved.

Owner:宁波曼汶智能装备有限公司

Universal bending machine

The invention discloses a universal bending machine which comprises a slanting wedge knife holder which can vertically and horizontally move and a supporting frame which is positioned at the two ends of the slanting wedge knife holder and has the supporting effect, wherein bending knives are installed on one side surface of the slanting wedge knife holder; an angle pressing block which is parallel to the a slanting wedge knife holder is arranged on the bending knife facing the slanting wedge knife holder and is installed on a drive frame which can vertically move; the blade part of the angle pressing block is opposite to a blade of the corresponding bending knife; a bending platform for bearing a plate to be bended is arranged below the angle pressing block; the two ends of the bending platform are supported by the supporting frame; the angle pressing block is composed of a plurality of pressure blocks which can be clamped with the drive frame; at least one clamping table is arranged on the top surface of each pressure block and is matched with a clamping groove formed in the side surface or the lower surface of the drive frame; and when the clamping table on each pressure block is inserted into the corresponding clamping groove formed in the drive frame, each pressure block is hung below the drive frame. By the universal bending machine, materials can be bent in various shapes and at various angles, and can be bent towards different directions so as to meet various bending needs.

Owner:JIANGSU BVM INTELLIGENT TECH

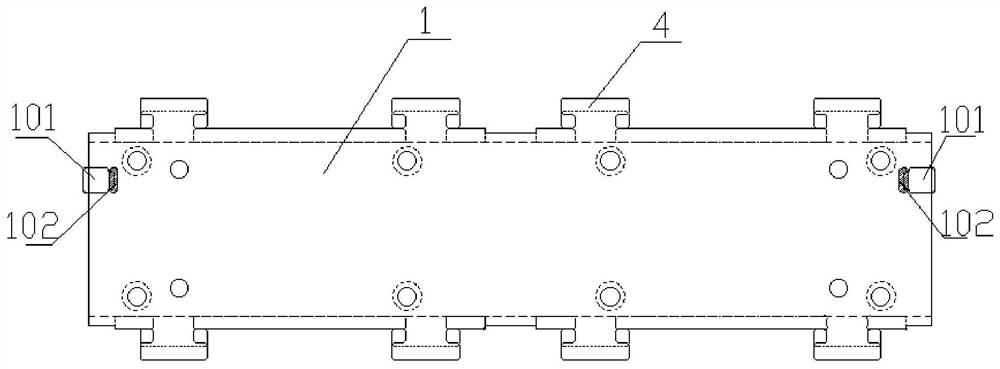

Separating type bending upper die plate assembly

InactiveCN114682657AGuaranteed reliabilityPromote repairShaping toolsClassical mechanicsStructural engineering

The invention relates to a separated bending upper die plate assembly which comprises an upper die plate, the separated bending upper die plate assembly further comprises a first bending connecting piece and a second bending connecting piece, convex protruding blocks are arranged on the two opposite sides of the upper die plate, the end, with the smaller diameter, of each protruding block is connected with the upper die plate, and the other end, with the smaller diameter, of each protruding block is connected with the first bending connecting piece. The first bending connecting piece and the second bending connecting piece are both provided with fixing grooves matched with the protruding blocks, the side, away from the fixing grooves, of the first bending connecting piece is provided with a first bending angle, and the side, away from the fixing grooves, of the second bending connecting piece is provided with a second bending angle. Compared with the prior art, the invention has the advantages of reliable positioning and connection, convenience in replacement, wide application range and the like.

Owner:SHANGHAI QIANGJING METAL PROD

A steel bar bending machine device for building construction based on plc control

InactiveCN110883266BStable jobPlay a supporting roleMetal working apparatusCircular discArchitectural engineering

The invention discloses a steel bar bending machine device for building construction based on PLC control, which includes a hollow workbench and a disc connected to the upper end of the workbench in rotation. The steel bar bending device uses a PLC steel bar bending system. A first motor is fixedly installed on the inner top of the workbench, and the output shaft of the first motor penetrates to the upper end of the workbench and is fixedly connected to the axis of the lower end of the disk. The present invention can control the operation of the electric push rod by setting the stabilizing mechanism and the clamping mechanism, so that the connecting plate pushes the sleeve to move down, so that the supporting rod is pressed downward, and the supporting seat replaces the roller to support the workbench , so that the steel bar bending device is more stable, avoiding the deviation of the steel bar bending angle, and can control the operation of the second motor to adjust the distance between the movable nip roller and the fixed nip roller, so as to clamp and fix the steel bars of different specifications , to meet the bending requirements of steel bars of various thicknesses.

Owner:ZHONGHENG CONSTR GRP

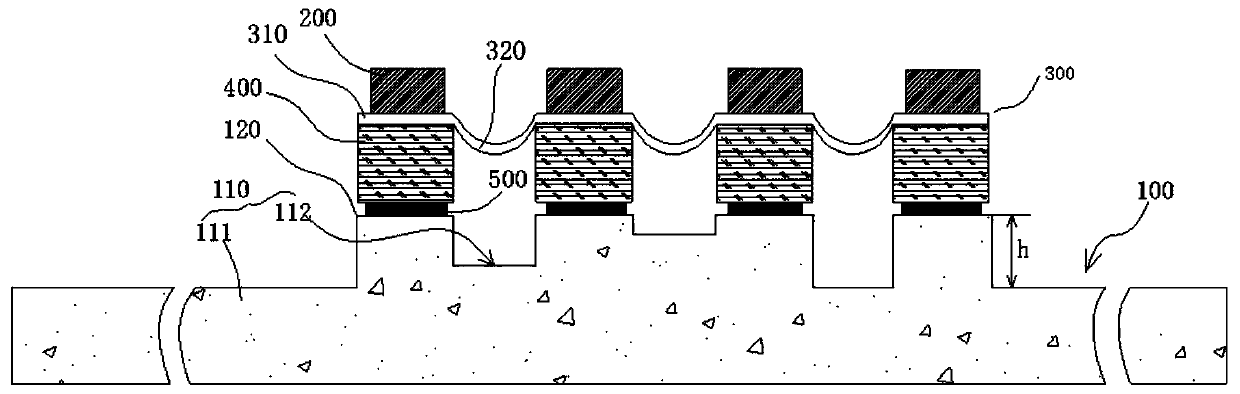

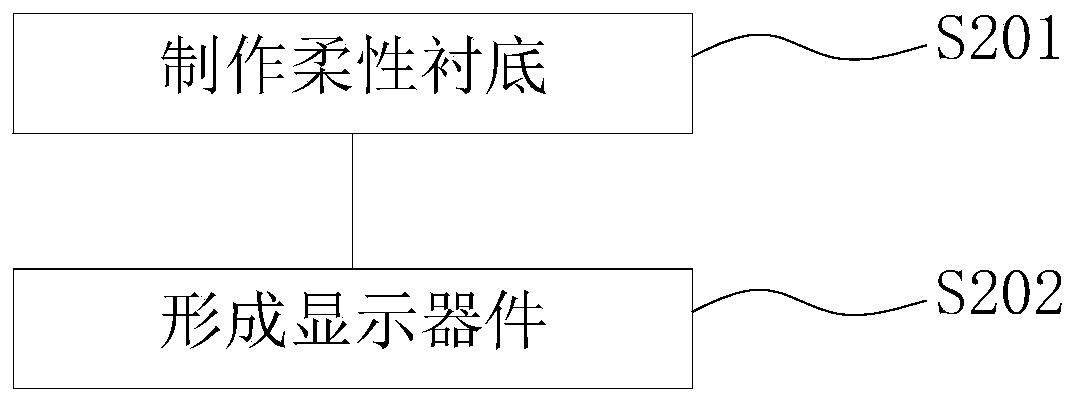

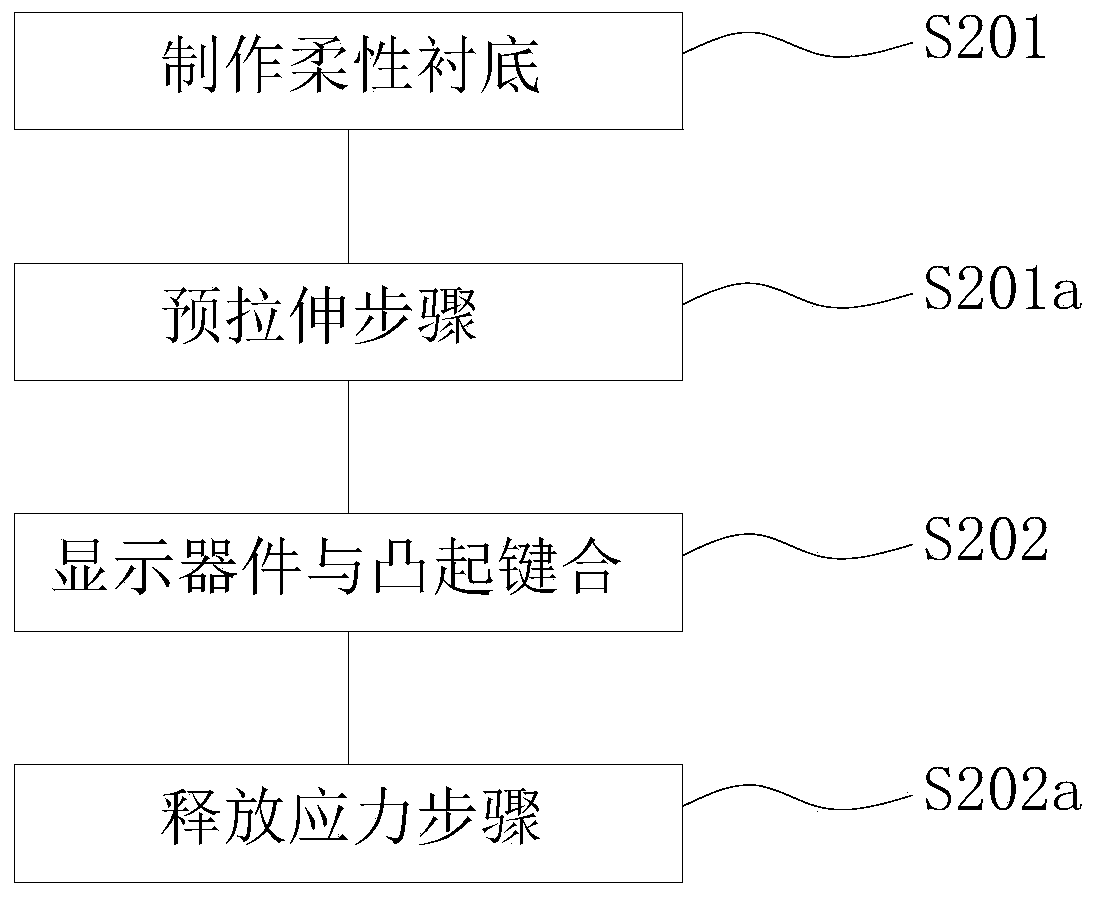

Display screen body, display device and manufacturing method of display screen body

The embodiment of the invention provides a display screen body, a display device and a manufacturing method of the display screen body. The display screen body comprises a flexible substrate and a display device, wherein the flexible substrate comprises a body part and more than three bulges arranged on the surface of the body part, the body part comprises a fixing part and to-be-extended parts, each to-be-extended part is located between two adjacent bulges, and at least two to-be-extended parts are different in thickness; and the display device is arranged on the sides, which are away from the body part, of the bulges. According to display screen body in the embodiment of the invention, the display screen body comprises a flexible substrate and a display device, the flexible substrate comprises the body part and the plurality of bulges arranged on the surface of the body part. The body part comprises the fixing part and the to-be-extended parts located between every two adjacent protrusions, at least two to-be-extended parts are different in thickness, and the two to-be-extended parts are enabled to bear stretching of different degrees, so that the display screen body can meet the bending requirements of different special-shaped curved surfaces.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

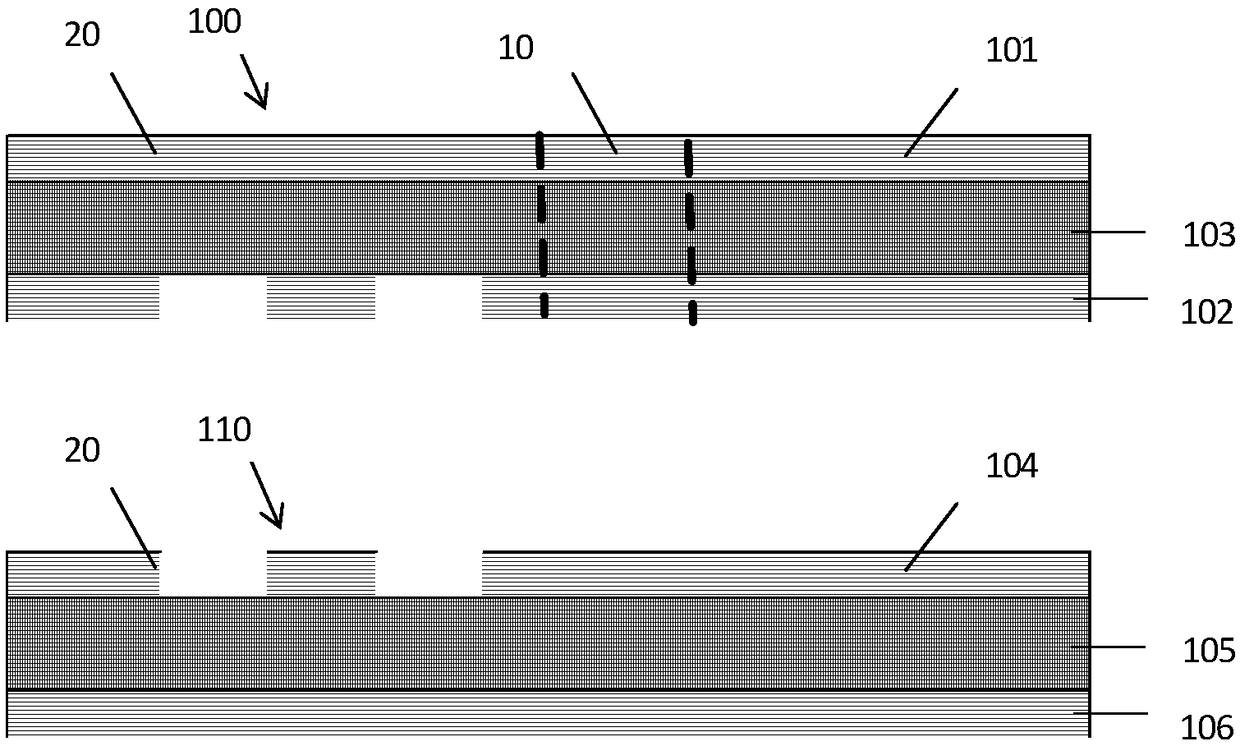

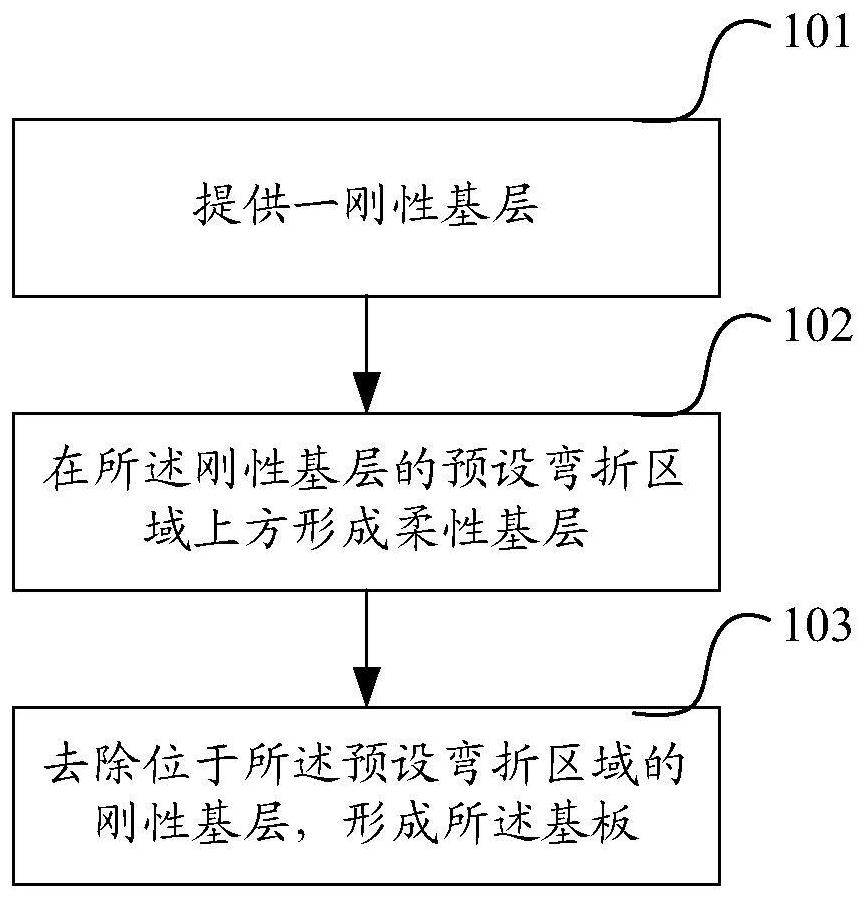

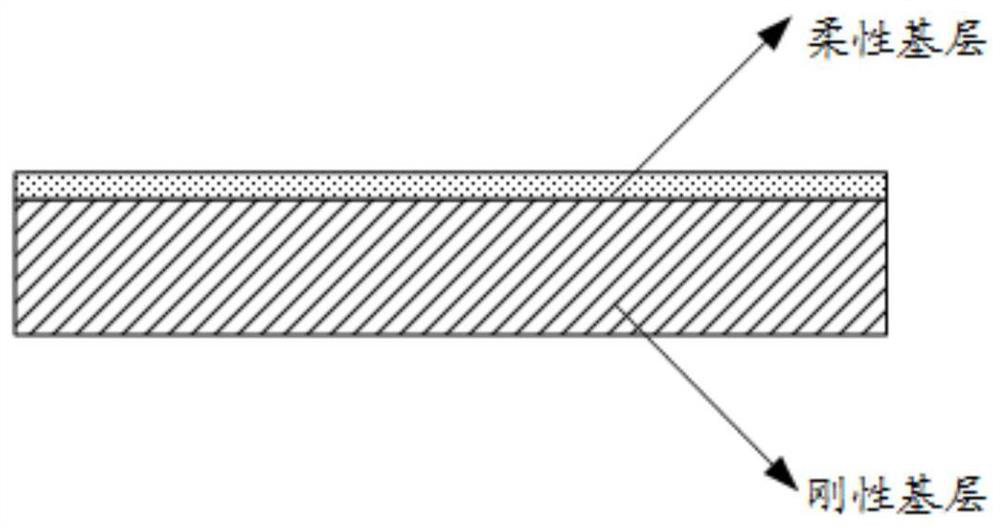

Method for manufacturing a substrate, substrate, and display device

ActiveCN109935740BMeet bending needsReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a manufacturing method of a substrate, a substrate, and a display device. The method includes: forming a flexible base layer over a preset bending area on a provided rigid base layer, and then removing the rigid base layer located at the preset bending area, so that the manufactured substrate is only at the preset bending area. The flexible base layer, while the remaining areas are still rigid base layers, can not only meet the bending requirements of the substrate, but also effectively reduce production costs, improve production efficiency, and improve the mass production of products.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Steel bar bending device used for building construction site

The invention discloses a steel bar bending device used for a building construction site, and relates to the technical field of steel bar processing in building construction. The steel bar bending device disclosed by the invention comprises a base, a hydraulic cylinder, a third fixing plate and rolling shafts; a plurality of slotted holes are formed in the surface of the third fixing plate; the two ends of each rolling shaft are each fixedly provided with a supporting rod; the two ends of each supporting rod are rotatably connected with the inner wall of the corresponding first slotted hole through bearings; a first bending slot is formed in the circumferential side face of each rolling shaft; a set of fixing rings is fixedly arranged at the two sides of each first bending slot; and the hydraulic cylinder is used for controlling the third fixing plate to move vertically. According to the steel bar bending device disclosed by the invention, the third fixing plate is driven by the hydraulic cylinder to move downwards, so that the rolling shafts on the third fixing plate can cooperate with fourth fixing plates to process a plurality of steel bars simultaneously, and thus, the bendingefficiency of the steel bars is greatly increased; moreover, the bent steel bars are high in strength and long in service life; labor strength is greatly reduced; and processing cost is reduced.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Semi-bent printed circuit board and manufacturing method thereof

ActiveCN108419384BSolve crackingImprove reliabilityPrinted circuits structural associationsMultilayer circuit manufactureStructural engineeringMechanical engineering

The invention provides a half-bent printed circuit board and a making method thereof. The making method includes: pre-arranging a bent area on an inner-layer circuit board; arranging non-conducting wires in a copper-free area of an inner-layer circuit layer of the bent area; especially arranging non-conducting wires in a copper-free area of an outer-layer circuit layer in a matched manner; especially arranging the non-conducting wires according a specific layout mode to form a specific half-bent circuit board making process. The half-bent circuit board made by the making process can reduce stress directly acting on the circuit board in the process of bending, the problem that the inner-layer circuit board in the bent area cracks during board bending is solved, certain bending needs are metwithout adopting expensive PI films, and cost reduction and meeting of bending needs are well balanced; the half-bent circuit board has high reliability and excellent thermostability.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com