Process for quenching die-cutting rule band steel for printing

A die-cutting knife and strip steel technology, which is applied in the printing field, can solve problems such as poor bending and forming, and achieve the effects of stable process operation, low production cost, and easy control of process parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] What adopted in the present embodiment is 50# strip steel.

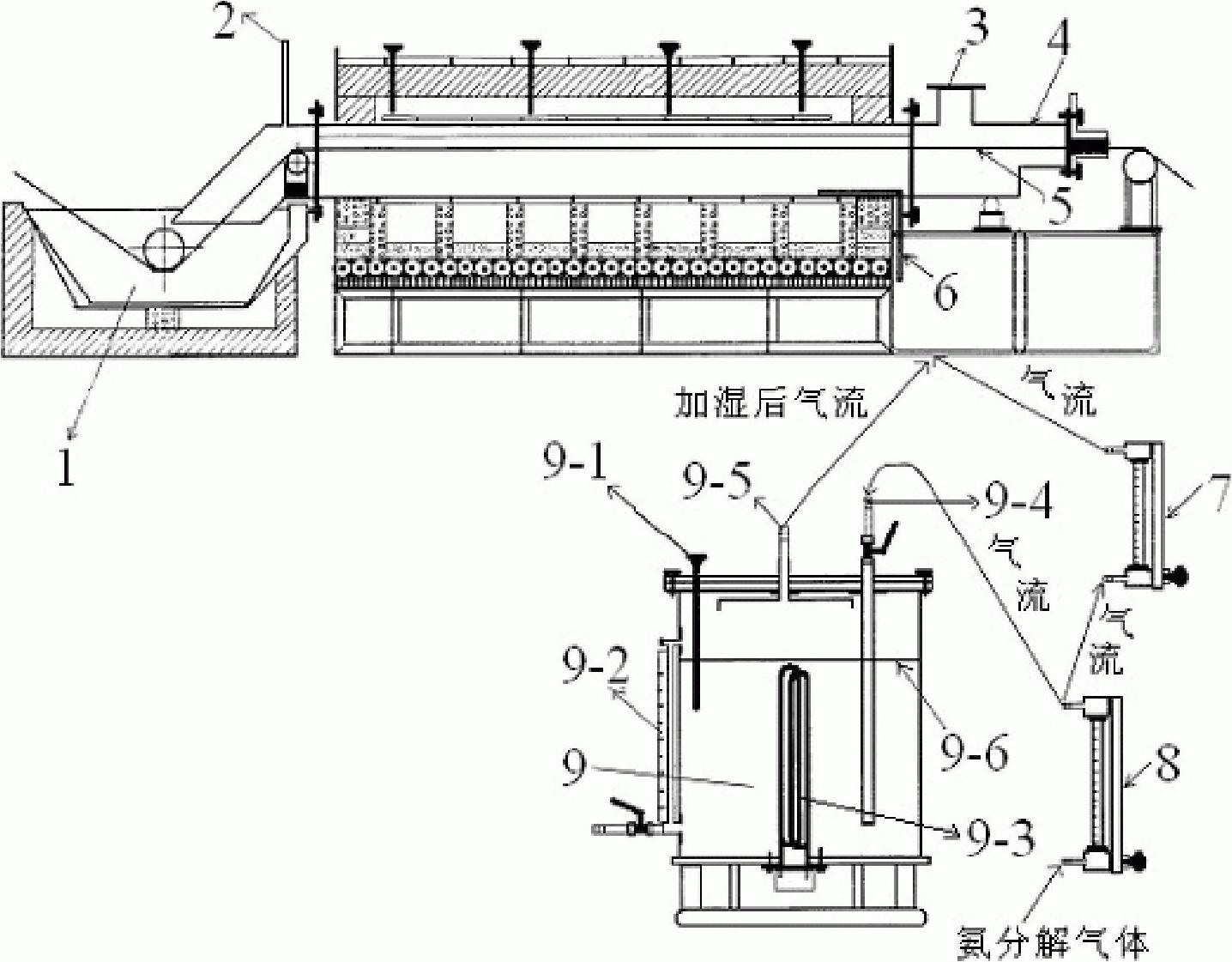

[0042] as attached figure 1 As shown, the company's lead-bath strip steel quenching furnace has four zones of temperature control. The total length of the furnace tube is 8.68 meters, the width of the furnace tube is 0.45 meters, and the height of the furnace tube is 0.24 meters. It is a square furnace tube. The calculated inner volume of the muffle tube is 0.95 cubic meters. According to the requirements of the present invention, the total protective atmosphere is calculated to take an upper limit of 3 cubic meters, that is, the total ammonia decomposition gas flow rate passed into the muffle tube is 3m 3 / h. The furnace temperature setting is 925°C in the first zone, 925°C in the second zone, 940°C in the third zone, and 945°C in the fourth zone. this invention figure 1 The lead bath strip steel quenching furnace shown in the figure can process six steel strips with a thickness of 0.71mm and a width of 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com